Radial Force Analysis of Polydioxanone Coronary Stent by Finite Element Method

QUE Zhi-wen(阙志文),ZHANG Pei-hua(张佩华)*

1 Key Laboratory of Textile Science and Technology,Ministry of Education,Donghua University,Shanghai 201620,China

2 College of Textiles,Donghua University,Shanghai 201620,China

Introduction

Bioabsorbable stent is the fourth revolution in interventional cardiology for healing coronary artery stenosis[1].It can gradually degrade,without causing inflammatory response in the human body.Based on the development of assisting contemporary multislice computed tomography and magnetic resonance to image,bioabsorbable stent may be suitable for surgical revascularization in the future.Polydioxanone (PDS)is a bioabsorbable material and has been introduced for more than 30 years as the martial of suture[2].According to the curative effect of 21 patients,Repici et al.proved that the PDSbased stent which was mesh-type cylinder structure,was effective and safe to treat refractory benign esophageal strictures[3].Vondrys et al.succeeded in healing the tracheal narrowing for 4 children by PDS-based stents[4].In conclusion,PDS-based stent is safe to implant into the body.However,there are few reports about PDS-based stent applying to cure cardiovascular disease.

In the middle of the 1990s,finite element method (FEM)was applied to researching the performances of coronary stent.Due to its low cost,short cycle,and high accuracy,FEM became a classical method to optimize and predict the performance of coronary stent.Pant et al.optimized the Cypher stent (Johnson & Johnson Co.)performances,such as recoil,tissue stress,haemodynamic disturbance,uniformity of drug distribution,and flexibility[5].A series of Wu et al.predicted the performances of different stents by FEM[6-9].Therefore,the radial force of stent may be studied by FEM.

Many papers discussed the radial force of permanent stent,but a few papers studied that of bioabsorbable coronary stent by FEM.Because the strut of PDS-based stent was so thick that it might affect the blood flow,we designed a new geometry of PDS coronary stent by referring to the geometries of S7 stent(Medtronic AVE Inc.) and PDS-based stent.Through researching relationship between the crown angle and the compressed stent stress,this study explored the relationship between the angle of crown and the radial force of PDS coronary stent.

1 Experimental

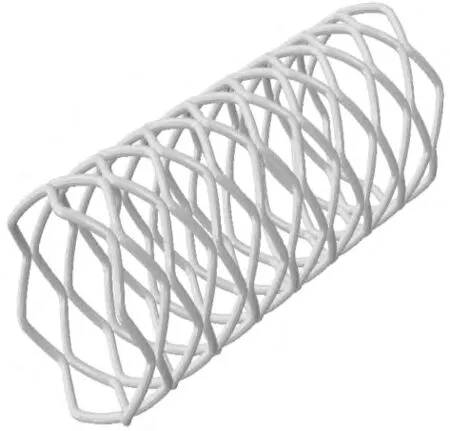

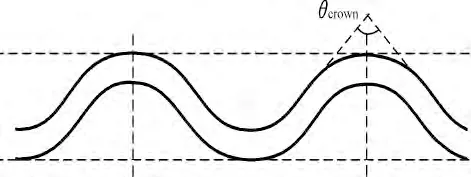

PDS monofilament was a homopolymer (Ethocon Inc.)with Poisson's ratio of 0.35 and Young's modulus of 1.5 GPa[10].There were 16 rings in the longitudinal direction and 6 crowns on each circumferential ring in the designed coronary stent whose internal diameter and length were 3 mm and 8 mm respectively,as shown in Fig.1.Figure 2 showed the crown angle (θcrown)in the two-dimensional crown.

Fig.1 The PDS stent with 50.04° of crown

Fig.2 θcrown in the design stent

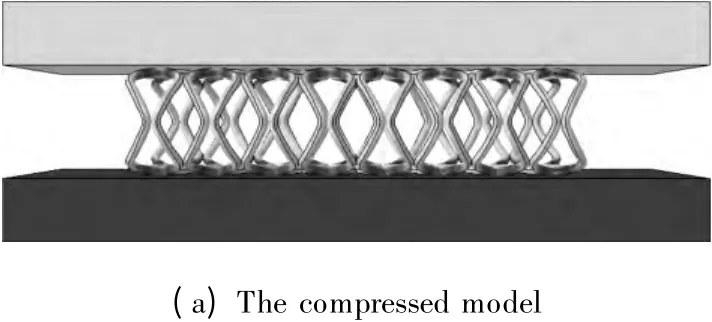

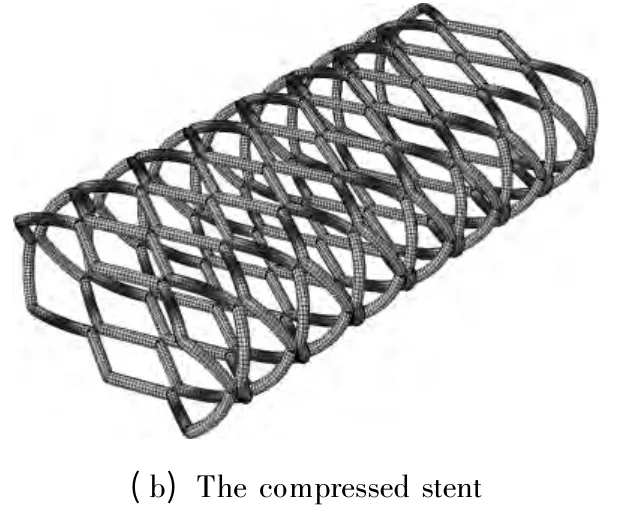

The model was compressed by the top platform.The top platform set as the rigid body,so the two platforms had different color in Fig.3(a).The geometry of top and bottom platforms was assigned to be 12 mm in length,5 mm in width,and 1 mm in thickness,as shown in Fig.3(a).The compressed speed was 2 mm/min and the amount of compression was 1.5 mm.The models were simulated by ABAQUS/Explicit 6.10.1(Dassault systemes simulia Corp.,Providence,RI,USA).

Fig.3 The compressed model and the compressed stent

The relation between the stress and the radial force is given by

where F is the radial force and S is the compressed area.According to Eq.(1),the stress of stent could represent its radial force.

2 Results and Discussion

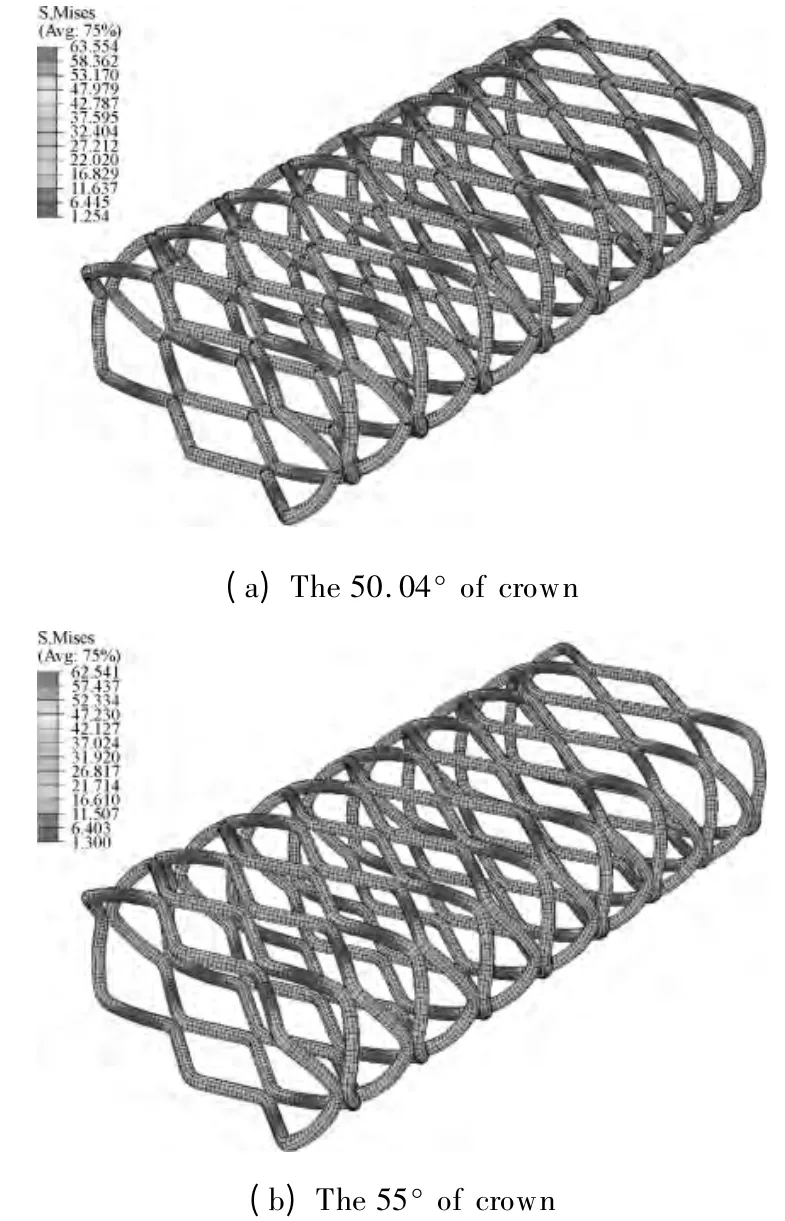

With different crown angles,the compressed stents of the models and the stress of the stents were shown in Fig.4.It was obtained that the stress of stents did not decrease with the increase in θcrownin Fig.5.The arc length of crown increased with increasing θcrown.Because a longer arc length relieved the stress,the radial force of stents decreased at the beginning.But a longer arc length would cause more extrusion between crowns.So the radial force of stents whose θcrownwas between 85° and 95°increased.The stent with θcrownof 50.04° got the greatest stress.The stent with θcrownof 75° got the smallest stress as shown in Fig.5.In conclusion,the radial force would not decrease with the increase in θcrown.When θcrownwas equal to 75° and 50.04°,the stents got the maximum and minimum radial forces,respectively.

Fig.4 The stressed stents of the different angles

3 Conclusions

The radical force of PDS coronary stent reached the maximum value when its θcrownwas equal to 50.04° and got the minimum value when its θcrownwas equal to 75°.The radial force of stents was not directly proportional to the angle of the crown.

[1]Bourantas C V,Zhang Y J,Farooq V,et al.Bioresorbable Scaffolds:Current Evidence and Ongoing Clinical Trials [J].Current Cardiology Reports,2012,14(5):626-634.

[2]Ray J A,Doddi N,Regula D,et al.Polydioxanone (PDS),a Novel Monofilament Synthetic Absorbable Suture [J].Surg Gynecol Obstet,1981,153(4):497-507.

[3]Repici A,Vleggaar F P,Hassan C,et al.Efficacy and Safety of Biodegradable Stents for Refractory Benign Esophageal Strictures:the BEST (Biodegradable Esophageal Stent) Study [J].Gastrointestinal Endoscopy,2010,72(5):927-934.

[4]Vondrys D,Elliott M J,McLaren C A,et al.First Experience with Biodegradable Airway Stents in Children[J].The Annals of Thoracic Surgery,2011,92(5):1870-1874.

[5]Pant S,Limbert G,Curzen N P,et al.Multiobjective Design Optimisation of Coronary Stents [J].Biomaterials,2011,32(31):7755-7773.

[6]Wu W,Chen S S,Gastaldi D,et al.Experimental Data Confirm Numerical Modeling of the Degradation Process of Magnesium Alloys Stents [J].Acta Biomaterialia,2013,9(10):8730-8739.

[7]Wu W,Gastaldi D,Yang K,et al.Finite Element Analyses for Design Evaluation of Biodegradable Magnesium Alloy Stents in Arterial Vessels[J].Materials Science Engineering:B,2011,176(20):1733-1740.

[8]Wu W,Petrini L,Gastaldi D,et al.Finite Element Shape Optimization for Biodegradable Magnesium Alloy Stents [J].Annals of Biomedical Engineering,2010,38(9):2829-2840.

[9]Wu W,Wang W Q,Yang D Z,et al.Stent Expansion in Curved Vessel and Their Interactions:a Finite Element Analysis [J].Journal of Biomechanics,2007,40(11):2580-2585.

[10]Bezwada R S,Jamiolkowski D D,Lee I Y,et al.Monocryl®Suture,a New Ultra-Pliable Absorbable Monofilament Suture[J].Biomaterials,1995,16(15):1141-1148.

Journal of Donghua University(English Edition)2013年5期

Journal of Donghua University(English Edition)2013年5期

- Journal of Donghua University(English Edition)的其它文章

- Electrospun Small Diameter Tubes to Mimic Mechanical Properties of Native Blood Vessels Using Poly(L-lactide-co-ε-caprolactone)and Silk Fibroin:a Preliminary Study

- Properties of Scaffold Reinforcement for Tendon Tissue Engineering in vitro Degradation

- Mineralized Composite Nanofibrous Mats for Bone Tissue Engineering

- Promoted Cytocompatibility of Silk Fibroin Fiber Vascular Graft through Chemical Grafting with Bioactive Molecules

- Fatigue Performance of Fabrics of Stent-Grafts Supported with Z-Stents vs.Ringed Stents

- Effect of Media on the in vitro Degradation of Biodegradable Ureteral Stent