Low Viscosity Automatic Transmission Fluids with Enhanced Friction Durability

Kenji Yatsunami Samuel H.Tersigni TANG Hong-zhi Lee D.Saathoff Christopher S.Cleveland2 Mark Jones

Abstract:This study focused on the development of a new low viscosity automatic transmission fluid (ATF) with enhanced friction durability to meet the needs of new step type automatic transmissions. Recent high fuel prices encourage increased efficiency in the driveline, including the transmission. Reduction in fluid viscosity and wider use of slip control in torque converter clutches are two ways to practically improve fuel efficiency. Increased torque and more shifting is seen with a variety of new transmission hardware platforms, such as wet starting clutches, dual clutches and seven- or eight-speed ATs.This suggests the need for enhanced levels of friction durability from the ATF.The new challenge from this hardware for the ATF formulator lies in the need to simultaneously meet the wear, friction durability and torque capacity requirements at low viscosity in a cost-effective manner.

This report introduced a new low viscosity fluid that represents a different commercial ATF formulation style.The new chemistry employs a low viscosity for increased fuel economy, while easily doubling the friction durability of current conventional ATFs and offering higher torque and better EP.

Key words:six-speed ATF; low viscosity; friction durability

中图分类号:TE626.38 文献标识码:A

0 Introduction

Automobile manufacturers obtain some corporate average vehicle fuel economy (CAFE) benefits by employing lower viscosity ATFs. Previous generations of ATFs had a 100 ℃ kinematic viscosity (Kv100 ℃) in the range of 7.0 to 8.0 cSt; the new generation of ATFs has a fresh oil Kv100 ℃ between 5.4 and 6.4 cSt[1]. Accordingly, low temperature (-40 ℃) and start-up viscosities (0 to 25 ℃) are also lower with the new ATFs. Lower viscosity (thinner) fluids reduce transmission churning (or spin) energy losses in the transmission, the extent to which depends on the test protocol, hardware platform and specifically the temperature range used to evaluate fuel economy benefits. In most testing, the magnitude of the fuel economy benefit is roughly equivalent to the precision of the test being used to measure it, so careful test operation, statistical design of experiments and numerical analysis of the results are necessary[2].

Lower viscosity ATFs can be a challenge for the transmission hardware, especially with respect to pump losses and gear and bearing durability. Thinner fluids leak easier through pumps and seals. Likewise, a lower viscosity fluid usually means thinner protective films for clutches, bearings and gears, unless fluid design is specifically altered to compensate for the drop in kinematic viscosity[3]. Higher quality base oils may be needed for the lower viscosity fluids to ensure their robustness with respect to volatility, which affects oil volume within the transmission during operating life.

Meanwhile, in addition to the ATF changes, most automakers have moved to new hardware, including additional gears (i.e., six-, seven- and eight-speeds), start-up devices and lighter transmissions, to further enhance fuel economy in their automatic transmissions (ATs). The additional shifting energy can affect the durability of the transmission, particularly in the clutch packs (friction plates) and the fluid. Along with more clutch applications, the new AT hardware designs typically offer smaller sumps that allow less fluid volume and less time in the sump for the ATF to release air and reduce foam. The combination of new hardware and less ATF requires an increased level of additive performance. Many ATFs on the Asian market contain additives designed well before the release of the new six-speed transmission hardware.

Since many of these new transmission systems involve high-energy requirements, additive technology must be developed to meet the increasing energy requirements of these advanced systems.Additive packages for automatic transmission fluids are often formulated with several components, including, extreme pressure agents, anti-wear agents, anti-oxidants, corrosion inhibitors, metal deactivators, rust inhibitors, friction modifiers, dispersants, detergents, anti-foam agents and viscosity index improvers. However, not all additives interact predictably or favorably with one another. The friction properties are particularly important in clutches that need more friction to transfer torque but less friction in gears, bearings and seals.

Another important performance requirement for an automatic transmission fluid is its ability to prevent noise, vibration, and harshness of shift (NVH) from occurring in a transmission.During operation, a vehicle experiences a combination of torsional and axial vibrations that can affect vehicle performance and occupant comfort when the magnitude of the vibrations exceeds a certain threshold.These vibrations and their effects are major contributors to NVH. Potential sources of NVH include engine firing pulses, valve motion, engine vibrations and tire-road interactions - any of which can induce self-excitation or forced vibrations in the vehicle.Vibrations from these sources are transferred through engine mounts, transmission bearings, drive shaft bearings, tires (via steering) and axle suspensions to the passenger compartment by way of the vehicle frame, steering wheel or brake pedal.

For reasons discussed above, the optimum performance additive and fluid design for the new step-AT hardware may require a significant increase over existing commercial ATFs in four performance areas: 1) friction durability and higher torque capacity in the shifting clutches and the torque converter; 2) anti-foam and anti-aeration durability; 3) anti-wear and extreme pressure capacity at lower viscosity; and 4) anti-rust and anti-corrosion properties.There are significant oxidation and viscometric performance benefits that come to ATFs by employing higher quality base oils and lower finished ATF viscosities, so less advancement of additive technology may be needed in these two performance areas.EP, friction durability and corrosion performance all require ATF additives that migrate to (and adsorb onto) either a steel or paper surface.Usually a balance of surface-active components is required to achieve acceptable overall ATF performance; this need for balance usually limits significant performance breakthroughs[4].

This paper reports investigations into a new six-speed ATF additive design using performance tests common to Asian automakers (original equipment manufacturers, OEMs). Each OEM has a set of ATF qualification tests which usually have additive appetites different from those of the tests of other OEMs. Yet there is enough regional similarity of test rigs and procedures (JASO, CEC, ASTM) to allow definition of a generic Asian six-speed ATF profile, which would be different both in test performance and additive design from either of the corresponding optimum European or North American six-speed ATFs. The paper introduces a new Asian step-ATF additive and offers supporting data from friction durability, torque capacity, EP, wear and rust testing, in

support of corresponding performance claims.

1 New Six-Speed ATF

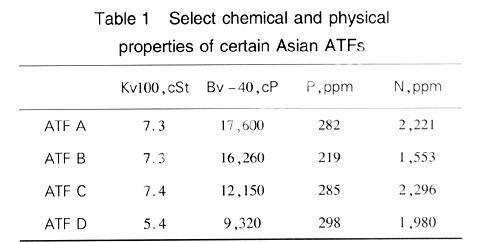

A new six-speed Asian additive system has been developed by this laboratory with critical performance features highlighted in this section. The finished ATF performance is shown below with the fluid code ATF-6. ATF-6 is formulated using conventional mineral oil only, with a 100 ℃ kinematic viscosity of 5.6 cSt and a -40 ℃ Brookfield viscosity of under 10,000 cP. Table 1 contains a limited viscometric and elemental profile of select Asian factory-fill ATFs, coded as ATF-A to ATF-D.

1.1 EP and Wear Performance

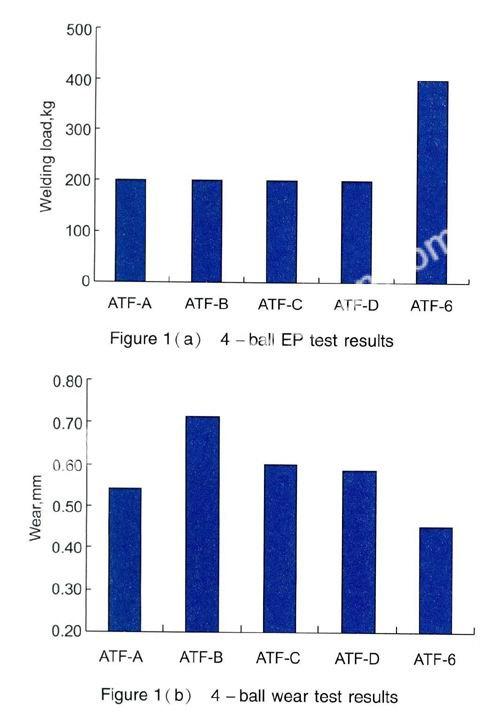

Figures 1(a, b) shows results from the 4-ball EP and 4-ball wear tests, which are standard industry procedures for the region[5-6]. In the case of EP, the benefit to ATF-6 over the comparison fluids is significant beyond a 95% confidence level. The benefit of ATF-6 in the wear test is measurable but less significant.Most importantly, in EP and wear, ATF-6 at a 5.6 cSt Kv100 ℃ is as good as, or better than, other commercial fluids formulated at 7.2 cSt.

1.2 Torque Capacity Level and Durability

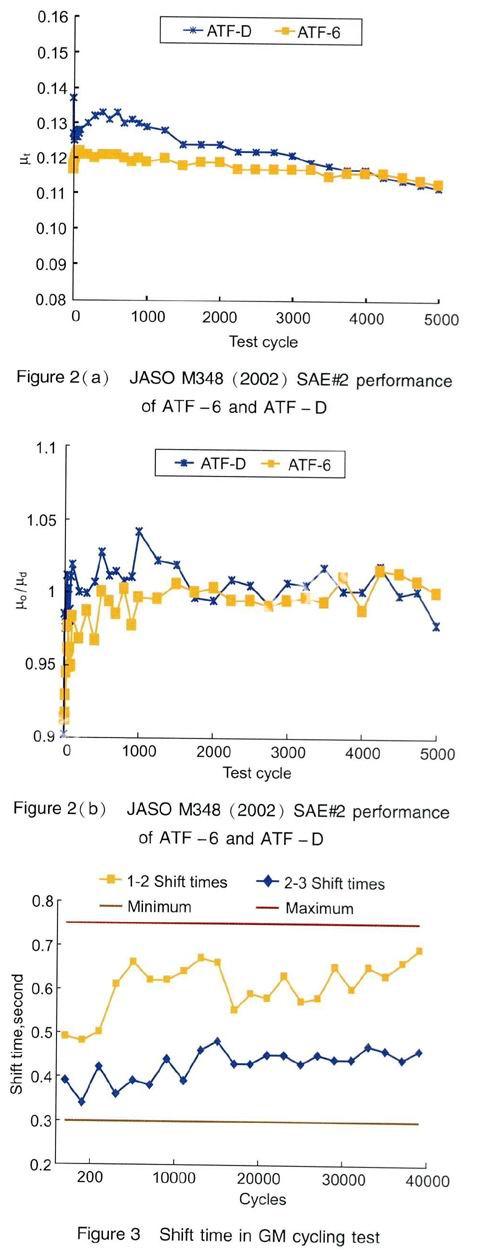

The JASO M348 (2002) SAE#2 procedure using the NW-461E friction material evaluates torque capacity (μt) and shifting clutch friction durability over 5,000 cycles (43 hours), as part of the current JASO M315-2002 ATF specification.Figures 2(a, b) offer results on the torque capacity μt and shifting clutch (μ0/μD) durability of ATF-6 and ATF-D. While the ATF-D system suffers a continuing drop in torque capacity with test time (15% drop at 5,000 cycles), ATF-6 offers an equivalent level of torque but more stable torque capacity. (Minimum performance over the 5,000 test cycles is most relevant.)

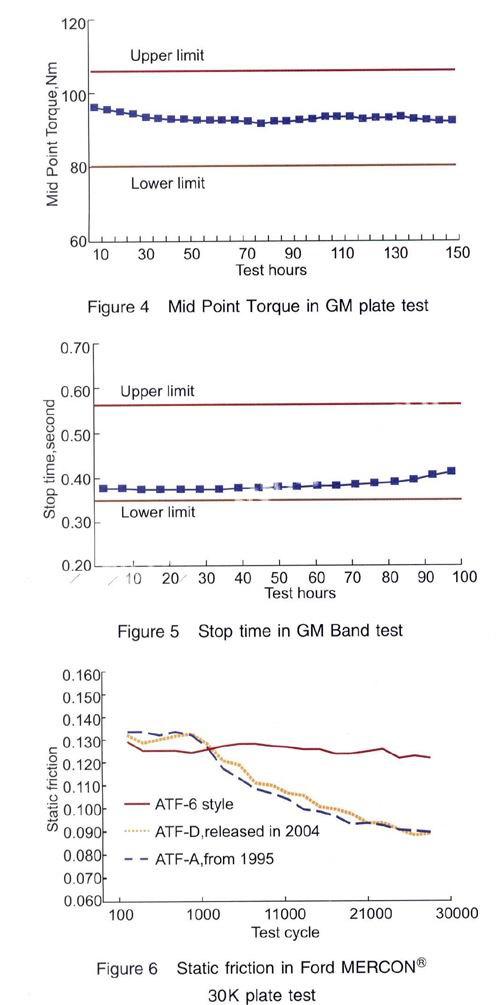

The ATF-6 style fluid also provides excellent durability in friction tests required in the USA by Ford and General Motors (DEXRONk). The ATF-6 style fluid was evaluated in the GM cycling test, GM plate friction test, GM band test and the Ford 30K fiction test; the results demonstrate excellent friction stability in these tests. Test results are shown in Figures 3, 4, 5 and 6.

1.3 Low Speed Friction Durability

The JASO M349-2001 Low Velocity Friction Apparatus (LVFA) test carefully measures friction in the low speed (0-300 rpm) regime, most relevant to shift start-up devices.The Coefficient of Friction (COF) level μ is measured as a function of relative speed (rpm, v), time (test hours), temperature (ATF sump) and plate friction measurement method (sweep or discrete-step mode).

The number of test hours required for the slope of either the 40 ℃ or 80 ℃ μ-v curve to become negative, at the 50 rpm(0.3 m/s) and 150 rpm (0.9 m/s) speed point, is the standard JASO definition of fluid failure (friction durability lifetime).Note that JASO friction durability is defined in terms only of μ-v slope, not friction level, so fluids with steadily dropping low speed friction levels may falsely appear to be durable.(Significant reductions in torque capacity may challenge the safety factors of the transmission calibration.)Since field vehicle shudder investigations frequently find improper friction levels and/or slope in their “root cause” analysis, a more useful measure of friction system robustness is to inspect the entire μ-v curve as a function of test time and sump temperature.

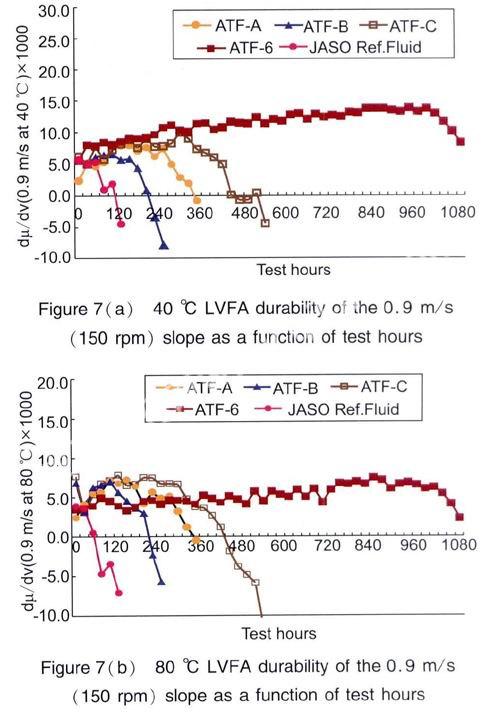

Figures 7(a,b) reports friction durability lifetimes as defined by the JASO M349 method for several ATFs of Table 1.Figure 7(a) shows the 40 ℃, 150 rpm (0.9 m/s) slope durability.Figure 7(b) shows data from 80 ℃ testing. Among the fluids listed in Figures 7(a,b), ATF-C is known by this laboratory to have the longest LVFA durability of any ATF in Table 1, at approximately 450 hours. As shown in Figures 7(a,b), ATF-6 easily reaches the 1000-hour durability mark, representing a two-fold increase over ATF-C, which is a 12-fold improvement over the industry reference fluid Toyota T-III.

1.4 Low Speed Friction Robustness

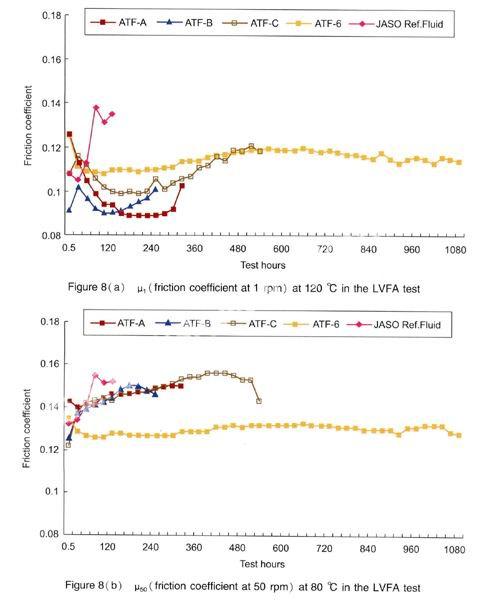

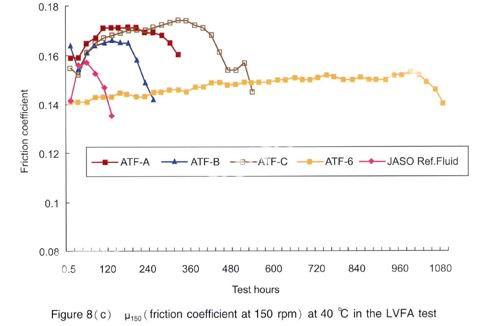

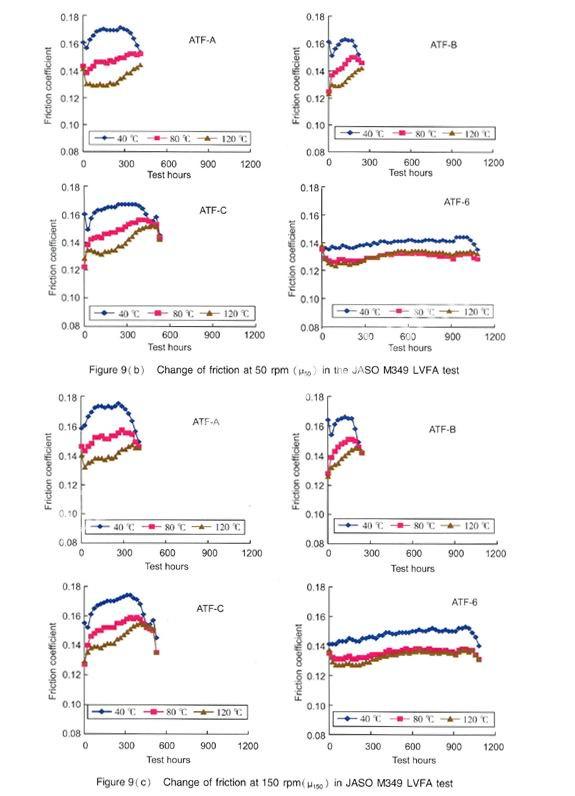

ATF-6 offers a friction coefficient that is uniquely stable with respect to temperature in the 40 ℃ to 120 ℃ range, which represents the range of sump temperatures experienced by the ATF in a variety of applications. Each of the Figures 8(a-c) contains the reference set of fluids, with friction profiles representing each combination of temperature (40 ℃, 80 ℃ and 120 ℃) and sliding speed (1, 50 and 150 rpm). The extreme condition of 1 rpm and 120 ℃ represents the boundary friction regime; ATF-6 is the most stable fluid under this condition.The other extreme condition of 150 rpm and 40 ℃ is closest to the thin film (or potentially the hydrodynamic) friction regime; again ATF-6 is the most stable fluid under this condition for over 1,000 test hours.

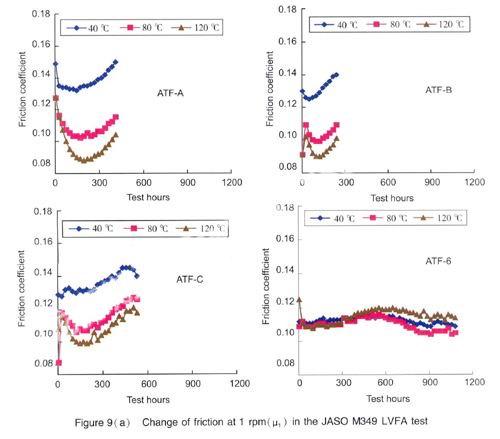

Figures 9(a-c) exhibit LVFA (JASO M349) friction at 40 ℃, 80 ℃ and 120 ℃ and sliding speeds of 1, 50 and 150 rpm.Commercial fluids ATF-A, -B and -C show higher friction coefficient at 40 ℃ but lower friction at 120 ℃. Some of these μ1 differences in friction coefficient with temperature approach a level of 0.040 or 40% with ATF-A. In the case of ATF-6, the μ1 difference is less than 0.010 or 5% across the temperature range.Similar trends are also seen in friction at 50 rpm (μ50) and 150 rpm(μ150). The friction coefficient of ATF-6 is effectively independent of temperature and this robustness will allow new transmissions to operate more smoothly with less complex calibrations.

Torque capacity of the fluid can be defined by the lowest friction level obtained during the LVFA test. Normally, the lowest friction can be seen in μ1 (friction coefficient at 1 rpm) at 120 ℃. As shown in Figure 8(a) and Figures 9(a-c), ATF-6 provides 9%~18% higher torque capacity as compared to the other commercial fluids. Similar phenomena were seen in the Ford 30,000 friction test, as shown in Figure 6.

2 Conclusions

In summary, this paper reports development of a mineral oil based, Asian focused ATF that offers over 1,000 hours of LVFA friction durability, twice the performance of any current commercial Asian ATF, with comparable torque capacity.Even at a low finished fluid viscosity, the additive system delivers anti-wear and EP performance well above other higher viscosity fluids in the region.This suggests that good EP performance can be achieved with friction-durable fluids.The fluid provides excellent friction properties, including durability and stability with respect to temperature.The fluid represents a qualitatively new level of durability which may enable new types of transmission hardware or calibrations.

Acknowledgements

The authors thank coworkers at Afton′s automatic transmission fluid research labs in Japan (Takuo Takano), England and the United States (Dave Strait, Kevin Strait, Dave Harer) for their help.

References:

[1] GMN 10060, General Motors DEXRONk-VI ATF Service-Fill Specification[S].

[2] Box G,Hunter W,Hunter J.Statistics for Experimenters[M].New York:Wiley & Sons, 1975.

[3] Harvey P Nixon, Harry Zantopulos. Observations of the Impact of Lubricant Additives on the Fatigue Life Performance of Tapered Roller Bearings[C]. SAE Paper 952124.

[4] A G Papay. Automatic Transmission Fluids DEXRONk II and Beyond[A]. Proceedings of 43rd STLE Annual Meeting[C]. Cleveland Ohio, USA: 1988.

[5] ASTM D2783, Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids[S],1995.

[6] ASTM D4172, Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid[S],1994.

收稿日期:2008-08-19。

作者简介:Kenji Yatsunami, male, graduated in chemical engineering of Tokyo Institute of Technology in 1968.He started his carrier of lubricant additive formulation development at Mitsubishi Monsanto Chemical and is responsible to ATF formulation development at Afton Chemical Tsukuba Laboratory in Japan. He is the author of several technical papers and Patents.