动力换挡系统和换挡策略标定

杨一凡

采埃孚(中国)投资有限公司

ZF (China)Investment Co.,Ltd.

上海工程中心

简介:

自动变速器中的电子及液压元件代替了传统手动挡车辆中驾驶员将变速箱从一档切换到另外一档的工作。控制软件中的参数须做出相应的调整,以实现平顺的换挡,对于追求舒适性的换挡要求来说,最完美的换挡是让驾驶员以及乘客无法察觉到换挡过程,另外适宜的换挡策略对于车辆的驾驶性也是非常重要的。自动变速器标定工程师的任务就是调整控制软件中的参数,以达到车辆的最佳表现。

自动变速器标定

自动变速器的标定是指调整变速器控制软件内的控制参数,通过调整这些参数,用以实现在各个驾驶工况以及各种环境条件下对车辆换挡表现的良好控制。

在应用开发过程中,自动变速器在实车上的标定是非常重要的,同时也占用了最长的开发周期。所有的参数都必须根据特定的发动机,车重,主减速比,液力变矩器特性,驾驶性要求等进行调整。

对于ZF自动变速箱的标定来说,换挡过程控制(HPSYS)以及换挡策略控制(ASIS)是主要的标定对象。

换挡过程控制的标定

ZF的6HP变速器内通过一个单行星齿轮组,一个双行星排和五组换挡元件(既离合器以及制动器)将来自发动机的输出扭矩以不同的组合形式传递到变速器输出端从而驱动动力总成。换挡过程控制的任务是以电子液压系统控制换档元件从而驱动相应的齿轮组,挡位的切换是通过离合器或制动器的打开与闭合而从机械上实现的。

Introduction

In an automatic transmission,electronic and hydraulic components have to take over the tasks of a driver to shift from one gear to another.In order to have a smooth transition in shifting from one gear to another,parameters in the control software have to be adjusted accordingly,so that best of all,the driver and the passengers in the car do not even recognize this shifting process.In addition,it is necessary that a proper shifting strategy has to be implemented.It is the task of a calibration engineer to adjust the parameters in the control software to achieve an optimum performance.

Definition of automatic transmission calibration

Automatic transmission calibration is adjusting parameters of functions in the transmission control software,which are not fixed in their values,to make the control suitable for a vehicle to perform well in all driving and environments conditions.

The automatic transmission calibration in prototype vehicles is a very important phase during application development,and it also lasts the longest.All the parameters must be properly adjusted for the specific engine,vehicle mass,final drive ratio,torque converter characteristics,requirements of drivability and etc.

For the calibration of an automatic transmission in ZF,the shift process control (named HPSYS)and the shift strategy control (named ASIS)are mainly calibrated.

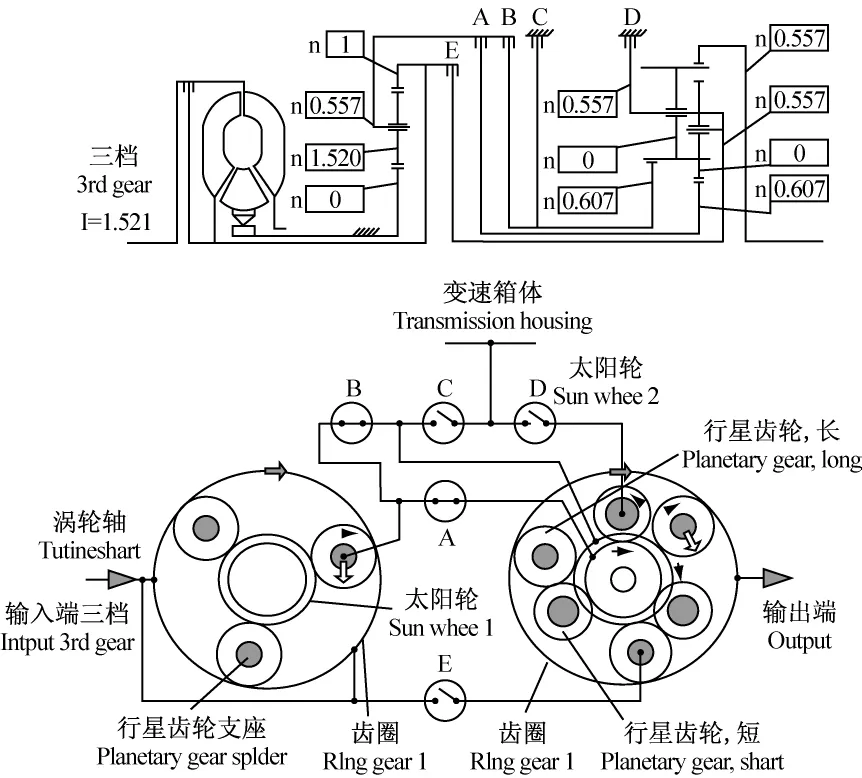

图1 三档的动力传递Fig.1 Power flow of 3rd gear

例如在三档,液力变矩器涡轮驱动前部齿圈,单行星齿轮组以及离合器E的外鼓。

前部齿圈1驱动行星轮,行星轮围绕一号太阳轮旋转,由此便驱动了一号行星支架,同时驱动了离合器A的外鼓和离合器B的内鼓通过离合器A的结合,在双行星排内的三号太阳轮被驱动,从而带动短行星组。

二号太阳轮被结合的离合器B所驱动,由于长行星齿轮组此时与短行星齿轮组相啮合,不能围绕二号太阳轮相对自转并驱动了锁死的双行星排行

Calibration of the Hydraulic Planet Gear System(HPSYS)

ZF 6HP transmissions have one single planetary gear set,one double planetary gear set and 5 shift elements(clutches and brakes),which transfer the torque from engine output to power train with different combinations.Task of HPSYS is the controlling of shift elements by electronic-hydraulic system,gear shifting is mechanically realized via clutches engaging and disengaging.

图2 四档的动力传递Fig.2 Power flow of 4th gear

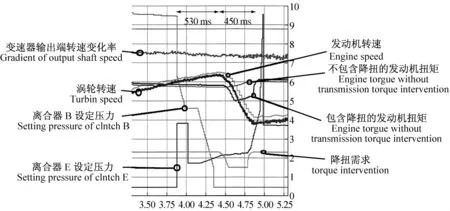

图3 典型的三四动力升档Fig.3 Typical graph for a power up shifting from 3rd to 4th gear

对于该三四的动力升档来说,换挡指令是由换挡策略控制软件根据当前的油门开度以及变速器输出端转速共同决定并且释放的。一旦换挡过程控制软件接受该换挡指令,离合器B将会通过降低油压而打开;同时离合器E将通过充油模型增加油压而结合。当离合器B的完全打开时,涡轮转速和发动机转速应该开始被离合器E的结合而拉向同步转速。在动力换挡过程中,可标定的发动机降扭要求将通过总线通讯发给发动机控制模块,要求发动机此时减少一定的扭矩输出。通过适当的发动机降扭以及压力标定,变速器会把涡轮转速拉到同星架,其转动方向与发动机方向相同。

在四档中,离合器A和E的结合实现了不同的速比。

对于三四的动力升档,要求结合的离合器由A和B切换到离合器A和E,也就是说需要离合器A保持结合,在结合离合器E的同时松开离合器B.

换挡过程控制标定需要标定工程师通过油压的建立与释放控制换挡的过程。标定时需要驾驶车辆同时监控系统内的变量,例如发动机转速与扭矩,变速箱离合器油压等等。例如图三中所示的曲线。步转速并完成换挡。

换挡时间(包括反应时间和滑摩时间)必须控制在一定的范围内,从而兼顾换挡舒适性与避免离合器负载过大而异常的磨损。换挡舒适性可以通过输出轴转速的变化率进行评估。

在匹配标定过程需要避免出现以下的情况,因为此类情况降低了换挡的舒适性或增加了离合器的负荷而产生磨损。

图4 动力升档三四中,离合器B过早分离Fig.4 Power up shifting from 3rd to 4th gear with clutch B disengaged too fast

图5 动力升档三四中,增加离合器E的换挡压力Fig.5 Power up shifting from 3rd to 4th gear with increased shifting pressure to clutch E

For example,in the 3rdgear,the turbine drives the ring gear of the front,the single planetary gear set and the outer plate carrier of clutch E.Ring gear 1 drives the planetary gears,which roll round fixed sun wheel 1.This drives the planetary gear spider 1and at the same time the outer plate carrier A and the inner plate carrier of clutch B.with engaging of clutch A.The sun wheel 3in the double planetary gear set is driven;this meshes with the short planetary gears.Sun wheel 2is driven via engaged clutch B.The long planetary gears,which are in engagement with short ones,cannot roll round fixed sun wheel 2and drive the blocked double planetary gear carrier in the direction of engine rotation.

Similarly in the 4thgear,a different ratio is realized via the engagement of A and E.

A power up shifting from 3rdto 4thgear requires the engaged clutches from A and B switch to A and E,meaning the clutch A stays engaged and the clutch E need to be engaged,while the clutch B is disengaging.HPSYS calibration allows the calibration engineer to control how the shifting process from one gear into the next is performed.The calibration is done by driving the vehicle and monitoring different system parameters,such as engine speed and torque,transmission clutch pressure etc.An example for a typical simplified display is shown in Fig.3.

For the power up shifting from 3rdto 4thgear,a shifting command is released by the ASIS software dependent upon current accelerator pedal and output shaft speed.Once the HPSYS software accepts the shifting command,the shifting element B will be disengaged by decreasing oil pressure;meanwhile shifting element E will be engaged by increasing oil pressure.The torque will be transferred by an overlapping process from clutch B to clutch E.When clutch B is totally disengaged,the turbine speed and engine speed should be able to pull down to synchronous speed by engaging of clutch E.A calibrated torque intervention value will be sent to the engine control module to request an engine torque reduction at the same time.With proper engine torque decreasing and pressure of clutch E,the automatic transmission pulls down turbine speed to synchronous speed and finishes the shifting.

Shifting timing(reaction time and slipping time)must be within a certain range to achieve shift comfort and keep the clutches from wearing.Shift comfort can be judged from oscillations of output shaft.

The following examples show settings that should be avoided,as they are decreasing shifting comfort or increasing clutch wear:

图6 动力升档三四中减少发动机降扭请求Fig.6 Power up shifting from 3rd to 4th gear with decreasing torque intervention

标定工程师根据采集到的数据曲线调整相应的变量并重复这个过程,直到达到理想的换挡表现。

以下是换挡过程控制标定中主要比配的项目。

以上所有功能会在不同温度下进行标定及验证

换挡策略标定(ASIS)

换档过程的标定决定着如何实现平滑的挡位切换,而换档策略决定了应该在什么时机实现挡位切换。换档策略通常由客户(整车厂)所定义,使用运动型的激进换档曲线,舒适型的换档曲线或者是经济型的换档曲线取决于车型的定位基本的换档曲线是由当前油门踏板开度和变速器输出轴转速确定的。例如下图图七

图7 换挡曲线Fig.7 ASIS shift map

According to the observed curves,the calibration engineer adjusts parameters and monitors again the values.This is done iteratively,until the desired performance is achieved.

In the HPSYS calibration,mainly the following functions will be calibrated.

All the functions above are calibrated and verified at different temperatures

Calibration of Adaptive Shifting Strategy(ASIS)

While calibration of the HPSYS deals with how the change from one gear to the next is performed smoothly,the shifting strategy decides in general when the shifting process from one gear to the next is performed.In general the target for this is requested by the customer,who for example prefers a sportier,a more comfortable or an economical behavior.

A basic shift map is a map of shifting proposal which depends on the current accelerator pedal value and the output shaft speed.An example is shown in fig.7.

Fig.7 shows a typical basic shift map.The xaxis presents the output shaft speed/velocity of the vehicle;the y-axis presents the accelerator pedal value from 0to 100%.The solid lines are the up shifting lines;When the driving point(related to x and y)goes cross an up shifting line from left to right or from up to down or the mixture of these two directions,the shift map will release an up shifting command accordingly.For example,in case 1launching from stand still in 1st gear with 38%throttle,once the output shaft speed reaches 500rpm,1-2up shifting line is crossed,and 1-2up shifting will be proposed.

The dashed lines are the down shifting lines.When the driving point goes cross a down shifting line from the right to left or from down to up or the mixture of these two directions,the shift map will release a down shifting command accordingly.For example,in case 2driving with130kmh with 30%of accelerator pedal constantly,once the accelerator pedal is pressed up to 93%,a 6-5down shifting will be proposed.

The shift map is of significant importance for the ASIS calibration and therefore the comfort and drivability.This basic ASIS shift map is used for general driving conditions.Nevertheless,if certain special driving situations are detected,gear proposals from the shift map will be limited to release,earlier released etc.To do this,the calibration engineer calibrates special functions for improved dynamic drivability,some examples are the follow-

图七中展示了基本的换挡曲线,二维坐标的X轴为变速器输出轴转速(可换算为车速);Y轴为加速踏板油门开度,范围为0至100%。实线为升档曲线;当由车速与油门开度共同决定的工况点从左到右或自上到下或以以上两种方向的组合穿过升档曲线,换挡曲线将相应地释放升档指令。例如工况一中,从静止一档以38%油门开度起步,一旦变速器输出轴转速达到500转每分钟,一二升档线被从左到右穿过,一二升档的指令即被触发。

虚线为降档线。当工况点自右到左或自下到上或以以上两种方向的组合穿过降档曲线。换挡曲线将相应的释放降档指令。例如工况二中六档30%加速踏板油门开度稳定在时速130公里驾驶,一旦加速踏板被踩到大于93%,则六五动力降档将被触发。

换挡曲线是换挡策略控制中最重要的标定内容,其决定了驾驶性及舒适性。基本的换挡曲线用于通用的驾驶工况。但同时,如果一些特殊的驾驶工况被软件所识别,来自于换挡曲线的换挡请求将被限制或推迟释放。通过这些特殊的功能标定可以优化动态驾驶性,以下是一些特殊工况的举例。

Some other special driving situations are summarized in Fig.8.保证传动系的稳定性。.

其他一些特殊的驾驶工况入下图。

图8 特殊驾驶工况Fig.8 Special driving situations

环境条件

为了使车辆在任何工况以及环境条件下达到良好的驾驶性,匹配标定的工作也需要在高寒,高温以及高原环境下完成。

高寒测试:由于变速器的控制是由液压系统实现,所以在低温环境中变速箱油的粘度与常温下有所不同,因此对换挡过程有较大的影响。在低温状况下为了达到同样的驾驶表现,冬季需要在高寒地区进行冬季标定。同时一些换挡策略标定如ESP换挡干涉,暖机模式也需要在冬季测试中标定并验证。

在高温环境中,变速器机油有可能会被加热到超过100摄氏度而且发动机表现也会不同。在夏季测试中,工程师将调整相关的变量以应对这些特殊的变化。

在高原驾驶中,由于参与燃烧的氧气稀薄,发动机输出的扭矩和功率会相对减少。变速器控制需要做出相应的调整来应对较低的气压对驾驶性带来的影响。

总结

自动变速器标定需要工程师拥有全面的动力总成,机械,液压以及电力电子的知识。由于应用匹配的过程需要经历冬季测试,夏季测试以及高原测试,所以完成整个项目需要较长的开发周期。在这段时间中标定工程师需要支持变速箱装车启动,标定每种工况的换挡过程,为达到最适合的驾驶性而标定换挡策略,进行极端环境测试。

标定的最终的目标是非常清楚的:为终端客户提供良好的换挡表现与驾驶性。

Environmental Conditions

It has to be made sure that the system performs well in any kind of driving condition and in any kind of environmental conditions,such as cold climate,hot climate and driving at high attitudes.Therefore,the calibration work needs to include ride work in these conditions as well.

Cold climate trip:The transmission control is realized by hydraulic system.At cold temperature,the viscosity of the hydraulic oil changes and therefore impacts the shifting process strongly.To achieve good driving performance in a low temperature environment,winter tests and calibration work are carried out in cold places during winter.Some special ASIS functions like ESP shift inhibition,warm up model will be also calibrated and verified during this winter test.

In a hot climate,transmissions will be heated up over 100°C and the engine performances will be different as well.During summer test,the calibration engineer adjusts the control parameters to account for these changes.

During driving at high attitude the output torque and power will be less.Transmission control in high attitude places must be adapted against less engine performances in lower ambient pressure.

Summary and conclusion

Automatic transmission calibration requires knowledge about power train,mechanics,hydraulics and electric/electronic.As the calibration phase requires also driving in cold &hot climate,and at high altitude,a long term development is required for calibration projects.During that time calibration engineer supports the PIO (put in operation),calibrates shifting processes for every different shifting situation,calibrates shifting strategies to get best drivability,and goes to extreme environments tests.The target is clear:to provide the best shifting behavior and drivability to the end customer.