Research of Energy-saving Control of Oil-well Power Heater Based on RNN Neural Network

SUN Jingen,YANG Yang

(Shenyang Ligong University,Shenyang 110159,China)

Research of Energy-saving Control of Oil-well Power Heater Based on RNN Neural Network

SUN Jingen,YANG Yang

(Shenyang Ligong University,Shenyang 110159,China)

For the beam pumping unit,the power consumption of oil-well power heater accounts for a large part of the pumping unit.Decreasing the energy consumption of the power heater is an important approach to reduce that of the pumping unit.To decrease the energy consumption of oil-well power heater,the proper control method is needed.Based on summarizing the existing control method of power heater,a control method of oil-well power heater of beam pumping unit based on RNN neural network is proposed.The method is forecasting the polished rod load of the beam pumping unit through RNN neural network and using the polished rod load for real-time closed-loop control of the power heater,which adjusts average output power,so as to decrease the power consumption.The experimental data show that the control method is entirely feasible.It not only ensures the oil production,but also improves the energy-saving effect of the pumping unit.

RNN neural network;oil-wells;power heating;energy-saving

As the environment is getting worse and worse,people′s daily life has been affected.So we must strive to develop green economy and strengthen energy conservation and emissions reduction measures.Oil exploitation is a relatively large energy consuming industry,so it needs energy conservation and emissions reduction.In oil exploitation,beam pumping unit is the most commonly used oil extraction equipment,and the use count is huge.As to how to decrease the energy consumption of the pumping unit,the related articles present methods of energy conservation[1].For most of the oil field,due to the long-term exploitation,the oil wells have no enough liquid supplying and its submergence depth is very low and there are complicated conditions of oil extraction such as high viscosity and wax,sandy,too much gas,flooded and strong corrosion and so on appear,In order to guarantee the normal work and oil production of the pumping unit,for oil wells which have high viscosity and,wax and,sandy,the pumping unit always configures power heaters which can heat the oil wells,to lower oil viscosity and lighten the load of the pumping unit.In this way,it can not only increase oil production,but also decrease the failure rate of the pumping unit[2].The power consumption of the pumping unit equipped with power heaters includes two parts,the power consumption of motor and that of the power heater.The second part almost accounts for half of the whole power consumption.So decreasing the power consumption of the power heater can directly reduce the power consumption of the pumping unit.Aiming at the current situation of power heater control and energy-saving measures,the article proposes an energy-saving control method of the oil well power heater based on RNN neural network.The core of the method is forecasting the polished rod load of the pumping unit through RNN neural network and constituting a closed-loop control of the power heater by the polished rod load.The experimental data show that the control method is completely feasible.It can decrease the power consumption of the power heater and the energy-saving effect is obvious.It can achieve the purpose of energy conservation and emissions reduction of the oil field[3].

1 THE OVERVIEW OF THE CONTROL METHOD OF OIL-WELL POWER HEATER

With the continuous deepening of the oil field development,for the oil production plants based on high pour-point oil,the pumping unit must configures power heater through which heat the oil and light it,so that we can lift the crude oil to the ground smoothly.At present the physical methods of oil well heating includes two kinds.One is hollow rod hot-line;the other is the energy into heat energy and lighting the crude oil by heating it in order to lift it to the ground.At present,there are three kinds of commonly used methods of oil-well power heater control[4],as outlined below:

1)Continuous control method

In order to guarantee the normal work and oil production of the pumping unit,the power heater operates at full power and runs continuously long-term.Although this method can ensure the pumping unit work normal,the oil production continues to decrease with the submergence depth of the oil-well becomes lower and the continuously running power heater will waste a lot of electrical energy[5].So the method has no energy-saving effect.

2)Changing the power method

This method is periodically altering the output power of the power heater to achieve the energy-saving purpose.But how to determine the output power time of the power heater is very difficult and it can only rely on the technicians′ experience to adjust the power heater′s power.So it does not have operability[6].

3)Timing control method

This method make the power heater operates at full power,but it runs periodically by clock control,not runs continuously.The shortcomings of the method is the same with the changing power method-it is difficult to determine the running time and the stop time of the power heater and it also can only rely on the technicians′ experience to determine the time.Due to the continuously change of the oil-well condition,this metod does not have operability[7].

All of the methods above can′t break through the open-loop control of the power heater and can′t realize the power heater adjusting automatically as the load of the pumping unit changes.To realize the real time automatic control of the power heater,a closed loop control system regarding the power heater as control object should be formed.

2 THE REALIZATION OF ELECTRIC HEATING CONTROL BASED ON RNN NEURAL NETWORKS

2.1 The principe of how the RNN neural network predict the load of the pumping unit

For the pumping unit normally produced,the polished rod load is mainly be affected by the flow condition,the extent of wax deposition and clotting of the oil in addition to the liquid production of the well.In the case of the liquid production is constant,when the flow condition is worse or the extent of wax deposition and clotting is deteriorated,the polished rod load will be obviously increased,otherwise the load will be reduced.So we can control the mode of operation of the electric heating through monitoring the load of the pumping unit[8].That is,starting the power heater when the load is large,and stopping it when the load is low.So the key to this problem is how to measure the polished rod load of the pumping unit.The method so far is regular inspection,and measuring directly by the load sensor requiring the halt and start-up each time.So the measure process is not only complex and has a knock on the pumping unit which will affect the lifetime of it,but also makes us don′t know the real time operating condition is complex due to the periodical inspection.In addition,the operating condition of the pumping unit is complex and the load sensor cannot adapt to the long-term working condition.That is to say the load sensor can not realize the real-time measurement of the polished rod load.Since we cannot directly measure the polished rod load of the pumping unit in real time,other methods should be used.Researchers have proposed indirect measurement of the polished rod load.However,the method requires the speed of the landing top and the speed of the top and bottom dead center of the beam pumping unit is zero,so the load error of this position is large.This article proposes an indirect measurement method which forecasting the polished rod load of the pumping unit based on the RNN neural network[9].The variation of physical quantities that the pumping unit involves are nonlinear and these physical quantities have no certain mathematical relationships,so we can build the mapping relationship between the main physical quantities which can be directly measured and the polished rod load utilizing the nonlinear approximation ability of the neutral network.Taking the real-time and complexity of the pumping unit into consideration,the main physical quantities selected should not only can be easily real time measured but also can reflect the polished rod load of the pumping unit,so choosing the motor power,polished rod displacement and motor current as the input variables of the neural network and the polished rod load as the output variable[10].Also,the continuity and dynamic characteristic of the polished rod load are considered.So the neural network structure is intended to be RNN neural network—recurrent neural network.RNN neural network train by BP algorithm,so the neural network that adopted in this paper might name it ′BP-RNN′ model as well.Descriptions of its working principle are below:

The beam swing angle(θ),is measured by angle sensor,motor power(A),is measured by power transmitter,and motor current(I),is measured by current transmitter.The beam pumping unit is cyclically operating and the period of different type are not necessarily the same,but the pumping unit′s cranks are all rotated 360 degree in a period.So using the rotation angle of the crank to determine the number of measurement points in a cycle is more intuitive.Generally we can adopt 5,10 or 15 degree as measuring distance and one distance corresponding to a sampling point which is represented byk.The′BP-RNN′ model that this paper select has three input variables and one output variable,as show in figure 1.Three input variables are respectively the motor powerA(k),the polished rod displacementS(k)and motor currentI(k).Among them,S(k)is calculated by theθ(k)according to the beam forearm length and the output variable of the neural network is the polished rod loadP(k+1).Neural network hidden layer weightsWijand thresholdsBiin table 1 and table 2.The output layer weightsWkand thresholdsBkin table 3 and table 4.

Figure 1 BP-RNN Neural network diagram

Table1NEURALNETWORKHIDDENLAYERWEIGHTWij

J1J2J3J4J5J6I1-0 6064-1 2240-0 6723-0 53800 8276-2 0144I2-0 56270 3436-0 7771-1 42250 6882-1 5930I30 0325-1 22341 71350 1430-0 8506-1 9010I4-1 56070 3105-1 1922-3 40711 77902 1424I53 5005-3 04833 4956-4 4224-3 7098-3 3918I6-0 2985-0 43751 3028-0 06940 83900 0168

Table2NEURALNETWORKHIDDENLAYERTHRESHOLDBi

i123456Bi-1 8872-1 13230 7334-0 3774-1 1323-1 8872

Table3NEURALNETWORKOUTPUTLAYERWEIGHTWk

k123456LWk0 91632 7138-1 24216 44272 35773 6090

Table4NEURALNETWORKHIDDENLAYERTHRESHOLDBk

k123456Bk-1 3529-0 98760 2673-0 7539-1 14621 7352

As can be seen from the figure 1,the BP network of ′BP-RNN′ neural network model has three layers— input layer,hidden layer and output layer. The input layer has six input variables. In addition toA(k),S(k),I(k),the other three are the previous three values of the polished rod loadP(k+1)—P(k),P(k-1)andP(k-2).This can not only consider the dynamic characteristic,but also reduce the calculation amount of the neural network. The number of neurons of the hidden layer can be determined by the training precision. As for the BP theoretical computing process,this article won′t specify and it can be seen in resource[11].Generally speaking,the oilfield data center saved the historical data of each pumping unit.These data include well number,data of the indicator diagram(polished rod load and displacement),motor power,motor current,pumping parameters,speed,stroke,etc.That is to say,owning these historical data means owning the training sample data of the neural network.The composition of the sample data will be specified in the section of testing results and analysis.

2.2 The realization of the closed-loop control of Oil well electric heating

In order to achieve real-time closed-loop control of the oil well electric heating,the control system requires hardware devices and software programming.The control system block diagram is shown in Figure 2.

Figure 2 Well electric heating control blook diagram

As can be seen from Figure 2,the oil well electric heating control system is comprised by controller,angle sensor,power transmitter,current transmitter,data display and parameter setting unit,power heater,etc.The core of the system is controller which is to complete the tasks of measurement,data calculation,the prediction and control of the neural network.The working process of the system is shown as below:The angle sensor can use the beam pumping unit dedicated angle sensor which is used to measure the angle of the beam pumping unit movement(θ)and the controller convert the data of the angle sensor into polished rod displacement(S(k))through program;The power transmitter is in charge of converting the motor power into the signal that the controller received and the controller convert the received power signal into the real-time power of the motor(A(k));The current transmitter is to transform the motor current to the signal that the controller received and the controller convert the received current signal into real-time current of the motor(I(k));With the data ofA(k),S(k)andI(k),the controller forecasting the polished rod load in real-time through the trained neural network application.When the forecasting load is larger than the set start-up corresponding value,the controller starts up the power heater;when the forecasting load is lower than the set halt corresponding value,the controller stops the power heater.

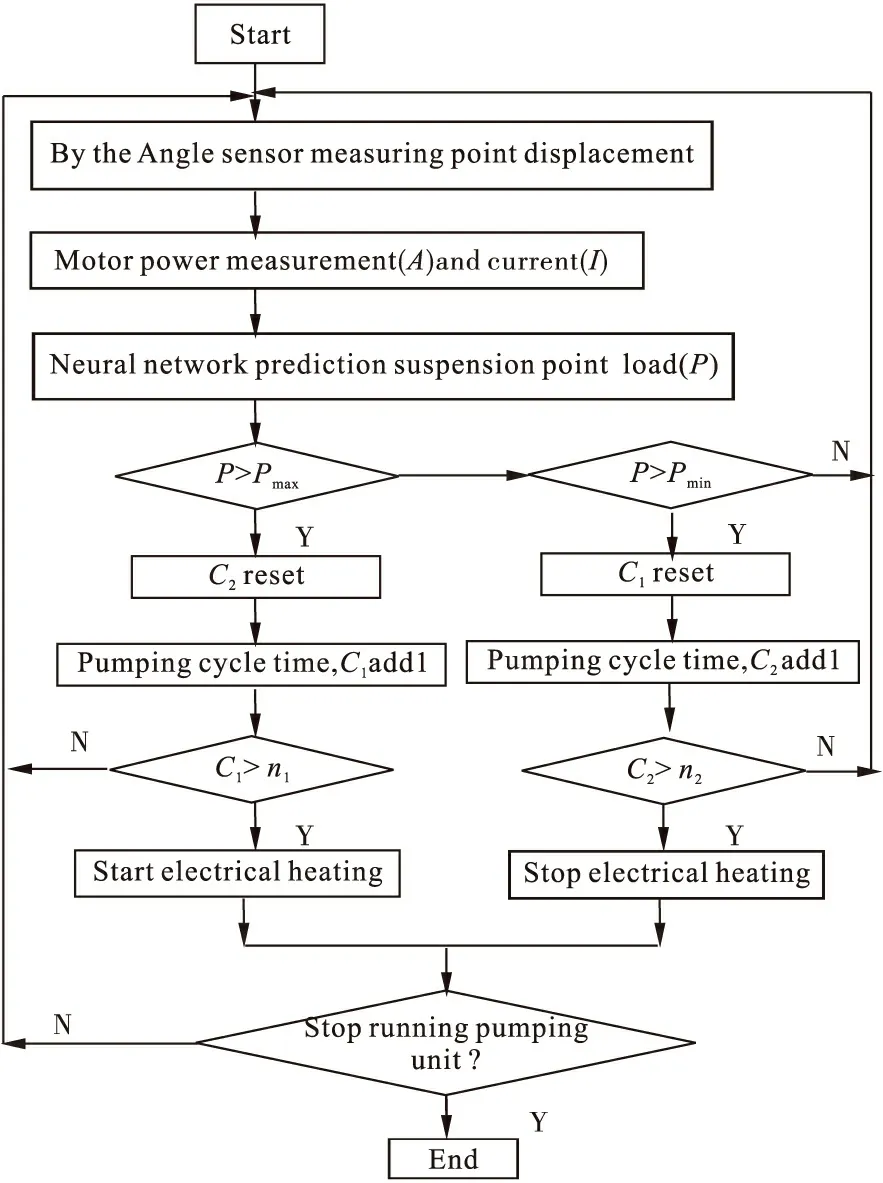

So it realized the closed-loop control of the power heater through the controller according to the polished rod load.The parameters that the control system required is inputted through data display and parameter setting unit and these parameters include some technical data of beam pumping unit(such as beam forearm length,maximum load,etc.),the weight parameters of neural network,the control frequency that the power heater allows to start and stop and so on.While the closed-loop control of power heater is realized by forecasting the polished rod load through neural network,considering the complexity of the working condition of pumping unit,in order to ensure the normal operation,other factors that influence the electrical heating should be considered.For example,set reasonable maximum and minimum load parameters that used for electric heating start-stop control and prevent frequent movement of the power heater and so on.The basic flow of the electric heating closed-loop control is shown in Figure 3.

In Figure 3,PmaxandPminare the parameters of set maximum polished rod load and minimum polished rod load,which are the basis of starting and stopping the power heater.C1andC2are the counters.C1is used for accumulating the work cycle times of the pumping unit when the real-time polished rod is larger than the set load andC2is used for accumulating the work cycle times of the pumping unit when the real-time polished rod is lower than the set load.Their role is equivalent to time delaying function,preventing the frequent movement of the power heater.n1andn2are the set value corresponding to counterC1andC2.

Figure 3 The flow chart of the well electric heating control

3 TEST AND RESULT ANALYSIS

3.1 The profile of the testing pumping unit

The closed loop control system of oil well electric heating based on RNN neural network breakthrough the traditional oil well electric heating control method.Utilizing this method to test an oil well and the technical data of the testing well are as follows:

Well number: JING29-35

Pumping Model: CYJY12-12-5-73HB

Motor rated power: 45kw

Power heater rated power: 45kw

Stroke: 5.30m

Pumping speed: 2.84beats/min

Mode of production: Within Hotline

3.2 The samples collecting data of the neural network

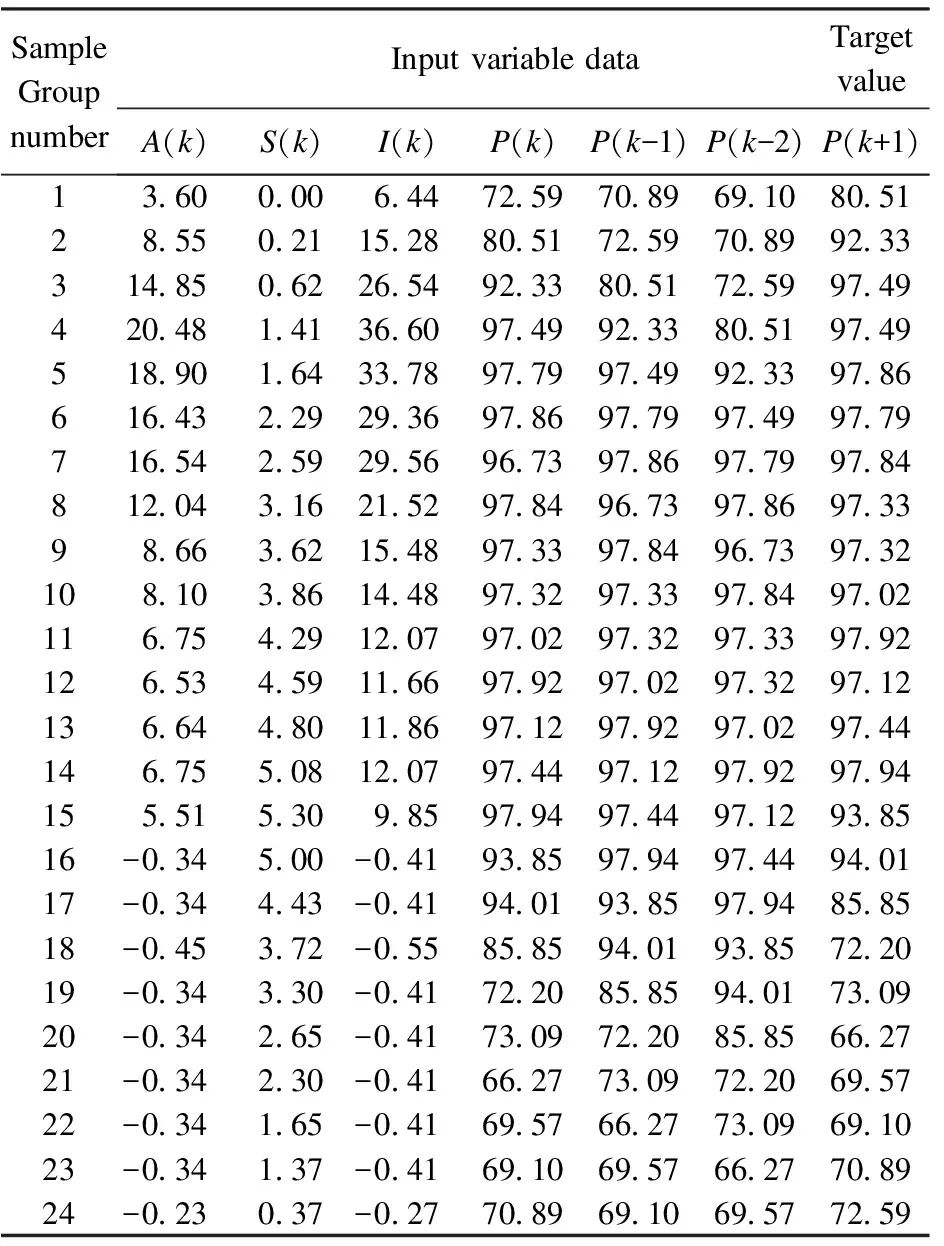

Get the historical data of JING29-35 from the oilfield data center and these data include the load,displacement,motor power and motor current of the pumping unit. Due to large amount of data,this article won’t list them.For illustrative purpose,take the example of the pumping unit data of one cycle to illustrate the composition of the sample data.The crank of the pumping unit turns 360 degree in a cycle and chooses 15 degree as one sampling point,so it needs 24 times of data sample in a cycle.Table 5 is about the historically original data of one cycle.From the historically original data in table 5 and according to the mapping relation of the input and output of the ‘BP-RNN’ model,can compose the sample data that the neural network training needed.Table 6 lists part of the sample data-six groups of samples.According to the rule of table 6,the historical data of a cycle can compose 24 samples of data groups.

During the trial,the neural network is trained using offline mode and utilizing Matlab tools and the training results are directly applied to the controller program.Although table 6 only lists 24 groups of samples,the actual training is using multiple groups of data samples that composed by the data of multiple operating cycles of the pumping unit.The more data samples,the more accurate is the load that the neural network forecasted.

Table 5 THE DATE OF A CYCLE

Table6NEURALNETWORKTRAININGSAMPLEDATA

SampleGroupnumber InputvariabledataTargetvalueA(k)S(k)I(k)P(k)P(k-1)P(k-2)P(k+1)13 600 006 4472 5970 8969 1080 5128 550 2115 2880 5172 5970 8992 33314 850 6226 5492 3380 5172 5997 49420 481 4136 6097 4992 3380 5197 49518 901 6433 7897 7997 4992 3397 86616 432 2929 3697 8697 7997 4997 79716 542 5929 5696 7397 8697 7997 84812 043 1621 5297 8496 7397 8697 3398 663 6215 4897 3397 8496 7397 32108 103 8614 4897 3297 3397 8497 02116 754 2912 0797 0297 3297 3397 92126 534 5911 6697 9297 0297 3297 12136 644 8011 8697 1297 9297 0297 44146 755 0812 0797 4497 1297 9297 94155 515 309 8597 9497 4497 1293 8516-0 345 00-0 4193 8597 9497 4494 0117-0 344 43-0 4194 0193 8597 9485 8518-0 453 72-0 5585 8594 0193 8572 2019-0 343 30-0 4172 2085 8594 0173 0920-0 342 65-0 4173 0972 2085 8566 2721-0 342 30-0 4166 2773 0972 2069 5722-0 341 65-0 4169 5766 2773 0969 1023-0 341 37-0 4169 1069 5766 2770 8924-0 230 37-0 2770 8969 1069 5772 59

3.3 The simulation

Matlab is acombination of two words matrix and laboratory,meaning matrix factory.Used to provide access to LINPACK and EISPACK matric interfaces package.Then it gradually developed into the general technological calculation chart visual interactive systems and programming languages.

Figure 4 Matlab operate interface

Figure 5 Matlab operate plotperform

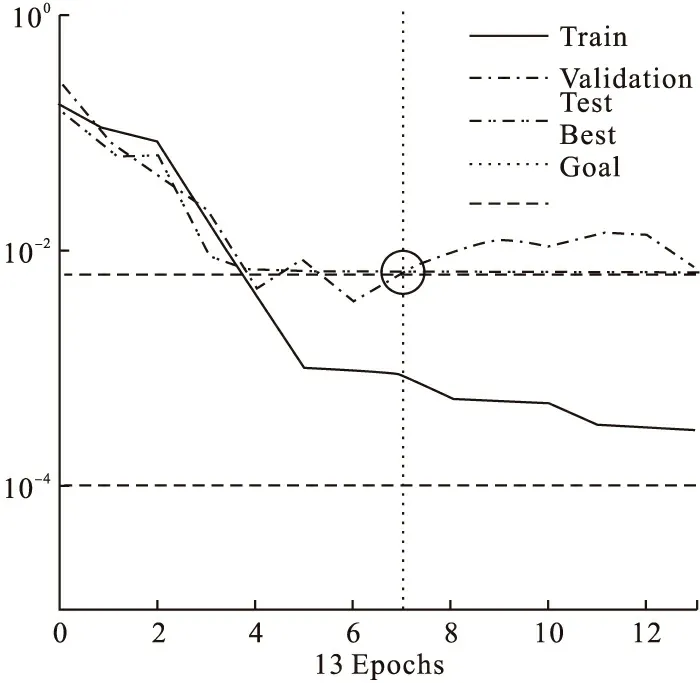

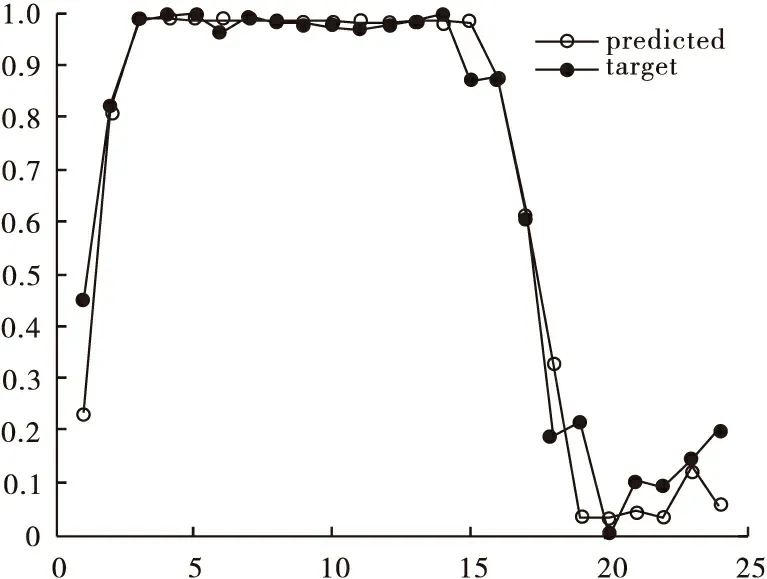

During the simulation,the accuracy of the neural network is tested.Some pre-processing is needed before the training data can be used by the network.Each column of the input data should be normalized to[0.0 1.0] linearly.Select 14 groups of experimental data as training sample of neural network,in addition to select 10 groups of experimental data as test sample.BP algorithm to select the initial learning rate parameter 0.03,the number of learning toN=1000 times.Learning rate changes with the number of learning in figure 4.From figure 5,the best validation performance of Matlab operate plotperform is 0.0061018 at epoch 7.And antinormalization should be preformed to achieve the orginal scale.The neural network toolbox in Matlab is applied in the simulation for training and testing.Figure 6 shows the difference between the output of the trained neural network and the target.

Figure 6 The actual output compared with training

The simulation between the prediction and target proves the validity of the application of neural network.

3.4 Test results

The control system was put into operational testing in the oil well that the JING29-35 pumping unit was in and it set the electric heating start and stop parameters—Pmax=89.80kN,Pmin=79.00kN,n1=n2=10.Under normal working condition of the pumping unit,the data that the controller recorded when the power heater is operating are below:

Working hours of the pumping unit:t=210.13 hours.

Run time of the power heater:tON=158.6 hours.

Stop time of the power heater:tOFF=51.53 hours.

We might as well take the power saving rate of the power heater forηandη=tOFF/t.So the power saving rate of the power heater of the testing pumping unit is:

η=tOFF/t

=51.53.82/210.13×100%

=24.52%

The power saving rate above is defined relative to continuous run of the oil well electric heating.When the electric heating is continuous,the power heater is running in full power.So the power saving rate is zero on the definition above.From the power saving rate of the testing oil well,we can see that the power saving rate of the power heater reached 24.52%under normal working condition of the pumping unit and the energy-saving effect is very obvious.

4 CONCLUSION

1)For the energy consumption of the pumping unit,the power consumption of the power heater of oil-well accounts for the majority of the pumping unit.So decreasing the energy consumption of the power heater is an important approach to reduce that of the pumping unit.

2)The control method of the oil well electric heating based on RNN neural network that the article proposed breakthrough the traditional oil well electric heating control method.The core of the method is forecasting the polished rod load of the pumping unit through artificial neural network and constituting a closed-loop control of the power heater to adjust the output average power of the power heater for the purpose of electric heating energy saving.

3)In control method of the oil well electric heating based on RNN neural network that the article proposed breakthrough the traditional oil well electric heating control method.Else,other factor is considered.

4)The application instance verified the validity of the electric heating control method.For the testing oil well,under normal working condition of the pumping unit,the power saving rate of the power heater reached 24.52%and the energy-saving effect is very obvious.If the method was volume applied,it will greatly reduce the electricity costs of oil producting and achieve the purpose of energy conservation and emission reduction reaching green economy.

[1]Su Desheng,Liu Xiangang,Lu weixiang,et al.Summarizes of energy saving of Weak-beam Oil-pumping Units[J].Petroleum Machine,2001,29(5):49-53.

[2]Cai Xiuli,Zhou li.Pilot Study of oil-pumping energy saving[J].Oil Field Energy Saving,2006,17(2):24-29.

[3]Ramkamal Bhagavatula,Olu A.Fashesan,Loyd R,et al.A Computational Method for Planned Kinematic Analysis of Beam Pumping Units[J].Journal of Energy Resources Technology,2007,12(6):19-26.

[4]Wang Heyan,Wang Zonghe.Develop Intelligent Control Device[J].Modern Making Engineering,2005,22(9):97-99.

[5]Ma Guangjie,Zhang Jizhen,Yang Jing,et al.Develop Power Device of Weak-beam Oil-pumping Units[J].Petroleum Machine,2006,34(5):32-34.

[6]DING Bao,QI Wei-gui,ZHU Xue-li.A Study of Energy2Saving Control of Oil Pump Based on Fuzzy Neural Network Prediction[J].ACTA ELECTRONICA SINICA,2004,32(10):1742-1745.

[7]Bernie Miller,Nicholas Boyaci.Hydraulic diaphragm electric submersible pump improves completion design lowers lifting costs[J].World Oil,2006,23(7):42-35.

[8]Li Xiaopeng,Meng Tao,Zhao Chun.Experimental Study on a Novel Linear Electromagnetic Pumping Unit[J].IEEE Transactions on Magnetics,2007,9(3):36-58.

[9]Barry J,Ding Li Yu.Selecting radial basis function network centers with recursive orthogonal least squares training[J].IEEE Trans Neural Networks,2000,11(3):306-314.

[10]Zhang Jianjun,Li Changxi.Indirect Measure Method of Dynamometer Card of Beam Pumping Unit[J].J.Huazhong Univ.of Sci.& Tech(Nature Science Edition),2004,32(11):35-37.

[11]Rahman S,Bhatnagar R.An expert system based algorithm for short-term load forecast[J].IEEE Trans on Power System,1998.3(2):392-399.

马金发)

date: 2013-12-09

Biography: SUN Jingen(1962—),male,associate professor,Research direction:mainly engaged in intelligent control,power electronic technology,energy saving control,PLC application aspects of teaching and scientific research work.

1003-1251(2014)04-0087-08

TH71DocumentcodeA