Experimental study on vapor explosion caused by interaction between high temperature molten aluminum and water

LIU Yu(刘雨), LÜ Zhong-jie(吕中杰), HUANG Feng-lei(黄风雷),GUO Xue-yong(郭学永), SHEN Zheng-xiang(沈正祥)

(State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing 100081, China)

Experimental study on vapor explosion caused by interaction between high temperature molten aluminum and water

LIU Yu(刘雨), LÜ Zhong-jie(吕中杰), HUANG Feng-lei(黄风雷),GUO Xue-yong(郭学永), SHEN Zheng-xiang(沈正祥)

(State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing 100081, China)

In order to study the mechanism of steam explosion caused by the interactionbetween coolant and melted metal drops with high temperature, the process of explosion generated by water following interaction with molten metal drops is carried out. In the experiment,liquid aluminum and water with different ratios and different temperatures were evaluated, and the influence of different water temperatures on the steam explosion was studied. The corresponding rules of steam explosion at the different experimental conditions were derived. The difference between experiment resultants was analyzed. The experimental results show that when the ratios of liquid aluminum to water are within a certain range, explosions maybe happen, and the higher the temperature of water is, the less likely explosions will occur while other conditions remain the same. The research results would provide an insight into controlling steam explosion.

vapor explosion; fragmentation; molten melt; molten fuel coolant interaction (MFCI)

When a high temperature liquid comes into contact with an evaporable low temperature liquid, steam explosion is likely to occur. Steam explosion is a violent multiphase flow phenomenon, including a high transformation of heat and quality, which result in many complex physical phenomena, such as high rate exchange, high thermal imbalance, hydraulic instability, pressure wave, and fragmentation of droplets, etc. This kind of explosion is an imbalanced and instable state which contains kinetic processes with complex thermal fluid interaction, involving complex thermal physical phenomena, small time scales (microsecond), and wide temperature ranges. So the research on its mechanism is difficult. Up to now there is no comprehensive knowledge of the mechanism and evolving process of steam explosion, which made it difficult to assessment of this process[1-6].

An experiment device composed of a high-temperature molten metal resistance furnace and a molten metal pool is designed in this research for a visualized experimental study. With this device, high-temperature molten metal steam explosion experiments can be carried out to study the rules of steam explosion when high-temperature molten metal contacts water, with different ratios of liquid aluminum to water.

1 Mechanism of steam explosion generated by high-temperature molten metal with coolant

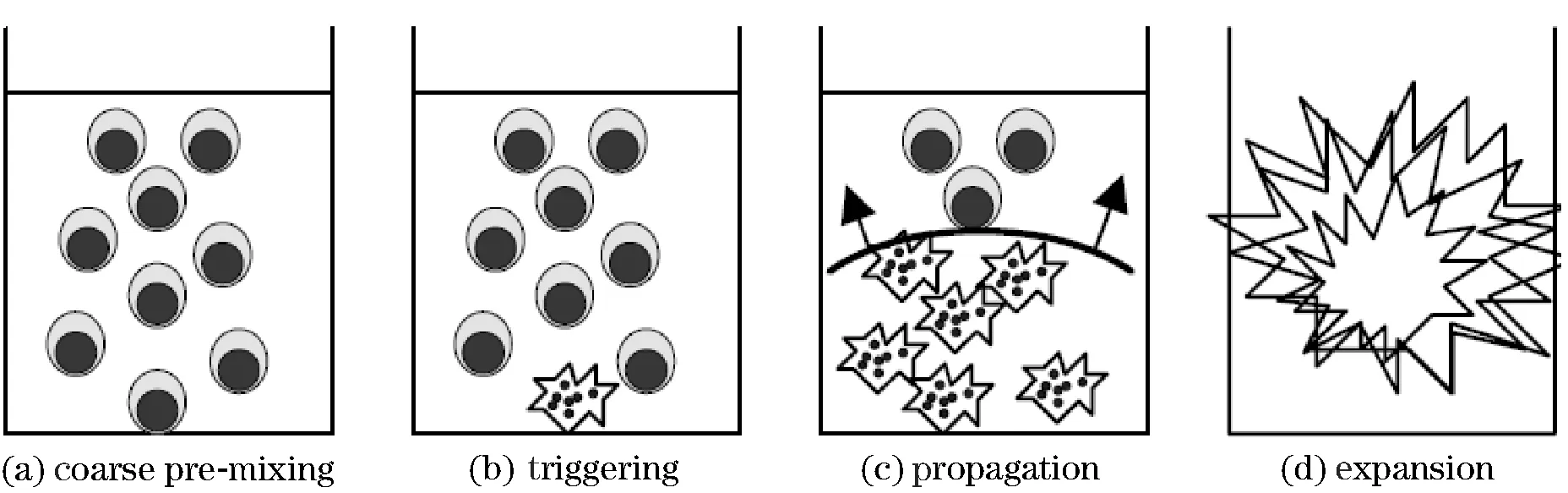

Many researchers have analyzed fuel coolant interaction (FCI) phenomenon and its process, and have proposed many theories about explosion, such as Kim-Corradini model, Ciccarelli-Forst model, Fausk model, etc. Board and Hall, based on steam explosion experiments, presented steam explosion could be divided into four stages: ① Coarse pre-mixing. In this stage, the molten metal is fragmented into little drops in the coolant and spread, and becomes a coarse mixed area. ② Triggering. In the coarse mixed area, the steam film of the surface of the molten drops collapses and results in the direct contact between the molten drops and the coolant, which produces a sharp quick transfer of heat and evaporation and causes the molten drops to fragment. The enlarged area of heat transfer after the fragmentation reinforces the heat transfer itself and forms a local high-pressure zone. This process is called triggering. ③ Propagation. The local high-pressure produced in the triggering stage expands to its surrounding area. In the process of pressure-spreading, the molten drops in the surrounding area are also fragmented, and the heat-transferring area is greatly enlarged and the transfer is remarkably accelerated, which produces more high-pressure steam and enhances the pressure waves. ④ Expansion. In this stage, the high-pressure steam generated by the high-speed heat-transferring between the molten matter and the coolant expands outward and may destroy the surrounding structure. This theory, now widely accepted by scholars, is illustrated by Fig.1[7-8].

Fig.1 Fourstages of vapor explosion

2 Experimental research

2.1 Experimental system

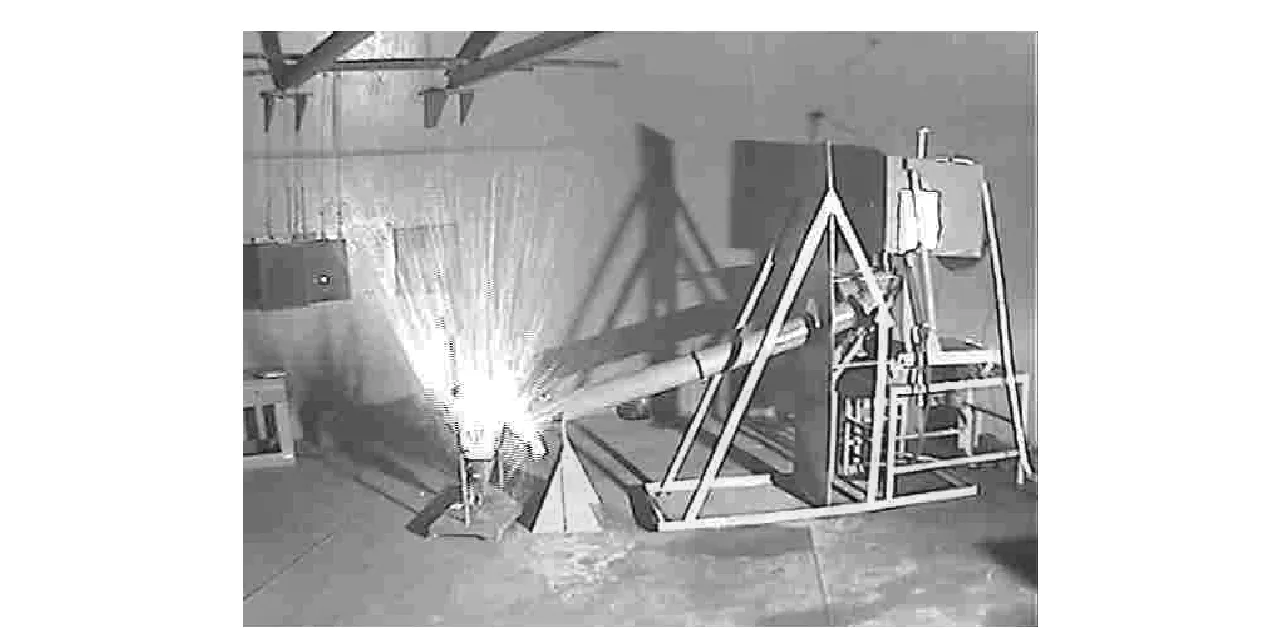

Fig.2 Experiment system

The whole experiment system is composed of heating system, operating and controlling system and testing system, as illustrated in Fig.2. The experimental process can be described as follow. First, the aluminum is heated by the heating system until it melts and reaches the preset temperature. Then the liquid aluminum is poured into the sink under the control of the operating and controlling system, and the experiment data are recorded by the testing system.

2.2 Influence of different ratios of water and liquid aluminum on steam explosion

In the experiment, the sink is made of carbon steel, Ф15.8×30 cm, semi-closed; the water temperature is 18 ℃; 0.1 kg to 4.0 kg water and 4.0 kg to 8.9 kg of aluminum are used, respectively.

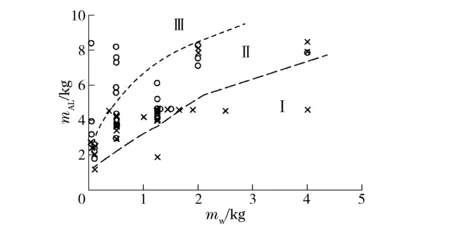

Ⅰ—non-explosion zone; Ⅱ—mixed zone; Ⅲ—explosion zoneFig.3 Map of steam explosion

A map about the influence of the mass of water and aluminum on steam explosion is presented in Fig.3,obtained based on the data in Tab.1.

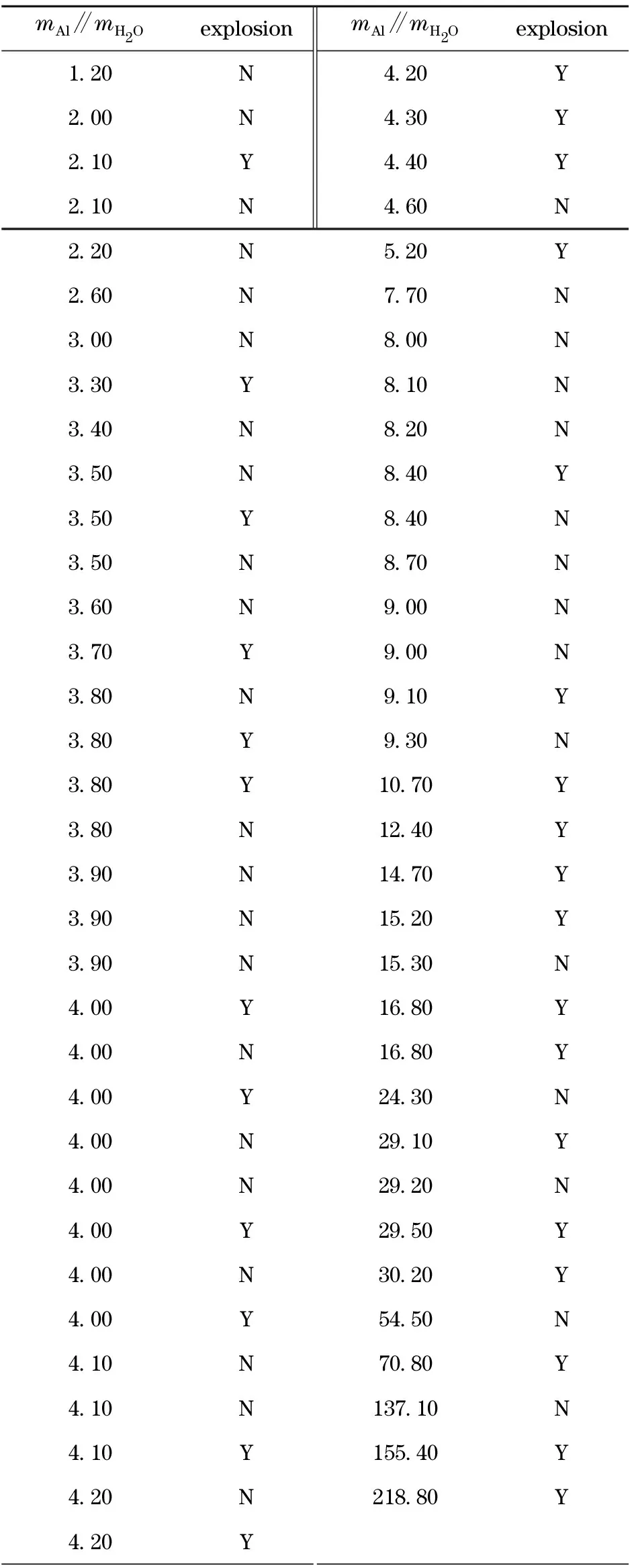

Tab.1 Influence of different ratios of water and liquid aluminum on steam explosion

Y—explosion; N—no explosion

In Fig.3, the steam explosions can be divided into three zones. In the non-explosion zone (Ⅰ), the mechanisms of non-explosions are different. In the low water-quantity area, the limited water produced little steam, and explosion wouldn’t happen even if a large quantity of liquid aluminum is put in. when the quantity of water is larger than that of liquid aluminum area and liquid aluminum is poured into the water, the aluminum is quickly cooled down, and it is hard for the explosion to happen. In the explosion zone(Ⅲ), liquid aluminum provides plenty of heat energy for the mixture, and the water evaporates fast, and the liquid aluminum mixes with the steam fiercely, thus resulted in explosion. Between the explosion zone and the non-explosion zone is the mixed zone, which fully exhibits the complexity of the mechanism of the explosion caused by molten aluminum when it is in contact with water.

2.3 Influence of water temperatures on steam explosion

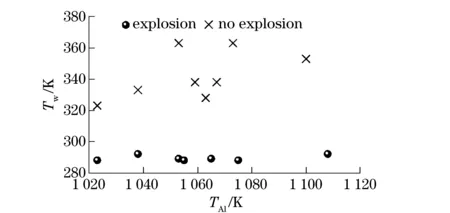

In the experiment, the temperature of liquid aluminumranges between 1 023 K and 1 108 K; water temperature is between 288 K and 363 K; and the sink, measured as Ф15.8 cm×30 cm, is made of carbon steel material and it is semi-closed. Water temperature influence is shown in Fig.4.

Fig.4 Steam explosions with different temperatures of water

As shown in Fig.4, when the temperature of the liquid aluminum remains the same, steam explosions would happen when the temperature of the water is below 300 K. when the water temperature is above 300 K, steam explosion does not occur. This is mainly because a tangential stress will be formed on the surface of the liquid aluminum with the temperature decreased, surface tension is listed as follows[9-10]

(1)

whereσ0is the initial surface tension of liquid metal, andT0is its initial temperature.

So, the tangential shear stress generated through the Marangoni effect on the cooling point could be listed as follows

(2)

whereδis the thickness of heat-transferring layer on the liquid aluminum surface.

When the temperature of the liquid aluminum remains the same, because the temperature on liquid metal surface changed drastically, the lower the temperature of the cooling water is, the larger the tangential shear stress will be produced on the surface of the liquid metal, which results in the radii of the particles generated during the fragmentation of the liquid aluminum even smaller. That is, the larger mass-surface ratio of fragmented particles, the larger heat-transferring area, more steam will be produced in a shorter time and steam explosion is more likely to occur. On the other hand, the higher the temperature of the cooling water is, the smaller the mass-surface ratio of the fragmented particles will be, which results in a smaller heat-transferring areaand steam explosions impossible under the same conditions.

2.4 Analysis of the production of the experiment

The experiment production shows different shapes and rules due to different experiment conditions and different degrees of fragmentation, and reflects the complexity of the fragmentation process when molten metal drops interact with water. The interaction process of molten drops and water can be deduced from the shapes of the production of the experiment. According to the character of the shapes, the production of the experiment can be largely divided into three types: round-drop resultants, multi-porous resultants, and powdery resultants, as shown in Fig.5.

Fig.5 Main types of experiment production

When molten aluminum is poured into water, the liquid aluminum spreads in the cooling water. Since there is a fairly large discrepancy of temperature on the contacting surface between these two materials, the water on the contacting surface quickly evaporates and forms a steam film, which produces a local impact on the surface of the molten aluminum at the same time and changes its shape or even makes it fragmented. Round-drop resultants are formed because when steam explosions occur, the temperature of the molten aluminum is already decreased while aluminum is not completely fragmented. With the temperature of the cooling water increased, the interaction of the aluminum and water becomes moderate, so the molten aluminum is never fragmented again till the final solidification. This is how the aluminium maintains a state of round drops, as is shown by Fig.5a. Multi-porous resultants are formed as follow:When steam explosions happen, the impact generated by the steam pushes some drops of water into the molten metal. The water drops evaporate, expand and quickly explode within a limited space, breaking the molten metal drops into multi-porous structures. With the shapes of the molten metal drops change, their temperature decreases rapidly. When the metal drops reach the solidification point, the change of their shapes also comes to an end, as shown in Fig.5b. Powdery resultants are formed when steam explosions happen. Under this condition, molten metal drops go through a complete fragmentation and becomes tiny particles, as shown by Fig.5c. In the experiment, the surface area of original molten metal drops is increased many times when they are changed into multi-porous or powdery resultants, and these two sorts of resultants are the main reasons of steam explosions generated when molten aluminum is poured into cool water.

3 Conclusions

The fragmentation process of high-temperature molten metal drops when interacting with water is explored by steam explosion experiments. A high-speed video camera is used to observe the fragmentation process. Some main conclusions can be drawn as follows:

① According to the experimental results, the rules of steam explosion are obtained by studying the different ratios of aluminum and water .

② When the temperature of molten aluminum remains the same, the lower the temperature of the cooling water is, the easier steam explosions occur, and vice versa.

③ There are three experiment resultants in the current experiments, among which the multi-porous and powdery resultants, which are resulted by the violent fragmentation process, have many times larger surface area than that of the original molten metal drops.

[1] Berthoud G. Vaporexplosions[J]. Annual Review of Fluid Mechanics, 2000, 32 (1): 573-611.

[2] Ciccarelli G , Frost D L. Effect of fluid flow velocity on the fragmentation mechanism of a hot melt drop [J].Progress in Astronautics and Aeronautics, 1992, 154 (1):134-361.

[3] Corradini M L, Kim B J, Oh M D. Vapor explosion in light water reactor: a review of theory and modeling[J]. Progress of Nuclear Energy,1998,22(1):171-177.

[4] Corradini M L. Vapor explosion: a review of experiment for accident analysis[J]. Nuclear Safety, 1991,32(3):337-362.

[5] Fletcher D F, Denham M K. Validation of the CHYMES mixing model[J]. Nuclear Engineering and Design, 1995,155:85-96.

[6] Fletcher D F. Steam explosion triggering: a review of theoretical and experimental investigations[J]. Nuclear Engineering and Design, 1995,155:27-36.

[7] Kim B, Corradini M L.Modeling of small—scale droplet fuel/coolant interactions[J].Nuclear Science and Engineering,1988,98:16-28.

[8] Ciccarelli G, Frost D L. Fragmentation mechanisms based on single drop steam explosion experiments using flash X-ray radiography[J].Nuclear Engineering Design, 1994,146:109-132.

[9] Fauske H K. On the mechanism of uranium dioxide·sodium explosion interactions[J].Nuclear Science Engineering,1973,51:95-101.

[10] Board S J, Hall R W. Recent advances in understanding large scale vapor explosions[C]∥Proc Comm Saf Nucl Install Meet. Sodium-Fuel Interact Fast Reactor, Tokyo, 1976: 249-293.

(Edited by Wang Yuxia)

2013- 01- 26

TL 364.4 Document code: A Article ID: 1004- 0579(2014)02- 0147- 05

E-mail: journal@bit.edu.cn

Journal of Beijing Institute of Technology2014年2期

Journal of Beijing Institute of Technology2014年2期

- Journal of Beijing Institute of Technology的其它文章

- Expert ranking method based on ListNet with multiple features

- Investigating fatigue behavior of gear components with the acoustic emission technique

- Contour tracking using weighted structure tensor based variational level set

- Consensus problem of multi-agent systems under arbitrary topology

- One-piece coal mine mobile refuge chamber with safety structure and less sealing risk based on FEA

- Three-dimension micro magnetic detector based on GMI effect