Assessment of Cultivation M ethod for Energy Beet Based on LCA Method

Chunfeng ZHANG,Feng LIU,Yuangang ZU,Qingying MENG,Baoguo ZHU,Nannan WANG

1.Center for Post-doctoral Studies,Northeast Forestry University,Harbin 150000,China;2.Center for Post-doctoral Studies,Heilongjiang Academy of Agricultural Sciences,Harbin 150000,China;3.Jiamusi Branch of Heilongjiang Academy of Agricultural Sciences,Jiamusi154007,China

Organism is of regenerative properties and carbon cycle balance nature and the biological resources provide the conditions for environmental coordination-based energy raw materials.The effective use of bio-energy has become an international trend[1].To achieve environmental coordination-based society,it is necessary to establish the supply system of biological raw material,that is,a large area of production or planting of energy crops is required[2].

Currently,the fossil fuels are gradually depleted,and the greenhouse effect and other natural disasters occur frequently.The development of bio-energy with regenerative capacity is a top priority.Beet is one of the main crops in the dry farming in Hokkaido,Japan,and it occupies an important position in the rotation of crops.The annual cultivation area of beet accounts for about the annual cultivation area of 25%of total dry crops(about 68000 hm2),and the annual sugar production is0.8million t[3].To ensure the growing area of beet and learn the planting experience from the U.S.and Brazil[2],it is necessary to take the currently planted beet as ethanol to extract raw material for production.

As an energy crop,beet is one of crops containing high energy in the crops planted in Hokkaido,Japan[3].It is concentrated for collection and has advantage of transportation costs easy to be reduced when compared to the unused residue resources.Meanwhile,the trait of raw materials is stable,conducive to the extraction of ethanol.What can be used in the beet is not merely the roots.The studies of Ogata et al.[4]show that the beet stems and leaves contain high energy,and are also raw materials for ethanol extraction.If planting beet as the raw material for the extraction of ethanol and other biofuels,Hokkaido can be converted into the supply base of bio-energy.

In order to overcome these shortcomings,the basic plan of Japanese food,agriculture,and rural areas points out that it is necessary to strengthen the direct seeding technique of beet,reduce the labor time by 20%,and increase the yield by 10%.To achieve this target,the soil and suppression conditions suitable for direct seeding are analyzed.The surface soil with the particle size of below 20mm accounts for more than 80%of pale volcanic ash soil[5](occupying 37%of dry farming soil in Hokkaido),and if it is pressed down appropriately,the direct beet seedling emergence will be significantly increased[6].

Through the survey,the link with large field energy input to crop production is generally the soil movement operation,such as plowing and soil preparation[7].To create an energy-saving cultivation system,an effective way is to simplify or totally omit the part of the above mechanical operation.Light-colored volcanic ash soil is of good drainage and softness nature,and many other characteristics,and there is possibility of simplification or even omission in terms of farming and soil preparation[7].

Up to now,there are few experiments studying the beet to be planted as the raw material for ethanol.This study simplifies the ploughing and land preparation operation as far as possible,and combines it with the direct seeding cultivation method,to explore the energy-saving cultivation technique and production capacity of beet as the energy crop.

Meanwhile,this article compares it with the current transplant cultivation method in terms of growth period and yield characteristics of beet.According to LCA(Life Cycle Assessment)method,this article also analyzes the energy balance in the cultivation process,and the possibility of beet as the energy crop to be cultivated,and assesses the environmental impact.

1 Materials and methods

1.1Energy-saving cultivation of beet

1.1.1 Soil for experiment and experimental treatment.The field experiment in this study was carried out in Dry Farming Department,Center for Agricultural Research in Hokkaido,Japan.The site for experiment is located in central Tokachi plain(a region with typical agricultural dry land in Japan),and the temperature is similar to that of northern China.

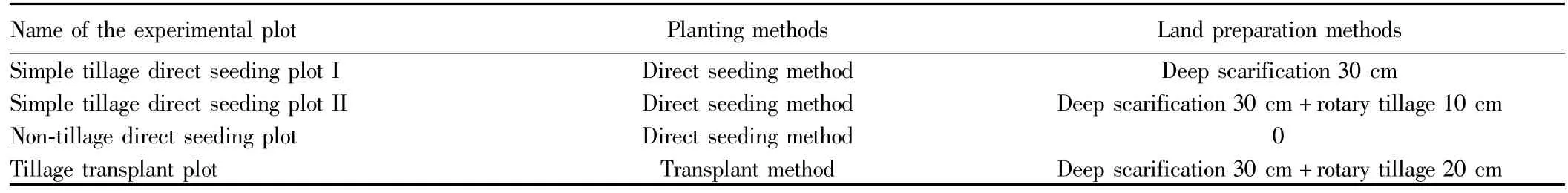

The experimental period is two years(2009-2010),and the soil for experiment is pale volcanic soil.The experimental treatments are shown in Table1.According to the experiment,the cultivation methods can be divided into direct seeding method and transplant method(hereinafter referred to as tillage transplant plot).According to the land preparation method,in the direct seeding,it is divided into simple tillage plot I(hereinafter referred to as simple tillage direct seeding plot I),plotⅡ(hereinafter referred to as simple tillage direct seeding plot II),and non-tillage plot(hereinafter referred to as non-tillage direct seeding plot.

Table 1 Composition of the experimental plot

The land preparation machinery for simple tillage direct seeding plot I is subsoiler,with the tillage depth of 30 cm;the land preparation machinery for simple tillage direct seeding plot II includes subsoiler and rotary tiller,with the tillage depth of 30 cm and 10 cm,respectively;there is not any land preparation operation before sowing for the non-tillage direct seeding plot.The tillage transplant plot refers to the conventional cultivation system of Hokkaido as a reference[9],that is,the tillage depth of subsoiler is30 cm,and the tillage depth of rotary tiller is20 cm.

However,due to the fine particle size of topsoil of the pale volcanic ash soil,the rotary tillage is barely carried out after the deep scarification locally,and there is usually only one land preparation operation.

According to the survey results of growth period and yield in 2009,there were no significant differences between simple tillage direct seeding plot I and simple tillage direct seeding plot II.In 2010,the field experiment was only carried out in the simple tillage direct seeding plot II,and the treatment for simple tillage direct seeding plot I was omitted.

In 2009,the fore-rotating crop in the experimental plot was wheat,and the plot was ploughed up after harvest;the ground surface was levelled.In 2010,the fore-rotating crop in the experimental plot was unplanted,and the treatment was the same as that of previous year.The area of field for experiment was2000m2,8 ridges in each plot,and the planting density is the same;80000 plants were set in 1 hm2of plot,with the planting distance of21.5 cm and ridge distance of 60 cm.There were 4 treatments in the experiment plot in 2009 and there were3 treatments in the experiment plot in 2010.The experiment plot was repeated three times in the two years,and it is arranged in a random manner.

1.1.2 Farming summary.The seed for the experiment was"Beihai87"coated seed which was a variety likely to be popularized for the local direct seeding.The fertilizer for the experiment was special fertilizer for beet,and the name of fertilizer was S.014.The application rate of fertilizer was 1000 kg/hm2,and the sowing and fertilization were carried out at the same time.

The seeding period in the direct seeding plot was April 19,2009 and May 2,2010;the seeding-machine for the experiment was the vacuum extraction seeding-machine(Tabata TEB-4WR),which completed the ditching,fertilizing,planting and repression at the same time.

The transplant period of tillage transplant plot was April 25,2009(39 days after sowing),and May 2,2010(36 days after sowing).The artificial transplant was adopted,and the land preparation operation was carried out in the three days before planting.

After seeding or transplanting,the field management was carried out in accordance with conventional methods.To control weeds before planting in the direct seeding plot,the soil chemical treatment was carried out in 2010,and the direct seeding plot completely omitted the intertillage weeding operation in the two years.

1.1.3 Survey items and survey methods.The survey items during the growth period of beet include germination rate,plant height and leaf number.

The survey method for the germination rate survey is as follows:

The ratio of the actual number of seedling to the theoretical number of seedling in continuous2m was calculated,three points were surveyed in each experiment plot,and then the average was taken.After that,the position of germination,plant height,leaf number and yield were surveyed.The survey items in the harvest period include root weight,stem and leaf weight,and sugar content.

The survey method for sugar content is as follows:15 consecutive plants in the survey position were chosen for determination,and the analysis device was the automatic analysis device for sugar content(Venem,Sugar Beet Analyzing System).To study the relationship between the individual weight and sugar content,the sugar content of roots,stems and leaves of individual sample was determined,and the instrument for experiment is BRIX sugar meter(IATC-1E handheld sugar polarimeter).Meanwhile,the beet roots in the direct seeding plot were graded for survey.

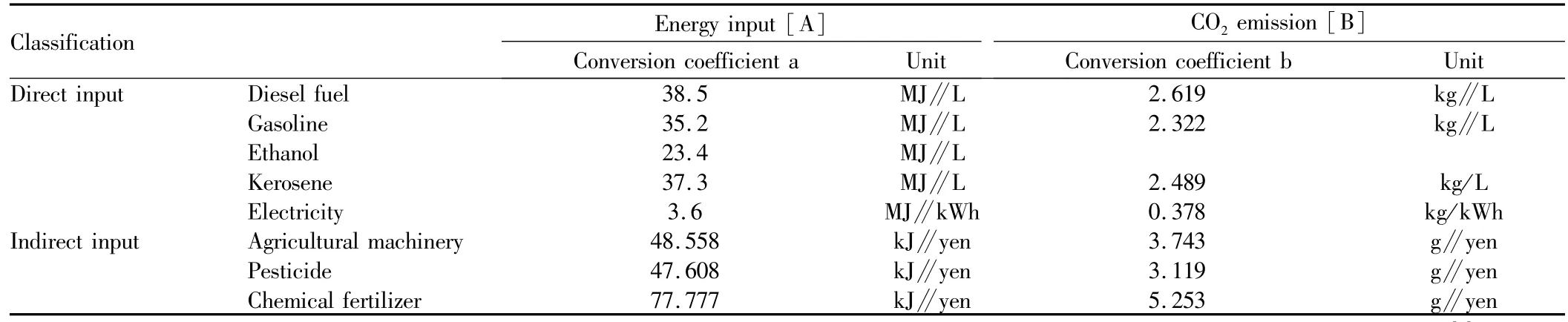

1.2Energy balance and CO2emission Based on the differences in the operation system,we carry out analysis of direct and indirect energy input as well as the direct and indirect CO2emission,according to 1 hm2of area.

The object of analysis includes field operation,transportation of means of production,and transportation of harvested product,but the input to the extraction of ethanol in the plant is not within the scope of this analysis.

The analysis and calculation results of fuel energy conversion coefficient and CO2emission conversion coefficient can be shown in Table 2.

Table 2 Calculation of fuel energy conversion coefficient and CO2 emission conversion coefficient

1.2.1 Direct energy input and CO2emission.The direct energy input includes the conversion value of energy of electricity and fuel needed by the greenhouse nursery operation and field operation.

According to the operating system of various experimental treatments,we calculate the fuel consumption required for 1 hm2based on formula(1).

where Qb1is the direct input energy(MJ/hm2);V is the fuel consumption in the mechanical operation(L/hm2);φis the conversion coefficient(MJ/L)(Table 2[A]).

The operating system of various treatments is shown in Table 3,and it is the same case for the experimental machinery.As for the application of herbicides and fungicides,the soil treatment is carried out after sowing only in the direct seeding plot;for other experiment plots,the spraying amount and frequency are the same.

For the transport of production materials,the distance between the farmers and cultivation site is assumed to be 3 km,and the loading amount of truck is assumed to be4 t.According to the frequency of transport needed by each treatment,the fuel consumption is calculated.For the transport of harvested product,the distance between the cultivation site and the ethanol extraction plant is assumed to be 10 km,and the loading amount of the truck is assumed to be 10 t.The fuel consumption is calculated using the same method.

The electricity used for the greenhouse seedling cultivation in the tillage transplant plot is calculated by Koga et al.[10]at49.5 kWh/hm2.The consumption of kerosene for heating in the greenhouse is also calculated.Through the survey,we can find that the greenhouse area required for per hectare of transplanted seedlings is29.7m2.The nursery generally needs3 weeks from 10 March.According to the energy consumption of 50000 kcal/h,when the minimum temperature of the greenhouse isassumed to be5℃,the amount of kerosene consumed is 37 L/hm2[11].

Table 3 Each operating system's operation name

The CO2emission in the cultivation site is calculated with the field operation machinery as the emission target of CO2.Based on the type of fuel input,the coefficient in Table 2[B]is used,and it is calculated according to formula(2).

where Cb1is the direct CO2emission(kg/hm2);V is the fuel consumption in machinery operation(L/hm2);τis the CO2direct emission coefficient(kg/L)(Table 2[B]).

1.2.2 Indirect energy input and CO2emission.Indirect input refers to the energy consumed in the manufacture of agricultural machinery,pesticides and chemical fertilizers for each cultivation system.Meanwhile,along with the energy consumption,the CO2is emitted.The calculation of the indirect energy input and CO2emission requires enormous computing data,so it is very complex.

Therefore,out operation is based on the Industry Association Table of National Institute for Environmental Studies[12],and it is calculated in accordance with the local sale prices of agricultural machinery,pesticides and chemical fertilizers.

The energy consumed for the transport of agricultural machinery from the manufacturing plant to the cultivation site,and the CO2emission,are not calculated in this paper.The indirect energy input and CO2emission are calculated based on formula(3)and(4),respectively.

In formula(3),Qb2is the indirect energy input(MJ/hm2);R is the sale price(farm machinery,pesticides,and chemical fertilizers)(yen/hm2);εis the energy conversion coefficient(MJ/yen)(Table 2[A]).In formula(4),Cb2is the indirect emission of CO2(kg/hm2);R is the sale price(farm machinery,pesticides,and chemical fertilizers)(yen/hm2);δis the unit coefficient of CO2emission(kg/yen)(Table 2[B]).

In this study,the sales price of agricultural machinery uses the sales price provided by Hokkaido Industry Federation[13].Meanwhile,the service life of agricultural machinery prescribed by the industry[14]is used to calculated the annual input costs.

In the cultivation system,except beet transplant machine and beet harvester,beet and other cultivated crops share the machinery.According to the local rotation system,it is derived by quartering the indirect energy input of agricultural machinery and indirect emission of CO2.The sales prices of chemical fertilizers and pesticides refer to the sales prices of Hokkaido Agricultural Society as a reference[15].

1.2.3 Energy balance and total CO2emission.The beet energy is converted into the ethanol conversion amount by the sugar harvest,and the energy output is calculated according to formula(5).Formula(6)is the energy balance,and input-output ratio is calculated according to formula(7).0.55 in formula(5)is the measured coefficient of ethanol converted from beet[16-17].

where Qais the total energy output(MJ/hm2);S is the sugar equivalent amount(kg/hm2);0.55 is the efficiency of conversion of beet sugar into ethanol;23.4 is the heat productivity of ethanol(MJ/L);Q is the energy balance(MJ/hm2);Qcis the inputoutput ratio of energy.

The total CO2emission is the sum of direct and indirect emission of CO2.CO2absorbed for the crop photosynthesis is an important part of the carbon cycle,and it is considered that using the amount of CO2absorbed for the crop photosynthesis and total CO2emission to calculate the carbon cycle is not proper.

The studies of Koga et al.[10]show that the farmland carbon cycle and the soil surface carbon balance are significantly correlated with the depth of tillage and the residue treatment after harvest.According to the existing conditions,we do not take the CO2balance as the calculation object,but only calculate the total CO2emission of different cultivation systems.

2 Results and analysis

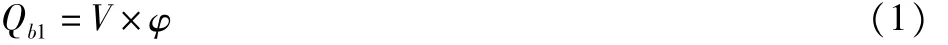

2.1The impact of various cultivation systems on emergence,grow th and harvest Sowing depth and germination rate are shown in Table 4.The upper part of the table is the data in 2009 and the lower part of the table is2010 data.The soil crushing performance of topsoil is good,resulting in consistent sowing depth,and the germination rate in various plots is above 80%.

There are not significant differences in the germination rate between the treatments.However,the germination period in simple tillage direct seeding plot I is slightly longer than the germination period in other experiment plots,and the seedlings are irregular,so the treatment in 2010 is omitted.

Table 4 Sowing depth and germination rate survey

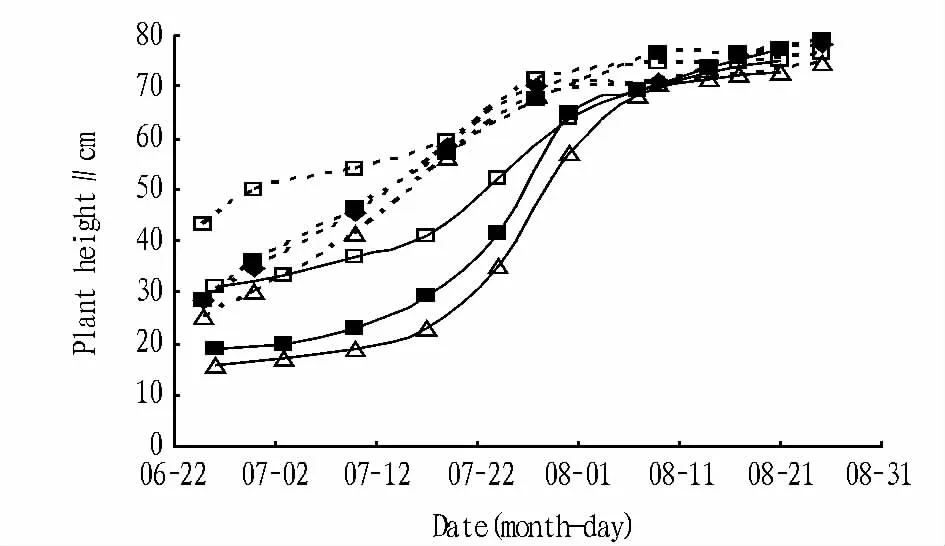

The plant height is shown in Fig.1,and the direct seeding plot gradually catches up with transplant plot after the mid-July.In terms of the tillage method,it is poorer in non-tillage direct seeding plot than in simple tillage plot,but in early August,it basically reaches the same level.Over the time,the leaf number also shows the same tendency.The two years of experimental results show that compared with the beet transplant cultivation,the growth is rapid under direct seeding cultivation.

Fig.1 The plant height over the time

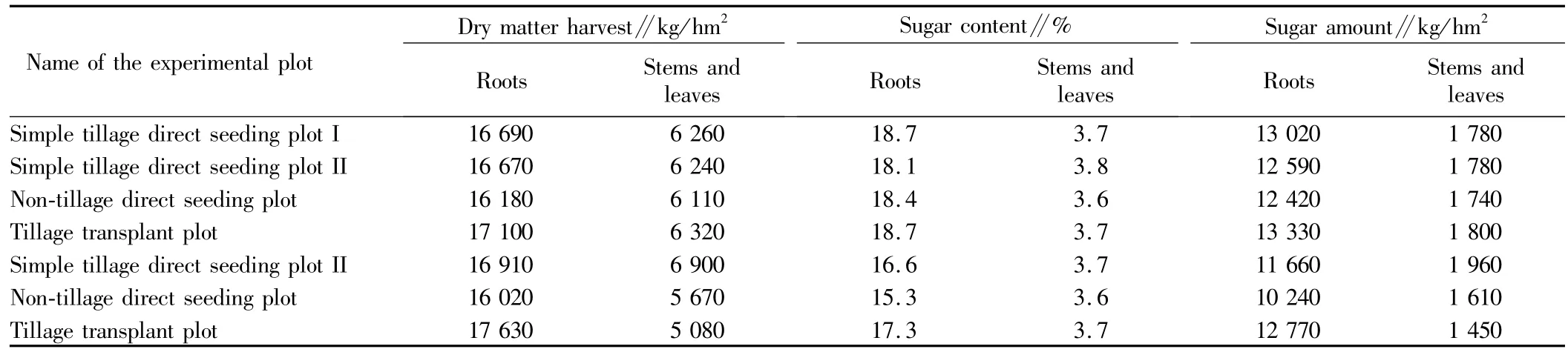

The survey results of dry matter harvest,sugar content and sugar amount are shown in Table 5.The differences between various treatments are not significant.In the Hokkaido Tokachi area,the root harvest yield is reduced by about 14%under beet direct seeding when compared with transplant.However,the survey of Hokkaido Beet Association in 2004 shows that there is only the difference of10%in the harvest between excellent direct beet seeding cultivation technique and transplant[18].

This experiment was carried out in the pale volcanic ash soil with good soil physical properties.Compared with transplant plot,the root weight in direct seeding plot was reduced by 2.4%-5.4%in 2009;the root weight in direct seeding plot was reduced by 4.1%-9.2%in 2010.

The main reason for the yield reduction lies in the phenomenon of continuous short of seedling in the direct beet seeding plot.There are no differences in the measurement results of sugar content between direct seeding plot and transplant plot.There are also no significant differences in the root weight and sugar content between the cultivation methods in the direct seeding plot.

These results prove that the non-tillage direct seeding method with less energy input can help us still obtain higher beet yield in the pale volcanic ash soil.

Moreover,this experiment recycles some stems and leaves plunging into the soil after the harvest,and utilizes them as raw materials for energy.Taking non-tillage direct seeding plot for example,the sugar amount of stems and leaves is 14% -16%of that of roots,and the sugar yield in stems and leaves per hectare is 1610-1740 kg.

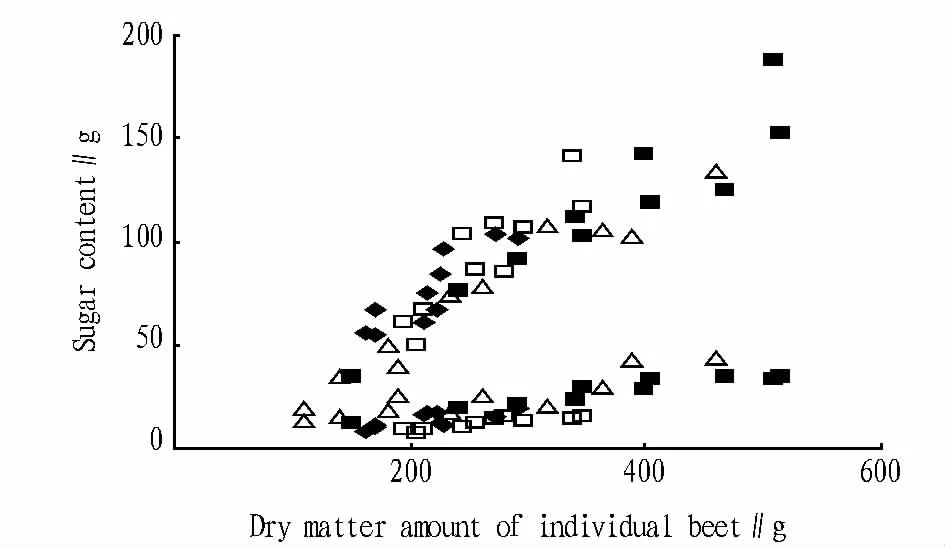

The relationship between dry matter harvest of individual beet and sugar amount is shown in Fig.2.In the figure,the straight line signifies beet roots and the line below signifies the stems and leaves of beet.As can be seen from the figure,there is a direct proportion relationship between the dry matter amount and individual beet amount,but there is almost no relationship between the dry matter amount and the cultivation methods as well as the land preparation method.It can also indicate that the dry matter amount of individual beet is correlated with the energy it contains.

Based on this relationship,as for the beet direct seeding,in order to prevent yield decrease caused by the shortage of seedlings,it can appropriately increase the sowing amount,and ensure the yield per unit area,to obtain the same yield as that under transplant.

In the future,it is necessary to take it as the basic research and clarify the relationship between the cultivation density and harvest.

Table 5 The survey results of dry matter harvest,sugar content and sugar amount

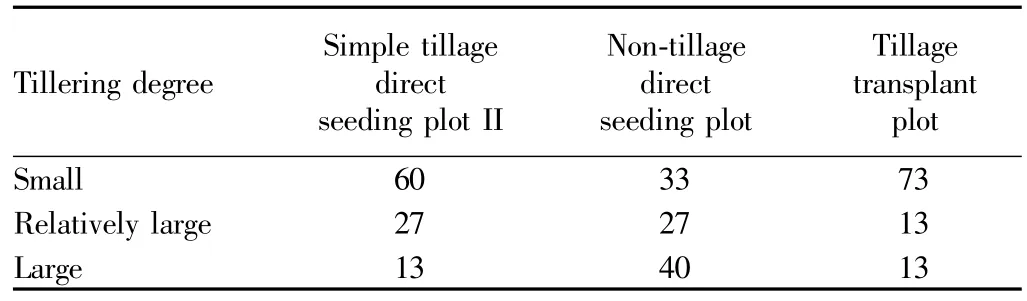

When harvesting the beet in the non-tillage direct seeding plot,there is the phenomenon of lateral roots.The survey results(Table 6)show that"relatively large"and"large"account for 67%,but for the tillage transplant plot,it is only 26%.The tillering situation in simple tillage plot II is between the two.

Tillering roots can be easily absorbed by soil.However,it is likely to cause damage in treatment,resulting in the decay and low rate of finished products.With the production of beet as the raw material for ethanol,the tillering root evaluation is an indispensable subject in the future.

2.2Energy gain and CO2em ission

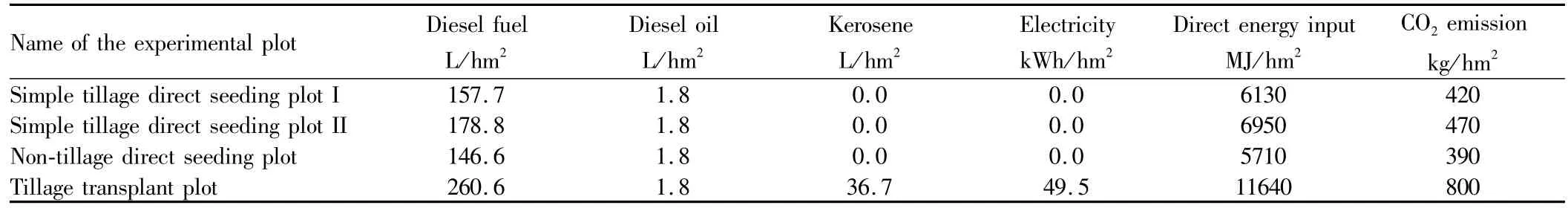

2.2.1 Direct energy input and direct CO2emission.The direct energy input in various cultivation systems is shown in Table 7.

In this experiment,the system with the largest direct seeding input is simple tillage direct seeding plot II,with the input of 6950 MJ/hm2;the system with the smallest direct seeding input is nontillage direct seeding plot,with the input of 5 710 MJ/hm2.

Fig.2 The dry matter amount of individual beet and sugar amount in 2010

The non-tillage direct seeding plot without carrying out land preparation operation has the maximum energy-saving effect,and it is reduced by 51%when compared with the energy input of tillage transplant plot.

Table 6 Survey results on lateral roots(2006) Unit:%

The study also shows that compared with the transplant method,the minimum energy input under tillage direct seeding can be reduced by 40%.The lowest CO2emission is in non-tillage direct seeding plot(390 kg/hm2),and the highest CO2emission is in transplant plot(800 kg/hm2).

The direct CO2emission under non-tillage direct seeding method is reduced by 51%when compared with the tillage transplant method.

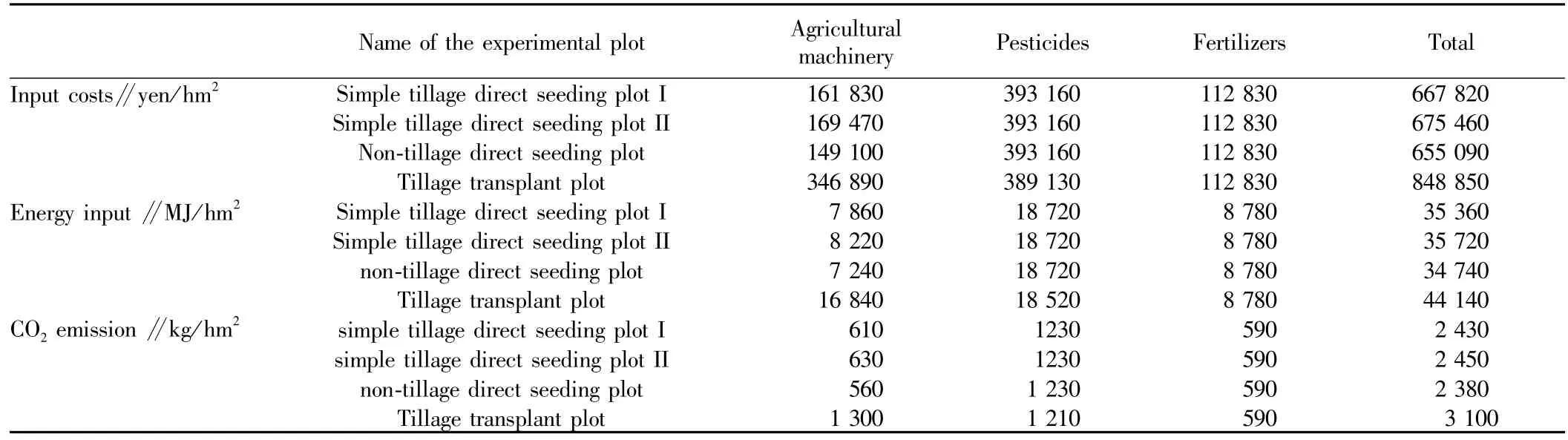

2.2.2 Indirect energy input and indirect CO2emission.In the manufacturing of agricultural machinery,pesticides and chemical fertilizers,the indirect energy input and indirect CO2emission are shown in Table 8.Among them,the energy input of pesticides is the most,and except tillage transplant plot,the energy input of agricultural machinery and chemical fertilizers are basically the same.

The analysis results of the experiment plot show that the energy required by the manufacture of agricultural machinery for simple tillage direct seeding plot I,simple tillage direct seeding plot II and non-tillage direct seeding plot,is less than 50%of the energy required by the manufacture of agricultural machinery for tillage transplant plot.The gap is mainly caused by land preparation machinery or transplant machinery.

In various systems,since the application rate of chemical fertilizers and pesticides is basically the same,there is a small difference in the energy input between the two.The indirect CO2emission also shows the same tendency.The gap between indirect energy input and indirect CO2emission,and direct input can reach as high as4-6 times.

In this study,the service life of agricultural machinery uses the theoretically recommended service life,and the actual service life of agricultural machinery is longer than the theoretically recommended service life.

Therefore,in order to pursue the accuracy of the analysis,it is necessary to survey the actual service life of agricultural machinery.

Moreover,this article takes the crop of beet as an analysis object,and the agricultural machinery shared by all the crops in the rotation system divided by the rotation crop types is the part of agricultural machinery used for beet.In the future,it is necessary to carry out LCA evaluation of whole rotation system.

Table 7 Direct energy input and direct CO2 emission

Table 8 Indirect energy input and indirect CO2 emission

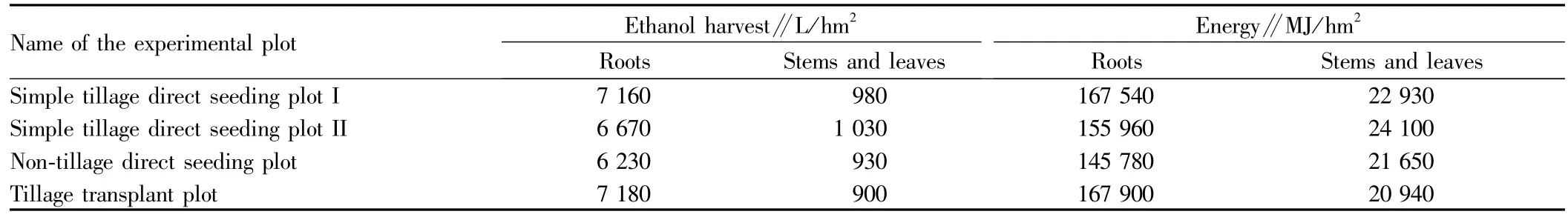

2.2.3 Energy balance and total CO2emission.The average conversion amount and energy output of ethanol in the two years are shown in Table 9.The amount of ethanol is converted from the beet sugar,so it is the highest in the tillage transplant plot,reaching 7180 L per hectare,and the converted energy reaches167900 MJ/hm2.

Compared with tillage transplant plot,the yield of non-tillage direct seeding plot with the lowest harvest is reduced by 13%,reaching 6230 L per hectare.The studies of Ogata et al.[18]show that relying on various devices and techniques,the conversion rate can be improved.

We analyze some stems and leaves abandoned in the previous beet harvest.Taking non-tillage direct seeding plot for example,the conversion amount of ethanol reaches930 L/hm2,and the energy output in this part is expected to increase to 21650 MJ/hm2.

Table 9 Theoretical yield of ethanol and energy

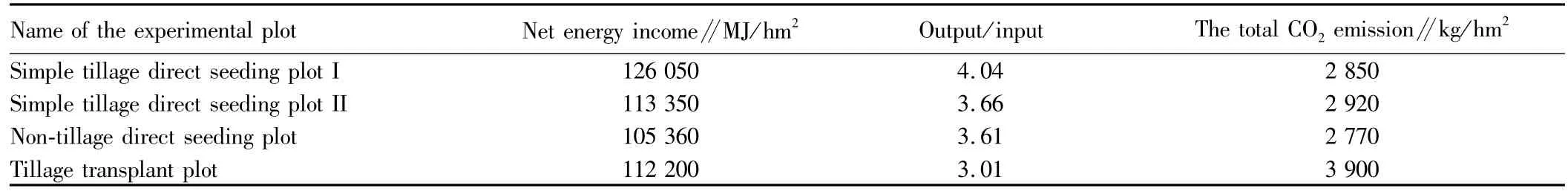

The average energy balance and total CO2emission in two years are shown in Table 10.Energy gain is the difference between energy output and energy input.Experimental results show that it is the highest in simple tillage direct seeding plot I.For the tillage transplant plot,the energy output is high,but the energy input is also high,and the offset between the two makes its energy gain lower than that of simple tillage direct seeding plot.

For the non-tillage direct seeding plot,the low harvest makes the energy gain low.The productivity indicator is the ratio of output to input.The productivity of the study in direct seeding is higher than in transplant,with the range of 3.61-4.01.

Total CO2emission is the lowest in the non-tillage direct seeding plot(2770 kg/hm2),lower than that in tillage transplant plot(3900 kg/hm2),which fully proves thismode of production reduces the environmental impact.

Table 10 The energy balance and total CO2 emission of roots

3 Conclusions

Beet is regarded as the raw material for bio-energy,and we explore the energy-saving cultivation technique.Through two years of research,we identify the following results:

(i)It is likely to generate lateral roots in the non-tillage direct seeding plotwhen compared with the simple tillage direct seeding plot,but there are not significant differences in the germination,growth period and yield.The root harvest in the non-tillage direct seeding plot is reduced by 2.5%-9.2%when compared with the existing tillage transplant plot.(ii)Through the LCA method,in terms of the energy gain,the input-output ratio of nontillage direct seeding plot is 3.61-4.04,higher than that of tillage transplant plot.The two-year analysis results show that the energy gain of non-tillage direct seeding plot is 105 GJ/hm2,and its total CO2emission is71%of that of tillage transplant plot,reducing the impact on the environment.

4 Discussions

Beet is one of the major dry land crops in Hokkaido.It is widely grown in Northeast China,North China,northwestern inland or frontier provinces,and it occupies an important position in the relationship between the sugar industry and the growers.The studies of Venturi et al.[19]show that when the direct seeding beet is used as energy,the ratio of output to input is 2.8-3.2.The gap is mainly caused by the difference in the sugar beet production between regions.

In this study,the productivity of non-tillage direct seeding plot is higher than that of tillage transplant plot.As described in this study,the development of stable production technology that can avoid the lateral roots will be an important subject.As Japan's domestic consumers voice desire to change the sugar prices in order to be in line with the international standards,the price of sugar will be bound to decline,according to the waning sugar demand in Japan.

To maintain the normal crop rotation system and ensure sustainable land use,it is necessary to guarantee the beet cultivation area in the production.So,in Hokkaido,Japan,it is necessary to grow beet as the raw material for bio-energy at low cost,study and evaluate its cultivation techniques.

We explore the low-cost cultivation technique of beet as the raw material for bio-energy,and analyze the energy gain of various cultivation systems.At the same time,using LCA method,we evaluate the impact of various cultivation systems on environment.The results show that in terms of input-output ratio,the direct seeding cultivation of beet is superior to transplant cultivation,and the load of direct seeding cultivation on environment tends to decline.

[1]Hokkaido Sugar Beet Association.Sugar beet yearbook[M].Sapporo:Nikosha Co.,Ltd.,2005:9.

[2]Agriculture&Livestock Industries Corporation[J].Sugar Information,2006(17):1-20,56-64.

[3]Bassam N.Energy plant species[M].Sapporo:Nikosha Co.,Ltd,.1998:81-84.

[4]Ogata N,Tanaka M.Possibility of breeding sugar and fodder beets for ethanol production[J].Proceedings of the Japanese Society of Sugar Beet Technology,1998(40):41-49.

[5]Tomioka E.Hokkaido soil[M].Sapporo:Nikosha Co.,Ltd.,1985:33.

[6]Hokkaido.Association of Japanese Society of Soil Science and Plant Nutrition.Hokkaido agriculture&soil and fertilizer[M].Sapporo:Nikosha Co.,Ltd.,1999:342.

[7]Hokkaido.Prefectural Tokachi Agricultural Experiment Station,Improvement of technology for direct planting of sugar beets[M].Sapporo:Nikosha Co.,Ltd.,2003:27.

[8]Social Organizations,Journal of the Japan Institute of Energy(Editor).Biomass handbook[M].Marvelous AQL,2005:2-6,369.

[9]NANZHAIGJ,SENKOU YY,DONGYD.On endangered species considering environmental loads[M].Marvelous AQL,2002:80-91.

[10]Koga N,Tsuruta H,Tsuji H,et al.Fuel consumption-derived CO2emissions under conventional and reduced tillage cropping systems in Northern Japan[J].Agriculture Ecosystems&Environment,2005(99):213-219.

[11]Nakatsu S,Higashida S.Effects of minimum tillage on upland soil and crop yields[J].Hokunou,2006,73(2):134-141.

[12]Hokkaido.Government Agriculture Department,Agricultural Working Integration in Hokkaido Ⅱ(in Japanese)[M].Sapporo:Nikosha Co.,Ltd,2000:48-51,76,387-393.

[13]Koga N.Use of LCA for assessing environmental impacts of arable crop production in the Tokachi Region of Hokkaido[J].Hokunou,2004,71(1):8-16.

[14]Nansai K,MoriguchiY,Tohno S.Embodied energy and emission intensity data for Japan using input-output tables(3EID)[M].Inventory Data for LCA.National Institute for Environmental Studies,Japan,2002.

[15]Society of Hokkaido Agricultural Machine Industry.An agricultural machinery designated sales price list[M].Sapporo:Nikosha Co.,Ltd.,2005:30-33.

[16]Okamura T.The basics of agriculture mechanization[M].Sapporo:Nikosha Co.,Ltd.,1991:353-379.

[17]Hakoyama S,Katagi I,Kawaguchi K,et al.Effect of amino N and sodium in sugar beet root biomass on conversion of sugar into alcohol[J].Proceedings of the Japanese Society of Sugar Beet Technology,1993(35):110-116.

[18]Ogata N,Tanaka M.Evaluation of ethanol conversion efficiency of B.vulgaris L.in an anaerobic fermentor[J].Proceedings of Hokkaido Crop Breeding Society,Biomass and Bioenergy,1997(38):86-87.

[19]Venturi P,Venturi G.Analysis of energy comparison for crops in European agricultural systems[J].Biomass and Bioenergy,2003(25):235-255.

Asian Agricultural Research2014年2期

Asian Agricultural Research2014年2期

- Asian Agricultural Research的其它文章

- Training and Recommendations on the Lower Limbs Exp losive Force of Juvenile Amateur M en Sprinters

- Efficiency Evaluation of Vegetable Specialized Cooperatives Based on Data of Chongqing Municipality

- Effects of Soil C/N Ratio on Apple Grow th and Nitrogen Utilization,Residue and Loss

- Drought and Waterlogging Characteristics during the Grow th Period of Summer Maize in Luxi Plain Areas

- Model for Predicting Climatic Yield of Sugarcane in Nanning City

- Incentives for the Quality and Safety Traceability System of Agricultural Products