Optimization of Extraction Process of Polyphenols from Chrysanthemum morifolium and the Development of Chrysanthemum Rice Wine

Weiyi CHEN Yufeng ZHANG Zoukai HUANG Ruyi ZHENG Caiyun HUANG Xunjian CHEN Yuhan FU Weixin WANG

Abstract[Objectives] This study was conducted to provide a theoretical basis for the extraction and comprehensive utilization of functional active components of Chrysanthemum morifolium polyphenols. [Methods] With C. morifolium as a raw material, polyphenols were extracted by water extraction. The extraction process of polyphenols were optimized by single factor tests on solid-liquid ratio, extracting time and times. Old rice wine selected as the base wine was added with C. morifolium polyphenol extract, honey, citric acid and other auxiliary materials to prepare a kind of chrysanthemum old rice wine. Through sensory analysis combined with fuzzy mathematics comprehensive evaluation method, the optimal formula of chrysanthemum old rice wine was determined, and the corresponding physicochemical indicators of the obtained chrysanthemum old rice wine were tested. [Results] The optimal soaking process for C. morifolium was as follows: extraction time of 20 min, a solid-liquid ratio of C. morifolium to warm water at 1:40, extraction times of 3 times. The physical and chemical indicators of the chrysanthemum wine obtained from the above optimal formula were as follows: sugar content 5%, ethanol content 11%, and pH value 4.04. The chrysanthemum old rice wine obtained was clear and transparent, and the fragrance of chrysanthemum was coordinated with the mellow aroma of rice wine. The taste was refreshing and suitable for the vast majority of people to drink. [Conclusions] The new type of chrysanthemum old rice wine combines the polyphenolic active substances in C. morifolium with the low ethanol content of old rice wine, which not only improves the utilization rate of C. morifolium, but also strengthens the health function of old rice wine products, improves the quality of old rice wine, and promotes the healthy and rapid development of the old rice wine industry.

Key wordsPolyphenol; Chrysanthemum morifolium; Forest phenol; Fuzzy mathematic analysis; Chrysanthemum old rice wine

DOI:10.19759/j.cnki.2164-4993.2023.05.015

Chrysanthemum morifolium is a white chrysanthemum produced in the northern mountainous area of Macheng City, Hubei Province, centered around Futianhe Town. It is one of the national geographical indication agricultural products[1]. In recent years, the extraction of functional active substances from chrysanthemums has received widespread attention, but there has been little research on the functional active substances in C. morifolium. The main active ingredients of chrysanthemums are flavonoids and phenolic compounds[2], which have certain pharmacological functions such as antioxidation and anti-aging, and are widely used in the production of food, tea, and pharmaceutical products[3-4].

Plant polyphenols have always been a hot research topic. The separation and extraction process of polyphenols has been continuously optimized, and the output of polyphenols has been greatly improved[5]. In addition to traditional solvent extraction methods, there are also various new extraction methods such as microwave extraction, supercritical fluid extraction, enzymatic hydrolysis, and microbial fermentation[6]. Gong et al.[7] used the ethanol extraction method to optimize the extraction of polyphenols from chrysanthemums. Under the optimal process conditions, the extraction rate of polyphenols was 7.82%. Fu[8] used the enzyme-assisted salting-out extraction to extract phenolic substances from Tagetes erecta, and the recovery of polyphenols reached 95.45% under the optimal conditions. The development of these new techniques has provided convenience for the extraction of plant polyphenols, but their high production costs are not suitable for industrial production. On the contrary, traditional solvent extraction methods, especially when using water as a solvent, have the advantages of simplicity, low cost, and no residual risk, making them more suitable for large-scale extraction. Therefore, in this study, the water extraction method was adopted to extract polyphenols from C. morifolium, aiming to provide a theoretical basis for the extraction and comprehensive utilization of functional active ingredients in chrysanthemums.

Dew wine can be produced using plant polyphenol extracts as a raw material and distilled liquor, fermented liquor or edible alcohol as a base material by blending and mixing the two and reprocessing[9]. Song et al.[10] co-fermented chrysanthemum extract with barley juice and developed a fermented chrysanthemum beer with high market value. Zhang et al.[11] developed a healthy chrysanthemum glutinous rice wine by blending fermented glutinous rice wine and chrysanthemum as raw materials. In this study, C. morifolium and old rice wine from Macheng Muzi Store were selected as raw materials to develop a formulated chrysanthemum old rice wine. The new type of chrysanthemum old rice wine combines the polyphenolic active substances in C. morifolium with the low ethanol content of old rice wine, which not only improves the utilization rate of C. morifolium, but also strengthens the health function of old rice wine products, improves the quality of old rice wine, and promotes the healthy and rapid development of the old rice wine industry[12]. Today, with the rapid development of science and technology, low ethanol content and health benefits have created the marketing of dew wine, which is in line with modern peoples living standards and health concepts.

Materials and Methods

Materials and reagents

C. morifolium: Macheng City, Hubei Province; old rice wine: Macheng Muzi Store in Huanggang City; Anhydrous ethanol (analytical pure): Hubei Xin Runde Chemical Industry Co., Ltd.; Folin-Ciocalteu reagent (biochemical reagent): Dingrui Chemical; gallic acid (analytical pure): Shaanxi snuote Bio-tech Co., Ltd; anhydrous sodium carbonate (analytical pure): Wuhan Geeyeschem Chemical Co., Ltd.

Instrument and equipment

YP1201N electronic balance: Shanghai Sunny Hengping Instrument Co., Ltd; SP-723 visible spectrophotometer: Shanghai Spectrum Instruments Co., Ltd; pH-280 pen type pH meter; WZS handheld refractometer; LH-J80 alcohol content refractometer; round-bottom flask; distillation flask; condensing pipes.

Experimental methods

Establishment of polyphenol standard curve

The methods of Wang[13] and Sun et al.[14] were adopted while making appropriate modifications. In specific, 0.25 g of gallic acid was weighed, and added with water and diluted to a constant volume of 50 ml to obtain a mother solution. Next, 0.0, 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5 and 4.0 ml of the mother solution were added into 50 ml volumetric flasks, and diluted into a series of solutions with different concentrations. Next, 0.1 ml of each solution was added into a 100 ml volumetric flask, which was then added with 2.5 ml of folin-phenol reagent, and the obtained solutions were mixed well. And 4 min later, 2 ml of 75 g/L Na2CO3 was added, and the solutions were stood at room temperature for 2 h. The absorbance was measured at 760 nm.

Determination of total polyphenols and calculation of recovery

First, 10 g of chrysanthemum was weighed, and added with 75% ethanol in a 500 ml round-bottom bottle at a ratio of 1:30 (g/ml). After refluxing in a water bath at 70 ℃ for 1 h, the mixture was filtered to obtain a filtrate. The absorbance was measured according to the above method. The extraction rate was calculated based on the regression equation.

Extraction rate of polyphenols (calculated by gallic acid) (μg/g)=[(C×V/M)/1000]×100%

In the formula, C is the mass concentration of polyphenols, μg/ml; V is the total volume of polyphenol extraction solution, ml; and M is the weight of chrysanthemums, g.

Recovery (μg/g)= Extraction rate of polyphenols/Total polyphenol content in chrysanthemums.

Extraction process of polyphenols from C. morifolium

Chrysanthemums were extracted by steps of weighing, soaking in warm water (100 ℃), filtering to obtain filtrate, measuring absorbance, calculating extraction rate (based on gallic acid), and converting to recovery.

Single-factor and orthogonal experiments

The effects of three single factors, namely the solid-liquid ratio of C. morifolium to warm water, extracting times and time, on the recovery of C. morifolium polyphenols were studied. The solid-liquid ratios were taken as 1:10, 1:20, 1:30, 1:40, and 1:50 (g/ml); the extracting times were 1, 3, 4, and 5 (times); and the extraction time was taken as 5, 10, 15, 20, and 25 (min). Based on the optimal values of single-factor experiments, an orthogonal experiment was conducted to determine the optimal extraction process by determining the recovery value.

Development of chrysanthemum old rice wine

The chrysanthemum tea obtained through the above optimal extraction process and the base liquor of old rice wine were blended, and the blending ratios of chrysanthemum tea and old rice wine were 30:70, 40:60, 50:50, 60:40, and 70:30, respectively. In order to improve the taste, 2 g of honey and 2 g of citric acid were added to each group of chrysanthemum old rice wine during the preparation process to adjust the flavor and make its taste more mild[15]. After mixing, the chrysanthemum old rice wine was pasteurized at 63 ℃ for 30 min and naturally cooled to room temperature.

Ten trained students in food major (5 women and 5 men) with a foundation in sensory evaluation were selected. The sensory evaluation group evaluated and scored the blended chrysanthemum old rice wine from four aspects: color, smell, taste, and tissue status[16], and referring to the fuzzy mathematical comprehensive analysis method proposed by Liu et al.[17] and Gao[18], appropriate modifications were made to determine the optimal taste of chrysanthemum old rice wine. Corresponding physicochemical index tests were performed on the chrysanthemum old rice wine obtained from the optimal formula. A pH 280 pen type pH meter and a WZS handheld refractometer were used to measure its pH value and sugar content, respectively. According to GB 5009 225-2016 Determination of Ethanol Concentration in Liquor[19], the chrysanthemum old rice wine were distilled and cooled to collect the distillate, which was measured for ethanol content using an LH-J80 alcohol refractometer. The obtained physical and chemical indicators were recorded and collated.

Referring to the sensory requirements in GB/T 27588-2011 Lu Jiu[20], a sensory rating standard for chrysanthemum old rice wine were developed with appropriate modifications, as shown in Table 1.

Results and Analysis

Drawing of standard curve

The standard curve was drawn with the concentration of gallic acid standard as the x-axis and the absorbance A at the wavelength of 760 nm as the y-axis (Y), as shown in Fig. 1.

According to the standard curve of gallic acid, the linear regression equation could be obtained as: y=0.000 4x-0.001 6; R2=0.998 9. According to the standard curve of gallic acid, there was a good linear relationship when its mass concentration was between 50 and 300 μg/ml.

Determination of total polyphenols and calculation of recovery

According to the absorbance value measured by water bath refluxing, it was substituted into the standard curve for calculation accordingly. It could be concluded that the total polyphenol content in chrysanthemums was 25.68 mg/g. Compared with the total polyphenol content in other varieties of chrysanthemums, Zhang et al.[21] selected two representative types of chrysanthemums, Hangzhou white chrysanthemum and Huai chrysanthemum, and analyzed their total polyphenol contents using colorimetry. The final results showed that the total polyphenol contents of the two chrysanthemum varieties were 25.80 and 39.80 mg/g, respectively. Dong et al.[22] extracted polyphenols from wild chrysanthemums using ethanol. When the ethanol concentration was 80%, the total polyphenol content in wild chrysanthemums was the highest, reaching 7.83 mg/g. Xue et al.[23] used thermal reflux to extract total polyphenols from Tagetes erecta. Under the optimal solid-liquid ratio of 1:20, the total polyphenol content in T. erecta was 43.74 mg/g. The extraction and determination methods for total polyphenols are similar, but for different chrysanthemums, the content of total polyphenols varies greatly. The reason for this may be due to different polyphenol contents of different raw materials.

Agricultural Biotechnology2023

Analysis of single-factor experiments

Effects of solid-liquid ratio on recovery of polyphenols

The effects of solid-liquid ratio on polyphenol recovery were investigated using solid-liquid ratio as the x-axis and recovery of polyphenols in chrysanthemum as the y-axis (Y).

As shown in Fig. as the solid-liquid ratio continued to increase, the recovery of polyphenols in C. morifolium also increased. However, when the solid-liquid ratio was 1:40, the growth became slow and even remained almost unchanged. The reason for changes in the curve was that when the amount of C. morifolium was fixed, increasing the amount of warm water would also reduce the concentration of polyphenols in C. morifolium, which was conducive to the dissolution of polyphenols[24]. Therefore, it could be concluded that the suitable solid-liquid ratio for C. morifolium extraction was 1:40. In practical life, when soaking chrysanthemums in warm water, the solid-liquid ratio could be appropriately increased, but the ratio should not be increased too much, because doing so not only does not increase the content of polyphenols in chrysanthemums, but also cause waste of water resources[13].

Effect of extracting times on recovery of polyphenols

The effects of extracting times on polyphenol recovery were investigated using extracting times as the x-axis and polyphenol recovery in chrysanthemums as the y-axis, as shown in Fig. 3.

It can be seen from Fig. 3 that with the extraction times of C. morifolium increasing, the polyphenol recovery gradually increased. The growth rate of the curve gradually slowed down after 4 times of extraction, which might be due to that excessive extraction times led to a decrease in concentration, and some chrysanthemums would be lost during each extraction process, ultimately leading to the growth rate getting slow gradually. Therefore, the appropriate extraction times were set to 4.

Effects of extracting time on polyphenol recovery

The effects of extracting time on polyphenol recovery were investigated using extracting time as the x-axis and polyphenol recovery in chrysanthemums as the y-axis, as shown in Fig. 4.

As shown in Fig. 4, as the extracting time of C. morifolium increased, its polyphenol recovery gradually increased. However, when the extracting time was 15 min, the growth rate of the curve was almost 0 and tended to be stabile. Therefore, 15 min was set as the suitable extracting time for C. morifolium.

Orthogonal experimental analysis of polyphenol extraction

Based on the results of the three single-factor experiments mentioned above, an orthogonal factor level table (Table 2) could be obtained. The L9(34) orthogonal table was used for orthogonal experiments, as shown in Table 3.

According to the results of the orthogonal experiment in Table 3, factors that affected the recovery of polyphenols in C. morifolium were: A (extracting time)>C (solid-liquid ratio)>B (extracting times). The optimal extraction process for C. morifolium polyphenols was A3C3B1, that is, extracting time of 20 min, a solid-liquid ratio of C. morifolium to warm water at 1:50, and extraction times of 3. Under these conditions, the polyphenols in C. morifolium were extracted and the recovery of polyphenols was calculated to be 57.12%, which was still relatively low. Xue et al.[23] used three different methods (thermal reflux extraction, ultrasonic assisted extraction, and microwave extraction) to extract polyphenols from T. erecta, and calculated the recovery of polyphenols under the optimal solid-liquid ratio. Ultimately, the recovery of polyphenols in T. erecta was all over 90%. The low recovery might be due to limited extraction of chrysanthemums by water extraction method, which could not make polyphenols completely dissolve. In addition, different varieties of chrysanthemums and experimental procedures also have a certain impact on the recovery of polyphenols. Therefore, multiple extraction methods can be adopted simultaneously during the experimental process to fully dissolve polyphenol substances in chrysanthemums.

Development results and analysis of chrysanthemum old rice wine

Determination of the optimal blending ratio for chrysanthemum old rice wine

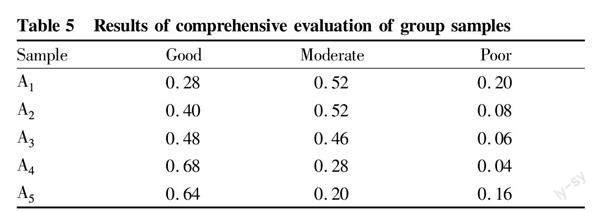

Five groups of samples were numbered in sequence, and members of the sensory evaluation group evaluated them one by one. The results are shown in Table 4, where the values represent the number of people for corresponding level.

Each number was divided by 10, and the fuzzy mathematics comprehensive evaluation method was used for analysis to obtain five sets of fuzzy matrixes for samples. The results were as follows:

R1=0.30.30.40.60.30.10.10.80.10.30.40.3; R2=0.50.40.10.60.20.20.20.800.50.40.1;

R3=0.60.30.10.50.500.40.600.50.30.2; R4=0.80.200.40.50.10.80.200.60.30.1;

R5=0.90.100.30.30.40.70.20.10.60.20.2

The comprehensive evaluation of sample 1 was: A1=(0.20.20.40.2)×R1=(0.280.520.20); Similarly, it could be obtained that A2=(0.400.520.08), A3=(0.480.460.06), A4=(0.680.280.04), and A5=(0.640.200.16). The results were filled in Table 5 in order.

After calculation, five sets of results were obtained, and assigned based on the principle of weighted average with corresponding values (B1=3; B2=2; B3=1). The values of each group were averaged, and the obtained results were sorted and analyzed.

The average values of the five groups of samples ranked as group 4 (2.64)>group 5 (2.48)>group 3 (2.42)>group 2 (2.32)>group 1 (2.08), that is, when the blending ratio of chrysanthemum tea to old rice wine was 60:40, the sensory score was the highest. The peak value of group 4 was the highest (0.68). Therefore, the optimal blending ratio of chrysanthemum old rice wine was determined to be 60:40.

Analysis of physical and chemical experiments

The chrysanthemum old rice wine obtained from the above optimal formula was tested for its corresponding physical and chemical indicators, and the results were as follows: sugar content 5%, ethanol content 11%, and pH value 4.04. The chrysanthemum old rice wine presented in the end was clear and transparent, and the fragrance of chrysanthemums was coordinated with the mellow aroma of rice wine. The taste was refreshing and suitable for the vast majority of people to drink.

Conclusions and Discussion

In this study, the folin-phenol reagent method was adopted to extract polyphenol compounds from C. morifolium, and an orthogonal experiment was then determined using three single factors. Finally, the primary and secondary factors that affected the recovery of polyphenols in C. morifolium were obtained as A (extraction time)>C (solid-liquid ratio)>B (extraction times). It could be determined that the optimal soaking process for C. morifolium was as follows: extraction time of 20 min, a solid-liquid ratio of C. morifolium to warm water at 1:40, extraction times of 3 times, under which the polyphenols in C. morifolium were extracted with a recovery value calculated to be 65.12%.

With old rice wine as the base wine, a polyphenol extract of C. morifolium and corresponding auxiliary materials were added for blending, and the optimal ratio of chrysanthemum wine was obtained as 60:40. Meanwhile, the physical and chemical indicators of the chrysanthemum wine obtained from the above optimal formula were as follows: sugar content 5%, ethanol content 11%, and pH value 4.04. The chrysanthemum old rice wine obtained was clear and transparent, and the fragrance of chrysanthemums was coordinated with the mellow aroma of rice wine. The taste was refreshing and suitable for the vast majority of people to drink.

References

[1] XU L, CHEN KL. Main problems and exploration in the production of Chrysanthemum morifolium in Hubei Province[J]. Research and Practice on Chinese Medicines, 2013, 27(2): 3-5. (in Chinese).

[2] WANG TT, WANG SK, HUANG GL, et al. Bioactive component content and antioxidant activity of chrysanthemum flower (Chrysanthemum morifolium Ramat) extract[J]. Food Science, 2013, 34(15): 95-99. (in Chinese).

[3] WANG F. Research progress on chemical constituents of chrysanthemums[J]. China New Medicine Forum, 2008, 8(3): 23-24. (in Chinese).

[4] QU L, WANG T, DONG YZ, et al. Research progress on chemical constituents of Chrysanthemum morifoliuin and their pharmacologic activities[J]. Drug Evaluation Research, 2015, 38(1): 98-104. (in Chinese).

[5] XIN T, ZHANG RF, DENG YY, et al. Separation and purification of polyphenols in rice bran by macroporous resins[J]. Scientia Agricultura Sinica, 2016, 49(19): 3818-3830.

[6] YUAN FH, ZHAO LL, PANG JL. Study on extraction, separation and antioxidant activity of phlorotannins[J]. Food Research and Development, 2019, 40(18): 219-224. (in Chinese).

[7] GONG JH, GE Q, CHEN LC, et al. Optimization of extraction process for polyphenols from Chrysanthemum morifolium[J]. Food Science and Technology, 2013, 38(10): 224-227. (in Chinese).

[8] FU XQ. Enzyme-assisted salting-out extraction of lutein and phenolic compounds from Tagetes erecta L.[D]. Xinjiang: Shihezi University, 2019. (in Chinese).

[9] OU Z. Research status and prospect analysis of Lu Jiu at home and abroad[J]. Modern Food, 2019, 20(14): 46-49. (in Chinese).

[10] SONG R, WANG ST. Study on the application of chrysanthemum extract in beer fermentation[J]. Chemical Research, 2018, 29(4): 411-414. (in Chinese).

[11] ZHANG SL, LI XG. Development of chrysanthemum glutinous rice wine [J]. The Beverage Industry, 2008, 11(1): 30-32. (in Chinese).

[12] WANG BB, WANG Q, LYU P. Questionnaire survey and analysis on the development status of old rice wine in Muzidian, Macheng, Hubei Province[J]. Journal of Huanggang Normal University, 2011, 31(1): 57-60. (in Chinese).

[13] WANG M, TIAN ZY, WANG WX. Study on the extraction and antioxidant function of chestnut shell polyphenols[J]. Food Research and Development, 2018, 39(22): 66-72. (in Chinese).

[14] SUN ZY, CHEN SY, CHEN YX, et al. Optimization of horseradish tree leaves polyphenols extraction and research of its antibacterial properties[J]. The Food Industry, 2018, 39(05): 70-74. (in Chinese).

[15] WANG YF, MAO ZH, CHEN MB, et al. Preliminary study on the influence of different raw material ratios on the quality of old rice wine[J]. Liquor Making, 2019, 46(01): 51-54. (in Chinese). (in Chinese).

[16] ZHU J, LYU FF. Development of study on sensory evaluation in food[J]. China Condiment, 2009, 4(5): 29-49. (in Chinese). (in Chinese).

[17] LIU Y, JIA ZL, LI QM, et al. Optimization of matcha milk beverage formula[J]. Science and Technology of Food Industry, 2019, 40(14): 100-107. (in Chinese).

[18] GAO W. Production technology of the honey-chrysanthemum liquor[D]. Sichuan: Sichuan Agricultural University, 2016. (in Chinese).

[19] GB 5009 225-2016 National food safety standard: Determination of ethanol concentration in liquor[S]. (in Chinese).

[20] GB/T 27588-2011. Lu Jiu [S]. Beijing: Standards Press of China, 2011. (in Chinese).

[21] ZHANG JY, JIANG HY, YUAN XY, et al. Content analysis of the flavonoids, polyphenols and water-extracts in chrysanthemum[J]. Chinese Agricultural Science Bulletin, 2010, 26(9): 102-105. (in Chinese).

[22] DONG J, ZHANG HC, QIN J, et al. Determination of total polyphenols and flavonoids in ten bee pollen extracts[J]. Food Science, 2008, 29(12): 246-249. (in Chinese).

[23] XUE HK, DAI N, TAN JQ, et al. Extraction kinetic modelling of total polyphenols and total anthocyanins from marigold flowers: Comparison of extraction methods[J]. Food Research and Development, 2020, 3(15): 18-24. (in Chinese).

[24] SUN HY, HU KZ, GUO ZL, et al. Industrial optimization and antibacterial activity study on ultrasonic extraction of polyphenols from Rosa roxburghii[J]. China Food Additives, 2016, 10(2): 57-64. (in Chinese).

Editor: Yingzhi GUANGProofreader: Xinxiu ZHU

Received: June 18, 2023Accepted: August 20, 2023

Weiyi CHEN (2003-), female, P. R. China, major: development and utilization of natural products.

*Corresponding author. Weixin WANG (1976-), female, P. R. China, associate professor, PhD, devoted to research about development and utilization of natural products.

- 农业生物技术(英文版)的其它文章

- Effects of Seed Dressing with Microbial Inoculum on Nutrient Composition and Biological Yield of Silage Corn

- Study on Factors Affecting Aerobial Plate Count in Raw Milk

- Discussion on the Main Reasons for a Large Number of Père David’s Deer (Elaphurus davidianus) with Abnormal Antler Shedding

- Role and Effects of Eucommia ulmoides Leaves in the Growth Process of Livestock and Poultry

- A Study on the Interest Linkage Mechanism of the Taxus Industry Chain in Pengshui Miao and Tujia Autonomous County

- Therapeutic Effect and Mechanism of Jipei Dilong Ointment on Acute Soft Tissue Injury in Rats