MXene-based flexible pressure sensor with piezoresistive properties significantly enhanced by atomic layer infiltration

Zilin Qi,Tinwei Zhng,Xio-Dong Zhng,Qing Xu,Kun Co,**,Rong Chen,*

a State Key Laboratory of Digital Manufacturing Equipment and Technology,School of Mechanical Science and Engineering,Huazhong University of Science and Technology,Hubei,430074,China

b State Key Laboratory of Materials Processing and Die&Mold Technology,School of Materials Science and Engineering,Huazhong University of Science and Technology,Hubei,430074,China

Keywords: MXene Atomic layer deposition Pt infiltration Piezoresistive Flexible pressure sensor

ABSTRACT The flexible pressure sensor has been credited for leading performance including higher sensitivity,faster response/recovery,wider detection range and higher mechanical durability,thus driving the development of novel sensing materials enabled by new processing technologies.Using atomic layer infiltration,Pt nanocrystals with dimensions on the order of a few nanometers can be infiltrated into the compressible lamellar structure of Ti3C2Tx MXene,allowing a modulation of its interlayer spacing,electrical conductivity and piezoresistive property.The flexible piezoresistive sensor is further developed from the Pt-infiltrated MXene on a paper substrate.It is demonstrated that Pt infiltration leads to a significant enhancement of the pressure-sensing performance of the sensor,including increase of sensitivity from 0.08 kPa-1 to 0.5 kPa-1,extension of detection limit from 5 kPa to 9 kPa,decrease of response time from 200 ms to 20 ms,and reduction of recovery time from 230 ms to 50 ms.The mechanical durability of the flexible sensor is also improved,with the piezoresistive performance stable over 1000 cycles of flexure fatigue.The atomic layer infiltration process offers new possibilities for the structure modification of MXene for advanced sensor applications.

1.Introduction

As an essential part of wearable technology,the flexible sensor is promising for various applications including human health monitoring and human-machine interface [1–6],owing to the mechanical compatibility of the flexible structure as well as the progress in the integration of multi-modal sensors[7,8].In particular,flexible pressure sensors[9,10]have demonstrated potential for body motion monitoring and electronic skin [11–17],as well as energy harvesting [18].Based on the piezoresistive effect that transduces external pressure stimulus into resistance change,the piezoresistive pressure sensor has the advantages of simple device structure,low fabrication cost,linear response,and easy integration with electronics [19,20].The studies on piezoresistive pressure sensors have been mostly related to innovations on piezoresistive sensing material and fabrication methods,in addition to the morphological engineering of the sensing material[21–30].

Because of its compressible lamellar structure,the Ti3C2TxMXene is a piezoresistive material with electrical resistivity affected by its interlayer spacing[31–35].Its surface contains various functional groups(Tx)that can be modified or removed,leading to possibilities to adjust electrical or mechanical properties over wide ranges [29,36].MXene can also be assembled into continuous film on most flexible substrates,exhibiting mechanical flexibility and electrical stability with potential for flexible piezoresistive pressure sensors [37–40].On the other hand,pressure sensors based on typical MXene material still face limitations on sensing range,sensitivity and response/recovery time.In order to improve the sensor performance of MXene,several approaches have surfaced with regard to its microstructure or morphology,including the adjustment of the interlayer distance of MXene [32],the implementation of novel aerogel structure in the piezoresistive functional layer for ultra-high sensitivity [41],the development of MXene-Coated fabric composite for wearable applications [42],the design of ultrasensitive microcrack structure for enhanced sensitivity and fatigue resistance[12],as well as the introduction of a composite interface to enhance mechanical or electrical properties,such as composite aerogel with hierarchical nano-fibrous cellular structure for superior compressibility [21].Recently,the method of “atomic layer infiltration (ALI)” has been reported to modify the structure and properties of nanostructured materials[43].Based on a conventional atomic layer deposition(ALD)process,it allows vapor phase infiltration of atoms or functional groups into the pores or voids in the nanostructure[44].Studies on Pt-infiltrated MXene using the ALI method have demonstrated dramatic improvement in the electrical and thermal properties of MXene,because of the curing of Ti-defects by the Pt atoms as well as the formation of covalent Pt–C bonds between the layers in MXene[45].However,it is not clear whether the interlayer distance or the piezoresistive properties of MXene can be modulated by atomic layer infiltration of functional atoms or molecules.According to the principle of piezoresistivity for bare Ti3C2TxMXene(Fig.1(a)),externally applied pressure induces a change in contact resistance (RC) between the conductive layers by narrowing the interlayer distance (DC) and increasing the contact area.Then,intercalation of functional species such as Pt into the interlayer space(Fig.1(b))could possibly impart new mechanisms of interlayer deformation and contact resistance.These are defined by the properties (size,conductivity,bonding,etc.) of the infiltrated species.In fact,a similar hypothesis has been tested for graphene,where the introduction of rigid molecular chains covalently attached to the basal plane allows the tuning of interlayer spacing and piezoresistive properties[46].

Fig.1.Flexible piezoresistive sensor based on Ti3C2Tx MXene modified by atomic layer infiltration.(a) Piezoresistive response due to variation of interlayer spacing (in red) under external pressure;(b) Infiltration of Ti into the interlayer of MXene using atomic layer deposition (ALD);(c) Complete sensor fabrication process,with an actual image of the sensor shown in the lower-right corner.

Here,we demonstrate the modification of interlayer structure and piezoresistive properties of Ti3C2TxMXene through the intercalation of Pt using ALI.The morphology,structure,and chemistry of the MXene particles before and after ALI treatment are characterized,confirming the insertion of Pt nanoparticles into the interlayer space,the increase of interlayer spacing,as well as the formation of Pt–C covalent connection.In addition,flexible piezoresistive sensor devices are developed on a filter paper substrate(Fig.1(c)),where MXene particles with and without ALI treatment were respectively assembled into conductive membrane under vacuum suction filtration.Pressure sensing performances of the devices were tested to evaluate the effect of ALI treatment,demonstrating an increase of sensitivity from 0.08 kPa-1to 0.5 kPa-1,decrease of response time from 200 ms to 20 ms,decrease of recovery time from 230 ms to 50 ms,and increase of sensing range from 5 kPa to 9 kPa.Furthermore,piezoresistive properties of the ALI-treated flexible sensor are well maintained through mechanical fatigue test over 1000 cycles of flexure.

2.Experimental section

2.1.Atomic layer infiltration (ALI) treatment of the MXene powder

Micro powders of Ti3C2TxMXene (Beijing Beike New Material Technology Co.,Ltd) were subject to Pt infiltration under the ALD process(Fig.1(b)),which was performed in custom-developed powder ALD equipment.The ALD process uses MeCpPtMe3and oxygen as precursor gases(respectively designated as “precursor A′′and “precursor B′′),as well as nitrogen as a carrier gas for MeCpPtMe3.To start the ALD,the MXene powder sample loaded in the deposition chamber is fluidized withprecursor Bfor 60 s.Two ALD cycles are then performed for Pt infiltration,and each cycle consists of four precisely-timed deposition steps summarized as t1-t2-t3-t4,where t1and t3are respectively the purging time forprecursors A and B,and t2and t4are respectively the time for rinsingprecursors A and Busing pure nitrogen.All the above time periods were set as 200 s.

2.2.Fabrication of flexible piezoresistive pressure sensor

Fig.1(c) presents the process for the fabrication of a flexible piezoresistive sensor based on Ti3C2TxMXene.Briefly,MXene powders(pristine or ALI-treated,100 mg) were uniformly dispersed in 5 mL of deionized water,by using ultrasonic stirring for 20 min.The obtained colloidal solution was transferred into a vacuum filtration device,allowing the dispersed MXene powders to deposit onto waterlogged filter paper(Cellulose acetate)and form a continuous thin film of black color.As a contrast experiment against the ALI-treated MXene,Pt-modified MXene film was also prepared from raw MXene film by the liquid impregnation method,where 4 μL of nitrate platinum solution(18% wt.)was used to excessively impregnate a raw MXene film prepared from 5 mL of MXene colloidal solution to ensure a 1:100 M ratio of Pt/Ti.To develop a flexible piezoresistive sensor device,sample films on the filter paper substrate were cut into strips of 20 mm by 10 mm,and silver wires were glued with silver conductive paste at both ends,followed by air drying.In order to encapsulate the MXene sensor,PDMS was evenly spread-coated on the top and bottom sides of the device,which was then subjected to vacuum seasoning for 4 h.

2.3.Characterization and measurement

Before and after Pt infiltration,the morphology of the MXene powder was examined by field emission scanning electron microscopy(FE-SEM,Helios Nanolab® G3 CX,FEI).Elemental composition was measured by energy-dispersive X-ray spectroscopy (EDX),and the structural phase composition was analyzed using X-ray diffraction(XRD,MAXima_X XRD-7000) with Cu Kα1 radiation (λ=0.154 nm) from 5°to 65°.X-ray photoelectron spectroscopy(XPS,AXIS-SUPRA+,Kratos®)spectra were obtained to accurately analyze the composition and chemical bonds in the MXene samples.The interlayer structure of the MXene specimen before and after Pt infiltration was studied using high-resolution transmission electron microscopy (HR-TEM,Talos® F200X).To test the piezoresistive properties of the sensor,a constant DC voltage of 2 V was applied to the two-terminal device while the current passing through the device was monitored with a source meter(Keithley®2636B).Different levels of normal pressure ranging from 0 to 30 kPa were applied to the sensor in order to measure the sensitivity of sensors,and the corresponding current signals were recorded.To test the piezoresistive performance of the flexible sensor against flexure fatigue,out-of-plane flexure was cyclically introduced on a mechanical test frame (Instron®MicroTester 5944) while the sensor resistance was measured with a digital multimeter (Keysight® 34465A).In each test cycle,out-of-plane flexure of the planar device was imposed through linear relative movement of the test frame,up to 0.2 mm with a speed of 0.1 mm/s,along the axial direction of the device.

3.Results and discussion

SEM imaging of the un-modified Ti3C2TxMXene powder presents microscale particles (Fig.2(b)) with organ-like lamellar structure,with gaps separating multiple parallel layers from each other (Fig.2(d)).Nanoscale fine features can be further observed on the surface of each laminated layer(Figure S1).After the ALI treatment,the MXene particle does not exhibit any obvious change in overall morphology (Fig.2(c)),but on higher magnification its laminated layers appearthicker(Fig.2(g));in addition,it shows an increase of Pt composition with uniform distribution according to EDX mapping (Fig.2(f) and (i)).The EDX also registered a Pt/Ti relative molar percentage of~1.2% after the treatment.Therefore,the thicker morphology of the laminated layers(Fig.2(g)) after the ALI treatment may be due to the attachment and accumulation of infiltrated Pt on the surface of each layer.

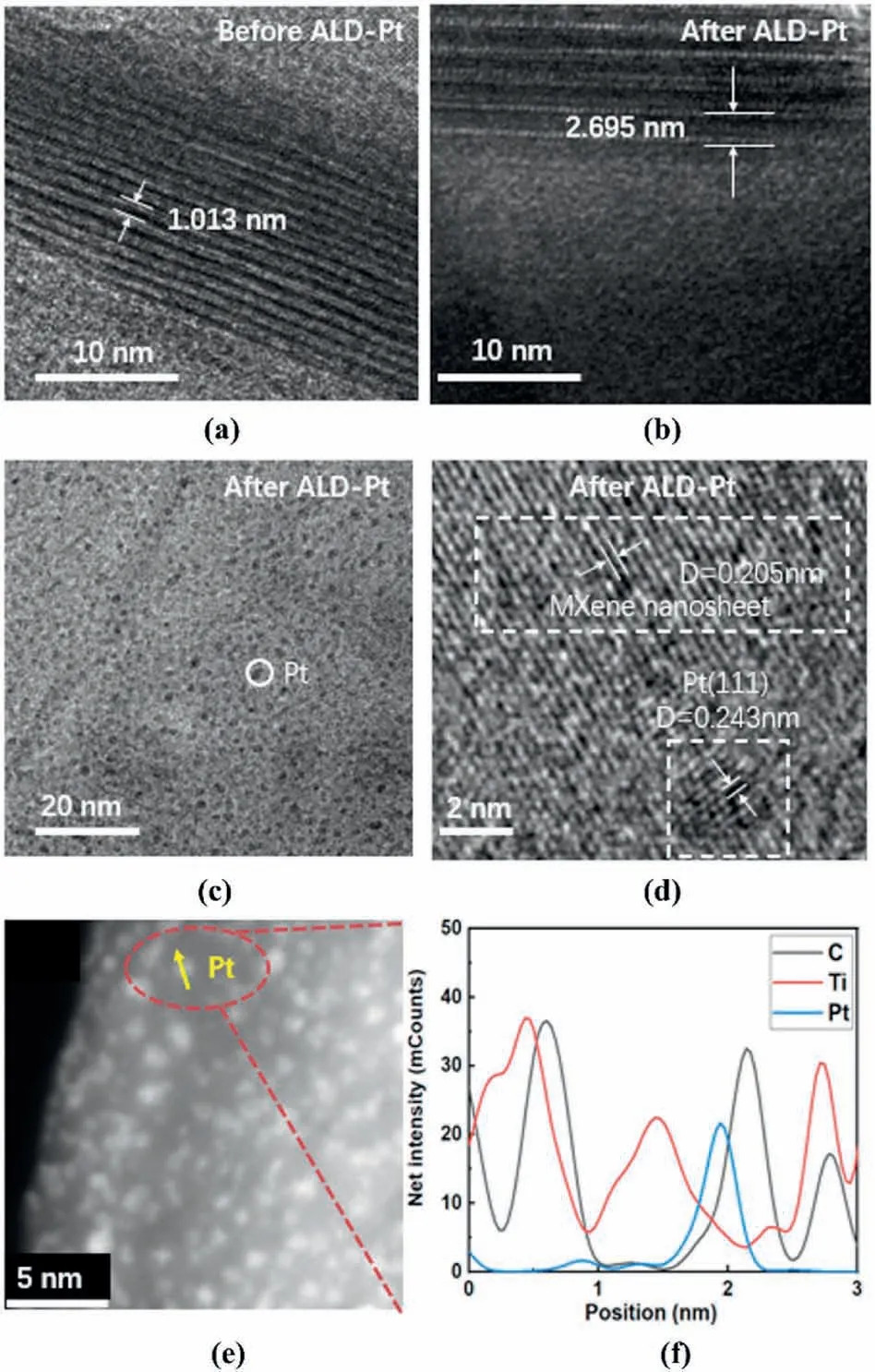

XRD spectra of the MXene powders (Figure S2) present typical diffraction peaks of Ti3C2for both samples before and after ALI treatment;however,there is no obvious indication for the appearance of a Pt crystalline phase,suggesting small size and wide dispersion of the Pt particles interfused by ALI treatment.HR-TEM observation(Fig.3(a and b)) confirms the 2D layered structure of MXene on the nanoscale,and more importantly,a significant increase of interlayer distance from~1.013 nm to~2.695 nm after ALI treatment.The infiltration of Pt leads to the formation of crystalline Pt nanoparticles (Fig.3(d)) with interplanar spacing of 0.223 nm,corresponding to the Pt (111) crystallographic plane.The Pt nanoparticles(Fig.3(c–f))are widely dispersed on the surface and in between the layers of MXene.The average size of the Pt nanoparticles is less than~2 nm,which might explain the missing of any observable XRD peaks from Pt.

Fig.3.TEM of pristine and Pt-infiltrated Ti3C2Tx MXene. (a) High-resolution TEM before Pt infiltration;(b) High-resolution TEM after Pt infiltration;(c) TEM image showing the precipitation of Pt nanoparticles on the surface of MXene;(d) High-resolution TEM of Pt nanoparticle on MXene;(e) Dark-field TEM image of Pt nanoparticles on the surface of MXene;(f) Line distribution of elements across a region in (e) covering a Pt nanoparticle.

XPS spectra offer more detailed chemical information about the MXene particles before and after ALI treatment.The survey-scan spectra(Fig.4(a)) clearly show the existence of O and F as surface functional groups attached to Ti3C2,as well as Pt in the ALI-treated sample with elemental concentration of~0.4 mol.%.The high-resolution C 1s spectra(Fig.4(b))show a slight decrease in intensity of the de-convoluted C–O and O––C–O peaks after ALI treatment,implying possible bonding of these functional groups with the infiltrated Pt atoms.The high-resolution Ti 2p spectra of untreated MXene (Fig.4(c)) can be de-convoluted into characteristic peaks for Ti3C2Txconsistent with reports in the literature[47].The appearance of the TiO2peak at 458.6 eV on the spectrum after the ALI treatment suggests some oxidation of Ti during treatment.On the high-resolution Pt 4f spectra(Fig.4(d)),the two dominant de-convoluted peaks at 71.2 eV and 74.5 eV suggest that most of the Pt exists in the form of metal,whereas the peaks at 72.2 eV and 75.5 eV indicate the covalent bonding of Pt–C[45].The formation of the Pt–C bond likely results from the following processes during Pt infiltration: (1) Occupation of Ti vacancy by Pt atoms,thus forming a strong covalent bond with the neighboring C atoms[34];and(2)Reaction of the Pt precursor with the C–O or O––C–O group on the MXene surface[29].Combining the above imaging and spectroscopic analysis,it may be concluded that the infiltrated Pt consists of mostly Pt nanoparticles that are uniformly dispersed in MXene and covalently connected to the MXene layers through the Pt–C bond.

Fig.4.XPS analysis of pristine and Pt-infiltrated Ti3C2Tx MXene.(a)Survey scan;(b–d)High-resolution spectra with de-convoluted peaks of C1s,Ti 2p and Pt 4f,respectively.

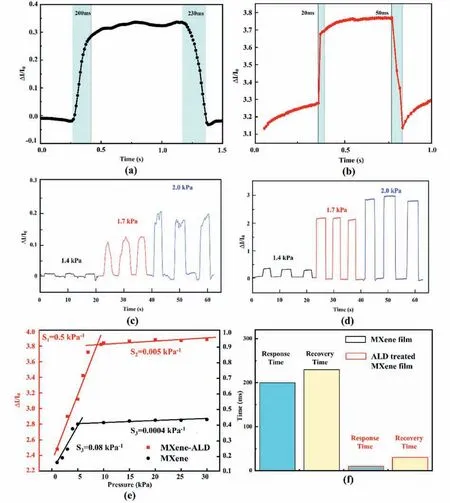

All the MXene-based flexible piezoresistive sensors exhibit typical Ohmic-type of electrical conduction(Figure S3),while the ALI treatment of the MXene powder brings about a >4 times increase of electrical conductance of the sensor device.The pressure-sensing performance of the piezoresistive sensor was further tested under normal pressure(Fig.5).The typical response and recovery of the sensors to the respective application and removal of external pressure are shown in Fig.5(a and b);the response and recovery under different applied pressures over multiple cycles are shown in Fig.5(c and d).The response is represented by the relative current change (ΔI/I0)=(I–I0)/I0,where I and I0are respectively the currents measured with and without external pressure.In addition,the response/recovery time is defined as the time for the current to reach 90% of the steady state level following the application/removal of external pressure.The sensor responses(ΔI/I0)as a function of applied pressure (P) are shown in Fig.5(e),from which the pressure sensitivity(S) is defined as S=(ΔI/I0)/P.For both ALI-treated and untreated MXene sensors,the sensitivity in the low-pressure range is significantly higher than in the high-pressure range.Such difference can be ascribed to the interlayer gaps in the MXene structure.Upon the application of external pressure,such gap decreases and the contact area between the conductive layers increases,thus causing significant increase of current;however,decrease of the gap will eventually lead to its complete closure at a certain pressure level,above which further increases of contact area and conductive current become harder with the increase of pressure.This may well explain the observed transition of sensitivity at a certain pressure limit,which is~5 kPa for MXene and~9 kPa for treated MXene.Such pressure limit also defines the applicable working range of the pressure sensor.Compared with untreated MXene,the wider sensing range (0–9 kPa) of the ALI-treated MXene can be ascribed to the enlarged interlayer gap(Fig.3(b)) which can accommodate larger mechanical strain.Furthermore,for ALI-treated MXene,the higher sensitivity(Fig.5(e))and the much shorter times for response and recovery(Fig.5(f))may be related to the enhanced efficiency of electron transport in the ALI-treated MXene,which contains additional inter-layer conductive paths from the Pt nanoparticle and the covalent Pt–C bond,as well as a reduced number of electron traps of Ti defects occupied by Pt atoms [45,48,49].It is also noteworthy that the times for response (20 ms) and recovery (50 ms) of the present sensor based on ALI-treated MXene are superior to some other reported MXene-based pressure sensors [50,51],which typically have response time >200 ms.Such fast response and recovery also meet practical application requirements[52].

Fig.5.Piezoresistive sensor performance under normal pressure.Typical response and recovery of(a)untreated MXene sensor and(b)ALI-treated MXene sensor;Response and recovery of(c)untreated MXene sensor and(d)ALI-treated MXene sensor under different pressures over multiple cycles;(e)Sensitivity as a function of pressure;(f) Comparison of response and recovery times with and without ALI treatment.

Mechanical flexibility and durability of the pressure sensors were evaluated through a flexural fatigue test on the piezoresistive performance over multiple test cycles.Out-of-plane buckling flexure of the thin planar device was introduced through linear axial displacement of the two fixtures relative to each other (Fig.6(a)),resulting in variation of flexure angle between 40°and 65°in each test cycle.The influence of ALI treatment on the stability and durability of piezoresistive sensor performance can be clearly observed: for the ALI-treated MXene sensor(Fig.6(c)),the magnitude and range of resistance variation is quite consistent,maintaining an “M-shape” for each cycle throughout the entire 1000 test cycles,whereas the raw MXene sensor(Fig.6(b))barely holds such consistency for more than dozens of cycles.The improved stability of piezoresistive performance could be hypothesized to be related to enhanced structural stability of the Ti3C2TxMXene particle after ALI treatment,through the curing of Ti defects occupied by Pt atoms on the surface of the conductive Ti3C2layer,as well as the additional “linkage” between the layers by the Pt nanoparticles and the Pt–C covalent bond.

Fig.6.Piezoresistive sensor performance under cyclic flexure.(a)Initial(left)and final(right)configurations of the flexible sensor during each flexure cycle;(b)Cyclic test results before ALI treatment;(c) Cyclic test results after ALI treatment.

4.Conclusion

A flexible piezoresistive sensor has been successfully developed based on ALD-modified MXene.The ALD treatment allows the infiltration of atomic Pt into the 2D lamellar structure of MXene,and leads to the occupation of the Ti defect sites,formation of a Pt–C covalent bond,and enlargement of interlayer spacing.Such modified chemical and structural characteristics result in increased electrical conductivity as well as enhanced piezoresistive properties of MXene,including higher sensitivity (0.5 kPa-1),faster response (20 ms),faster recovery (50 ms) and wider range of pressure sensing (0–9 kPa).The flexible sensor device based on the ALD-modified MXene is also highly durable,maintaining stable piezoresistive performance through a flexure fatigue test over 1000 cycles.All the above results confirm the superiority of “atomic layer infiltration” (ALI) for nanoscale chemical and structural modifications,which are particularly valuable for tailoring functional nanomaterials for future sensor applications.

Declaration of competing interest

There are no conflicts to declare.

Acknowledgements

This work is supported by the National Natural Science Foundation of China (51835005,52273237,51871103),National Key Research and Development Program of China(2020YFB2010401),the Hubei Province Natural Science Foundation for innovative research groups(2020CFA030),Tencent Foundation and the Independent Innovation Research Fund of Huazhong University of Science and Technology(2019kfyXMBZ025).The authors would also like to acknowledge the technology support from the Analytic Testing Center and the Flexible Electronics Research Center of HUST.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.nanoms.2022.10.003.

- Namo Materials Science的其它文章

- Advancing the pressure sensing performance of conductive CNT/PDMS composite film by constructing a hierarchical-structured surface

- In situ confined vertical growth of Co2.5Ni0.5Si2O5(OH)4 nanoarrays on rGO for an efficient oxygen evolution reaction

- Water-based synthesis of nanoscale hierarchical metal-organic frameworks:Boosting adsorption and catalytic performance

- An overview of recent progress in the development of flexible electrochromic devices

- Wearable and stretchable conductive polymer composites for strain sensors:How to design a superior one?

- Addressing cation mixing in layered structured cathodes for lithium-ion batteries: A critical review