Efficient Method for Accelerated Reliability Qualification Testing

REN Zhi-qian(任志乾), YU Zong-yue(于宗乐), TAO Jun-yong(陶俊勇), LIN Wu-qiang(林武强)

1 Science and Technology on Integrated Logistics Support Laboratory, National University of Defense Technology, Changsha 410073, China 2 PLA Troop No. 92537, Beijing 100161, China

Efficient Method for Accelerated Reliability Qualification Testing

REN Zhi-qian(任志乾)1*, YU Zong-yue(于宗乐)1, TAO Jun-yong(陶俊勇)1, LIN Wu-qiang(林武强)2

1ScienceandTechnologyonIntegratedLogisticsSupportLaboratory,NationalUniversityofDefenseTechnology,Changsha410073,China2PLATroopNo. 92537,Beijing100161,China

Based on the theoretical inference and experiment verification, a method was proposed to carry out the accelerated reliability qualification testing. First, theoretical inference was used to get the acceleration coefficients of super Gauss vibration stress and temperature stress. Then, by applying these coefficients, an accelerated reliability qualification testing curve was obtained from the standard tests. Finally, the actual experiment on a digital marine control device was carried out under the proposed testing method. The experiment result shows that the proposed method can reduce the total experiment time and improve the efficiency of the reliability qualification test.

superGaussvibrationstress;cumulativefatiguedamage;accelerationtesting;reliabilityqualificationtesting

Introduction

Reliability testing for qualification and production acceptance is the principal method to testify whether the product reliability can achieve the minimum acceptance threshold. At present, the commonly used standards use the experimental stress to simulate the typical environment and perform the reliability test. Consequently, the experiment would be both time and resource intensives. Thus, how to confirm the product reliability in less experimental time has become a hot topic in the reliability engineering. Wangetal.[1]studied the simulation-based acceleration testing method. Tanetal.[2]described the relations of accelerated stress and equipment life in constant acceleration test through the establishments of acceleration test life model and degradation model. Taletal.[3]studied the acceleration test method to reduce verification test time. Krasich[4-5]studied the product’s acceleration reliability qualification method. Turneretal.[6]adopted the accelerated degradation testing method in the reliability verification test to realize the acceleration. The goal of these researches is mainly to establish equivalent relations between the acceleration test stress and the standard test stress to obtain the acceleration coefficient. However, the current acceleration testing researches mainly focus on testing methodology on single strength and constant stress, and are used for the product’s life test. For the constantly changing comprehensive stress loading in the reliability test, no efficient stress conversion method or accurate acceleration coefficient can be used directly.

In reliability enhancement testing (RET), high efficient experimental stresses are applied in the product to finding out the product’s failures quickly and efficiently. The advantages of using RET have already been proved both in theory and in experimental practices[7-11]. Therefore, it has been widely used in stimulating product defects, improving experiment efficiency, and reducing experiment costs[12-14]. However, there are few researches about the acceleration relationships between the enhanced test stress and the standard test stress. The quantitative accelerated relationships between enhanced test stress and standard test stress are unclear, which causes the RET results can’t be used in the quantitative evaluation of product reliability index. Through the theoretical analysis and experimental data comparison, this paper has calculated acceleration coefficient of the super Gauss random vibration stress and temperature stress in the RET.

1 Acceleration Coefficient Analysis for Accelerated Reliability Qualification Testing

When a product’s reliability index (the product success rate under the specified condition in a given period of time) is under laboratory examination, the specified conditions should be provided to assess the probability that the product can complete its function within limited time. The accelerated reliability qualification testing method in this paper mainly aims at temperature stress and vibration stress.

1.1 Temperature acceleration coefficient analysis

(1) Theoretical analysis

Arrhenius model is the most common acceleration model, in which the product life follows the exponential distribution. The relationship between product life and temperature stress can be described as

(1)

whereLis the product life feature,Ais a constant,Eais the activation energy needed for stimulating the latent defect ,kis the Boltzmann constant, andTis the absolute temperature.

According to the Arrhenius acceleration model, temperature acceleration coefficient can be described as:

(2)

whereL1is the product life characteristic in the temperatureT1, andL0is the product life characteristic in temperatureT0.

(2) Experimental confirmation and analysis

This paper obtained a product’s working time and activation energy under different temperature. Table 1 shows the parameters obtained from the experiment.

Table 1 Implementation time and experimental condition of high-temperature test

According to the data in Table 1, the test time under room temperature (20℃) can be converted from the test time of Equipment 1 and Equipment 2 by using the acceleration coefficient in Eq. (2). Assuming that these two equipments have the same failure time under room temperature, the parameter activation energyEawould be 0.209 4, and the acceleration coefficients under different temperatures can be easily calculated.

1.2 Acceleration coefficient analysis of super Gauss vibration

(1) Theoretical analysis

(3)

The constantbis usually obtained from the experiment.

(2) Experiment confirmation and analysis

In the experiment, two same experiment objects are verified under super Gauss random vibration stress and Gauss random vibration stress of the same power spectral density. The experiment devices and setting are shown in Fig.1.

(a) Super Gauss

(b) Gauss

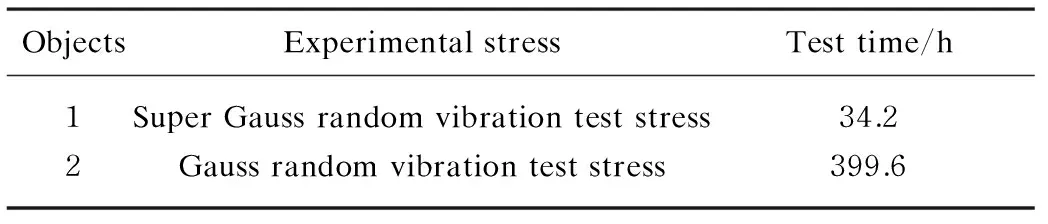

The same object failed in the same position under two stresses, shown in Fig.2. The failure time is shown in Table 2. From the experiment, the acceleration coefficient for this particular failure type is 11.7.

(a) Device failure under super Gauss stress

(b) Device failure under Gauss stress

ObjectsExperimentalstressTesttime/h1SuperGaussrandomvibrationteststress34.22Gaussrandomvibrationteststress399.6

1.3 Acceleration coefficient under multiple stress conditions

It has already been proved that both temperature stress and vibration stress have the acceleration effect on the product’s cumulative damage. This paper uses the multi-stress Arrhenius model in Ref.[15]to calculate the acceleration test coefficient under the multi-stress function. The multi-stress Arrhenius model’s expression is

L=eγ0+γ1φ1(S1)+γ2φ2(S2)+…+γpφp(Sp),

(4)

where,S1,S2, …,SPare thepexerted acceleration environment stresses;γ1,γ2, …,γParepundetermined parameters;φ1(·),φ2(·), …,φp(·) arepknown functions; andLis the product characteristic life under multi-stress.

According to Eq. (4), acceleration coefficient under the multi-stress is

A1A2…AP,

(5)

where,A1,A2, …,APare acceleration coefficients for the corresponding stress.

2 Experimental Profile Conversion

In the design of accelerated reliability qualification testing plan, we use the acceleration coefficient to convert the temperature and the vibration environment stress to the experimental stresses.

In the standard experiment, the temperature stress consists of several cycles, and each cycle has four stages: temperature rise, temperature drop, soaking stages in high or low temperature. For the soaking stage, the temperature stress can be calculated with Eq. (2). While, for the temperature rise and drop, the temperature stress can be converted with the following steps.

Step 1 The temperature of standard cycle can be described as

T0=a+bt,

(6)

whereaandbare constants, andtis the test time.

Step 2 The acceleration coefficient of temperature rise and drop is shown as:

(7)

Step 3 A small time difference Δtin the temperature rise stage is defined as

(8)

(9)

(10)

The accelerated temperature testing duration can be calculated. The random vibration profile can be calculated with the acceleration coefficient that is described in Section 1.2.

3 Case Study

We applied the proposed method for the accelerated reliability qualification test on a digital marine control device. The application process of reliability qualification test can be specified as follows.

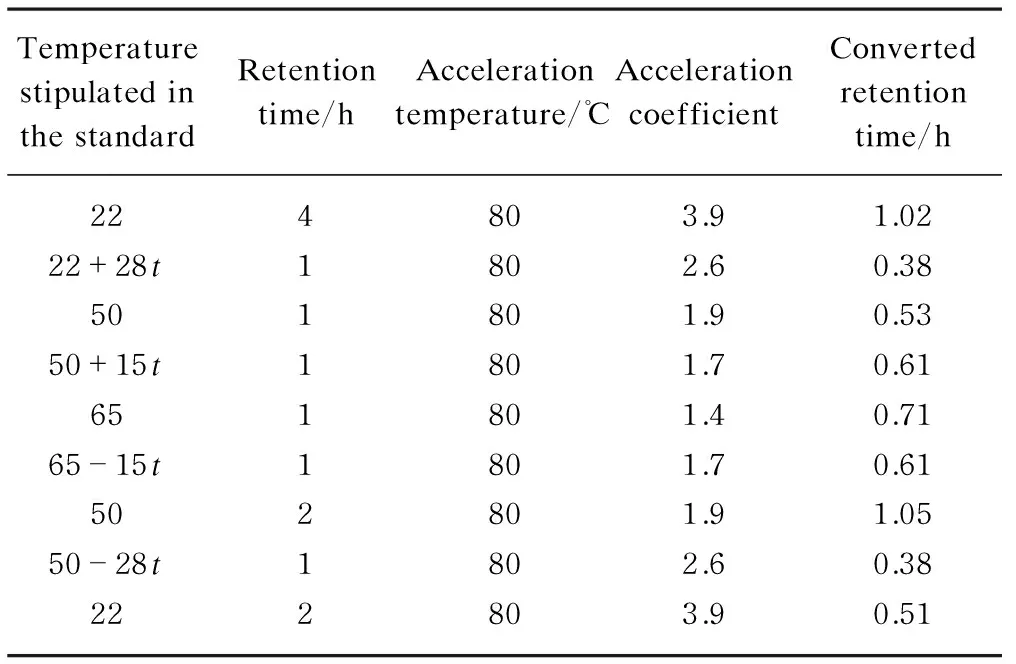

First, by using temperature acceleration coefficient in Section 1.1, the activation energyEais 0.209 4. The failure of two tested equipment appears in 100 ℃ in the high temperature step stress pre-test. Therefore, the temperature of the reliability qualification testing can be set lower than the failure experimental temperature, likely 80℃. According to determined activation energyEaas well as the acceleration temperature, the temperature experiment time of the reliability qualification testing plan can be converted from the standard temperature test time. The conversion process and result are shown in Table 3.

Table 3 Conversion of reliability qualification testing plan in standard test methods

According to the super Gauss vibration pre-test in Section 1.2, the super Gauss vibration acceleration coefficient is 11.7. The vibration test time of the reliability qualification testing can be converted from the standard vibration test. The super Gauss vibration test time for each cycle in the digital marine control device can be converted to 6/11.7=0.5 h.

According to accelerated reliability qualification testing, the test profile under high temperature stress and the super Gauss vibration stress are shown in Fig.3. The experiment can be carried out under this test profile, and then the reliability evaluation can be analyzed based on the test data.

Fig.3 The GJB899A section plane and the section plane of accelerated reliability qualification testing

From the above experiment, the proposed method can save 8.2 h in each test cycle (24 h for the standard test), and the experimental efficiency can be improved more than 1/3.

4 Conclusions

This paper has studied acceleration coefficients of temperature stress, super Gauss vibration stress, and other multiple stresses. The temperature acceleration coefficient and the vibration acceleration coefficient can be obtained through the theoretical and experimental analyses. According to the obtained acceleration coefficient, the conversion method of the accelerated reliability qualification testing profile from the standard test has been proposed. And the accelerated reliability qualification testing plan has been determined. Finally, the implementation of the test plan proved that with the proposed method, the efficiency of the reliability qualification testing could be improved more than 1/3.

[1] Wang Y S, Zhang C H, Chen X. Simulation-Based Optimal Design for Accelerated Life Testing [C]. ESREL2007 Risk, Reliability and Societal Safety: Proceedings of the European Safety and Reliability Conference, Stavanger, Norway, 2007,2: 1199-1205.

[2] Tan Y Y, Zhang C H, Chen X. Analysis of Incomplete Data of Accelerated Life Testing with Competing Failure Modes [J].ChineseJournalofMechanicalEngineering, 2009, 22(6): 883-889.

[3] Tal O, McCollin C, Bendell T. Reliability Demonstration for Safety-Critical Systems [J].IEEETransactionsonReliability, 2001, 50(2): 194-203.

[4] Krasich M. Accelerated Testing for Demonstration of Product Lifetime Reliability [C]. Proceedings of Annual Reliability and Maintainability Symposium, Framingham, MA, USA, 2003.

[5] Krasich M. Improvement of Sequential Probability Ratio Tests by Acceleration and Automation of Test Planning [C]. Proceedings of Annual Reliability and Maintainability Symposium, Washington DC, USA, 2005: 475-481.

[6] Turner M D. A Practical Application of Quantitative Accelerated Life Testing in Power Systems Engineering [J].IEEETransactionsonReliability, 2010, 59(1): 91-100.

[7] Silveman M. Why HALT Cannot Produce a Meaningful MTBF Number and Why This should Not Be a Concern [EB/OL]. (2009)[2014].http://www.opsalacarte.com/pdfs/Tech_Papers/MTBF_Prediction_HALT.pdf.

[8] Wang H, Chen X. Reliability Enhancement Testing and Its Application in Design and Production Phases of Radar [J].ModernRadar, 2008, 30(4): 26-28.

[9] Åberg S, Podgorski K, Rychlik I. Fatigue Damage Assessment for a Spectral Model of Non-Gaussian Random Loads [J].ProbabilisticEngineeringMechanics, 2009, 24(4): 608-617.

[10] Benasciutti D, Tovo R. Cycle Distribution and Fatigue Damage Assessment in Broad-Band Non-Gaussian Random Processes [J].ProbabilisticEngineeringMechanics, 2005, 20(3): 115-127.

[11] Jiang P. The Entire Axis Random Vibration Environment’s Fatigue Enhancement Mechanism Studies [D]. Changsha: National University of Defense Technology, 2003.

[12] Gregg K H. Accelerated Reliability Engineering: HALT and HASS [J]. Chichester: John Wiley & Sons LTD., 2000.

[13] Chu W H, Chen X, Tao J Y,etal. High Acceleration Length-of-Life Test (HALT) and the High Acceleration Stress Screens (HASS) [J].StructureandEnvironmentEngineering, 2002, 29(4): 23-37.

[14] Deppe R W, Minor E O. Reliability Enhancement Testing[C]. Proceedings Annual Reliability and Maintainability Symposium, Anaheim, USA, 1994: 91-98.

[15] Mao S S, Wang L L, The Reliability Statistics [M]. Shanghai: East China Normal University Publishing House, 1989. (in Chinese)

1672-5220(2014)06-0882-04

Received date: 2014-08-08

*Correspondence should be addressed to REN Zhi-qian, E-mail: rzq_rtl@nudt.edu.cn

CLC number:O346 Document code: A

Journal of Donghua University(English Edition)2014年6期

Journal of Donghua University(English Edition)2014年6期

- Journal of Donghua University(English Edition)的其它文章

- Optimization of Quality Consistency Problem of Electromechanical Component due to Manufacturing Uncertainties with a Novel Tolerance Design Method

- Effect of Starch Dodecenylsuccinylation on the Adhesion and Film Properties of Dodecenylsuccinylated Starch for Polyester Warp Sizing

- Interval Fault Tree Analysis of Excavator Variable-Frequency Speed Control System

- Combinatorial Optimization Based Analog Circuit Fault Diagnosis with Back Propagation Neural Network

- Reliability Allocation of Large Mining Excavator Electrical System Based on the Entropy Method with Failure and Maintenance Data

- Deployment Reliability Test and Assessment for Landing Gear of Chang’E-3 Probe