Effect of quenching and tempering processes on properties and microstructure ofG115 steel

Baowu Special Metallurgy Co.,Ltd.,Shanghai 200940,China

Abstract:The novel martensitic heat-resistant steel G115 was designed for thick-section boiler components of ultra-supercritical(USC) power plants at 630-650 ℃.The impact of the quenching and tempering processes on the properties and microstructure of G115 steel was explored.The samples that were quenched and tempered twice had a higher tensile strength at room temperature and 650 ℃,and the impact energy was significantly improved.The strength and impact energy increased in proportion to the increase in the first quenching temperature.The microstructure differences between the single and double quenched and tempered samples were examined using metallographic microscopy and scanning electron microscopy.The grain size of the double quenched and tempered samples was finer than that of the single quenched and tempered samples,and the tempered martensite lath is more visible,as are the carbides and other precipitates,which are finer and more uniformly distributed.As the first quenching temperature increased,the grains became coarser but more uniform.

Key words:G115; quenching and tempering; tensile properties; microstructure

1 Introduction

Coal-fired power generation is the most important component of our country’s power supply struc-ture.To reduce coal consumption,improve thermal efficiency,and reduce emissions,ultra-supercritical power plants with high parameters above 630 ℃ have become a crucial direction for the future development of coal-fired power generation units in our country[1-4].However,heat-resistant materials have always been a “stuck neck” issue that has limited the development of coal-fired power plants to high parameters.With an increase in steam tem-perature and pressure,ultra-supercritical thermal power units have raised the bar for the performance of heat-resistant materials,particularly in the follow-ing areas:(1) greater high-temperature durability and creep strength;(2) good oxidation and cor-rosion resistance;(3) excellent microstructure stabi-lity;(4) good cold and hot working properties;and (5) good welding properties[5-8].Presently,the rela-tively mature P92 can be used to manufacture large-diameter boiler tubes below 620 ℃,but when the steam temperature rises to the range of 630-650 ℃,no mature materials are currently available world-wide.To meet the needs of ultra-supercritical ther-mal power units with steam parameters of 630-650 ℃,Baosteel united Central Iron &Steel Research Institute and developed a series of new martensitic heat-resistant steels G115.G115 steel achieved excellent alloy high-temperature strength by adding boron while controlling Ni;controlling the ratio bet-ween boron and Ni increases the service temperature limit of the martensitic heat-resistant steel from 620 ℃ to 650 ℃,which has great engineering significance.Currently,the National Energy Administration has officially approved Datang Group’s Yuncheng 630 ℃ ultra-supercritical secondary reheat unit demonstration project.Presently,G115 steel is an optional material for high-temperature components such as the main steam pipeline of the new-generation 630 ℃ ultra-supercritical unit.The heat treatment of martensitic heat-resistant steel commonly uses normalizing and high-temperature tempering processes (see GB5310 for details).After G115 steel adopts the quenching and tempering processes in the industrial trial production process,the safety margin of the impact energy is small,making it difficult to meet the requirements of long-term stable service of high-pressure boiler materials.Therefore,this study investigated the micro-structure and properties of G115 using various quenching and tempering processes and provided data support for obtaining good comprehensive properties of G115 steel.

2 Test method

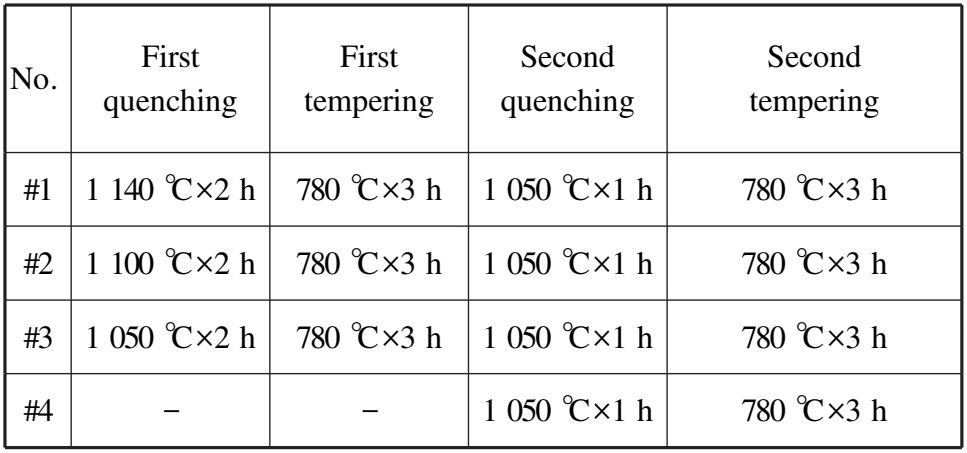

The G115φ530 mm bar is chosen as the study object.Table 1 shows its main chemical composi-tion.The main manufacturing process is as follows:40 t electric furnace+LF+VD→pouring 13.5 t steel ingot→forging into bar→quenching and tem-pering heat treatment.Table 2 shows the quenching and tempering processes,of which #1-#3 were quenched and tempered twice.The first quenching temperatures were 1 140,1 100,and 1 050 ℃,respe-ctively.After the first quenching and tempering,the second quenching and tempering were completed.#4 was only quenched and tempered once,and the pro-cess parameters are the same as the second quen-ching and tempering of #1-#3,namely 1 050 ℃×1 h/water cooling+780 ℃×3 h/air cooling.

Performance testing and microstructure analysis were performed on transverse specimens taken from the bar.The room temperature tensile test and the 650 ℃ high-temperature tensile test were performed on the SCL233200kN and SCL231200kN testing machines,with the test basis being GB/T 228.1 and GB/T 228.2.The impact performance was measured using JBN-300B equipment,and the material’s Charpy V-notch impact energy was tested according to GB/T 229,with a sample size of 10 mm× 10 mm× 55 mm.A metallographic microscope and an EVO MA25 scanning electron microscope were used to examine the microstructure,which was corroded with 5 g FeCl3+50 ml HCl+50 ml H2O solution.

Table 2 Heat treatment process of the G115 bar

3 Test results and analysis

3.1 Influence of quenching and tempering pro-cesses on performance

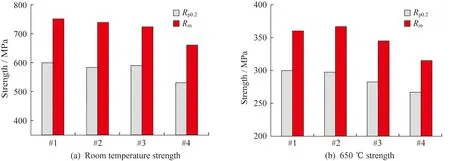

Fig.1 depicts the effect of the quenching and tempering processes on the room temperature strength and 650 ℃ high-temperature strength of the G115 bar.Fig.1(a) shows that the yield strength and tensile strength at room temperature of the double quenching and tempering processes (#1-#3) are greater than those of the single quenching and tempering processes (#4).The yield strength of #1-#3 is about 50-60 MPa higher than that of #4,and the tensile strength of #1-#3 is about 60-90 MPa higher than that of #4.The yield strength and tensile strength at room temperature show a downward trend as the first quenching temperature decreases from 1 140 ℃ to 1 050 ℃.Fig.1(b) shows that the effect of the quenching and tempering processes on high-temperature strength at 650 ℃ has a similar change trend.The 650 ℃ high-temperature yield strength and tensile strength of the #1-#3 samples are greater than those of the #4 sample;for #1-#3 samples,as the first quenching temperature in the double quenching and tempering processes decreases,the yield strength and tensile strength also have a certain downward trend.

Fig.1 Room temperature strength and 650 ℃ strength for different quenching and tempering processes

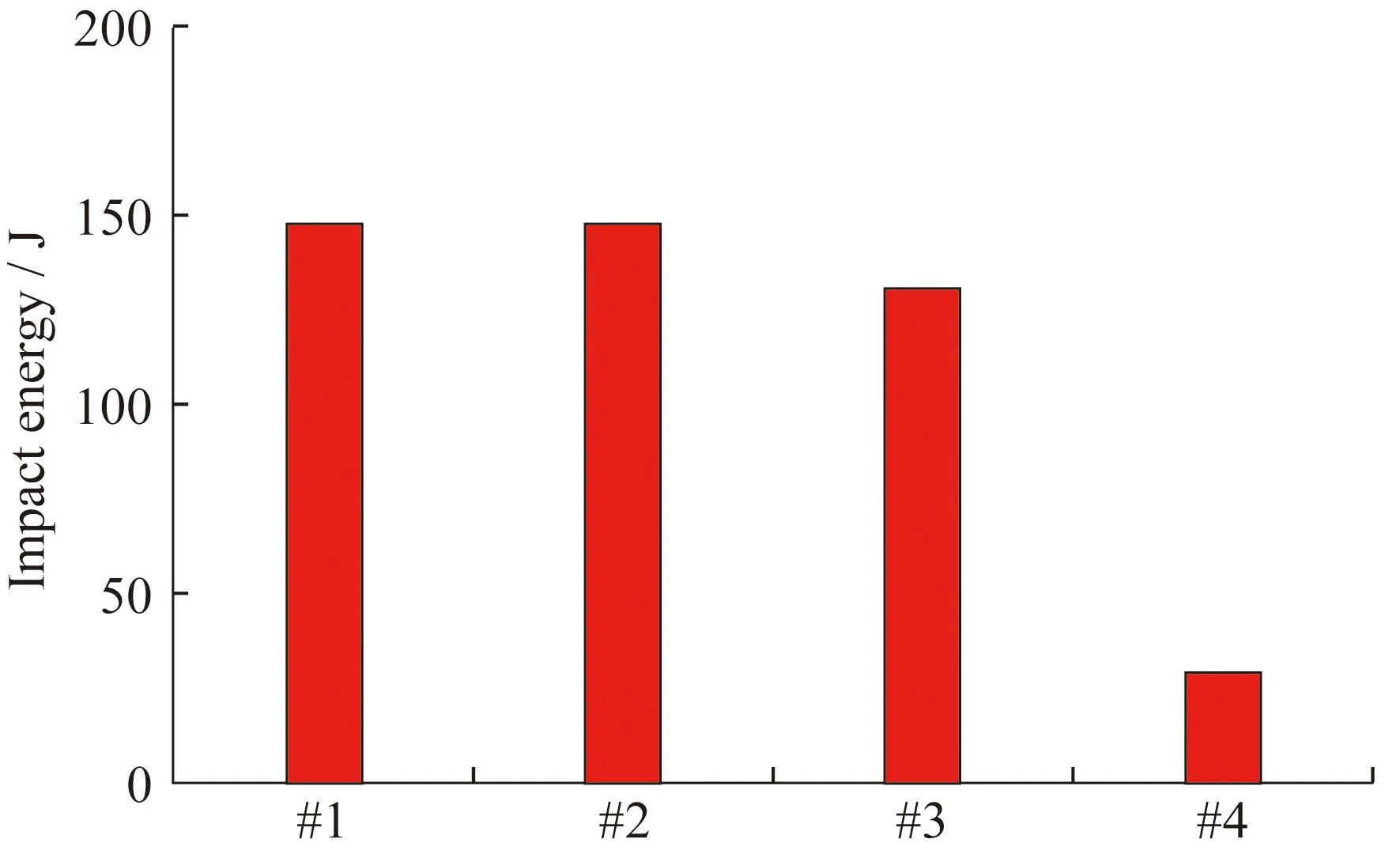

Fig.2 depicts the effect of different quenching and tempering processes on the average value of the impact energy at room temperature.The impact energy of the double quenching and tempering pro-cesses (#1-#3) is more than 100 J higher than that of the single quenching and tempering pro-cesses (#4);the impact energy of the #1 and #2 processes is equivalent,but when the first quenching temperature of the #3 process decreases to 1 050 ℃,the impact energy begins to decrease to some extent.From the effect of the quenching and tempering pro-cesses on the performance of G115,it can be inferred that the impact energy of G115 can be considerably improved by double quenching and tempering processes,and the strength at room temperature and high tem-perature can be improved to a certain extent,which is of great importance to the engineering application of G115 steel.Furthermore,increasing the first quenching temperature in the double quenching and tempering processes improves G115 performance.

3.2 Influence of quenching and tempering processes on microstructure

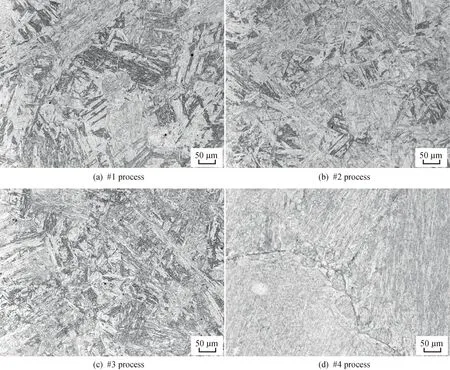

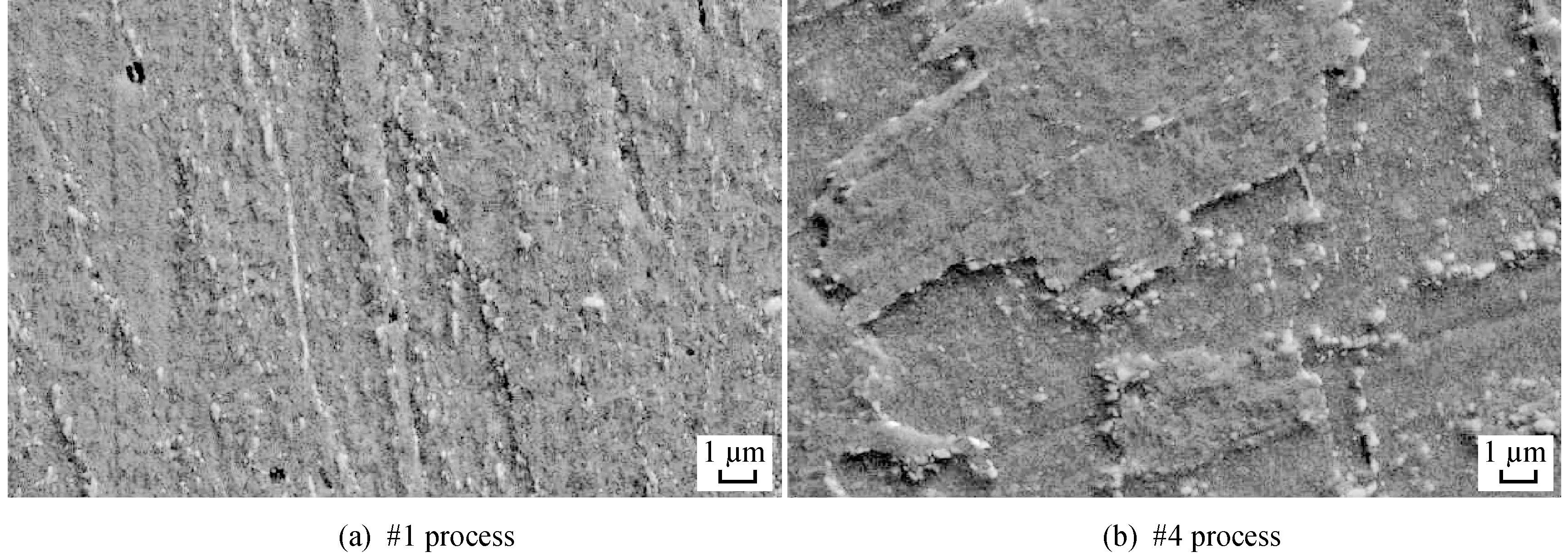

Fig.3 depicts the metallographic structure asso-ciated with various quenching and tempering pro-cesses.It is observed that the grain size of the double quenched and tempered samples (#1-#3) is con-siderably smaller than that of the single quenching and tempering processes (#4),and the retention of the tempered lath structure is more visible than that of the single quenching and tempering processes.Furthermore,the morphology of carbides and other precipitation phases using double quenching and tempering processes is smaller than that of single quenching and tempering processes,and the distri-bution is more dispersed,as depicted in Fig.4.Com-paring #1-#3,the grain size of #1 is slightly larger than that of #2 and #3,but the uniformity is better.The first high-temperature quenching treatment pro-motes the dissolution of large carbide precipitates as well as the homogenization of alloy elements.Further-more,during the first tempering treatment,fine and dispersed carbides can precipitate,providing a good microstructure for the second quenching and tem-pering treatment.As a result,there are more austeni-tizing nucleation sites during the second quenching and tempering,and the fine and dispersed carbides can pin the grain boundaries and obstruct the austenite formation.Grain growth and the martensite recovery process result in significant grain refinement and more obvious retention of tempered martensitic laths after double quenching and tempering.This is likely why the performance of double quenching and tempering processes (#1-#3) is superior to that of single quenching and tempering processes (#4).In the double quenching and tempering processes,the higher the temperature of the first high-temperature quench-ing treatment,the more adequate the dissolution of the precipitation phase and the higher the degree of homogenization of the alloy elements.

Fig.2 Impact energy of different quenching and tempering processes

Fig.3 Metallographic structure of different quenching and tempering processes

Fig.4 Precipitation morphology of different quenching and tempering processes

4 Conclusions

(1) The yield strength,tensile strength,and impact energy were improved using double quenching and tempering processes,with impact energy being especially significant.As the first quenching temperature of the double quenching and tempering processes rises,properties such as strength and impact energy tend to improve.

(2) The grain size of the double quenched and tempered samples is significantly smaller than that of the single quenched and tempered sample,and the structure of the tempered lath is more visible,with a finer morphology and more dispersed distribution of carbide and other precipitates.

Baosteel Technical Research2023年4期

Baosteel Technical Research2023年4期

- Baosteel Technical Research的其它文章

- Failure analysis of the needle valve body of R18CrNi8 steel

- Research progress on protective coatings against molten nitrate salts for thermal energy storage in concentrating solar power plants

- Study on gas metal arc welding of two types of TMCP steels

- Accuracy analysis of iron content of galvanized coating using an X-rayfluorescence spectrometer with an L-spectrum

- Effect of lump ore ratio on the metallurgical properties of blast furnace charge

- List of winners of excellent papers of Baosteel TechnicalResearch in 2023