Study on Honey Stirred Yoghurt

Lili WANG,Deligeer BAOYIN

Xing’an Vocational and Technical College,Ulanhot 137400,China

Study on Honey Stirred Yoghurt

Lili WANG*,Deligeer BAOYIN

Xing’an Vocational and Technical College,Ulanhot 137400,China

[Objective]In this study,the aim was to study the optimal formula and technique of honey stirred yoghurt. [Method]The optimum formula and production technique of the honey stirred yoghurt were confirmed by studying the effects of the additive amount of honey,the adding time of honey,thermal death point,the homogenization pressure and stability test on the sensory quality of stirred yoghurt. [Result]The experiment showed that the fermentation temperature of the honey stirred yoghurt should not be too high,and it should be close to that of common yoghurt.In addition,the fermentation time should not be too long,because along with the extension of fermentation time,there would be abnormal smell in the yogurt.The optimum formula and production technique were as follows:the additive amount of honey,sugarcane and fermentation agent was respectively 3%;two-section homogeneous pressures of the fresh milk wereⅠ:70 MPa,Ⅱ:30 MPa;the thermal death point was 85℃ and the time was 10 min;the fermentation occurred at 42℃,and the fermentation of the products was stopped when the ultimate acidity was among 0.70%-0.75%.[Conclusion]The study could provide some references for the production and processing of honey stirred yoghurt.

Honey;Stirred;Yoghurt

Y oghurt is a health care dairy product produced by the fementation of lactic acid bacteria mixed with raw milk which is pasteurized fresh milk.It not only contains all the nutrients fresh milk has,but also has its own unique flavour.The lactic acid bacteria of yoghourt can effectively inhibit the growth of harmful microorganisms in human intestinal tract,and also can prevent the accumulation of harmful substance in vivo secreted by harmful microorganisms.Drinking yoghourt with lactic acid bacteria often can delay aging,combat high cholesterol,and also can well prevent cardiovascular disease.What’s more, the yoghourt relieves the worries of people on lactose intolerance,thus it has good health care function to human body[1-3].

Honey contains carbohydrate, protein,inorganic salt,vitamin and many kinds of enzymes[4],thus it is a quality food for health and is worthy of popularization,in which fructose accounts for about 48%[5],which has many significant advantages to human body.Fructose has strong combining ability with cells in human body,thus it can gradually release energy in a stable condition,thereby improving the endurance of human body[5].There are abundant trace elements in honey, such as germanium (Ge),lithium(Li) and potassium (K),in which Ge has an important role in cancer prevention for human,and Li has a special effect in cardiovascular disease prevention. In addition,honey has good curative effects in facilitating the normal work of intestines and stomach,improving the malnutrition of children,treating burns and scalds as well as constipation,etc.,so it is a very good food for health[6-7].

The mixture of yoghurt and honey is not only a good medicine treating anaemia,but also a kind of beverage being rich in vitamin and improving energy[8-10],especially stirred yoghurt, which has the advantages of invigorating flavor,good mobility and convenient drinking,etc.compared with set yoghurt.Based on this,the study on the optimum formula and productiontechnique of the honey stirred yoghurt was carried out in this paper.

Materials and Methods

Materials

The varieties of honey:robinia, linden,vitex and wolfberry;cane sugar;fresh milk;leavening agent.Main instruments:electronic balance;homogenizer;base buret;thermostat water bath;constant temperature incubator.

Methods

The basic technological process

Raw milk+cane sugar+water homogeneity→sterilizing→cooling→inoculating→fermenting→stirring→cooling→preserving[4].

The determination of the varieties of honey and the corresponding additive amountFour kinds of common honey in the market were chosen,namely robinia honey,linden honey,vitex honey and wolfberry honey;according to the basic technological process,the varieties of the honey were determined using sensory evaluation by adding 3%four kinds of honey into basic formula which contains 80% fresh milk,15%water and 3%granulated sugar.Then the determined honey was chosen for the experiment of the effect of the additive amount of honey on the fermentation rate and taste according to basic technology,at the same time,a blank experiment was conducted,finally,the optimum additive amount was determined by sensory evaluation.

The determination of the adding period of honeyAccording to basic technological process,the determined variety and additive amount of honey of"The determination of the adding period of honey"were adopted,the honey was added at the following stages:before sterilization,after sterilization and before fermentation,after the utmostextentoffermentation. Then the optimum adding period of honey was determined by sensory evaluation,in which a CK experiment withouthoneywascarried outto compare the effects of the adding period of honey on the sensory quality of yoghurt.

The determination of homogeneous pressure and thermal death point

In the experiment,there were such two kinds of thermal death points as 85℃10 min and 65℃30 min,and such two kindsoftwo-sectionhomogeneous pressures asⅠ:100 MPa,Ⅱ:50 MPa andⅠ:70 MPa,Ⅱ:30 MPa,the cross test on the four conditions was carried out,finally,the optimum homogeneous pressure and thermal death point were determined.

The determination of the optimum fermentation technologyBased on the basic formula which contains 15% water and 3%granulated sugar,and in accordance with the determined conditions of"The determination of the adding period of honey"-"The determination of homogeneous pressure and thermal death point",3%leavening agent was added and then fermented at 42℃,finally,the end-point offermentationwasmeasuredby titration acidity.

Stability test100 ml honey stirred yoghurt and 100 ml common yoghurt were separately got and then stored at 5℃,the precipitation proportion of whey was measured every 3 d,finally, the stability between honey stirred yoghurt and common yoghurt was compared based on the precipitation percentage of yoghurt.

Results and Analyses

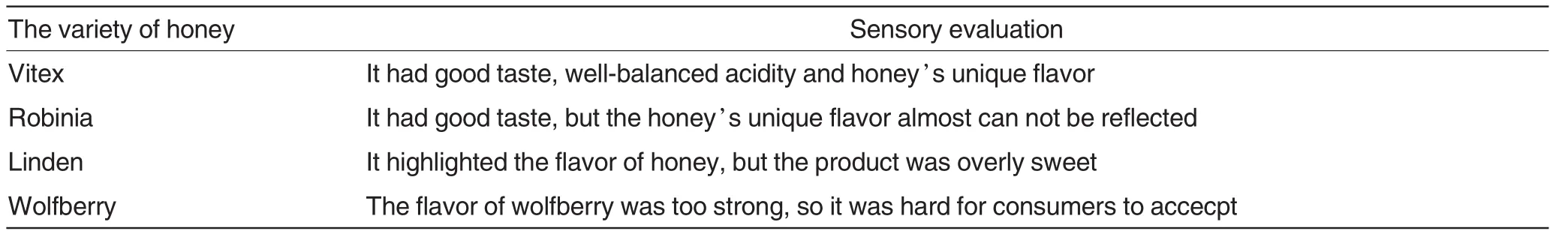

Effects of the varieties of honey on the sensory quality of products

As seen in Table 1,under the same additive amount of 3%honey, the sensory quality of vitex honey and linden honey was good,in which that of vitex honey was the best.

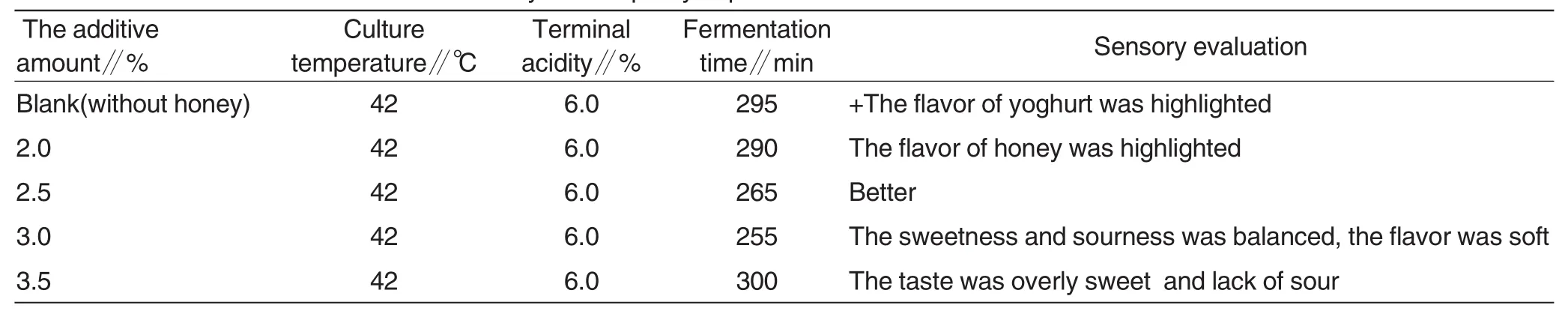

Effects of the additive amount of honey on the quality of products

As shown in Table 2,3%additive amount of vitex honey was the most suitable.When the additive amount was among 2%-3%,the fermentation rate gradually increased with the increase of additive amount,it may be that honey provided adequate carbon source for the growth of lactic acid bacteria,thereby promoting its fermentation rate.When the additive amount exceeded 3%,the fermentation rate slowed,it may be that with the increase of the additive amount of honey,the concentrations of glucose and fructose in fermented milk were too high,as a result,antibiotics and enzymes in high osmotic environment or honey generated inhibiting effect to the growth of lactic acid bacteria[5].

Effects of different adding periods of honey on the quality of products

As seen in Table 3,the sensory quality of the products was the optimal when the honey was added after sterilization and before fermentation.If thehoney was added before sterilization, most of the nutrients of the honey were destroyed during the high temperature sterilization,thereby causing the loss of nutritional ingredient,finally,the unique flavor of the honey can not be highlighted.If the honey was added after fermentation,although the nutritional ingredient of honey was kept, the honey was not involved in the fermentation,so the flavor of honey can not totally blend with the flavor of yoghurt,and the taste was poor.To keey the unique flavor and nutritional ingredient of honey stirred yoghurt,the honey should be added after the sterilization of milk at the temperature of 42-45℃,specially,the microorganisms from the honey may pollute sterilized milk in the link,therefore,the honey must meet the food grade standard and can not contain any pathogenic microorganisms.

Table 1 Effects of the varieties of honey on the sensory quality of products

Table 2 Effects of the additive amount of honey on the quality of products

Table 3 Effects of different adding periods of honey on the quality of products

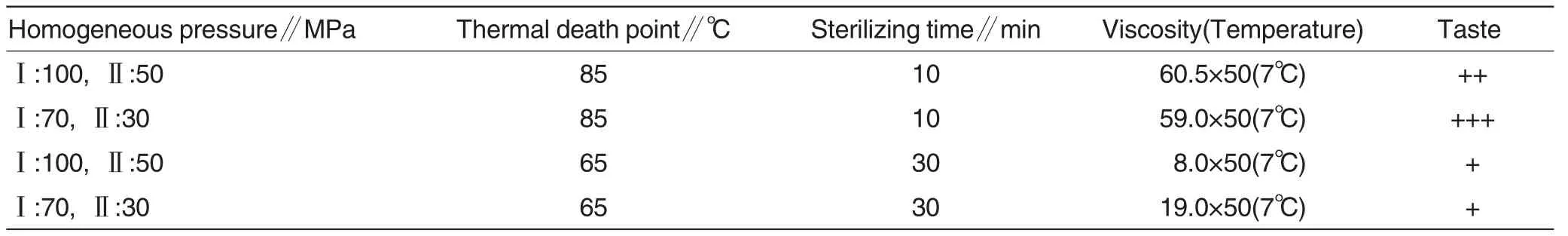

Table 4 Effects of homogeneous pressure on the quality of the products

Effects of homogeneous pressure and thermal death point on the quality of products

As seen in Table 4,the sensory quality of the products was the optimal when the homogeneous pressure wasⅠ:70 MPa,Ⅱ:30 MPa,the thermal death point was 85℃ and the time was 10 min.

Stability test

From Fig.1,it can be seen that the stability of yoghurt was improved obviously and the precipitation rate of whey was decreased obviously after adding honey,it may be that adding honey increased the viscosity of yoghourt to some extent and played the role of thickening,thereby improving the stability of the system.

Conclusions and Discussions

The fermentation temperature of the honey stirred yoghurt should not be too high,and it should be close to that of common yoghurt,namely 39-42℃.In addition,the fermentation time should not be too long,and 4-5 h was the best,because along with the extension of fermentation time,there would be abnormal smell in the yoghurt.The optimum formula and production technique were as follows:the additive amount of honey,sugarcane and fermentation agent was respectively 3%;two-section homogeneous pressures of the fresh milk wereⅠ:70 MPa,Ⅱ:30 MPa;the thermal death point was 85℃and the time was 10 min;the fermentation occurred at 42℃,and the fermentation of the product was stopped when the ultimate acidity was among 0.70%-0.75%.

To ensure the quality and unique flavor as well as nutritional ingredient of the products,it was suggested that the honey should be sterilized firstly and then be added into the sterilized milk,and the treating ways were:low temperature and high pressure treatment,vacuum treatment,the specific technological parameters needed to be further studied.For the effects of homogeneous pressure on the sensory quality of honey stirred yoghurt,the reasons were not very clear;under different homogeneous conditions, though the thermal death point was the same and the viscosity of the products was similar,the taste was absolutely different,so it was suggested that the effects of homogeneous pressure on the structure of fat globules should be studied.

[1]CHEN JS(陈驹声),WAN GY(万国余). Dairy products(乳制品)[M].Beijing: Chemical Industry Press(北京:化学工业出版社),1992:112.

[2]GUO Y(郭芸).The optimization of the manufacturing technique of milk soybean protein nutrition yoghurt(牛奶大豆双蛋白酸奶的生产工艺优化)[J].Farm Products Processing(农产品加工), 2011(12):91.

[3]TIAN QY(田其英).Research progress of the yogurt(酸奶的研究进展)[J].Sichuan Food and Fermentation(食品与发酵科技),2013(1):91-94.

[4]Native Products and Groceries Bureau, Ministry of Commerce of the People’s Republic of China(商业部土产杂品局). The basic knowledge of honey business (蜂蜜经营基础知识)[M].Beijing:China Commercial Publishing House(北京:中国商业出版社),1986:53.

[5]XU JL(徐家琳).The application of the dietary therapy of honey(蜂蜜的食疗应用)[J].China Livestock Products and Food(中国畜产与食品),1996(5):39.

[6]WANG SL(王树林).The selection and technology of the prescriptions of honey acid curd(蜂蜜酸凝乳配方筛选及工艺)[J].China Livestock Products and Food (中国畜产与食品),1997,4(3):113.

[7]Honey and care(蜂蜜与保健)[J].China Livestock Products and Food(中国畜产与食品),1995(4):186.

[8]ZENG L(曾理),JIANG X(江晓).Discussion on the culture conditions of lactic acid bacteria techniques(乳酸菌技术培养条件的探讨)[J].Chinses Journal of Health Laboratory Technology(中国卫生检验杂志),2004,14(2):253-255.

[9]ZHU JL(朱俊玲).The changes of pH value and lactic acid bacteria in yogurt with fructooligosaccharide during storage(酸乳在贮藏过程中pH酸度及乳酸菌的变化)[J].Science and Technology of Food Industry(食品工业科技),2004, 25(2):70-71.

[10]GUO QQ(郭清泉),ZHANG LW(张兰威),LIN SY(林淑英).The changes of Yogurt products during storage(酸奶制品在贮存过程中变化)[J].The Food Industry(食品工业),2002(1):27-29.

Responsible editor:Nanling WANG

Responsible proofreader:Xiaoyan WU

蜂蜜搅拌型酸奶的研究

王丽丽*,宝音德力格尔

(兴安职业技术学院,内蒙古乌兰浩特 137400)

[目的]研究蜂蜜搅拌型酸奶的最佳配方和工艺。[方法]通过研究蜂蜜添加量、蜂蜜添加时期、杀菌温度、均质压力及稳定性试验等对搅拌型酸奶感官质量的影响,确定了蜂蜜搅拌型酸奶的最佳配方和最佳生产工艺。[结果]试验得出,蜂蜜搅拌型酸奶的发酵温度不宜过高,发酵温度与普通酸奶相近;发酵时间不宜过长,因为随着发酵时间的延长酸奶会有异味产生。最佳配方和最佳生产工艺为:蜂蜜、蔗糖、发酵剂的添加量分别为3%;鲜牛奶二段均质压力为Ⅰ:70 MPa,Ⅱ:30 MPa,杀菌温度85℃、时间为10 min,并在42℃发酵,产品的最终酸度在0.70%~0.75%时停止发酵。[结论]研究可为蜂蜜搅拌型酸奶的生产加工提供参考依据。

蜂蜜;搅拌型;酸奶

王丽丽(1977-),女,内蒙古兴安盟人,讲师,硕士,从事农产品贮藏与加工工程研究,E-mail:351211592@qq.com。*通讯作者。

2015-04-26

修回日期 2015-07-20

*Corresponding author.E-mail:351211592@qq.com

Received:April 26,2015 Accepted:July 20,2015

Agricultural Science & Technology2015年8期

Agricultural Science & Technology2015年8期

- Agricultural Science & Technology的其它文章

- Simplified Cultivation Technology of Hua’an No.513——A New Summer Maize in Suixi County

- Research Progress on Heavy Metals Detoxification in Human Body

- The Strategies of Rainfall Accumulation and Utilization in New Countryside

- Advances in the Study of Protein Quality Traits and Main Influencing Factors of Wheat in China

- DNA Extraction from Half-grain Wheat Seeds without Using Chloroform

- Purification and Antimicrobial Assay of an Antimicrobial Protein from a Biocontrol Bacterium Strain K2-1 against Aquatic Pathogens