某重型车驱动桥桥壳结构强度及模态分析

黄 霞,丁 军,陈 松

重庆理工大学机械工程学院,重庆 400054

1.Introduction

As the matrix assembly of a main reducer,differential,and half axle,the driving axle housing primarily supports the auto load.On the one hand,axle load is transmitted through the wheels;on the other hand,traction,braking,lateral,and vertical forces acting on the driving wheel are transmitted through the frame through the suspension.To avoid axle housing deformation or fracture and to ensure that the gear of the main reducer engage normally and that half axle generates no additional bending stress,driving axle housing should have sufficient strength and stiffness as well as better dynamic characteristics in the moving process of automobiles.Based on a certain imported front driving axle of heavy-duty automobiles,this study made a structural strength and model finite element analysis of driving axle housing to improve its structural design.This study can provide important reference for the development on new products[1].

2.Establishment of axle housing structure and finite element model

The driving axle structure(Fig.1)is a separable axle with six parts.The left side of the left casing of the main reducer 6 is connected with the housing of hydraulic device 5 and half-axle casing 4 through the screw;the right side of the left casing of the main reducer 6 is connected to the right casing of main reducer 1,the housing of hydraulic device 2,and halfaxle casing 3 through the screw.The driving gear of the main reducer is supported on the bearing hole at the rear axle housing by a bearing.Supporting bearings for differential assembly are overwhelmingly supported on the bearing holes in the right and left casings of the main reducer.This axle housing uses a full floating axle.Reinforcements are distributed over the surface of the half-axle casing of the rectangular section.Both sides of the axle housing are supported on the bearing holes in wheel holes through a pair of wheel bearings.

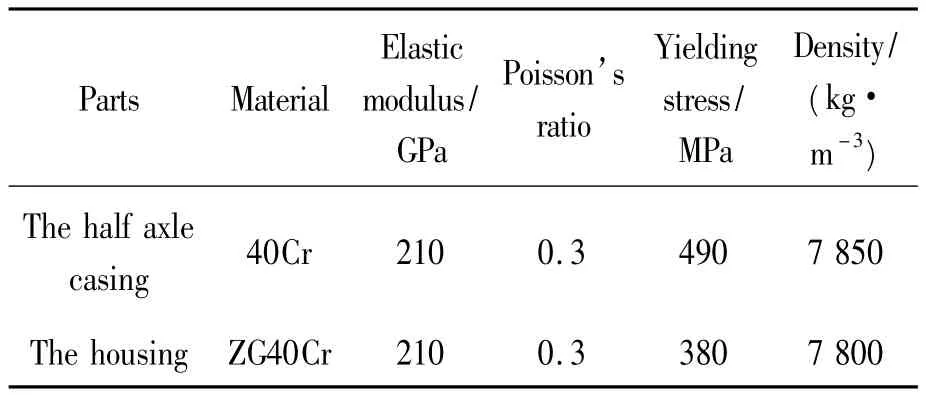

The quality of the finite element model as the discrete model of the original structure is directly related to the accuracy and precision of the solution.CATIA is used to establish a 3D model of the driving axle.This 3D model is induced to HyperMesh to divide the mesh.Material property assignment,load,boundary constraints,solving,and post-treatment are completed by ABAQUSsoftware.Considering the solving accuracy and efficiency,the element type for the half-axle housing and axle body in ABAQUS is the C3D4,a four-node tetrahedron.Each node has 3 degrees of freedom,namely,freedom of movement in the x,y,and z directions.A kinematic coupling constraint is used to simulate two screw connections on the axle housing through a bar unit.A discrete diagram of the housing mesh is shown in Fig.1.The total number of units is 2 277 645,and the total number of nodes is512 627.The materials for producing axle housing are half-axle casings made by 40Cr and a housing body(the cases of the main reducer and hydraulic device)made by ZG40Cr.The material properties are shown in Tab.1[2].

Fig.1 The FEM mesh for driving axle structure

Tab.1 Material properties for the axle housing

3.Calculation of axle housing strength and analysis of results

According to the Experimental Methods of Auto Drive Axle Bench(QC/T533—1999)and the specific arrangement of the bench experiment condition axle in the frame,axle housing is simplified to a twopoint simple support constraint in analysis and calculation.The supporting surface of the left bearing of the axle housing restricts the freedom of movement of nodes in the X,Y,and Z directions(according to the auto coordinate system),and that of the right bearing of the axle housing restricts the freedom of movement in the Y and Z directions.Such constraints cause the stress near the supporting surface of the bearings on both sides of the axle housing to be inconsistent with the actual situation.However,these constraints do not affect stress distribution in other parts of the axle housing[3-5].The full axle load of 12T,the maximum output torque of 65 000 N·m and the radius of 0.58 m are taken into consideration in this case.

3.1.Calculation of axle housing as automobile runs on an uneven road

When the vehicle is fully loaded and running on an uneven road,the vertical force is at its maximum when the impact load between the wheels and ground is considered.Two and a half times of the full axle load(12T)is applied over the leaf spring seat on both sides of the axle housing in a uniform load form.

The stress distribution of the axle housing under this condition is shown in Fig.2.The maximum Mises stress is 98 MPa,located in the transition zone of the dental arc of the axle housing.

Fig.2 The stress distribution of axle housing at the uneven road

3.2.Calculation of axle housing as automobile runs with maximum traction force

Without considering the lateral force,when the automobile is running in a straight line with the maximum traction force,the forces applied to the axle housing include the full axle load(applied over the leaf spring seat on both sides of the axle housing in uniform load form),the maximal tangential reaction force on the ground to the right and left driving wheels(applied to the rear wall of the leaf spring seat on both sides of the axle housing in uniform load form),and the reaction moment caused by the trans-mission of driving torque(applied to the place between the leaf spring seats on both sides of the axle housing).

Fig.3 The stress distribution of axle housing at the maximum traction force

The stress distribution of the axle housing under this condition is shown in Fig.3.The maximal stress of the axle housing,located within the transition zone of the dental arc of the axle housing,is 106 MPa,far lower than the yield limit of the half-axle casing materials(490 MPa).Under this condition,the static strength of the axle housing meets the requirement.The remaining high-stress areas are distributed in the connection between the leaf spring and half-axle casing.The maximum stress on this area is 83 MPa.The maximum deformation(0.345 mm)occurred at the rear of the main reducer housing.The stiffness of the axle housing meets the requirements stipulated in the Evaluation Index of Auto Drive Axle Bench Experiment:the maximum deformation for one meter of thread is less than 1.5 mm/m as the full axle load[6].

Fig.4 The deformation of axle housing at the maximum traction force

4.Model analysis and analysis of axle housing results

Axle housing is the bearing weight and power transmission part on the body structure.The vibration caused by components in axle housing and the excitation of the external environment significantly affects the body structure and vehicle performance.When the frequency of excitation undergone by the axle housing is close to a certain frequency of the axle structure,structural resonance may occur and thus increase dynamic stress.Strength will also fail or unallowed deformation will occur,thereby seriously affecting driving safety.Model analysis of axle housing yields the natural frequencies and vibration form of the axle housing.These results have important implications for the analysis of the dynamic response of the overall driving axle,the generation of dynamic load,transmission,and the vibration form to the system.

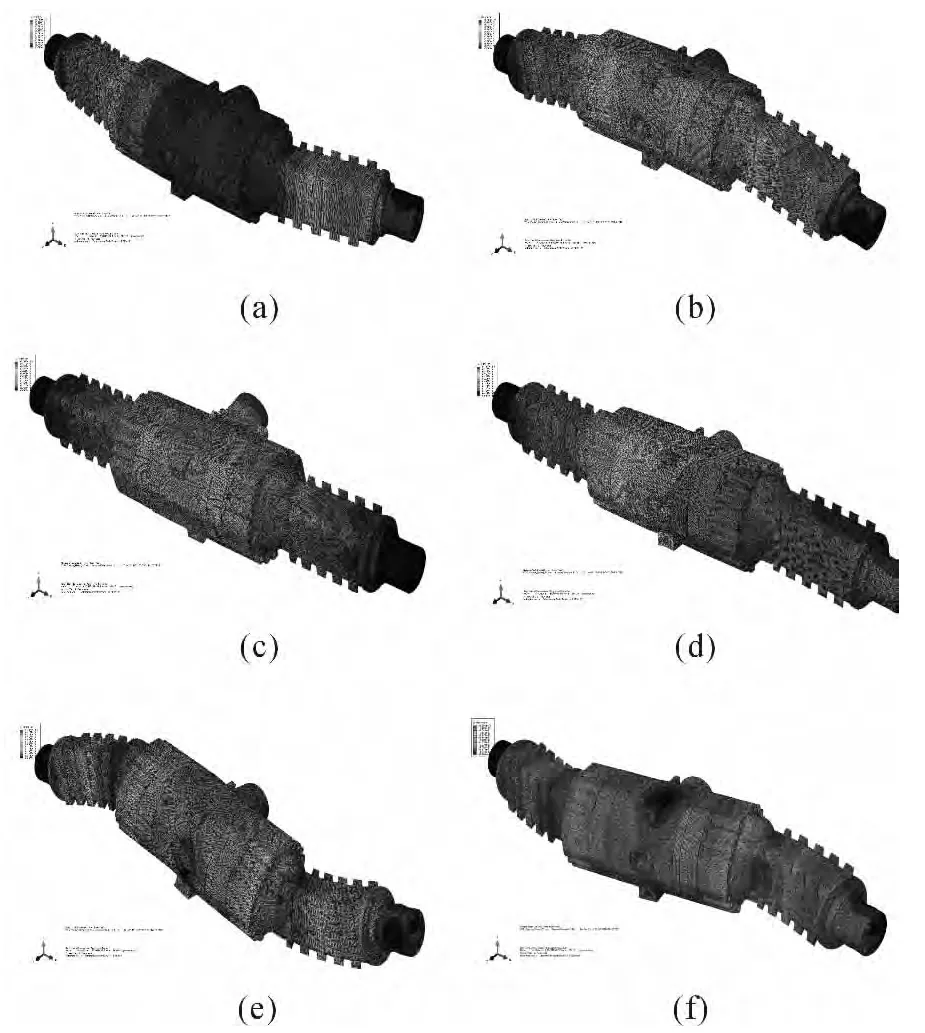

Based on the practical condition of this driving axle,the modal analysis module of ABAQUSis used to calculate the natural frequencies and modal shape of the axle housing in normal running.Structural vibration can be expressed as the linear combination of natural vibration modes in all levels.Among these modes,low-level vibration mode has a greater effect than a high-level vibration mode on structural dynamics.The natural frequencies of the top 12 levels and their corresponding modal shapes are extracted.These natural frequencies are shown in Tab.2.The vibration modes in levels 1 ~6 are shown in Fig.5.The vibration modes in levels 7~12 are omitted because of space limitations.

Fig.5 The 1 ~12 modal shape for the axle housing

The excitation from the road surface that the vehicle vibration system bears belong to vertical vibra-tion of 0 Hz to 50 Hz.The natural frequencies in the top 12 levels within the model of the driving axle housing are not in this range without generating axle housing resonance caused by excitation from the road surface.When the vehicle is running on a flat road,it is always affected by a symmetrical vertical load,which can easily excite the bending mode in the same direction of the axle housing structure.When the vehicle is running on an uneven road,it is primarily affected by a nonsymmetrical load.At that time,the anisotropic bending mode of the axle housing or the torsional bending modal combination can easily be induced.Based on the vibration mode diagram and animation of the calculation result,the top three levels of the models for this axle housing are of the bending mode;the last nine levels of the models are of the bending and torsion mixed mode.The axle housing structure is designed reasonably,providing reference for housing optimization[7-8].

Tab.2 The 1 ~12 natural frequency for vibration analysis(Hz)

5.Conclusions

CATIA is used to establish a 3D model of a certain imported driving axle housing of a heavy truck.This model is induced to HyperMesh to divide the mesh.ABAQUSis used to conduct the finite element analysis and calculation of the structural strength and model.The strength and stiffness of the axle housing meet the design requirements of the Evaluation Index of Auto Drive Axle Bench Experiment.The natural frequencies in all levels of the models are higher than the frequency of excitation by the road surface,without generating axle housing resonance.The structural design is reasonable,providing a certain theoretical basis for the design improvement and structural optimization of axle housing.

[1] LIU Weixin.Design for Vehicle Axle[M].Beijing:Tsinghua University Press,2004.

[2] DONG Yude,YAO Liangliang,LIU Zhen,et al.Finite element analysis and experiment of big horsepower tractor drive axle[J].Journal of Graphics,2012(33):24-28.

[3] LI Liang,SONG Jian,WEN Lingling,et al.Finite element simulation and test for fatigue life of commercial vehicle driving axle housing[J].Journal of Mechanical Strength,2008,30(3):503-507.

[4] ZHANG Lihua,XU Zhongming,SHI Fangyuan.CAE analysis on driving axle casing of commercial vehicles[J].Journal of Mechanical Design,2009(26):75-78.

[5] QC/T 533—1999.Experimental methods of auto drive axle bench[S].1999.

[6] QC/T 534—1999.Evaluation index of auto drive axle bench experiment[S].1999.

[7] QI Dongdong,SUN Huanwu,QI Lili,et al.Structural strength and modal analysis of heavy drive axle housing based on ANSYS[J].Journal of Mechanical Transition,2012(36):105-107.

[8] WANG Bin.The finite element analysis of stress strength and vibration of the automotive drive axle housing[D].Hefei:Hefei University of Technology,2008.