海洋混凝土结构

T.O.Olsen

(Dr.Techn.Olav Olsen公司,挪威)

1 Introduction

Most of the 50 offshore concrete structures are situated in the North Sea,but also in Asia,Australia and North America.

Offshore concrete structures are durable and behave well,if properly built and properly designed.Many platforms have passed their intended design lives,many have got their functional duties enlarged,and many have shown a remarkable strength towards abnormal events.The first five references give a relatively general description of these structures[1-5].

T.O.Olsen,S.Helland,J.Moksnes“Offshore Concrete Structures for tough Environments”[3]was presented at the fib(fib - fé dé ration internationale du bé ton)Symposium in London,and subsequently the fib state-of-art report,bulletin 50 “Concrete structures for oil and gas fields in hostile marine environments”,FIB[1].The reason the report was written is the very good experiences with offshore concrete structures subjected to severe loading.In addition the report presents an overview of these structures.

Structural design is an important part of offshore concrete projects,and is performed stepwise in time with increasing accuracy and increasing extent.When the structure is built,a comprehensive detail design including reinforcement drawings and bar lists will be available.Detail design and construction are typically performed simultaneously,but of course the design is ahead of construction.Nevertheless,this procedure saves time compared to the case that the entire detail design had to be completed prior to commencement of construction.

For the quality of the structure,the importance of the early design phases is significant.This is when the competitiveness is established,and also the robustness of the structure to meet changes at later stages.

Offshore structures are subjected to very severe loadings.The structures will during stages float.Redundancies are therefore expensive,and the meaning of robustness needs to be clearly understood.

The two latest completed offshore concrete projects are the two Sakhalin II platforms(installed 2005)and the Adriatic LNG Terminal(installed 2008).Different structures with different specifications,all of them will hopefully do an excellent job fulfilling the needs of their owners and the society.

Plans for further oil and gas exploitation in ever increasing harsh environments have accelerated the focus and interest for the efficiency of offshore concrete structures.

Right now a construction project is under way,the Sakhalin I platform being built in Russia.The dry dock at the construction site is in Nahodka,south of Vladivostok,this dry dock was also used for the construction of the two Sakhalin II platforms.

The experiences gained will be applied in other applications than for oil and gas related structures,such as foundations for offshore wind mills,terminals,tunnels in water,land extensions,and as proposed by Allan Sharp,as vertical access shafts to ultra long subsea tunnels.

After demonstrating the offshore concrete structures,the application for ultra long subsea tunnels will be demonstrated in this paper.

2 History and Background

Since the Ekofisk Tank was installed in 1973,49 other major offshore concrete structures have been built,or are being built.FIB[1]provides a list of these structures.

Fig.1 shows the tow of Beryl A in 1975,from its construction in sheltered Norwegian fjords on its way to the harsh environment of the North Sea,Fig.2.

Fig.1 and Fig.2 illustrate some of the design criteria for offshore structures,and at the same time they indicate why concrete may be the best choice of construction material.

Fig.1 Beryl A under tow to installation site,in 1975图1 将Beryl A拖运到安装现场,1975年

Fig.2 The environment of the sea图2 海洋环境

Fig.2 shows that it is not possible to build structures offshore.But they must be installed,and may have to be completed with respect to the foundation(piling,grouting)and topside installation.The degree of inshore completion influences the cost and safety of the field development.

The typical offshore concrete structure is of the caisson type,often termed Concrete Gravity Structure,CGS.The caisson provides buoyancy in the construction and towing phases,and a foundation structure in the operation phase.In addition the caisson may also provide storage volume for oil.This multiple usage of the structure may prove very economic,particularly when oil storage is required.

Steel structures may of course also be built to provide buoyancy and storage,but buoyancy at large water depth is demanding and expensive for steel structures.

The nature of hydrodynamic load is such that it is greatly reduced with increasing water depth.Therefore a buoyancy structure deeply submerged may be far more efficient than one just below the sea level.

Most countries of the world have a construction industry for concrete structures;few have for large steel structures.This is a competitive edge for offshore concrete structures.

The inshore construction of concrete offshore structures provides good conditions for quality construction.The construction site of Norwegian Contractors at Hinna,near Stavanger in Norway,was likely the best and most professional and effective construction site in the world,including onshore sites.The design and construction of 15 Condeeps created a large amount of expertise.Fig.3 illustrates the Condeeps built by the Norwegian Contractors.Dr.techn.Olav Olsen designed them,sometimes in collaboration with others.Fig.4 illustrates how the structures are built,coupled with the topside,towed and installed.

Fig.3 The condeeps图3 深水混凝土结构

Fig.4 Construction图4 施工

The construction commences in a drydock and continues at a deepwater site.The topside is built simultaneously with the concrete substructure;the two parts are mated inshore,if the water depth permits.Finally the whole structure is towed to field,ballasted and installed.

Probably the most impressive condeep is the Troll A platform,shown in Fig.5.The platform is not used for oil storage,and was complete with topside when towed out and installed at 303m water depth in the North Sea in 1995.

Fig.5 The Troll A Condeep,with other structures图5 深水混凝土结构Troll A与其它结构物

Parts of the Troll A structure were subjected to a water pressure of 3.5 MPa during construction,and carried the topside weight of 22,000 t 150 m above the sea level during tow-out(Fig.6).

Fig.6 The Troll A Condeep during tow-out图6 深水混凝土结构Troll A拖运过程中

Katie Meluha participated in the 10 year anniversary of the Troll A successful gas delivery to Europe(Fig.7).Note the gas risers(pipes)in the background,penetrating watertight the concrete structure at 303m,a well known technology in the oil and gas,as well as the hydroelectric industries.

Fig.7 Katie Meluha sings 303m below sealevel图7 Katie Melaha在海平面303m以下唱歌

It is obvious that the deadweight of the platform is of importance.The significance of weight and strength is illustrated in several of the references:B.Jakobsen,◦A.Eikenes,T.O.Olsen[6]and J.Moksnes[7].

Equally important as structural efficiency is the performance of the material over time.It is evident from Fig.2 that the environmental impact in terms of spray and seawaterisextreme. Fortunately high strength/high performance concrete is durable,and has proven so after many years in the North Sea and elsewhere.

A major project in Norway named Bestandige Betongkonstruksjoner(Durable Concrete Structures)documented the very good quality of the offshore concrete structures of the North Sea.The project was primarily aimed at bridges,in particular those in the marine environment.For comparison and correlation a number of platforms were included,some of them up to 25 years in service in one of the harshest areas of the world,in fact longer than their intended design lives.

Inspections and measurements document that the concrete in the offshore platforms is not flawless.But when the intended quality of concrete and cover to reinforcement are achieved,the concrete is very durable and serves its function very well.Based on measurements of chlorides in the cover zone,anticipated life of such concrete is more than 200 years[8-10].

There are virtually no costs associated with the maintenance of offshore concrete structures[5].

3 Other Applications

Fig.8 shows the construction of the Adriatic LNG Terminal,in Spain.When complete it was towed and installed outside Venice,Fig.9 shows the first shipload arriving in August 2009.

Fig.8 The Adriatic LNG Terminal being built in Spain图8 在建中的西班牙Adriatic液化天然气终端

Fig.9 The Adriatic LNG Terminal,first ship berthing August 10,2009图9 Adriatic液化天然气终端第一个船台,2009年8月10日

One quarter of the undiscovered reserves of hydrocarbons are expected to be in ice infested waters,predominantly in the arctic,but also in the Caspian Sea and other cold waters.

Concrete is a very well suited material to build rough structures for the arctic.Several structures are built.

Fig.10 shows these platforms when constructed in Nahodka south of Vladivostok,Russia,and Fig.11 shows one of them after installation,prior to deck installation.

Fig.10 Sakhalin II platforms at construction site in Nahodka图10 Sakhalin二号平台在Nahodka海域施工现场

Fig.11 Sakhalin II图11 Sakhalin二号

Fig.12 shows a proposal for a closed structure for fish farming.

Fig.12 Concept for closed fish farming图12 封闭的养鱼场

The offshore winds and waves may be utilized for renewable energy production.Particularly the windmills are being developed.Fig.13 shows a concept based on the same principles as the offshore concrete platforms,with as much as possible completed inshore,tow to field,and water ballasted for complete installation.

Fig.13 Concept for offshore wind mill图13 离岸风车

Proper strait and lake crossings is an issue of increasing attention,as the need for efficient transportation in the world is increasing at the same time as environmental concern is increasing[11-12].

If ferries are not desired,several possibilities are available,as shown in Fig.14.

Fig.14 Strait crossings图14 海峡两岸往来

Fig.15 shows how a submerged floating tunnel(SFT)may approach a village for quiet and clean transport.

Fig.15 Submerged Floating Tunnel(SFT)图15 海底悬浮隧道(SFT)

To protect two large gas pipes a shore protection tunnel was built on the west coast of Norway,Fig.16.

Fig.16 Shore protection tunnel图16 海岸保护隧道

In general,the future will see an increased use of the marine environment for man-made activities,and structures will be needed.We will benefit from the experience from the oil and gas projects,to achieve robust and safe structures for other applications of concrete in the marine environment.

4 Ultra Long Subsea Tunnels

There is a limitation on how long subsea tunnels may be built.

By suggesting intermediate access shafts,Sharp and Mainwaring[13]demonstrate that the length limitation can be avoided.This is of great significance for the transport of the world.

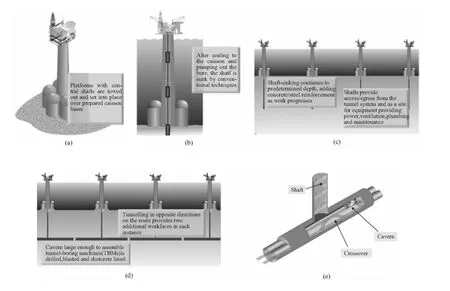

The concept,as shown in Fig.17,is simple.It combines the well known technologies of tunneling and offshore structures.The interface between the two(the tunnel and the access shaft),is also known from the industry,both the oil and gas industry and the hydroe-lectric energy industry.

Fig.17 Concept for ultra long subsea tunnels图17 超长海底隧道

Looking at the intermediate access shafts,they are very similar to the Draugen Conndeep platform,installed in the North Sea in 1993.This platform is shown in Fig.3 and Fig.4(construction phases),and in Fig.18.

Fig.19 illustrates the installation of the access between the shaft and the tunnel.The illustration is schematic;in a real case the actual soil conditions etc.must of course be considered.

Fig.18 The Draugen Condeep platform,installed in 1993图18 深水混凝土结构Draugen平台,安装于1993年

Fig.19 The construction process图19 施工过程

The access shafts have functions both in the construction phase and in the operational phase.Fig.20 illustrates the preparation for the operational phase,with two internal access shafts and double sealing for redundant safety.

Fig.20 Internal access shafts and barriers图20 内部通道和格栅

5 Conclusions

It is demonstrated that marine concrete structures fulfill the functions they are given.Particularly based on the large amount of experience gained from the oil and gas industry,these structures see an increased application also within other industries.

One important such application is subsea tunnels.By providing intermediate access shafts the length limitation is avoided,and new tunnel crossings are made feasible.

The technology required is well known from other industries.

[1]FIB.Concrete Structures for Oil and Gas Fields in Hostile Marine Environments[M].USA:FIB Bulletin 50,2009.

[2]Olsen T O.Offshore Concrete Structures[C].Rotorua,New Zealand:The New Zealand Concrete Industry Conference 09,2009.

[3]Olsen T O,Helland S,Moksnes J.Offshore Concrete Structures for Tough Environments[C]//Concrete:21st Century Superhero.London:FIB,2009.

[4]Olsen T O,Haugerud S A.Conceptual Design of Offshore Concrete Structures[C].Tokyo:8th Symposium on High Strength Concrete High Performance Concrete,2008.

[5]Sandvik K,Eie R,Advocaat J D,Godejord A,Hæreid K O,Høyland K,Olsen T O.Offshore Structures:A New Challenge[C].Acapulco:XIV National Conference on Structural Engineering,2005.

[6]Jakobsen B,Eikenes A。,Olsen T O.Recent development and potentials for high-strength offshore concrete platforms,NB,SINTEF,FIP,NIF[C].Stavanger:Utilization of High Strength Concrete,1987.

[7]Moksnes J.20 Years of R & D into HPC-Has It Been a Profitable Investment[C]//Leipzig:6th International Symposium on Utilization of High Strength/High Performance Concrete,2002.

[8]Bech S,Carlsen J E.Durability of Concrete Offshore Structures[C].Sandefjord,Norway:Proceedings:5th International Symposium on Utilisation of High Strength/High Performance Concrete,1999.

[9]Fjeld S,Hall,Hoff G,et al.The North Sea Concrete Platforms-20 Years of Experience[M].Houston:OTC,1994.

[10]Fjeld S,Røland B.In Service Experience with Eleven Offshore Concrete Structures[M].Houston:OTC,1982.

[11]Muttoni A,Haugerud S A,Olsen T O.The New AlpTransit Railway Across the Alps[C]//A Crossing Proposal for the Lake Lugano.Norway:Fourth Symposium on Strait Crossings,2001.

[12]Haugerud S A,Olsen T O,Muttoni A.The Lake Lugano Crossing-Technical Solutions[C].Norway:Fourth Symposium on Strait Crossings,2001.

[13]Sharp A,Mainwaring G.Method for Accelerated Construction of Ultra-long Subsea Tunnels(Japan-Korea/China-Taiwan) [C].Seoul,Korea:The 3rd CECAR,Civil Engineering in the Asian Region,2004.