Effect of laser heating on the microstructure and hardness of TRIP590 advanced high strength steel used for roll forming①

Wang Haibo (王海波

(School of Mechanical and Materials Engineering, North China University of Technology, Beijing 100144, P.R.China)

Effect of laser heating on the microstructure and hardness of TRIP590 advanced high strength steel used for roll forming①

Wang Haibo (王海波②

(School of Mechanical and Materials Engineering, North China University of Technology, Beijing 100144, P.R.China)

TRIP590 advanced high strength steel sheets were heated by laser with different powers. Changes of the microstructure and the hardness of TRIP590 steel under laser heating with different powers were investigated by metallographic microscope, scanning electron microscope, and hardness tester. The purpose was to study the effect of laser power on microstructure and hardness of TRIP590 steel. It is shown that the power of laser plays an important role on the microstructure and hardness of heated steel sheets. The results are helpful to determine suitable power for the laser auxiliary forming of Trip590 steel in order to obtain uniform microstructure and high hardness.

TRIP590 advanced high strength steel, laser heating, microstructure, hardness

0 Introduction

With the development of auto industry, the demand for combination property of steel is higher. TRIP steel provides a direction to solve the contradictions of strength and plasticity as advanced high strength steel which has been successfully researched. Many parts of a car can be processed by roll forming such as bumper, and at the same time the steel can be soften temporarily for easy molding by laser heating, and the property of the laser heating area is also improved after cooling. The properties of materials are determined by the microstructure which can be changed during the heat-treatment process, thus properties needed can be got by this way. So the research of the microstructure evolution of TRIP steel during the heating process is important for obtaining needed properties[1-4].

Many investigations were carried out on the relationship between the microstructure and mechanical properties of TRIP steel, as well as the changes of microstructure and properties under the heat-treatment process. Tang[3], et al. who did many researches on the TRIP steels, thought that bainite zone and isothermal two-phase zone annealing temperature are the main factors to influence the microstructure of TRIP steel. Xie[4], et al. fully demonstrated that advanced high strength steel had high strength, good ductility and low yield ratio. Ma[5]and Zhang[6], et al. studied the changes of microstructure and property under different heat-treatment process. Kang[7], Guan[8], and Wang[9], et al. did research in the forming mechanism, influence factors, properties, and development of the structure of TRIP steel. Xiong[10]studied the influence of heat-treatment process on microstructure and mechanical properties of super strength TRIP steel and how to make the treatment process optimized. Li[11]investigated the effect of austempering on the transformation induced plasticity (TRIP) of hot rolled multiphase steel. Mi[12], et al. studied that cooling at low temperature is favorable to structure refinement and the intermediate annealing decreases the cold rolling resistances and enhances the amount of final retained austenite. Kim[13]and Srivastava[14], et al. have done the analysis about the microstructure’s changes of TRIP steel under the heat-treatment process. In this paper, the effect of the laser heating power on the microstructure and properties is investigated. By comparing the experimental results, the most appropriate laser heating power for roll forming process is determined.

1 Experimental material and process

1.1 Experimental material

The sample used in the experiment is a long strip plate of TRIP590, with the width of 1.6mm and the length of 1250mm, and the content of each element is shown in the Table 1.

Table1 Chemical composition of TRIP steel sample (mass fraction ,%)

1.2 Experimental process

The surfaces of samples were wiped with acetone and precoated by the increased absorption coating before the experiment. After that, they were scanned by IPG fiber laser of different power (200, 300 and 500W) for laser scanning modification under the scanning speed of 30mm/min. Then the heated samples were rapidly cooled to room temperature and were cut into strips with a cutting plate.

Since the microstructure needs to be seen under an optical microscope and the scanning electron microscope, the samples are cut into appropriate square shapes with shearing machine, then coarse grinding, fine grinding and polishing are carried out for the next observation.

The polished sample is in full corrosion with nitric acid of 4% alcohol reagents, and then the microstructure image through metallographic microscope is obtained. The hardness of the samples is measured with the Rockwell hardness tester. Then the microstructures of the samples with laser heating power of 200W, 300W, 500W are compared with that without laser heating.

2 Results and analysis

2.1 Microstructure of the zones with laser heating and analysis

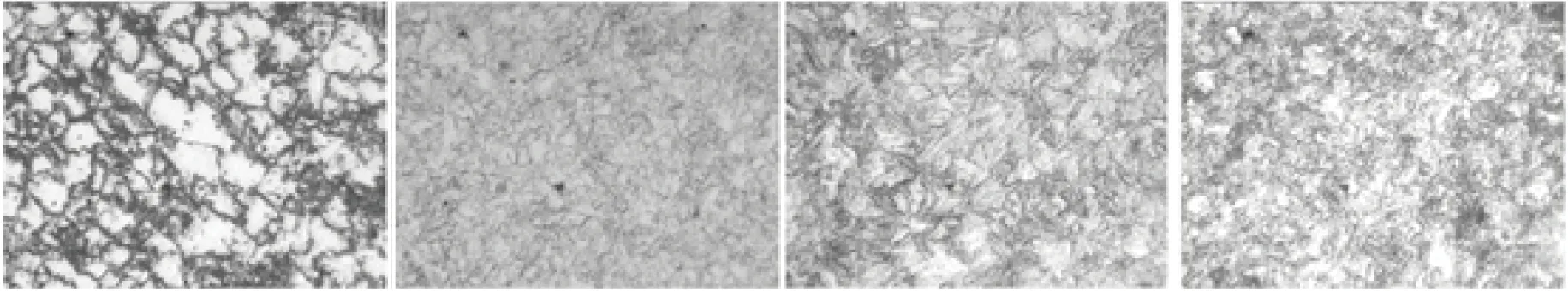

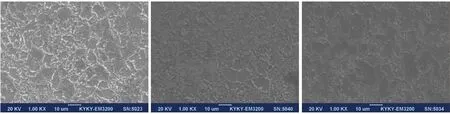

The microstructure of the TRIP590 steel sheets heated by laser with different powers is investigated with microscope and SEM and the results are shown in Figs.1 and 2.

(a) Non-heating (b) 200W (c) 300W (d) 500W

(a) Non-heating (b) 300W (c) 500W

From the microstructure image of TRIP590 steel with no laser heating, it can be clearly found that the white area is ferrite, in cubic shape, and bainite is strip or granular distributed at the grain boundaries, black. Residual austenite appears as island shape that is distributed in the boundary of ferrite grain and bainite grain, and the SEM image more clearly shows the polygon feature and size of ferrite structure. It can be found that the size of the matrix of ferrite grains is mostly in the range of 2μm~10μm, and the 5μm~10μm grains are in dominant position accounting for more than 80% of the total matrix area. It can be also explained that the recrystallization of coldly rolled organization is more fully in the critical area and the content of epiphytic ferrite generated in the cooling process is less because of the weak dispersion of ferrite grain size.

From the microstructure image of TRIP590 steel that is scanned under the 200W, obvious sheet and plate martensite are observed; and quenched martensite appeared when it is cooled in the air. A small fraction of the retained austenite is located in the big ferrite grain interior due to the slow diffusion of the intercrystalline carbon; and when the carbon saturation of austenite is deficiency, it is often accompanied by the presence of other phases (Such as Mao Island symbiosis with martensite).

From the microstructure image of TRIP590 steel that is scanned under the power of 300W, obvious sheet martensite is also observed. Comparing the microstructure image scanned by the power of 200W and 300W, the martensite is coarser. From Fig.2, SEM pictures under the 300W laser heating power, the island of residual austenite can clearly observed, but the total amount of which is less, and the grain becomes small.

From the microstructure image of TRIP590 steel that is scanned under the power of 500W, it can be found that the microstructure of the sample mostly becomes martensite. Among them, the white structure is martensite, and the black is carbide. The distribution of martensite is more uniform than the above conditions, and there is a small amount of carbide precipitation, and it has the tendency of non-crystallization. From Fig.2, SEM pictures under the 500W laser heating power, it can be clearly found the residual austenite is increased and the total amount of it is still small and the martensite is still in the dominant position.

2.2 The observation and analysis of microstructure in the boundary of heated and unheated sample

The boundaries between the heated and unheated areas of the specimens are investigated with the help of a microscope. The differences of the microstructure between the heated and unheated areas under different laser power are shown in Fig.3.

Fig.3 Micrographs of unheated and heated areas under different times and different laser heating power

In order to observe the differences of microstructure between the laser heating area and the non-heating area more intuitively, the microstructure at the interface needs to be observed as shown in Fig.3. From the comparison, it is shown that the phase composition of the sample is changed after laser heating from ferrite, bainite and residual austenite to martensite and residual austenite. Moreover with the heating power increased, the microstructure showed the residual austenite is decreased, but the martensite is increased.

Since the diffusion of carbon atoms is constrained by the first law of thermodynamics, the distribution of residual austenite in the micro-region obeys a certain statistics law. In a small region of the matrix, the distribution of austenite is also small and dense. Conversely, in other regions of the matrix, the distribution of austenite is large and sparse[15,16].

In addition, it can be found that the grain of the laser heating zone is smaller than that of non-heating zone. The reasons for this may be:

(1) In ultra-fast laser heating, the large degree of superheat and the short of the laser irradiation, cause a phase transformation driving force, which makes austenite nucleation rate increase rapidly. Thus, the size of austenite grain is refined.

(2) Ultra-fast laser heating makes austenite harden, which makes austenite spontaneously recrystallized, thus the size of austenite grain is refined.

(3) In ultra-fast laser heating, the isothermal time under high temperature is so short that it is not conductive to the growth of globular austenite grain, thus the fine austenite grain becomes easily.

2.3 Test and analysis of mechanical properties

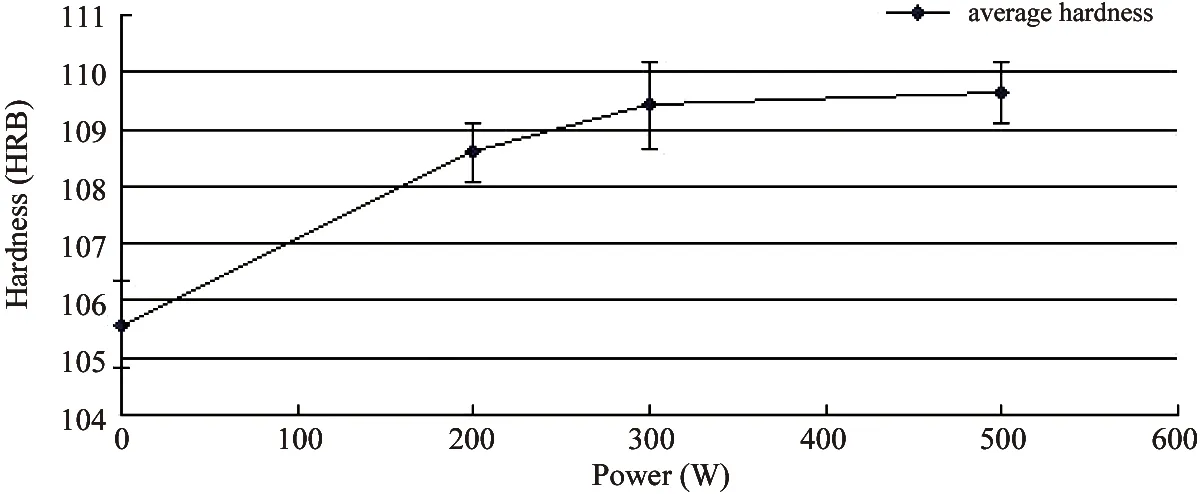

A Rockwell hardness tester is used to test specimen hardness, five measurements of each specimen are carried out, and then the five results are averaged. So the curve can be got.

From Fig.4, it is shown that the hardness of specimen could be improved by laser heating, and with the increase of laser heating power, the hardness is increased, but the increase is not obvious. The change of specimen hardness is decided by the changes of microstructure that is caused by laser heating. The increase of hardness is caused by several factors: the appearing of martensite after cooling of laser heating and the anisotropic crystal orientation, fine grain strengthening, amorphous organization because of fast cooling, and so on.

Fig.4 The relation between the average hardness and the laser heating power

3 Conclusions

(1) The microstructure of TRIP590 advanced high strength steel is changed by laser heating and a phase change is triggered. The microstructure becomes more uniform and the austenite becomes more refined after laser heating. The amount of the martensite is increased with the increase of the laser power while relative amount of residual austenite is reduced.

(2) With the increase of the laser heating power, the hardness of TRIP590 steel is gradually increased. The increase of the hardness corresponds to the change of microstructure triggered by laser heating;

(3) The uniform microstructure and the proper size of martensite can be obtained with the 300W laser power. The increase of the hardness with the laser power of 500W is not obvious comparing to that with laser power of 300W. Therefore, the laser power of 300W should be adopted for roll forming process.

[ 1] Wang X D, Wang L, Rong Y H. Current research condition and development of TRIP steel. Heat Treatment, 2008, 23(6):8-19

[ 2] Kuziak R, Kawalla R. Advanced high strength steels for automotive industry. Archives of Civil and Mechanical Engineering, 2008, 8:103-117

[ 3] Jiang H T, Tang D. Latest progress in development and application of advanced high strength steels for automobiles. Journal of Iron and Steel Research, 2007, 19(8):1-6

[ 4] Xie L L, Tang D. Study on formability of advanced high strength steel for automobiles. Journal of plasticity engineering, 2013, 20(2):84-88

[ 5] Ma T B, Shen Y F. Effect of heat-treatment on the microstructure and mechanical properties of the TRIP steel. Journal of materials and metallurgy, 2012, 11(2):132-145

[ 6] Zhang Y J, Liu Q Y. Influences of heat treatment on microstructure and mechanical properties of low carbon Si-Mn TRIP steel. Material and Heat treatment, 2011, 40 (12):166-170

[ 7] Kang Y L, Wang B. Structure and property of TRIP and its control process. Journal of iron and steel research, 1999, 03(6):62-66

[ 8] Guan Y J, Ji Z. Influences of material properties on laser bending process of sheet metal. Journal of Optoelectronics Laser, 2001, 01:87-90

[ 9] Wang L, Zhu X D. Light weighting of automobiles and advanced high strength steel. Baosteel Technology, 2003, 42(5):53-59

[10] Xiong Z L, Cai Q W, Jiang H T. Influence of heat treatment process on microstructure and mechanical properties of super strength TRIP steel. Heat treatment of metals, 2009, 34(9):83-87

[11] Li Z, Wu D. Effects of austempering on transformation induced plasticity of hot rolled multiphase steels. Acta.Metallurgica Sinica(English Letters),2007, 20(1):1-8

[12] Mi Z L, Li Z C, Fan D L, et al. Influence of heat treatment on microstructure and properties of a high strength cold-rolled TRIP steel. Transactions of Materials and Heat Treatment, 2011, 32 (10): 112-116

[13] Sung-Joon K, Chang J L, et al. Effects of heat treatment and alloying elements on the microstructures and mechanical properties of 0.15 Wt Pct C transformation-induced plasticity-aided cold-rolled steel sheets. Metallurgical and Materials Transactions A, 2001, 32A: 505-514

[14] Ashok K S, G J, et al. Effect of heat treatment on microstructure and mechanical properties of cold rolled C-Mn-Si TRIP-aided steel. Materials Characterization, 2006, 57:127-135

[15] Liu Q, Jiang H T, et al. Distribution and transformation behavior of retained austenite in TRIP Steel.Physics Examination and Testing, 2008,26(4):21-25

[16] Liu Q, Jiang H T, et al. Transformation behavior of retained austenite in TRIP steel under stress strain. Journal of plasticity engineering, 2009,16(1):156-161

Wang Haibo, born in 1980, associate professor. He received his B.S. and Ph.D degrees from Beihang University in 2004 and 2009 respectively. He works in North China University of Technology now. His main research interests include yield function, hardening model, forming limit and finite element simulation of metal forming processes.

10.3772/j.issn.1006-6748.2015.04.008

①Supported by the National Natural Science Foundation of China (No. 51205004, 51475003), Beijing Natural Science Foundation (No. 3152010) and Beijing Education Committee Science and Technology Program (No. km201510009004).

②To whom correspondence should be addressed. E-mail: rock_haibo@126.com Received on Oct. 26, 2014Jin Pengcheng, Yan Yu, Li Qiang

High Technology Letters2015年4期

High Technology Letters2015年4期

- High Technology Letters的其它文章

- Design of bilayer lengthened LDPC codes over expanded graph for relay channels①

- Secure planar convex hull protocol for large-scaled point sets in semi-honest model①

- Magnetometer calibration algorithm based on ellipsoid constraint①

- Motion mechanism analysis of two contacting rollers①

- Service optimization in programmable cloud network①

- Study and application of vibrating wire strain gauge in monitoring cable tension of FAST cable-net①