Numerical simulation of projectiles with different structures penetrating multi-storey concrete target board

JIN Shu-yun,ZHU Qian-qian,NING Qian-hui

(Science and Technology on Electronic Test & Measurement Laboratory,North University of China,Taiyuan 030051,China)

The deformation,broken and rupture of materials make the analysis of penetration process complicated,especially for the projectile penetration in the field of solid dynamics with high impact.At present,the analysis of penetration process is mainly made by domestic scholars according to a large number of penetration tests.Although some achievements are obtained,it is still not enough.In addition,the cost of prototype test is very high but poor repeatability.Therefore numerical simulation can be used for study of penetration process to sum up some rules to supplement the experimental research[1-4].Nowadays the research report about numerical simulation of projectile structure refinement is still rare.

This paper uses ANSYS/LS-DYNA,a finite element analysis software,to establish two kinds of projectile body structures for numerical simulation experiment and obtains the corresponding acceleration curves.The test plan is designed to obtain the measured acceleration curve.By comparing the simulating curves and measured curve,the effect of projectile structure on the acceleration curve is emphatically defined and studied.

1 Finite element model

1.1 Structural design of projectile body

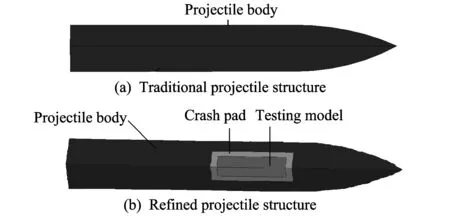

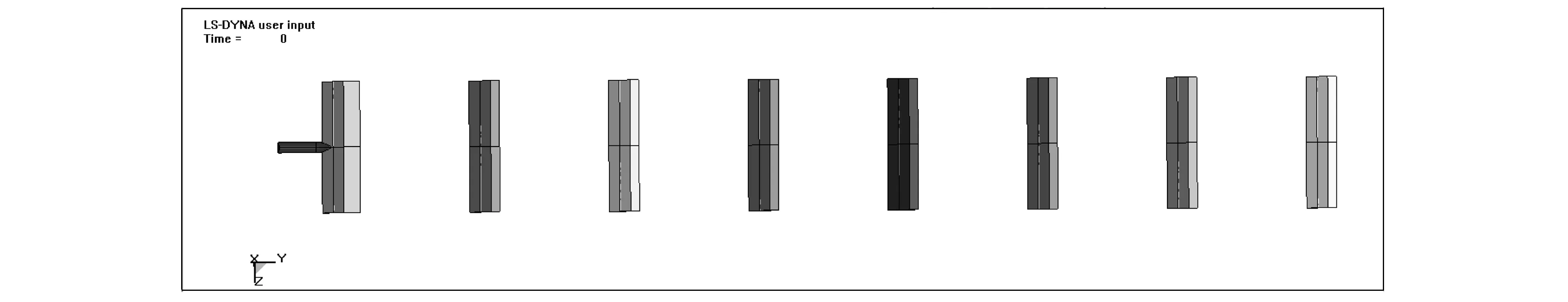

Traditional projectile structure is generally designed to have oval head and the whole body is simplified to one material (see Fig.1(a)).Taking projectile body acceleration curve as the penetration research object,this paper refines projectile structure,and puts it in crash pad and testing module which is the simplification of sensor and record module.To be convenient for calculation,the crash pad is surrounded around the test module (Fig.1(b)).The two kinds of projectile structures are shown in Fig.1.

Fig.1 Projectile with different structures

1.2 Basic assumptions of calculation

A coordinate system is established.It uses 3D entity unit solid164 for meshing through Lagrange algorithms,which makes the grid cell adhere to the materials and generates deformation of the unit along with flow of materials.

When geometric models of projectile and structure of concrete target board are established,the projectile and the target board have the following assumptions in the process of simulation:

1) Projectile and target board are considered to be uniform and continuous.The projectile is taken as a rigid body,and the concrete target board is regarded as infinite domain which has no initial stress and boundary effect.

2) Projectile vertically penetrates concrete target board,which means the angle of penetration is zero and gravity is disregarded.

3) The penetration process is adiabatic regardless of the air resistance and the impact from projectile vibration.

2 Simulation

2.1 Material model and parameters

In numerical simulations,the influence of the choice of material model on simulation results is important.The projectile and test modules in this paper both choose the common nonlinear plasticity model PLASTIC_KINEMATIC[5].In this model,the parameters are simple and easy to be determined.Its failure law is relatively flexible,so it can suit for a variety of engineering metal materials.The model parameters depend on the Cowper-Symonds expressions

(1)

(2)

whereEis Young's modulus,andEtis the stope of the bilinear stress strain.

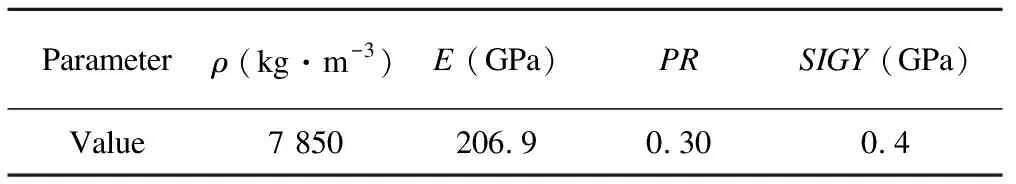

The material of projectile selects 45# steel and the parameters are shown in Table 1.

Table 1 Material parameters of steel

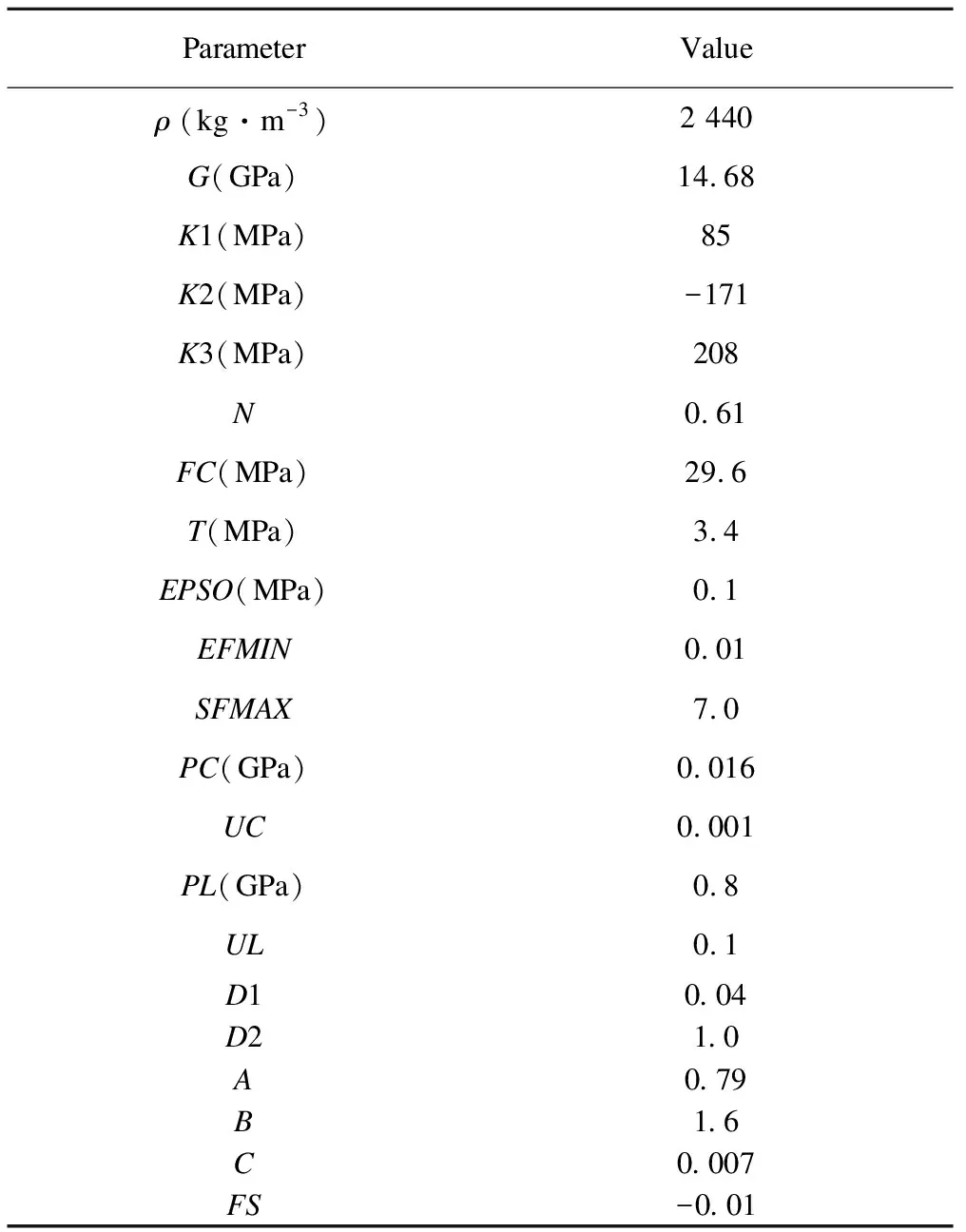

The concrete target board adopts Johnson-Holmquist-Concrete (J-H-C) damage accumulation model considering high pressure,high strain and large deformation.The material model,J-H-C[6],is constitutive equation of concrete damage with compression.Because this model only considers the destruction of the material in the case of compression,concrete unit will produce distortion but not failure,which seriously does not accord with the actual phenomenon.Only by adding MAT_ADD_EROSION[7]material model,setting the tensile strength and adding tensile failure criteria,the concrete target board will produce hole and avalanche phenomena due to the formation of micro crack’s extension and cut-through to be consistent with actual results.

The material of concrete target board and the parameters are shown in Table 2.

Table 2 Material parameters of concrete

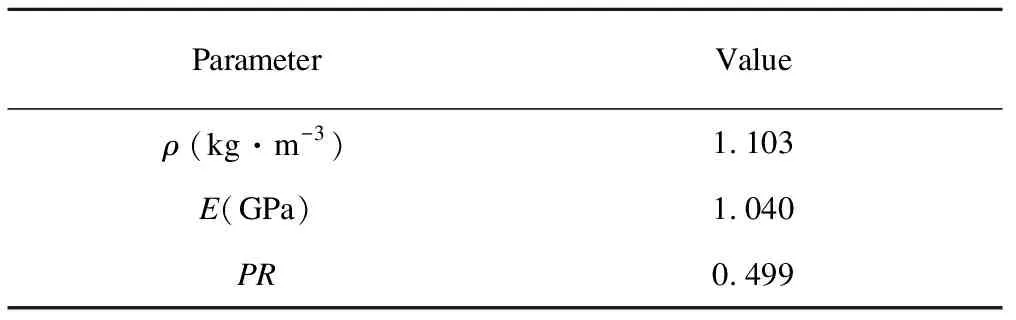

MAT_MOONEY-RIVLIN_RUBBER[8]is chosen as the rubber model of crash pad.The material parameters are shown in Table 3.

Table 3 Material parameters of rubber

2.2 Simulation

The size of simulation model is as follows: the projectile isΦ10 cm×50.5 cm (diameter×length).The target plate has 8 storeys.Among them,the size of the first level storey is 100 cm×100 cm×15 cm (length×width×thickness),and the others are all 100 cm×100 cm×8 cm (length×width×thickness).The distance between each storey is 120 cm and their initial velocities of penetration are all 0.691 cm/μs.

The measurement unit system cm-g-μs is used.In order to reduce the amount of calculation,with the symmetry of structure and load,1/4 target projectile of finite element models is established.In order to reduce the influence of grid on penetration,meshing method can be adopted according to Ref.[4],in which warhead and the target body center mesh using fine grid method,and the ratio of radii of the projectile and the grid side is about 6.0.

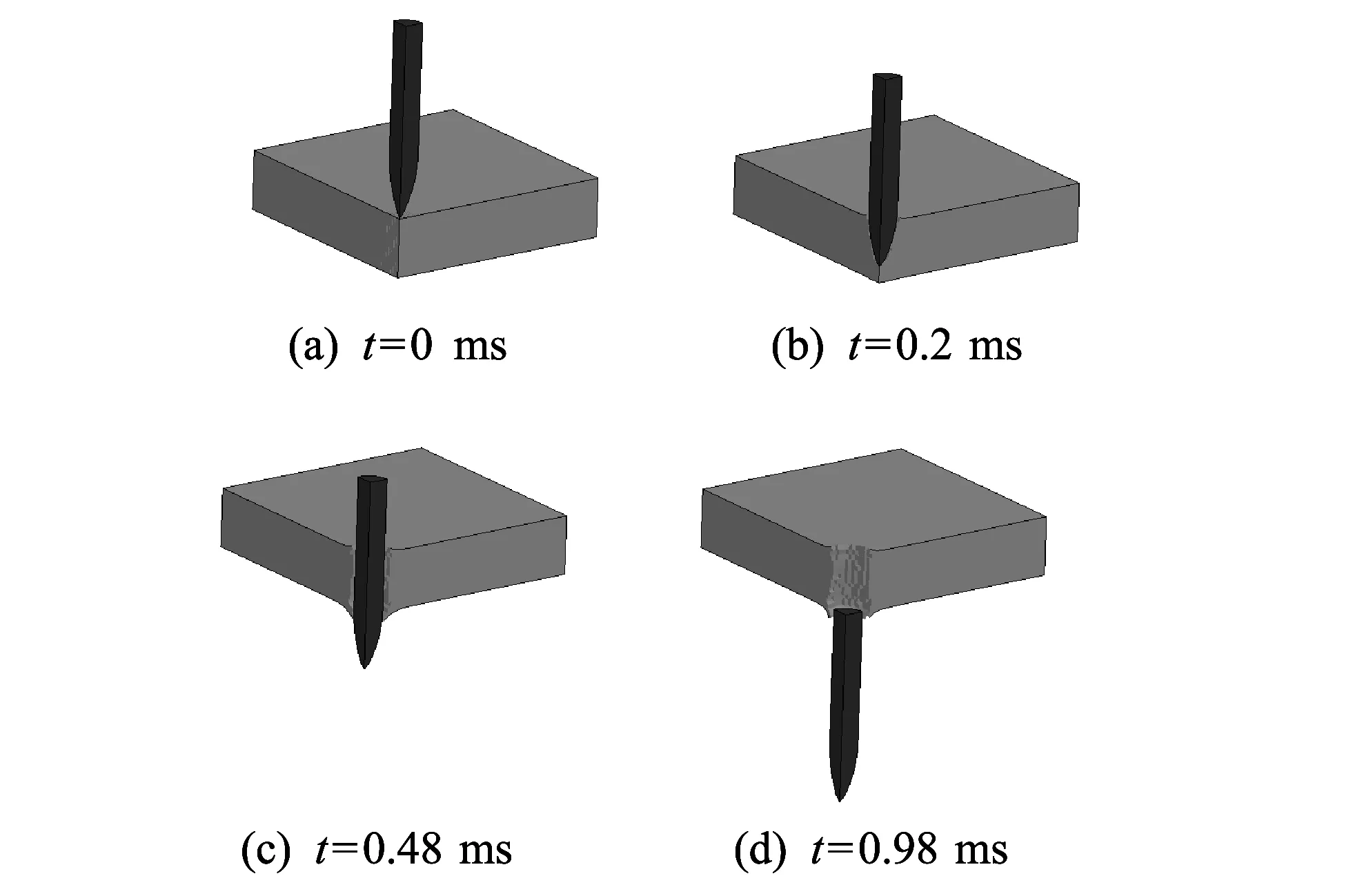

Between the projectile body and concrete target board,all the modules in the internal projectile adopt contact algorithm of plane-plane erosion.Between the projectile and target,plane-plane contact erosion algorithm is also adopted in each module of the internal projectile.When the plastic strain of steel board reaches failure value,the units are deleted to vividly simulate the fracture of target board as well as the interactive extrusion deformation between the projectile and target board.The time length of calculation is 1 600 μs and the step length is set at 16 μs.The 3D model of projectile penetrating concrete target board is shown in Fig.2.

Fig.2 3D model of projectile penetrating concrete target board

Fig.3 shows the penetration images of projectile the typical time of each stage: (a) is the early stage of opening hole; (b),for steady penetration phase; (c),for through phase; and (d) is completely passing through phase.It can be seen that the physical images given by numerical calculation are consistent with the theoretical analysis,which declares the simulation method in this paper is correct and it can reproduce the evolution processes of the penetration.

Fig.3 Penetration images of different time

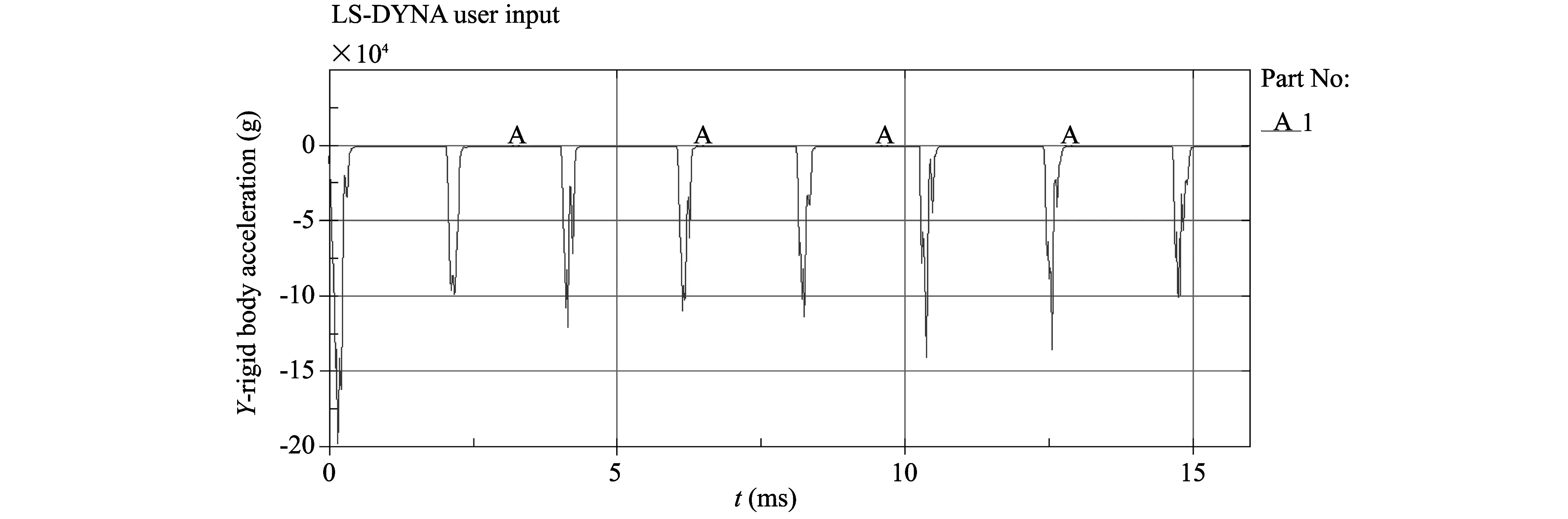

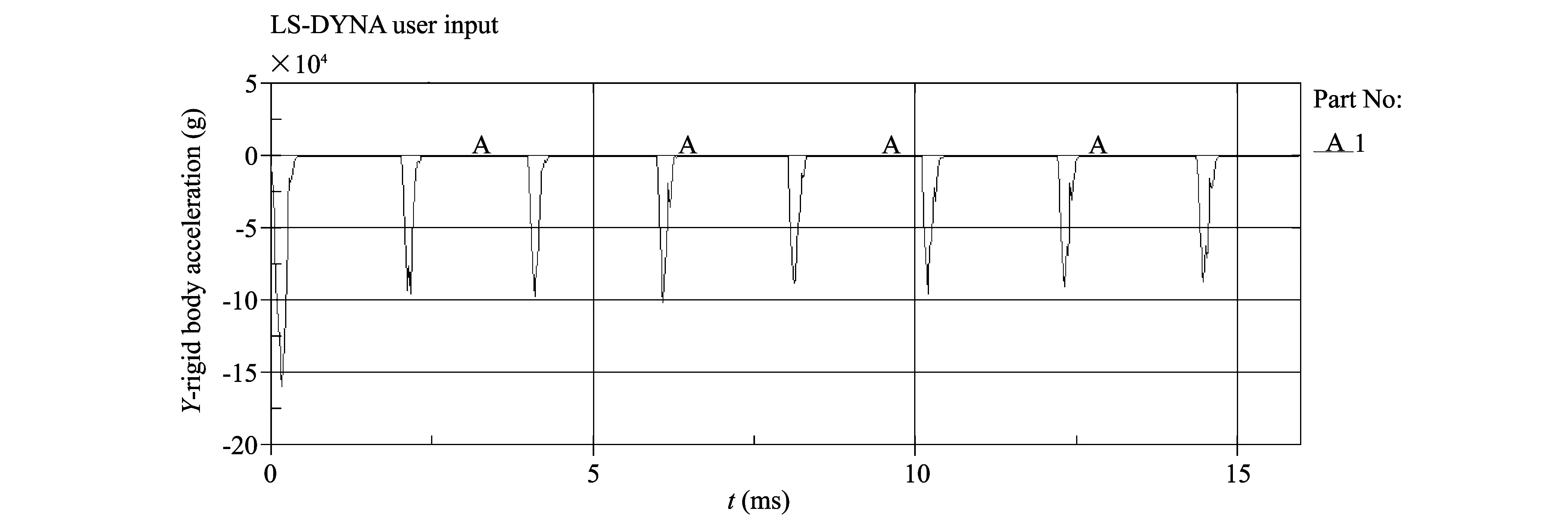

2.3 Curve analysis

The traditional simulation acceleration curve 1 of projectile is simplified as one which is shown in Fig.4.The simulation acceleration curve 2 of refined projectile is shown in Fig.5.

Fig.4 Acceleration curve of simplified projectile

Fig.5 Acceleration curve of refined projectile

3 Actual test experiment

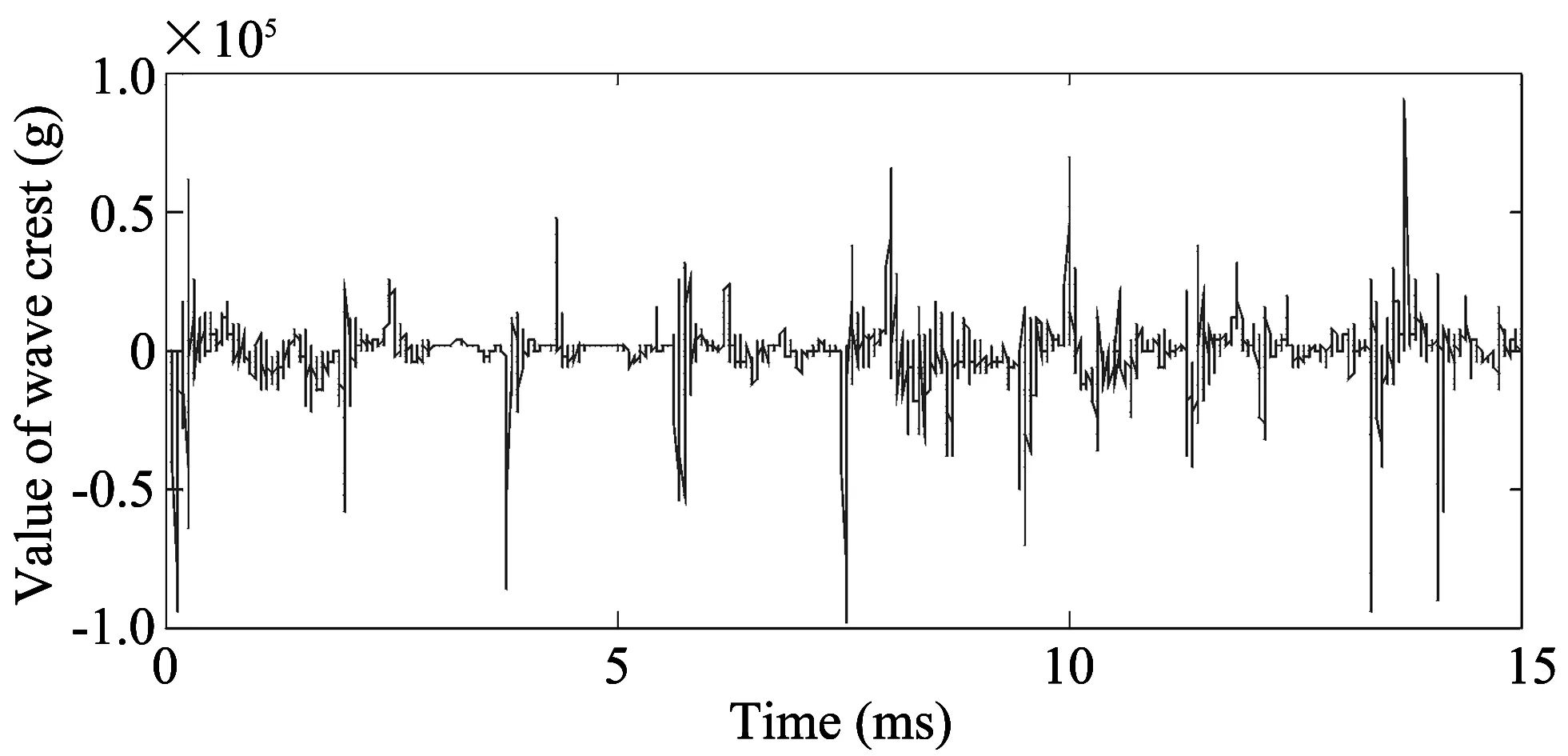

In test experiment,the measured projectile material is 45# steel and the target board is concrete.Furthermore,the projectile size,target board size and distance between each target borad are the same as those of the simulation.After the test experiment is completed,the record module is taken out from the projectile body,getting the actual measured acceleration curve,as shown in Fig.6.

Fig.6 Measured acceleration-time curve

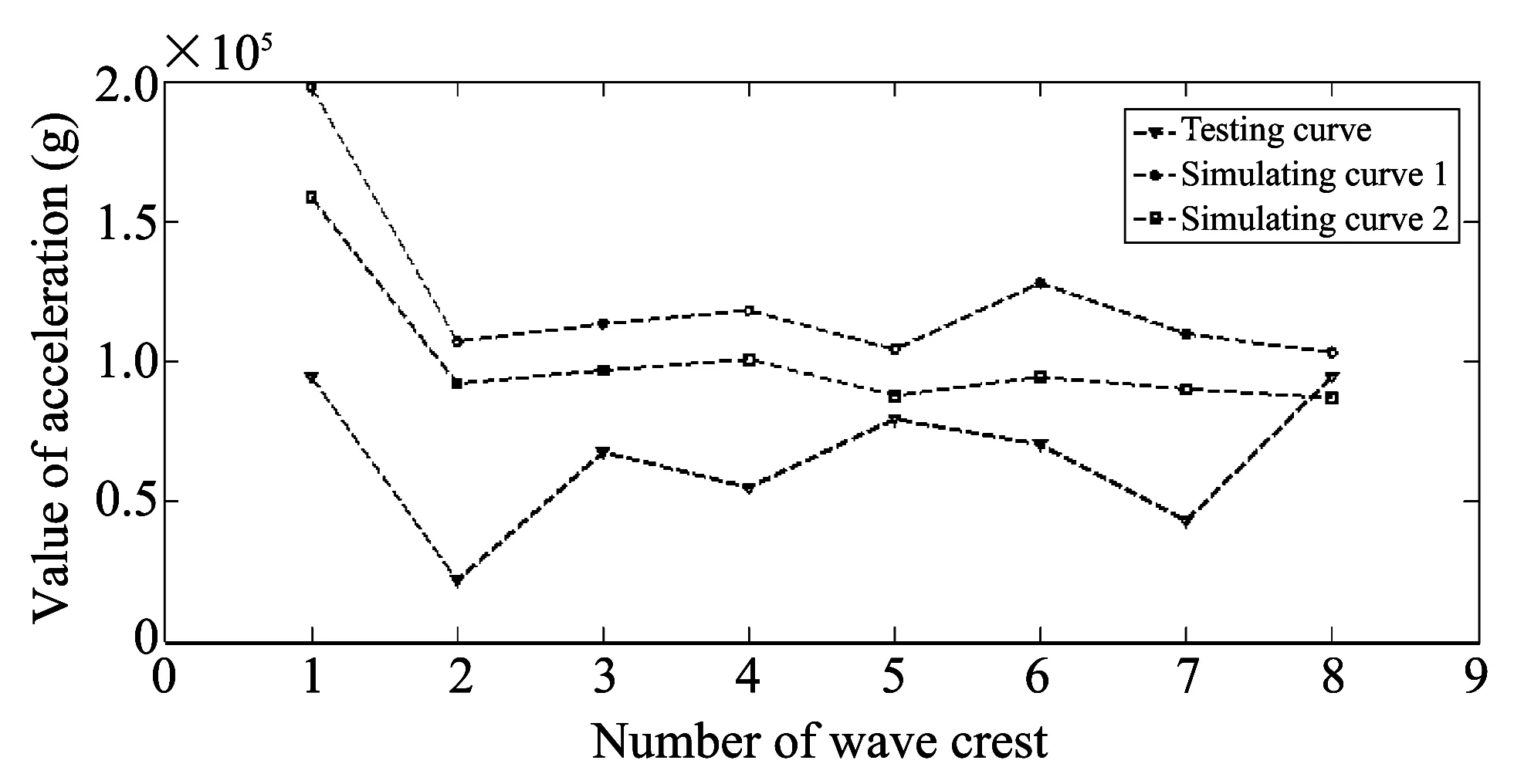

The acceleration peaks of the test curve and the simulation curve are compared,as shown in Fig.7.

Fig.7 Comparation of simulation curve and measured curve

By comparing the peaks,it can be known that the simulation curve 2 from the refined model is much closer to the peak of the actual curve.Therefore,in the later simulation research,the establishment of a projectile can refine the model and the data and have more reference value.

4 Conclusion

By combining the numerical simulation experiments of using ANSYS/LS-DYNA software for projectile penetration eight concrete targets with actual test of projectile,it uses acceleration curve from projectiles of two kinds of structure respectively to compare with the measured acceleration curve.The results of the test indicates that the acceleration curve of projectile with refined structure is more close to the measured acceleration.As a result,the acceleration curve got by refining structure of projectile has higher reference value in the simulation experiment.

In order to make the simulation closer to the pracitce,the further research is needed in material selection and parameters optimization.

[1] LIU Pu,SHI Kun-lin,HUANG Hui-dong.3D-numerical simulation acceleration of projectile penetrating steel target.Journal of Detection & Control,2006,28(1):25-28.

[2] WANG Mao-ying,ZHAO Ge,JIA Xiao-zhi,et al.Simulation on the equivalent relation of perforating through reinforced concrete and concrete target.Transactions of Beijing Institute of Technology,2011,31(6):631-633.

[3] NIE Ming-fei,LI Yu-long.Finite element simulation on ogive-nosed projectiles penetrating single and multi-layered concrete targets.Journal of Detection & Control,2009,31(4):78-83.

[4] GUO Xiang-hua,ZHANG Qing-ming,HE Yuan-hang.Study on behavior of semi-infinite concrete targets subjected to projectile normal penetration.Transactions of Beijing Institute of Technology,2011,31(7):765-767.

[5] YANG Rong,XU Wen-zheng.The numerical simulation for overload characteristic of the ammunition into concrete targets.Journal of Projectiles,Rockets,Missiles and Guidance,2009,(4):129-132.

[6] SHEN Li,GAO Shi-qiao,JIN Lei.Numerical simulation of projectile oblique penetration into concrete.Journal of Projectiles,Rockets,Missiles and Guidance,2012,(6):61-64.

[7] LSTC.LS-DYNA user manual.Version 970.Nonlinear dynamic analysis of structures in three dimensions.USA: Livemore Software Technology Corporation (LSTC),2001.

[8] Meyers M A.Dynamic behavior of materials.John Wiley & Sons,1994.

[9] JI Chong,LONG Yuan,WAN Wen-qian.Numerical simulation of projectile penetrating into steel fiber reinforced concrete.Journal of Plauniversity of Science and Technology(natural science edition),2005,6(5): 459-463.

[10] Holmquist T J,Johnson G R,Cook W H.A computational constitutive model for concrete subjected to large strains,high strain rates,and high pressure.In: Proceedings of the 14th International Symposium on Ballistics,Quebec,Canada,1993: 519-600.

[11] WANG Feng,WANG Xiao-jun,HU Xiu-zhang,et al.Oblique penetration of an ogive-nosed rod into the aluminum target.Explosion and Shock Waves,2005,(3): 265-270.

Journal of Measurement Science and Instrumentation2014年3期

Journal of Measurement Science and Instrumentation2014年3期

- Journal of Measurement Science and Instrumentation的其它文章

- A new measuring technique in detecting of high voltage three phase induction motor for single phasing

- Hardware implementation of adaptive filter for noise cancellation using TMS320C6713

- Error modeling of 3-RSR parallel robot based on D-H transformation matrix

- Signal de-noising method based on wavelet decomposition