Fatigue Performance of Fabrics of Stent-Grafts Supported with Z-Stents vs.Ringed Stents

LIN Jing(林 婧),SONG Ge(宋 戈),GUAN Xiao-ning(管晓宁),WANG Lu(王 璐),DU Jia(杜 佳),NUTLEY Mark,GUIDOIN Robert

1 Key Laboratory of Textile Science and Technology,Ministry of Education,Donghua University,Shanghai 201620,China

2 College of Textiles,Donghua University,Shanghai 201620,China

3 Division of Vascular Surgery,Peter Lougheed Health Center,Calgary AB T1X0L3,Canada

4 Departments of Surgery and Radiology,Laval University and Québec Biomaterials Institute,Quebec QC G1A0A6,Canada

Introduction

Endovascular aneurysm repair (EVAR)by means of stentgrafts to treat abdominal aortic aneurysmsis now is a wellaccepted surgical technique.Stent-grafts were commercialized rapidly and gained a broad clinical acceptability throughout the past two decades.However, specific post-operative complications described as endoleaks,continue to be an issue in some patients[1-2].Types Ⅲ and Ⅳ endoleaks are closely related to the failure of the device.That often may result from a suboptimal design feature which may,in rare cases,lead to fatigue and/or abrasion[3-8]of the stent-grafts.Our ongoing international program has analyzed the fatigue performance of fabrics supported with Z-stents and ringed stents submitted to a long-term in vitro fatigue simulation.Thus,the aim of this study is to put forward suggestions to improve the fabric characteristics and stent design that may prevent types Ⅲand Ⅳendoleaks[9].

1 Materials and Methods

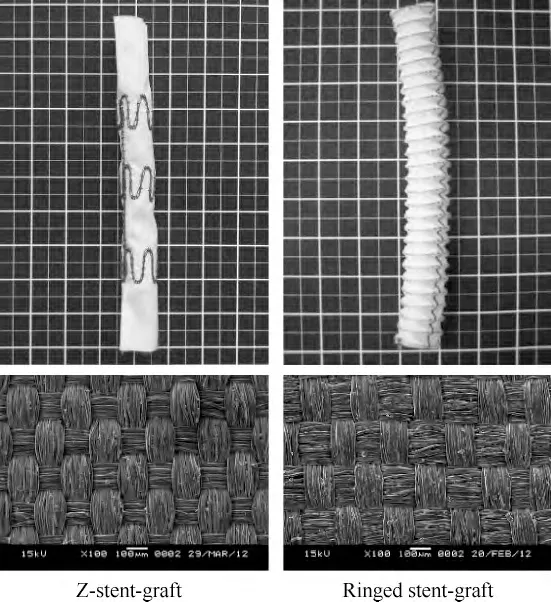

The Z-stent-graft manufactured in Donghua University was woven polyester tubular conduit sewn to the Z-stents,in a manner similar to some commercial devices.The ringed stentgraft used in these experiments was the Anaconda limb graft from Vascutek (Fig.1).The length was 100 mm while the diameter was 10 mm.Both structures of the fabrics were plain.

Fig.1 Comparison of two stent-grafts' fabrics

The in vitro mechanical fatigue simulation testing was also developed in Donghua University[7],which was designed to imitate principles of the human circulatory system and its mode of buckling motion.This instrument was applied to evaluating the fatigue performance of fabrics of stent-grafts supported with Z-stents vs.ringed stents.It permitted accelerated buckling of each stent graft with 200 cycles per minute under a pressure of 360 mmHg (3 times that of normal human pressure).A1 and S1 were the control specimens for the ringed stent-grafts and Zstent-grafts respectively,which the testing time was 0 h.The tests were carried out in duplicate and scheduled for 8 (A2,A3,and S2),24 (A4,A5,and S3),48 (A6,A7,and S4),and 168 (A8 and A9)h or stopped when holes were observed macroscopically.

After the in vitro mechanical fatigue simulation experiment,the specimens were analyzed non-destructively(gross observations)and destructively (fabric characteristics,mechanical properties)and the results were compared with the controls.

2 Results and Discussion

Table 1 recorded the scheduled time and the real testing time of two devices with Z-stents and ringed stents.The devices with ringed stents followed the scheduled time,while the devices with Z-stents demonstrated breaks in the fabric within 8 h.Thus,the experiment of devices with Z-stents did not continue beyond 8 h.

Table 1 Scheduled time and testing time of two devices

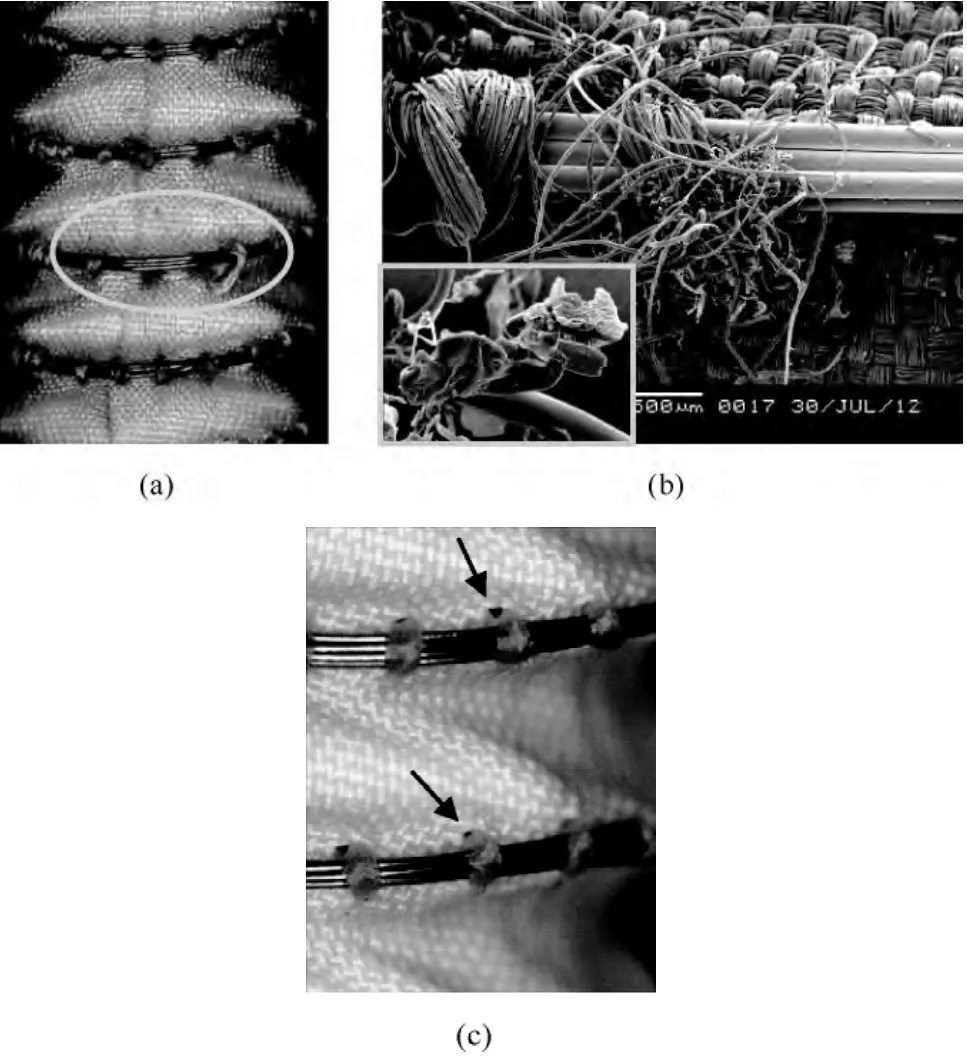

The fabrics supported with ringed stent-grafts remained intact after 48 h of in vitro testing (A2-A7).After 168 h,some minor suture fractures were identified (A9,Fig.2(a)),and the tips of the broken sutures were decomposed (Fig.2 (b)).The enlarged pinholes were observed on the all specimens (A2-A8)as well Fig.2 (c).The fabrics supported with ringed stents demonstrated only minimal suture damage and enlarged pinholes, without any evidence of significant fabric perforations.

Fig.2 A9 fatigue performance after 168 h in vitro test

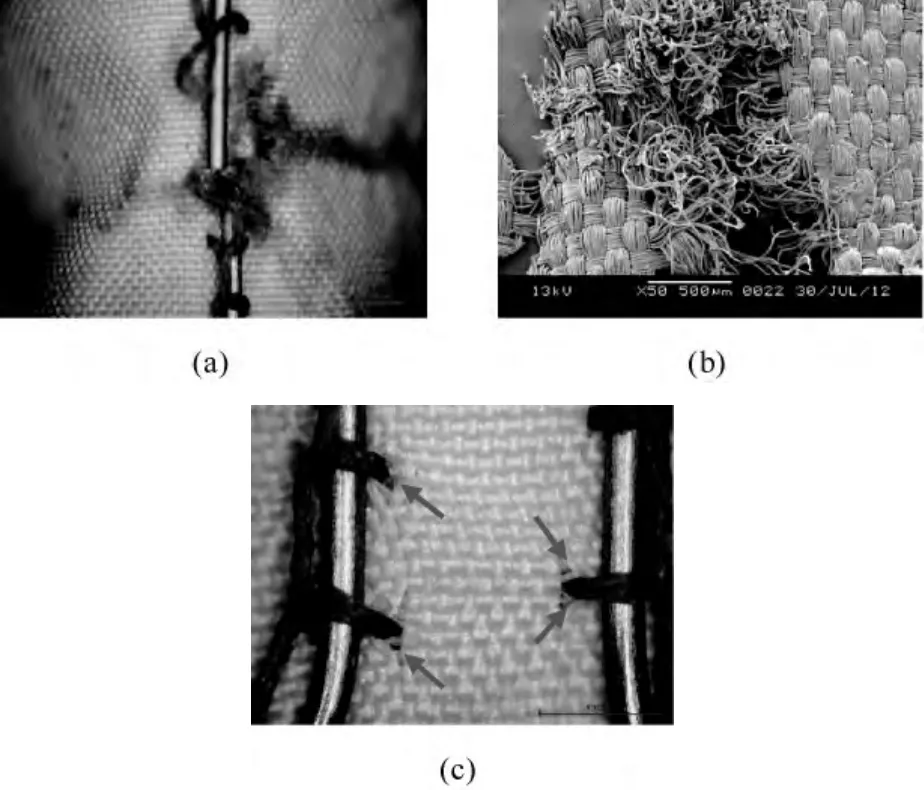

Comparatively, the fabrics supported with Z-stents demonstrated a greater number and degree of broken sutures as well as fraying and/or tearing of the fabrics at the apices of some stents within 8 h.The S2 showed different type of damage after 8 h of fatigue simulation testing.The evident buckling traces were observed on the surface of the fabrics,and the sutures were broken at the top of Z-shaped stents (Fig.3).A hole was also observed which was located at the apices of stents(a),and the fabrics were abraded significantly by the stents(Fig.3(b)).The vertical bar stent was also fractured (Fig.3(c)).

Fig.3 S2 fatigue performance after 8 h in vitro test

Similar damage was observed in S3 as S2 after 7 h of testing (Figs.4 (a)and (b)).An enlarged pinhole was observed adjacent to the stent (Fig.4(c)).

Fig.4 S3 fatigue performance after 7 h in vitro test

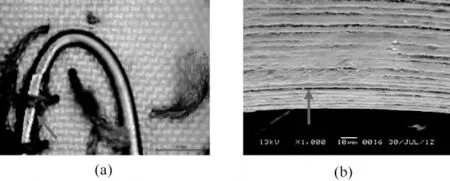

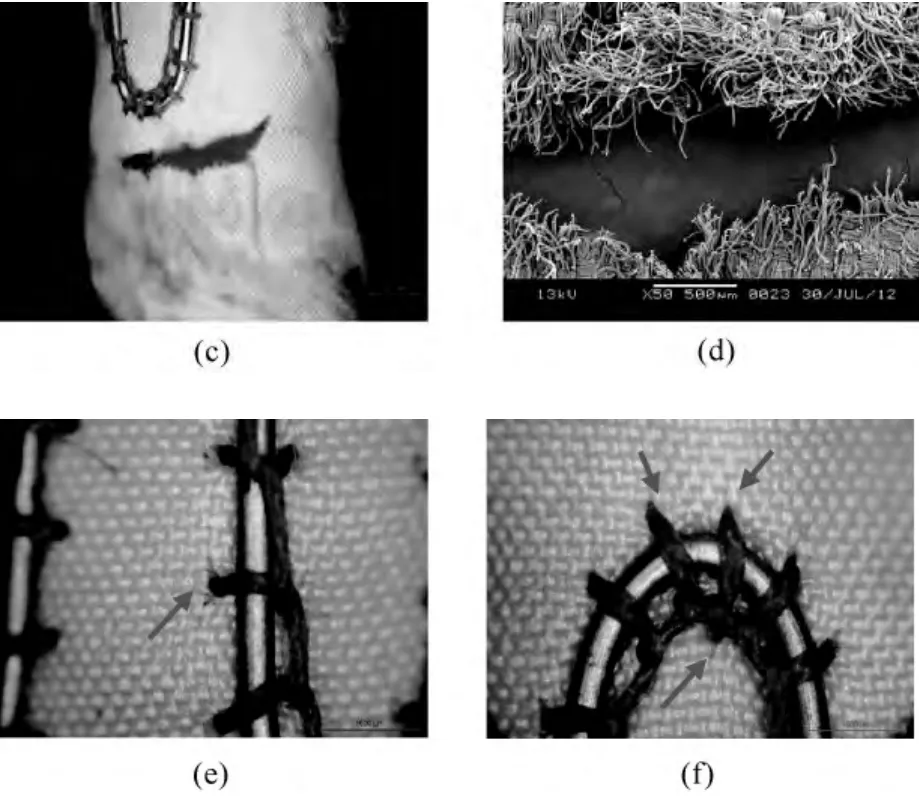

The S4 demonstrated significant damage (Fig.5).Some abrasions which appeared to be caused by the sutures could be observed on the surface of the stent (Figs.5 (a)and (b)).As with S2 and S3,the devices were damaged.Some sutures were ruptured and the suture holes were enlarged (Figs.5 (c)-(f)).

Fig.5 S4 fatigue performance after 6 h in vitro testing

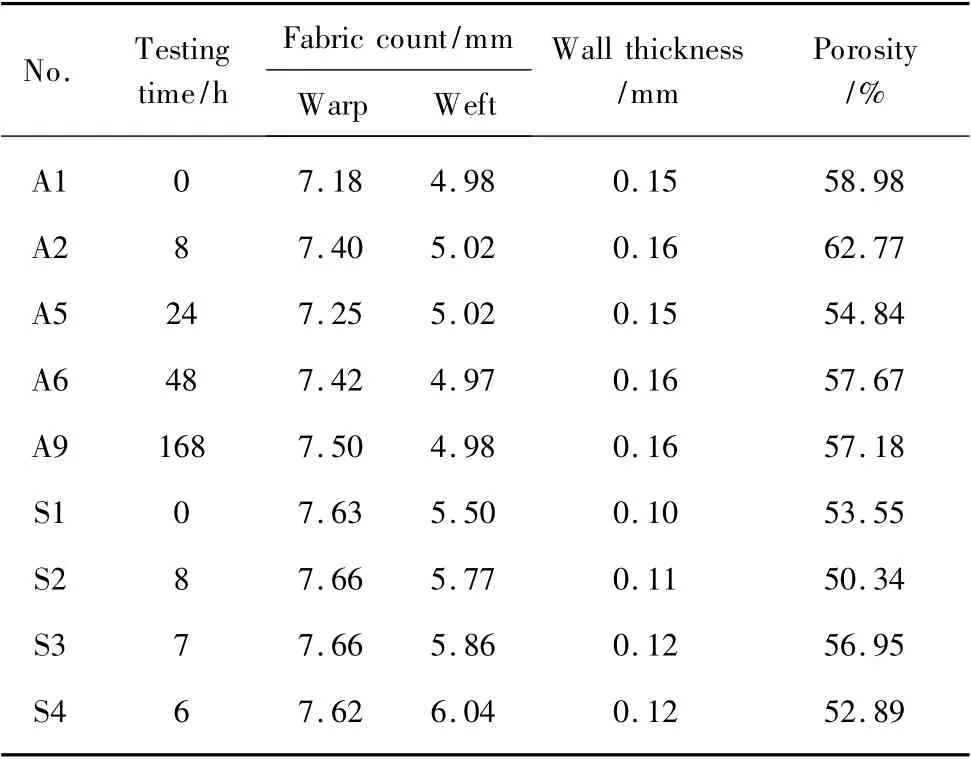

The fabric characteristics were listed in Table 2.There was no obvious difference before and after the fatigue testing.However,there existed some difference between the fabrics supported with Z-stents and ringed stents respectively.Although both the structure of fabrics supported with two configurations of stents was plain,the fabric count of fabrics supported with Zstents (7.63 × 5.50/mm)was higher than the one with the ringed stents (7.18 ×4.98/mm).The higher the fabric count was,the less small holes existed among the interlacing points of warp and weft,which caused the low porosity of fabrics supported with Z-stents.The wall thickness of fabrics supported with ringed stents was higher than the fabrics supported with Zstents,which made the fabrics supported with ringed stents to resistant to the abrasion better.

Table 2 Fabric characteristics of the two fabrics

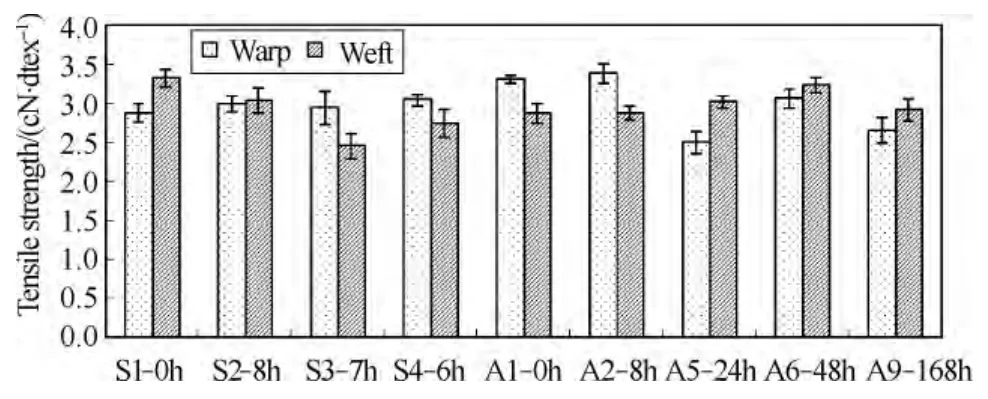

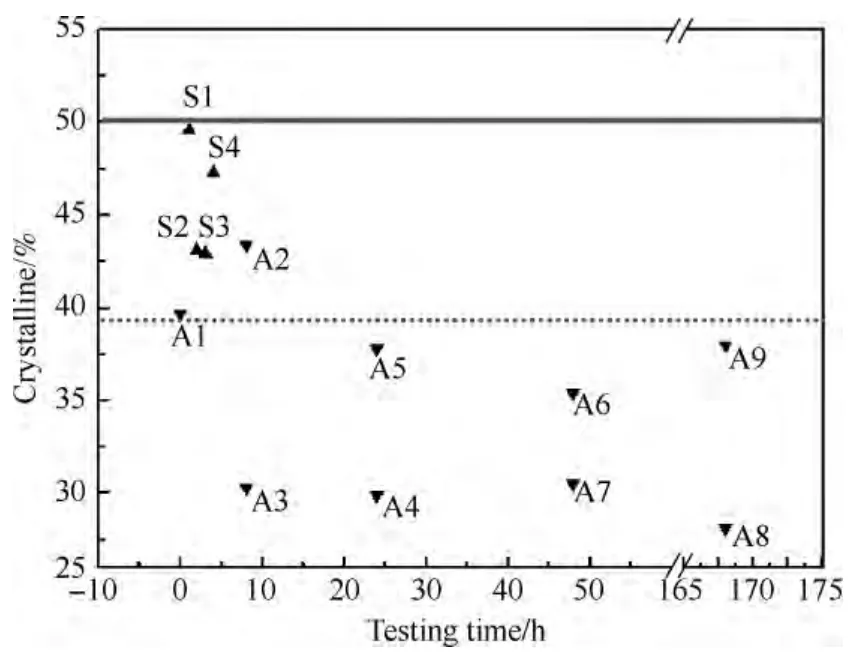

There was no obvious regular trend of the tensile strength of the fibers (Fig.6).When comparing S1 and A1,the difference was very small.In general,within 168 h,there was no significant difference between the tensile strength of the two fabrics of the devices before and after the fatigue experiment.Figure 7 demonstrated the crystallinity of all specimens.Compared with A1 (39.7%),the crystallinities of the specimens declined in all grafts except A2 (43.41%)after the fatigue experiment.At the beginning of fatigue experiment(within 8 h),the increase of the crystallinity of A2 may contribute to the destruction of amorphous area first.After 8 h,not only the amorphous area but also the crystalline region was destroyed and then caused the decline of crystallinity.

Fig.6 Tensile strength of the two fabrics

Fig.7 Crystallinity of all specimens

The fabric characteristics and tensile strength did not show a significant difference between the control and fatigue simulated specimens.However,the decrease of crystallinity demonstrated that the fatigue simulation damaged the crystalline region of fibers that contributed to the fraying and/or tearing of the fabrics caused by Z-stents.Based on the gross observation,the fatigue performance of fabrics supported with ringed stents proved to be superior:only minor damage was demonstrated by enlarged pinholes as a result of the tension on the sutures where the stent was sewn to the fabric.On the other hand,serious damage was observed in the Z-stents.With the buckling,the sharp apices of adjacent Z-stents made repeated contact with the fabric thus leading to damage of both the fabrics and adjacent sutures.With regards to the enlarged pinholes of sutures,it might be appropriate to look for another manner to sew fabric to stents.

3 Conclusions

The fatigue performance of fabrics supported with ringed stents is better than fabrics supported with Z-stents[10-11].The design of the sharp apices of Z-stents deserves more attention to decrease the fraying and/or tearing to the fabrics.The design of these stents must be revisited in order for low profile devices to be safer.

[1]White G H,Yu W,May J.Endoleak—a Proposed New Terminology to Describe Incomplete Aneurysm Exclusion by an Endoluminal Graft[J].Journal of Endovascular Surgery,1996,3(1):124-128.

[2]White G H,Yu W,May J,et al.Endoleak as a Complication of Endoluminal Grafting of Abdominal Aortic Aneurysms:Classification,Incidence,Diagnosis,and Management [J].Journal of Endovascular Surgery,1997,4(2):152-168.

[3]White G H,May J,Waugh R C,et al.Type Ⅲand Type ⅣEndoleak:toward a Complete Definition of Blood Flow in the Sac after Endoluminal AAA Repair[J].Journal of Endovascular Surgery,1998,5(4):305-309.

[4]Jacobs T S,Won J,Gravereaux E C,et al.Mechanical Failure of Prosthetic Human Implants:a 10-Year Experience with Aortic Stent Graft Devices[J].Journal of Vascular Surgery,2003,37(1):16-26.

[5]Wanhainen A,Nyman R,Eriksson M,et al.First Report of a Late Type III Endoleak from Fabric Tears of a Zenith Stent Graft[J].Journal of Vascular Surgery,2008,48(3):723-726.

[6]Major A,Guidoin R,Soulez G,et al.Implant Degradation and Poor Healing after Endovascular Repair of Abdominal Aortic Aneurysms:an Analysis of Explanted Stent-Graft[J].Journal of Endovascular Therapy,2006,13(4):457-467.

[7]Lin J,Wang L,Shen G,et al.Experimental Study of the Buckling Fatigue of the Stent-Graft's Textile Scaffold [C].Proceedings of 2011 International Forum on Biomedical Textile Materials,Shanghai,China,2011:461-465.

[8]Rodrigues A,Figueiredo L,Bordado J.Brasion Behavior of Polymeric Textiles for Endovascular Stent-Grafts[J].Tribology International,2013,63:265-274.

[9]Desai M,Bakhshi R,Zhou X,et al.A Sutureless Aortic Stent-Graft Based on a Nitinol Scaffold Bonded to a Compliant Nanocomposite Polymer is Durable for 10 Years in a Simulated in vitro Model [J].Journal of Endovascular Therapy,2012,19(3):415-427.

[10]Demanget N,Avril S,Badel P,et al.Computational Comparison of the Bending Behavior of Aortic Stent-Grafts[J].Journal of the Mechanical Behavior of Biomedical Materials,2012,5(1):272-282.

[11]Demanget N,Latil P,Orgeas L,et al.Severe Bending of Two Aortic Stent-Grafts:an Experimental and Numerical Mechanical Analysis [J].Annals of Biomedical Engineering,2012,40(12):2674-2686.

Journal of Donghua University(English Edition)2013年5期

Journal of Donghua University(English Edition)2013年5期

- Journal of Donghua University(English Edition)的其它文章

- Electrospun Small Diameter Tubes to Mimic Mechanical Properties of Native Blood Vessels Using Poly(L-lactide-co-ε-caprolactone)and Silk Fibroin:a Preliminary Study

- Properties of Scaffold Reinforcement for Tendon Tissue Engineering in vitro Degradation

- Mineralized Composite Nanofibrous Mats for Bone Tissue Engineering

- Promoted Cytocompatibility of Silk Fibroin Fiber Vascular Graft through Chemical Grafting with Bioactive Molecules

- Effect of Media on the in vitro Degradation of Biodegradable Ureteral Stent

- Radial Force Analysis of Polydioxanone Coronary Stent by Finite Element Method