A Dual Closed-Loop Digital Twin Construction Method for Optimizing the Copper Disc Casting Process

Zhaohui Jiang ,,, Chuan Xu , Jinshi Liu , Weichao Luo ,,,Zhiwen Chen ,,, and Weihua Gui ,,

Abstract—The copper disc casting machine is core equipment for producing copper anode plates in the copper metallurgy industry.The copper disc casting machine casting package motion curve (CPMC) is significant for precise casting and efficient production.However, the lack of exact casting modeling and real-time simulation information severely restricts dynamic CPMC optimization.To this end, a liquid copper droplet model describes the casting package copper flow pattern in the casting process.Furthermore, a CPMC optimization model is proposed for the first time.On top of this, a digital twin dual closed-loop self-optimization application framework (DT-DCS) is constructed for optimizing the copper disc casting process to achieve self-optimization of the CPMC and closed-loop feedback of manufacturing information during the casting process.Finally, a case study is carried out based on the proposed methods in the industrial field.

I.INTRODUCTION

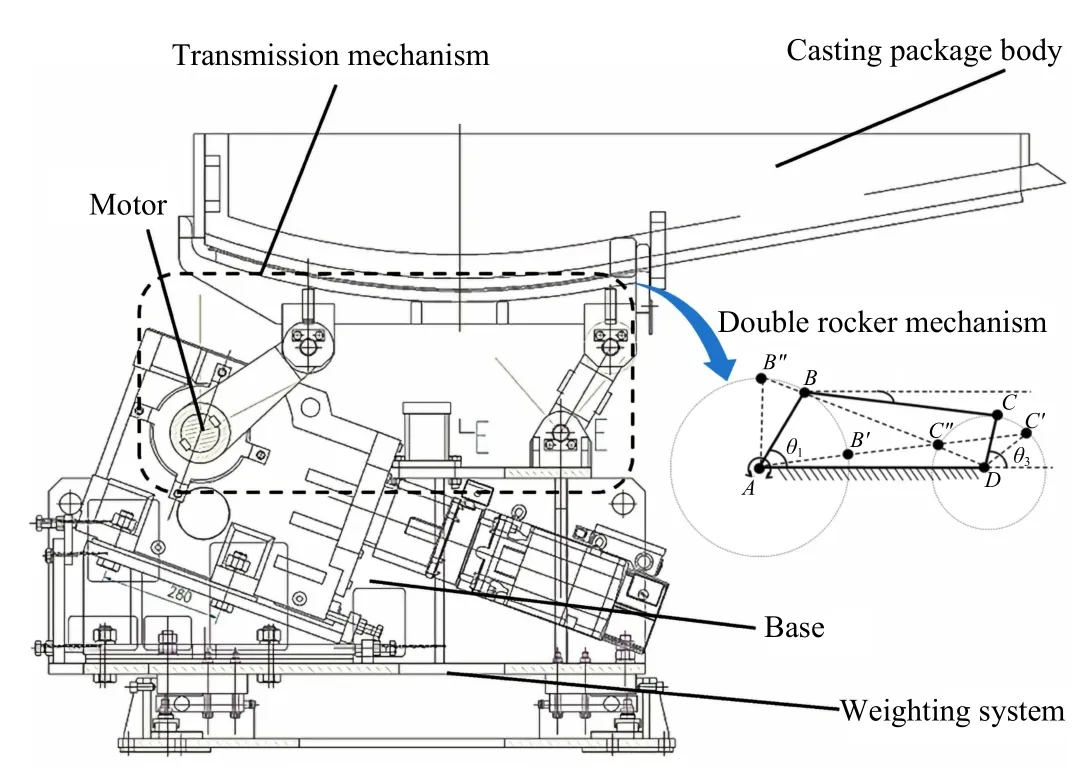

THE copper disc casting machine is essential for holding high-temperature liquid copper, casting high-quality copper anode plates, and providing regular anode materials for subsequent electrolytic copper processes in pyrometallurgical methods [1].It is also a piece of large-scale production equipment that integrates mechanism, electrical, hydraulic, and automatic control with other technologies [2].The structure of a copper disc casting machine is shown in Fig.1.It is primarily composed of an anode furnace, chute, tundish, casting package, disc casting mold, three-stage cooling device, mechanism take-up arm, cooling water tank, and forklift [3].The casting package receives liquid copper from the tundish and pours it quantitatively into the disc mother mold.After being cooled by a multistage cooling system, copper anode plates are formed.

The casting package motion curve (CPMC) is a crucial issue for the quantitative casting of copper anode plates, playing a decisive role in the quality, efficiency and safety of casting products.1) The casting process is complex, multi-variable,and requires multistage coupling, making it tricky to model accurately and construct a CPMC optimization model.2) Lacking real-time simulation, the CPMC cannot be optimized dynamically with changes in on-site working conditions,which makes it difficult to achieve high-quality production.Therefore, to quantitatively cast conventional burr-free copper anode plates in less time and meet production safety and high yield requirements, the CPMC of the casting system must be capable of self-renewal and optimization, intelligent perception, accurate simulation, and independent decision-making.

Currently, most copper smelters modify the casting package CPMC during the casting process based on human experience.However, this approach is insufficient for meeting both quality and efficiency requirements and cannot be dynamically optimized to accommodate changes in product requirements or process parameters.A better CPMC can only be obtained by stopping and repeating a test when a problem occurs before putting it into production operation.Consequently, optimal CPMC modeling and dynamic updating are imperative for efficient, high-quality, and large-scale manufacturing in the copper disc casting process.

Existing research on the casting process mainly focuses on three aspects: mechanism modeling, numerical simulation modeling, and control system design.1) Mechanism modeling of the casting process: Heaslip and Schade [4] used hydraulic models to study fluid flow in casting systems, significantly improving reliability and effectiveness.Yanget al.[5] established a comprehensive model coupling fluid flow,heat transfer, solidification, and solute redistribution based on the continuum theory.They realized the prediction of the temperature distribution and the thickness of a solid shell during casting.Honget al.[6] proposed a mixed-integer linear programming model and developed an iterated greedy metaheuristic, and produced reasonable casting time scheduling instructions.Caoet al.[7] proposed a theoretical criterion for the flow mechanisms of small orifice plates (thick-walled orifice plates and nozzles) and large orifice plates (thin-walled orifice plates) based on the orifice diameter ratio.The parameters were correlated, and a semi-empirical model of an orifice coefficient in the stable zone was established.Wuet al.[8]conducted a scale water-model experiment to investigate the trajectories, velocities and size distribution of bubbles in a continuous-casting mold based on a high-speed camera and a laser.They compared the results with independent hydraulic model studies.2) Numerical simulation model: Casting process simulation is one of the critical innovations of the last thirty years in the foundry world [9].Gebelin and Jolly [10]explored a wax injection process using traditional and numerical simulation methods.The results show that a numerical simulation method can better predict product defects in the casting process.Frankeet al.[11] studied the silicon ingot casting process temperature distribution under different conditions and optimized the casting process.Tieu and Kim [12]established a heat transfer model for continuous-casting slab embryos to calculate the slab temperature distribution and solid wall thickness for predicting the optimal casting speed.Hwang and Stoehr [13] applied computational fluid dynamics(CFD) to simulate the flow of molten metal through sprues and runners into the cavity for the first time and provided the information needed to improve casting quality and efficiency.In general, the application of CFD for molten metal fluid in the casting process has dramatically promoted the exploration and understanding of the casting process [14].3) Control system design: Tsuji and Noda [15] established a molten steel casting system based on a hydraulic method, realizing the goal of quantitative molten steel casting.Konget al.[16] proposed a multicycle disturbance suppression control system based on robust stability analysis for the casting process.It realizes liquid level control in the casting process with a disturbance observer and a set of filters with additional time-delay terms.In recent years, many casting process control schemes and systems have been proposed, which made certain contributions to automation upgrades to the casting process [17]-[20].In addition, 3D printing technology has shown great potential in the metal casting process, mainly reflected in the precise manufacturing of molds (including 3D sand printing and printed wax patterns).However, there is no clear application scenario for the copper plate casting industry [21], [22].

Traditional methods have explored some specific problems,which promote the optimization and upgrading of casting manufacturing processes.However, due to complex and changeable casting process production conditions, the lack of accurate CPMC modeling and real-time feedback simulation information makes it difficult to achieve dynamic optimization for CPMC modeling.Individual modeling, simulation, or controller design cannot integrate real-time casting process manufacturing information and does not have the ability for synchronous simulation, dynamic optimization, and decisionmaking.To achieve efficient and high-quality production, a copper anode plate casting system must have real-time simulation information feedback and CPMC adaptive optimization for the whole casting cycle.

In intelligent manufacturing, optimal decision control, complete life cycle condition monitoring and prediction, selflearning, and self-maintenance industrial manufacturing processes have become new development trends [23]-[25].A digital twin is a vital enabling technology for cyber-physical system [26], [27], which provides an effective solution for implementing the above goals.The origin of digital twins is attributed to Grieves [28].They have bright application prospects in health management, meteorology, manufacturing,processing technology, education, cities transportation,energy, and other industries [29].A digital twin reflects the real-time dynamic two-way mapping between a physical entity and a virtual model, covering the enabling technologies under five major categories: physics-based modeling, datadriven modeling, big data cybernetics, infrastructure and platforms, and human-machine interfaces [30], [31].Digital twin technology accurately simulates the production process in a virtual space in real-time, and the analysis results act on the physical system to form a closed-loop control of the manufacturing process [32].A digital twin system can be categorized at workshop and equipment levels in intelligent manufacturing.The workshop level mainly serves production scheduling and fault warning, and the equipment level mainly focuses on manufacturing [33].Tao and Zhang [34] discussed a workshop digital twin system construction mechanism and implementation method.Liuet al.[35] used a system engineering modeling method to build a synchronous simulation system and conducted an exploratory study on its operating mechanism.A digital twin system at the equipment level is the fundamental unit of intelligent manufacturing related to the intelligence level, production efficiency, and product quality of a manufacturing process.Zhang and Zhu [36] proposed a digital twin framework and verified it in an aero-engine fan blade manufacturing process based on a CNC lathe.Luoet al.[37],[38] proposed a hybrid predictive maintenance method based on digital twin (DT), combining DT and a data-driven model to predict CNC lathe tool life and achieved a certain effect.Yeet al.[39] proposed a digital twin framework for the spacecraft weighing frame crack monitoring problem, which improved the equipment health monitoring and management level.

Most existing literature mainly serves production equipment health management and early warning.Few studies address self-optimization based on a digital twin.For the quantitative casting process precasting stage, the control objective is to maximize the casting accuracy, shorten the time, and avoid splashing.It means that we can obtain an optimal CPMC to maintain the optimal casting package motion state at every moment.Nevertheless, lacking accurate modeling of the casting process and information feedback of realtime simulation, the actual production state is usually far from the optimal CPMC.Therefore, with the impetus of the comprehensive development of intelligent manufacturing technology, exploring the application of a digital twin in the casting process is of practical significance for optimizing and improving copper anode plates casting efficiency and quality.

To improve the manufacturing efficiency and quality of copper anode plates, the application of a digital twin in disc casting machines is researched and explored intensively in this paper.A novel digital twin dual closed-loop self-optimization(DT-DCS) application framework for a copper disc casting intelligent manufacturing system is proposed.Furthermore,the vital casting process mechanism models are developed.Finally, a copper anode plates casting process digital twin application case is realized and verified through combination with DT-DCS and the proposed mechanism models.The main contributions of this paper are presented as follows:

1) A liquid copper droplet model is presented to describe the liquid copper flow pattern of the casting package during the casting process.According to the relationship between the copper liquid level and the baffle in the casting package, the copper liquid flow in the casting process is defined as an open-channel hydraulic droplet and orifice outflow model.The model makes it possible to accurately describe the liquid copper outflow state in the casting package and the accumulation rate of liquid copper in the mold in the copper disc casting process.

2) A CPMC objective function is constructed for the first time.The casting process is innovatively discretized into several sub-units, and the objective function set is established for each sub-unit with the casting process indicators as constraints and the maximization of the cast liquid copper quality per unit time as the optimization objective, which provides a critical basis for the solution of the optimal CPMC.Based on the proposed optimization method, the optimal CPMC solution is realized.

3) A novel digital twin dual closed-loop self-optimization application framework for copper disc casting processes is proposed.Horizontal compliance with the base twin architecture paradigm is demonstrated and vertical compliance closely matches the characteristics of the specific application object.A dual closed-loop self-optimization process with five submodules is constructed.The closed-loop self-optimization and dynamic self-optimization of the digital twin model parameters are realized using real-time simulation data in a virtual space and manufacturing information in a physical space to ensure digital twin model reliability.

II.A DIGITAL TWIN DUAL CLOSED-LOOP SELF-OPTIMIZATION FRAMEWORK FOR COPPER DISC CASTING PROCESSES

The CPMC in most copper disc casting machine systems is usually set using human experience, so it is challenging to ensure dynamic optimization for production conditions, which leads to inefficient production, and product quality cannot meet demand.Digital twin technology maps an existing production system to a virtual model space.With its perfect logic operation mechanism and low trial and error cost, a virtual model can significantly enhance self-calibration and iterative optimization capabilities through real-time information feedback from the virtual space to the existing manufacturing system.

Given the advantages of a digital twin in intelligent manufacturing and the practical requirements of copper disc casting systems, a novel DT-DCS framework is proposed in this section.As presented in Fig.2, the application framework consists of three layers (a physical layer, a model layer, and an optimization layer), which transfers information between the physical and virtual spaces.According to the real-time manufacturing information of the digital twin and physical system,the CPMC is self-optimized by the dual closed-loop self-optimization structure.The horizontal DT-DCS component aligns with the underlying digital twin architecture paradigm, including the physical systems, data-sharing platforms, and twin systems.The vertical component closely matches the characteristics of specific application objects, including the physical,model, and optimization layers.

1) Physical system.The physical system is the foundation of the manufacturing process, covering the objective production environment, production equipment, power system, actuator,raw materials, sensors, products, and other production factors.There is a complex coupling state between entities in the physical layer.The equipment control system realizes the orderly connection between entities and to complete orderly product manufacturing.The physical parameters of each module in the equipment production process are collected and transmitted in real time through distributed sensors and the Internet of Things.Therefore, the physical system is a vital part of the DT-DCS framework.

2) Digital twin system.The digital twin system includes model construction and data interaction.The model is the basic unit of the digital twin system, revealing the internal physical laws followed by the digital twin system and directly driving the operation of each twin system component.Standard modeling methods can be divided into expert experience models, 3D modeling, high-precision numerical simulation,and data-driven models.The digital twin accurately maps the physical system to a virtual digital space, including a 3D model of the crucial entities and a mechanism model of each actuator in the physical system.The static dimensions of the model are modeled according to the factory parameters of the physical entities and the actual measurement results to ensure the modeling accuracy of the digital twin system.The 3D model in the digital twin system and the entities in the physical system have the same physical size, physical properties,movement methods, and constraints.The motion is determined by the constructed mechanism model and the initial conditions established in the physical system and the manufacturing information from sensors, which can realize the synchronous operation between the digital twin system and the physical system.

Fig.2.The digital twin-driven dual closed-loop self-optimization application framework for the copper disc casting intelligent manufacturing system.

3) Manufacturing information sharing platform.This component enables real-time data connectivity and behavioral interaction between the physical and digital twin system.The manufacturing information sharing platform breaks through the barriers between the physical and virtual spaces and process collection, storage, and information sharing.As a result,it becomes the basis for exchanging information in the manufacturing system, realizing real-time process data synchronization and standardized management, and ensuring data privacy,security, and quality.

4) Physical layer.The physical layer covers the devices and their related properties in the physical system.A copper disc casting machine includes all manufacturing equipment, power system, control system, raw materials, and products in the physical system.It has accurate twin models in the digital twin space, which have the same size and physical properties.When the physical system’s equipment attributes change, the information synchronization with the digital twin space is completed through the manufacturing information sharing platform, ensuring system component consistency.

5) Model layer.The model layer is the key to constructing the digital twin system.The operation rules and intrinsic properties of the physical system are transformed into the digital twin system through modeling so that each part of the digital twin system can operate accurately according to the objective state of the physical system.For this framework, the digital twin system model layer includes the liquid copper droplet model for the casting process (shown in the red dotted box in the upper part of Fig.3), which will be introduced in detail in the next chapter.The copper disc casting machine casting liquid copper droplet model accurately describes the flow pattern of the casting process, which provides the possibility for simulating the whole casting process and real-time CPMC optimization.The liquid copper droplet model determines the real-time flowqcof the casting package based on the initial conditions and current angle and compares it with the instantaneous flowqdetected by the on-site weight sensor, to establish a closed-loop optimization strategy.When the calculation error does not meet the set error rangeε, the model is iteratively optimized to ensure that the model real-time flow calculation result conforms to the actual production situation.Then the casting process simulation is realized, which is the foundation of CPMC optimization.This strategy realizes the realtime data interaction between the physical system and digital twin space in the model layer and further ensures the effectiveness of the digital twin system.

Fig.3.The diagram of dual closed-loop self-optimization.

6) Optimization layer.The optimization layer realizes the casting process simulation and CPMC optimization.First, in the optimization layer, a CPMC optimization model is established, which consists of the optimal CPMC objective function and the entropy variable mixture rate based crazy cat swarm optimization (EVMR-CCSO) algorithm (the detailed process is given in the next chapter) to achieve a fast iterative solution for the optimal CPMC.Since the physical model of the digital twin has achieved self-optimization at the model layer, the accuracy of the simulation is reliable.Therefore, in the digital twin space, the optimized CPMC is used to simulate the entire casting process.Then, according to the casting results, it is determined whether the current CPMC meets the set requirements, as shown in the green dotted box in the lower part of Fig.3.If not, the iterative optimization process is performed.At the same time, when the on-site working conditions (such as the initial weight and inclination angle of the casting package) have a sudden abnormal change, if the CPMC is applied according to the original setting, abnormal conditions such as splashing or even causing serious accidents may occur.Therefore, when the optimization layer receives the change in the on-site working conditions, it immediately re-executes the CPMC optimization solution and the whole simulation process to ensure that the CPMC is safe and reliable, thereby avoiding the occurrence of serious accidents.

III.MECHANISM AND OPTIMIZATION MODELING OF A COPPER DISC CASTING SYSTEM

In the DT-DCS, the equipment mechanism modeling plays a vital role in system construction, which is the basis for controlling the physical system.The modeling process comprises three parts: 1) Fluid modeling analysis of the casting package in the casting process; 2) CPMC optimization model construction; and 3) Optimal CPMC solution creation based on the proposed EVMR-CCSO algorithm.

A. Analysis of Modeling Process Characteristics

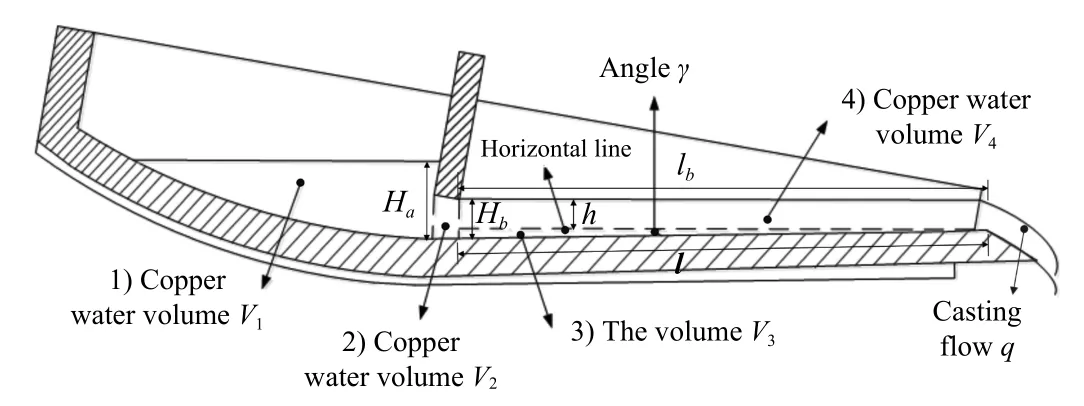

At the beginning of casting, the liquid copper level is above the baffle plate, the liquid copper inside the package accumulates until it reaches the baffle plate and then flows through the gate hole below and into the right side of the baffle plate.This flow belongs to orifice outflow in fluid mechanics.The liquid copper flows through the baffle plate and comes into direct contact with the air, which is free outflow.The liquid copper in the baffle plate orifice cross-sectional flow rate difference is large, belong to the large orifice.The thickness of the baffle plate isL=0.040 m, the diameter of the pipe isd≈0.065 m,L/d=0.615 <2, which is a thin-walled orifice.Because the liquid copper in the casting package is constantly smaller, the head of liquid copper out of the flow changes, for non-constant flow.Then the liquid copper flowing through the baffle plate at this time for the thin-walled large orifice is the non-constant free flow (gate hole outflow).

When the casting ladle rotates to a certain angle, the liquid copper flows out from the casting ladle and flows into the casting mold below in a sharp falling state, this flow belongs to the hydraulic drop phenomenon in fluid mechanics.During the casting process, the copper liquid surface is in contact with the atmosphere, and all points of its surface are subject to standard atmospheric pressure, which belongs to the open channel flow.In plunging water, when there is a barrier in the open channel, people call the phenomenon of slow flow overflowing from the top of the barrier and flowing into the channel below as weir flow.Therefore, in the modeling process,the free-falling water can be regarded as weir flow with a certain weir height, and the open channel flow can be calculated by using the weir flow formula [12].In general, when the flow restriction plate acts as a flow restriction, the flow phenomenon of liquid copper in the casting package is the flow out of the orifice and the flow of open channel plunge, while when the flow restriction plate does not work, the flow phenomenon of liquid copper is only the open channel plunge.

B. Copper Disc Casting Machine Casting Liquid Copper Droplet Model

To realize precise physical system simulation and quantitative casting control, it is necessary to model the copper flow from the casting package.A transmission mechanism controls the casting package movement, as shown in Fig.4.

Fig.4.Casting package structure diagram.

1) The liquid copper level above the baffle.As shown in Fig.5, the liquid copper in the package includes four regions,1, 2, 3, and 4, using a fluid region segmentation method the liquid copper in the package has four regions, 1, 2, 3, and 4.Based on the conservation of the liquid copper flow in the package, the liquid copper outflow flow equation is obtained as follows:

whereqrepresents the flow rate of the casting package, andVrepresents the volume of liquid copper in each region.

Fig.5.Liquid copper level above the baffle.

Based on the shape characteristics of each region, the equations of the corresponding regions are established, and the liquid copper outlet flow equation can be obtained based on the turbulence equation

where (2) and (3) are both recursive equations; ω= θ˙ is the rotational angular velocity of the casting body;his the liquid copper height at the exit of the casting body;HaandHbare

2) The liquid copper level below the baffle.Fig.6 shows the distribution diagram of the liquid copper in the casting package when the liquid copper level is lower than the upper surface of the baffle outlet hole.Similarly, based on area segmentation modeling, the change in liquid copper flow for each area is calculated, and the liquid copper outflow at the current time can be obtained.

Fig.6.The liquid copper level interface is lower than the baffle outlet hole interface.

Because only two parts of the liquid copper volume change need to be calculated at this time, the flow rate variation equation is as shown in (4)

Similarly, the derived liquid copper droplet model is shown in (5)

In (6),x1i,x2i, andyirepresent the casting angle in the casting package, the height of the liquid copper level at the package body exit, and the liquid copper flow rate at timei,respectively;MiandMcrare the weights of liquid copper remaining in the package at timeiand the critical weight of the liquid copper when the two models are switched, respectively.The liquid copper droplet casting model calculation process is as follows:

Step 1:Establish an initial casting package state, and determine a casting boundary condition;

Step 2: Based on the liquid copper droplet casting model and the model input, calculate the angle θ of the casting package at the next time, the change rateof the outlet liquid copper level, and the output flow rateq;

Step 3: Calculate the liquid copper outlet height levelhand the remaining weightMin the package;

Step 4: Evaluate whether the number of iteration calculations is satisfied, determine whether the casting quality and state quantity at this time are output when satisfied, if not,return to Step 2.

C. Casting Package Motion Curve Optimization Model Construction in the Forward Casting Stage

Casting liquid copper into a mold from the initial casting package position (the corresponding position when the upper edge of the casting package is horizontal) is called a forward casting process.The quick return phase is casting from the extreme position to the initial position.The angular velocity of forward casting is positive, and that of the quick return phase is negative.The casting package movement process depends on the CPMC.To build a reasonable CPMC model, it is necessary to analyze the entire casting process in detail.

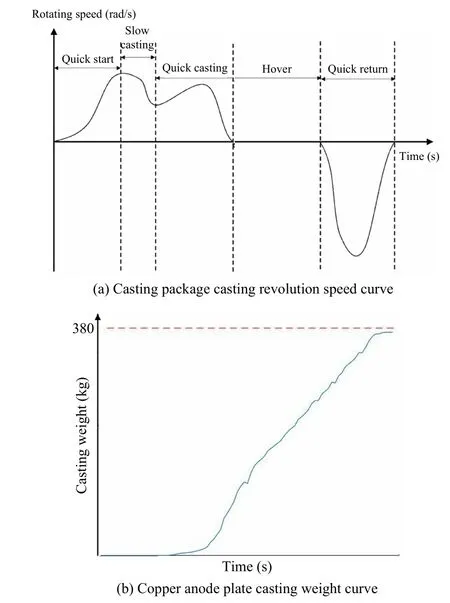

1) In the quick start process, to shorten the casting time and make the casting package quickly reach its casting location limit, it is necessary to increase the angular velocity of the casting package at the beginning (typically to a third of the maximum speed).

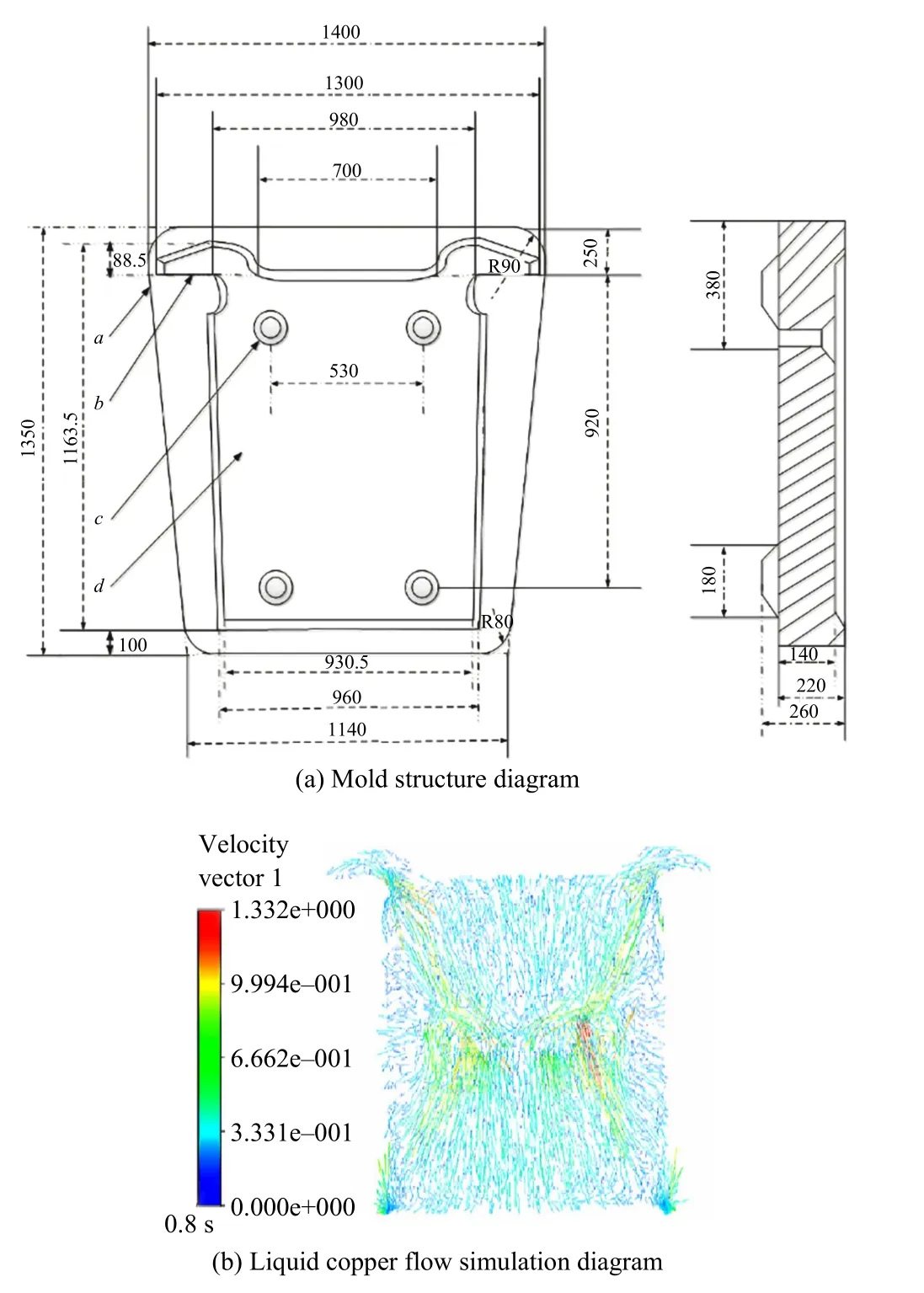

2) During slow casting, the angular velocity of the casting package is large at the end of the first sub-process, which might lead to burrs and cause the liquid copper to deposit in the ears.This is shown in Fig.7.To ensure the physical specifications of the copper anode plate, the angular velocity of the casting package is gradually reduced to approximately threefifths the maximum speed.

Fig.7.Mold structure diagram and liquid copper flow simulation diagram.

3) During the fast casting process, due to the presence of a certain amount of liquid copper with a buffering effect in the mold, increasing the angular velocity will cause the liquid copper to quickly reach the casting limit position of the casting package.The angular velocity will slowly be reduced as the casting package approaches the extreme position to prevent it from being too fast.

4) The hover sub-process refers to a state in which the angular velocity of the casting body is zero, which is the intersection of the curve and the horizontal axis in Fig.8.

Fig.8.Casting package speed and casting weight curve.

5) In the quick return process, because the weight of the liquid copper in the mold is close to the target weight, the liquid copper level in the casting package is already low enough.Therefore, the casting package return speed can be rapidly increased to minimize the casting time if the final casting weight is satisfied.

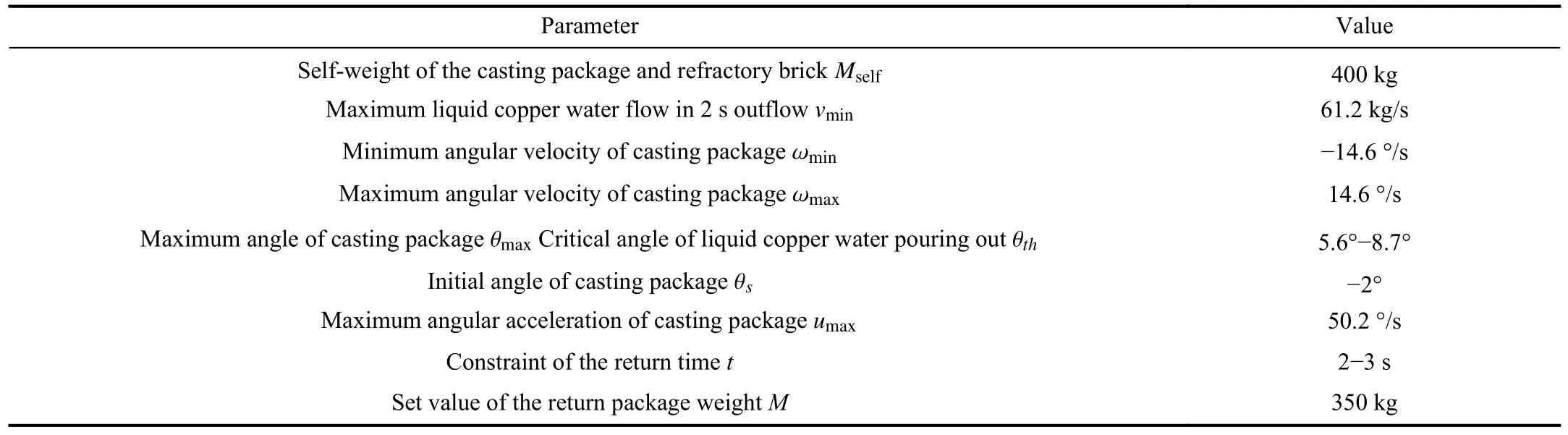

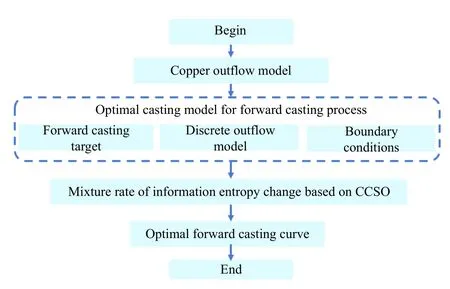

Based on the above analysis, the casting package constraint parameters and control targets can be obtained from on-site research and calculation.These are presented in Table I.To obtain a forward CPMC that meets on-site production requirements, based on the liquid copper droplet casting model established above and the field operation sub-process characteristics, a CPMC optimization model is constructed with the casting process index as the constraint and maximizing the casting quality of liquid copper per unit time as the optimization target.A flow chart of the CPMC optimization process is shown in Fig.9.

The forward casting process is divided into several discrete optimization units without impacting the total casting quality,which leads to the casting target being maximizing the casting quality of liquid copper in each optimization unit.Then,based on the casting package operating state, the constraint conditions are set.The CPMC optimization objective function group constructed is as follows:

whereMiis the weight in kilograms (kg) of the liquid copper cast by the casting package in periodi, which can be calculated using the liquid copper droplet casting model in (6), andMi=yiΔt;kindicates that the forward casting process has a total ofktime periods, i.e., the total casting time iskΔt; θsis the initial angle of the casting package in degrees (°); θeis the extreme position angle of the casting package in degrees (°);MSis the initial liquid copper weight in the casting package in kilograms (kg);Meis the weight of the liquid copper in the casting package at the end of the forward casting process in kilograms (kg); andMthis weight threshold at the time of switching the casting phase in kilograms (kg).If the difference between the current liquid copper weightMeand the initial liquid copper weight is greater than the threshold, the positive optimization setting phase is ended, and the quick return control stage commences.ui,ui-ui-1,Qhrepresent the angular velocity, angular acceleration and maximum casting flow rate of the casting package, respectively, and their units are degrees per second (°/s ) , degrees per square second (°/s2) and kilograms per second (kg/s), respectively.To ensure that the casting equipment is not damaged and that there is no splash phenomenon, these casting package parameters must be constrained.

IV.THE CASTING PACKAGE MOTION CURVE OPTIMIZATION MODEL SOLUTION

In the forward casting process, the CPMC optimization model is characterized by high model complexity and complex constraints, which makes a traditional optimization method difficult to implement [40].It has been considered that a group intelligence algorithm is applicable for solving this optimization problem [41], as it can solve the slow optimization speed and low accuracy issues in traditional optimization methods.Therefore, in this study, an EVMR-CCSO algorithm is proposed for quickly obtaining the optimal CPMC.

In the classic cat swarm optimization algorithm, each cat has two working modes (searching and tracking) [42], and all cats are randomly assigned during the algorithm initialization process.Because more cats in tracking mode are required in the early iteration stages to improve the algorithm convergence speed, and more cats in search mode are required in the later iteration stages to eliminate local extremum, a mixture rate with a dynamic change in information entropy [43] called the entropy variable mixture rate (EVMR) is designed toimprove the algorithm speed and accuracy.This makes the number of cats in search mode change dynamically with the position distribution (information entropy) of the cat group inD-dimensional space.

TABLE I KEY CASTING PACKAGE CASTING PROCESS PARAMETERS

Fig.9.Flow chart for casting curve optimization in the forward casting process.

[0,Lj]is defined as the range of thej-th dimension of the cat group inD-dimensional finite spaceS.Random variablesare defined as the position distribution of thei-th cat inD-dimensional space in thek-th iteration, which obeys aD-dimensional uniform distribution inD-dimensional finite space (its size is.Therefore, the joint probability density function of thei-th cat in theD-dimensional space in thek-th iteration is as follows (without considering the influence of the speed change on the position):

The positional distributionin space is determined byandVi,f(k-1), the probability of the position distribution of thei-th cat inD-dimensional space in thek-th iteration is as follows:

This study supposesc1-c2>0 for(k), and settingr1=1, we obtain

According to the definition of information entropy, the definition ofH(Xk) is the uncertainty of the position distribution ofNcats inD-dimensional finite spaceSin thek-th iteration,as follows:

wherebis set to 2, and its unit is bits.The function is monotonically decreasing.The clearer the position distribution of the cat group is, the largerp() is, which means it carries less information and the uncertainty of the cat group location distribution information, i.e.,H(Xk), is smaller.

The crazy cat group optimization algorithm is convergent,which means that the position distribution of the cat group gradually converges with iteration, and the location distribution information gradually becomes clear.Essentially, as iteration progresses, the value ofkgradually increases, and that ofH(Xk)gradually decreases.Therefore, the expression defining the EVMR is as follows:

whereH(Xk)maxandH(Xk)minrepresent the maximum and minimum values ofH(Xk), respectively.Thus, it is necessary to calculate the number of cats in search mode and tracking mode by calculating the EVMR before each iteration to improve the convergence speed and optimization precision of the algorithm.

The cat swarm in this mode is in a state of searching for the next location, so a mutation factor is introduced to change the position of each cat to jump out of the local extremum.

To ensure that the time required to cast a fixed weight of liquid copper in the forward casting stage is minimal, the structural fitness function is represented as follows:

When the weight of the liquid copper cast by the casting package reaches the weight threshold to switch the casting stage, the casting package casting time at this moment is calculated and used as the EVMR-CCSO algorithm fitness.The cat with the shortest casting time in tracking or search mode is taken as the optimal cat swarm position in this iteration and when entering the next iteration until iteration is completed.The proposed EVMR-CCSO algorithm for finding optimal forward CPMC is as follows:

Step 1: The upper limit of the total time period is set to T, a D-dimensional cat swarm with a population size of N is created, and the speed and position update parameters in tracking mode and the initial casting process conditions are set;

Step 2: The fitness of each cat and the best position are marked asPg;

Step 3: Based on the value of the EVMR, the cat swarm is assigned to the corresponding working mode;

Step 4: The crazy item is calculated, and the speed and position of the cat swarm are updated;

Step 5: The fitness is calculated and the best cat position is stored;

Step 6: Evaluate whether the iteration requirement is met; if yes, the current best cat position is output, i.e., the minimum casting time; otherwise, return to Step 3.

Thus, the optimal casting package CPMC in the forward casting process that satisfies the shortest casting time and no splashing can be obtained.

V.EXPERIMENTAL VERIFICATION

An industrial field case study is implemented to verify the effectiveness of the DT-DCS framework and the proposed casting process CPMC optimization model, and the results are verified and analyzed.

A. Experimental Environment

The case study is based on a factory’s TM18 double-mode copper disc casting machine.The dual-die disc casting machine was manufactured by Finland’s OUTOTEC, with 18X2casting templates and a production capacity of 100 tons per hour.The detailed parameters and working condition constraints of the tundish and casting package are given in Table I.The casting system power system is composed of a Siemens 1PH8 servo motor equipped with a single-disc brake module applied by a Kendrion 77-500-19B-15 electromagnetic release spring to address emergencies.To accurately perceive the real-time status information of the casting system, displacement sensors, angle sensors, and pressure sensors are installed in the casting package, casting mold, and at other positions.In the actual manufacturing process, the multisource information collected by the sensors in real-time is transmitted via highspeed Ethernet/IP over a local area network to an informationsharing platform, and the production equipment, digital twin model, multisource heterogeneous data, storage platform, and computing resources are integrated.Finally, casting process analysis and optimization are performed, and the quality of the finished copper anode plates is evaluated.

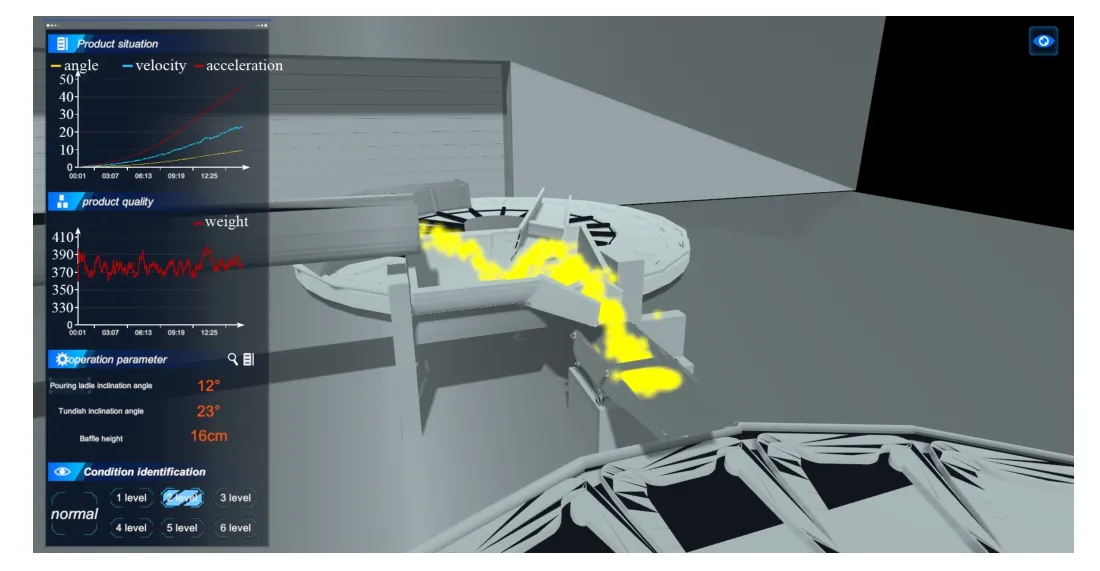

The copper disc casting digital twin system is the basis for realizing the intelligent casting process manufacturing in a virtual space.The system includes a high-precision 3D model of the casting equipment, algorithm library, program files,parameter set configuration file, human-computer interaction interface, database, and other components.The 3D casting equipment (such as the tundish, casting package, and casting mold) modeling is carried out in the SolidWorks software environment.The modeling parameters are derived from the equipment factory information and on-site measurement results, so that the geometric errors meet the production requirements.Based on a SQL server, a data-sharing platform realizes real-time information interaction between the physical and virtual spaces.

During manufacturing, on-site sensors acquire real-time manufacturing data and synchronize it to the SQL server manufacturing information-sharing platform.The DT hardware platform is based on four Intel Xeon Gold 5218 CPUs, with 128 computing cores and two Nvidia Tesla V100S GPUs to accelerate the casting process simulation.TheC# and APDL programming languages are used to realize parametric control and real-time result output of an ANSYS molten copper fluid simulation.Finally, the casting equipment casting motion process and the synchronous display of the simulation results are realized on the digital twin system Unity platform.

The DT-DCS system for copper disc casting is developed(as shown in Fig.10).The system incorporates a digital twin of the copper disc casting process, ensuring real-time synchronization with the actual casting process.The system interface provides a clear and intuitive visualization of important parameters and information related to the casting process.

B. DT-DCS Model Layer Comparative Experiments

Fig.10.Copper disc DT-DCS system UI.

Fig.11.Casting weight curve based on the liquid copper droplet model and on-site casting weight curve.

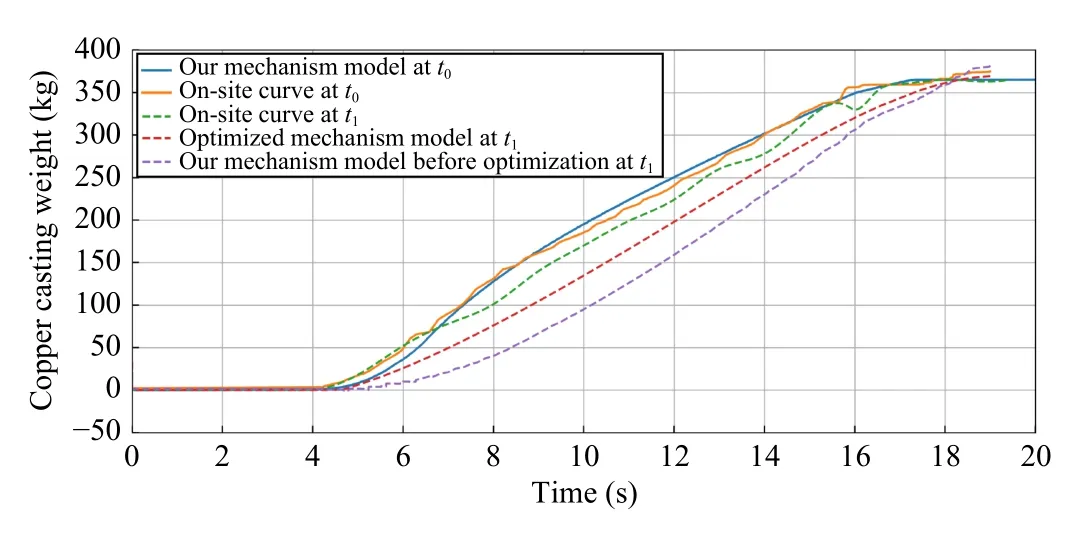

To verify the simulation accuracy of the model layer in the DT-DCS, the casting weight curve based on the proposed liquid copper droplet model and the on-site real-time casting weight curve are shown in Fig.11.The two curves in Fig.11 show the casting weight curve of the liquid copper droplet model and the on-site casting weight curve, respectively, at timet0, indicating that the proposed model can achieve a highprecision casting process simulation under set initial conditions.However, the initial casting package weight changed at timet1, and the simulation is performed according to the model parameters at timet0(see the mechanism model curve before optimization att1).As a result, the error between the simulation and the on-site casting weight curve exceeds the upper limit of the allowable errorε.At this time, the closedloop optimization strategy of the model layer is implemented,and the model parameters are updated until the error is met.The simulation curve (see the optimized mechanism model curve att1) trends towards the on-site casting weight curve at timet1.In the DT-DCS, the model layer obtains the on-site information in real-time from the manufacturing information sharing platform, compares and verifies the simulation curve,and further iterates the liquid copper droplet model parameters to optimize the model layer simulation results without manual intervention.

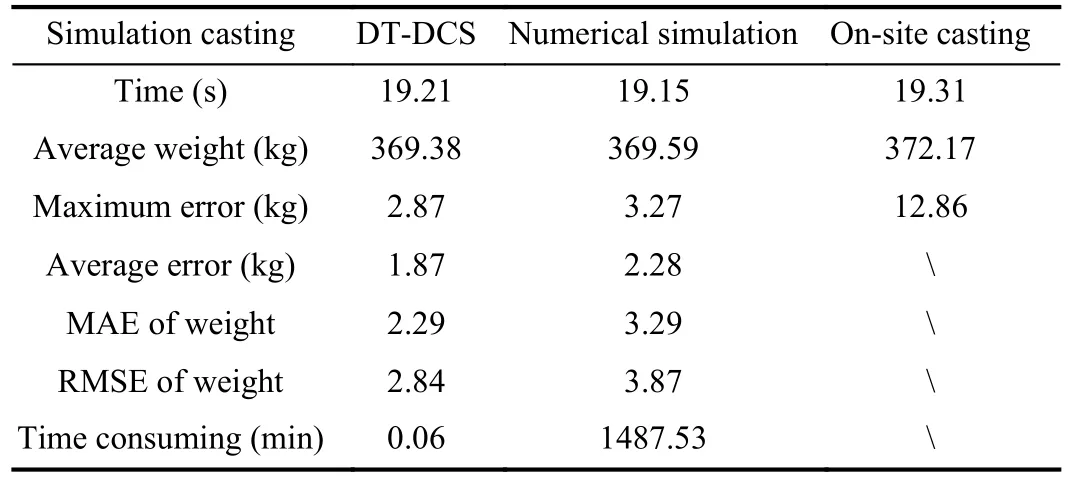

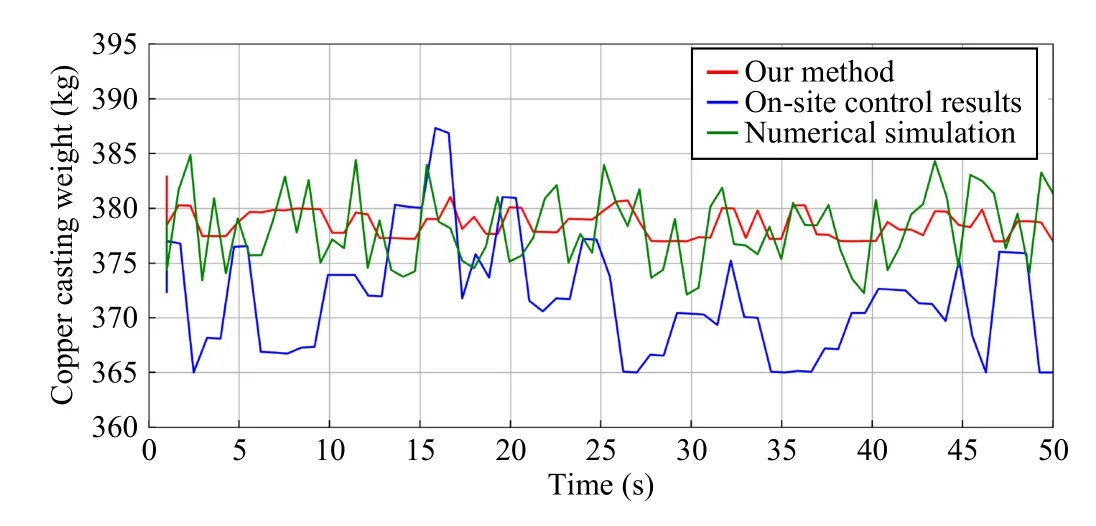

To further compare the accuracy of the proposed copper droplet model, 50 simulation experiments were carried out according to the CPMC manually set on-site, and the results are shown in Table II.Among them are: the proposed copper droplet model; the numerical simulation model (the numerical simulation experiment based on the Euler-Eulerian model in ANSYS Fluent software); the actual on-site casting weight curve; the three adopted the same CPMC settings.The actual on-site casting weight curve was regarded as the true value to evaluate the accuracy of the proposed model and the digital simulation model.The results show that the proposed model performs better than the numerical simulation model in the casting process MAE (mean absolute error) and RMSE (root mean square error) simulation error indexes, and both can simulate the casting process well.However, the proposed model is significantly better than the numerical simulationmodel in terms of time consumption, laying the foundation for real-time simulation and dynamic optimization of the model layer in the DT-DCS.

TABLE II SIMULATION ACCURACY COMPARISON OF 50 COPPER DISC CASTING PROCESSES

C. DT-DCS Optimization Layer Comparative Experiments

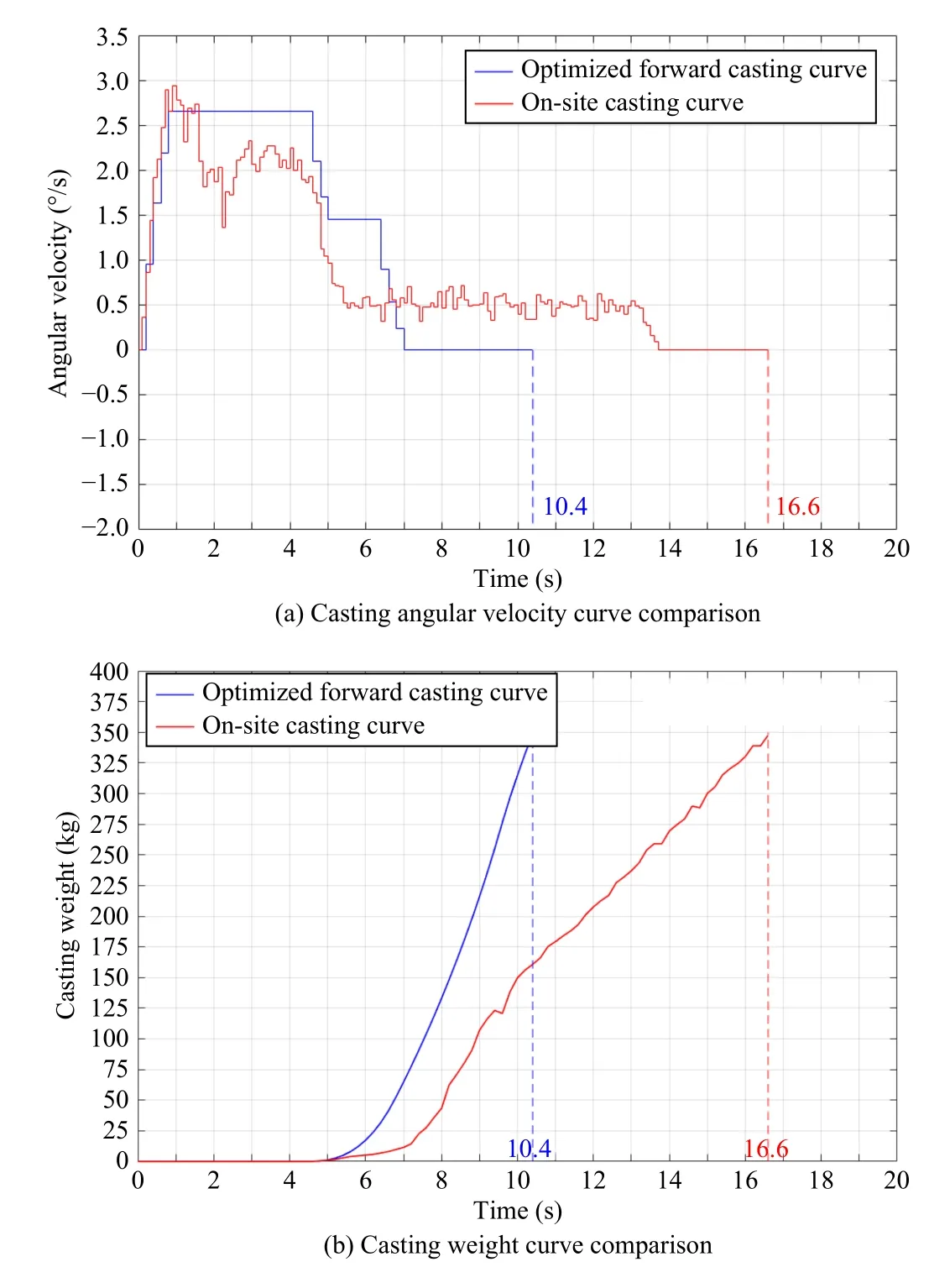

The result of the optimal CPMC solved using the optimization layer under an initial condition of 650 kg is shown in Fig.12.Based on the angular velocity motion curve in Fig.12(a), the casting package rotation speed in the quick start stage is rapidly increased by the motor.Whent= 0.8 s, the angular velocity reaches the peak and keeps operating at that speed.The maximum casting flow rate of the liquid copper isQmax=Qt=5.8s=61.01kg/s within 2 s of the liquid copper being poured out, which is less than the maximum liquid copper flow thresholdQthof the initial pouring.As the casting angle increases, the flow of the liquid copper poured from the casting package also increases rapidly, reaching a maximum att= 6.2 s.Whent= 6.6 s, the casting package moves to the forward casting limit position, the speed drops to zero, and the casting process enters the hovering sub-process.A comparison of the casting weight curves is shown in Fig.12(b).In both curves, the liquid copper casting begins att= 5.4 s.As the casting progresses, the optimized casting volume CPMC increases rapidly, and the liquid copper casting flow reaches the maximum att= 8.4 s.Whent= 10.6 s, the forward casting process ends, and the on-site data CPMC reaches its maximum att= 9.8 s, with the forward casting process ending att= 16.6 s.By comparison, the optimized curve shortens the casting time by 36.14 % compared with the artificially set onsite curve, greatly improving the casting efficiency.The result indicates that the optimal CPMC determined using the optimization layer shortens the time consumption and makes the fluid pouring in the casting process more stable, meeting the on-site needs.

Fig.12.Comparison of optimal and on-site casting curves under initial conditions of 650 kg.

Fig.13.Comparison of the casting process for one casting.

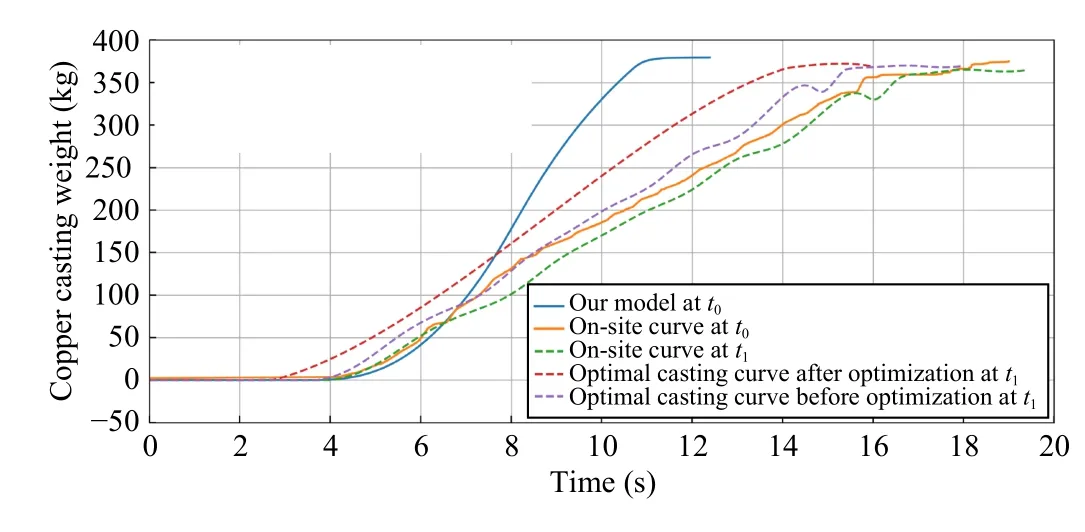

Fig.13 shows a comparison between the DT-DCS and the on-site casting weight curves in a complete casting cycle at timest0andt1.The initial liquid copper weight in the casting package fluctuates within the range of 650±40 kg.At timet0,the working condition is stable, the model layer has been optimized to meet the accuracy through a closed-loop optimization strategy, and the optimization layer determines the optimal CPMC with the initial condition at timet0.Before 6.5 s,the DT-DCS casting speed (see our method curve att0) was significantly lower than that of the on-site casting curve (see the on-site curve att0).This was because there was no copper buffer in the mold at the initial stage, and a breakneck casting speed easily causes the liquid copper to scour the bottom of the mold and cause splashing.With a certain weight of liquid copper in the mold, the DT-DCS rapidly increases the casting speed and significantly reduces the casting time while avoiding splashing.Att= 10.5 s, the casting package reaches the switching weight threshold from the forward casting to the quick return stage and enters the quick return control phase.Finally, the casting package returns to the initial position att=12.4 s, and the casting is finished.The final casting quality is 379.6 kg, which meets the requirement of the quantitative casting weight of copper anode plates at 380±4 kg.At timet1,the initial weight of the casting package has changed, and the apparent splashing phenomenon occurred in the on-site casting process (see the on-site curve att1, the weight curve has a significant drop aroundt= 16 s, indicating that the current copper industry has splashed in the mold).At this time, the accuracy of the model layer has decreased, and the initial CPMC optimization model optimization layer conditions have also changed.The casting weight curve of the casting process performed according to the optimal CPMC at timet0(optimal casting curve before optimizationt1) can no longer meet the on-site requirements.Therefore, it is necessary to implement a double closed-loop optimization strategy for the model layer and optimization layer to ensure the accuracy of the model layer and that the optimal CPMC conforms to the current working conditions.The casting weight curve corresponding to the optimized optimal CPMC (see the optimal casting curve before optimization att1) greatly improves casting time consumption, and the casting weight meets the weight requirements.In addition, because the movement speed of the casting package has been strictly limited, no liquid copper splashes on the optimized casting weight curve, effectively avoiding accidents.

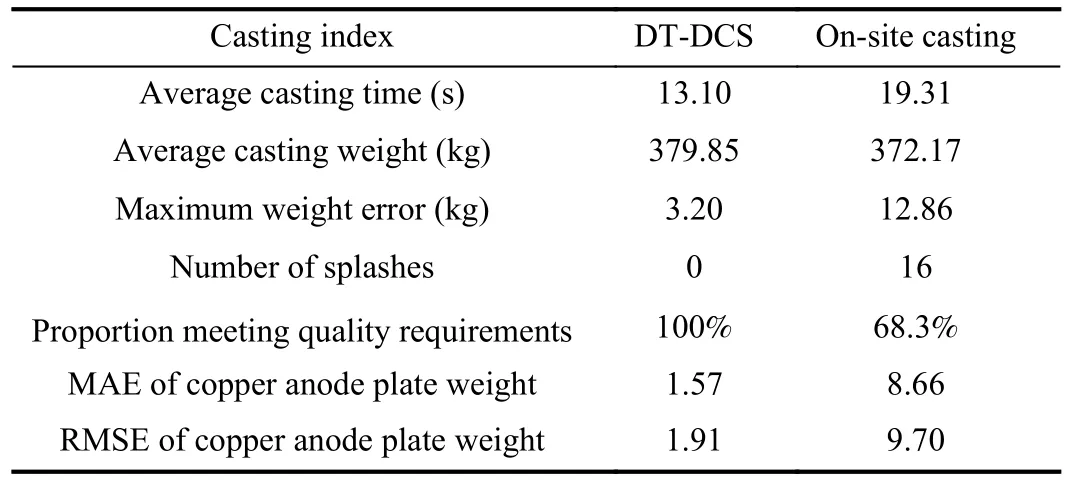

To demonstrate the improvement of the casting process more completely in the DT-DCS, 50 casting process comparison tests were carried out between the DT-DCS and the traditional production process, and production index statistics were measured (Table III).The average casting time in the production process decreased 32.16% from 19.31 s to 13.10 s.The average weight of the copper anode plates was significantly close to the 380 kg set by the production standard.The maximum weight error of the products produced using the DTDCS was 3.2 kg, and the maximum error under the manual setting was 12.86 kg.In addition, the casting product MAE and RMSE weight error indexes based on the DT-CMS decreased by 80.31% and 81.87%, respectively, compared with the on-site casting weight results of the copper anode plate.The quality of the copper anode plate has been greatly improved.In the case of manually setting the CPMC, 16 molten copper splashing events occurred, as shown in Fig.14.Due to the predictive simulation ability of the DT-DCS on the CPMC, it was ensured that no molten copper splashing occurred during the production process.The qualification of products manufactured using the DT-DCS reached 100%,which is a significant improvement compared to the 68.8%using the manually set CPMC.

TABLE III COMPARISON OF THE CASTING INDEXES OF 50 COPPER DISC CASTING PROCESSES

Fig.14.Casting weight comparisons of the developed control and manual settings.

From the above analysis, the DT-DCS greatly improves the production efficiency and quality of the copper anode plate casting process by implementing predictive simulation and iteratively optimizing the CPMC settings independently to prevent production accidents such as splashing.In this case,the DT-DCS comprehensively improved the level of on-site manufacturing and produced extensive economic benefits.

VI.CONCLUSION AND FUTURE WORK

Considering the complex structure and high coupling degree of existing disc casting machines, CPMCs set by human experience, low production efficiency, and unstable product quality, a DT-DCS framework is proposed.For the first time,according to the operation characteristics of a disc casting system, a casting package liquid copper droplet casting model is constructed.Then, the objective function of the optimal CPMC and an EVMR-CCSO iterative optimization algorithm are innovatively proposed to determine the optimal CPMC.Finally, a case study of the copper disc casting dual closedloop digital twin system is carried out based on the DT-DCS framework.After introducing the DT-DCS framework, the results show that the disc casting efficiency increased by 32.16%, the product qualification rate increased from the original 68.3% to 100%, and the occurrence of accidents such as splashing was prevented.The proposed method significantly improves the manufacturing process intelligence level.In the future, the optimization of the core DT-DCS model will be further studied to improve digital twin system simulation accuracy, and a data mining method will be applied to the DTDCS to discover more information in the manufacturing process for system fault diagnosis and other research services.

IEEE/CAA Journal of Automatica Sinica2024年3期

IEEE/CAA Journal of Automatica Sinica2024年3期

- IEEE/CAA Journal of Automatica Sinica的其它文章

- Set Stabilization of Large-Scale Stochastic Boolean Networks: A Distributed Control Strategy

- Dendritic Deep Learning for Medical Segmentation

- Achieving 500X Acceleration for Adversarial Robustness Verification of Tree-Based Smart Grid Dynamic Security Assessment

- Communication-Aware Mobile Relaying via an AUV for Minimal Wait Time: A Broad Learning-Based Solution

- Simulation Analysis of Deformation Control for Magnetic Soft Medical Robots

- Multi-Timescale Distributed Approach to Generalized-Nash-Equilibrium Seeking in Noncooperative Nonconvex Games