Study on Factors Affecting Aerobial Plate Count in Raw Milk

Luman HUO Yi LI Baiqin ZHENG Aijun LI Yanhui PAN Wang SONG Yunfei LIU Miaoyi ZHANG Xujian ZHENG

Abstract[Objectives] This study was conducted to investigate the main factors affecting the aerobial plate count in raw milk. [Methods] Drinking water, medicated baths and raw milk under different storage and transportation conditions were detected for the values of aerobial plate count to analyze their effects on the aerobial plate count in raw milk. [Results] Disinfection of drinking water tanks could significantly reduce the aerobial plate count in water. The use of medicated baths before and after milking could effectively reduce the aerobial plate count and had a significant bactericidal effect. The growth of microorganisms in raw milk stored below 4 ℃ was relatively slow. Regularly disinfecting drinking water tanks and disinfecting nipples before and after milking could reduce the aerobial plate count in the tanks and nipples. After raw milk was extruded, the temperature should decrease to 0-4 ℃ within 2 h, and the storage time should not exceed 48 h, which could effectively control the aerobial plate count in raw milk. [Conclusions] This study provides a reference for scientific control of the aerobial plate count in raw milk.

Key wordsRaw milk; Aerobial plate count; Drinking water; Medicated bath; Temperature

DOI:10.19759/j.cnki.2164-4993.2023.05.011

The aerobial plate count is an important indicator reflecting the health status of cows, pasture hygiene, and quality control of cold chain transportation during the production process of raw milk. Meanwhile, the aerobial plate count is also an important risk factor affecting food safety. If the aerobial plate count in raw milk exceeds the standard, it will damage the nutritional components of raw milk, accelerate spoilage, and make people prone to intestinal diseases after consumption, causing symptoms such as vomiting and diarrhea[1-3]. Countries around the world strictly control the aerobial plate count, and many countries even grade raw milk based on the main indicator of aerobial plate count and purchase it based on quality. Chinas standard GB 19301-2010 National Food Safety Standard: Raw Milk stipulates that the maximum number of colonies is 2×106 CFU/ml[4]. However, from the monitoring results of the aerobial plate count in raw milk in recent years, the aerobial plate count in raw milk varies greatly. Among the 1 638 batches of samples verified by our project team, 5.9% exceeded the limit, and the aerobial plate count in some areas still exceeded the standard, which poses certain risks. In order to control the aerobial plate count in raw milk, it is necessary to explore main factors affecting the aerobial plate count in raw milk. Research has found that the main influencing factors on the aerobial plate count in raw milk include the feeding process (feed, water, environmental hygiene, and cow health), milking process (methods and equipment), storage and transportation process (temperature and time), etc. In this study, the three stages of drinking water, milking, and storage and transportation were preliminarily explored, and the changes in the aerobial plate count in corresponding stages were detected under different conditions, providing reference for further controlling the aerobial plate count in raw milk.

Materials and Methods

Sample collection

Experimental location

The experimental dairy farm was a large-scale dairy farm in Hebei Province. Three types of samples were collected in the experiment, including drinking water, location around cows breasts, and raw milk.

Sampling of drinking water

Completely randomized experimental design was adopted, and a control group and an experimental group were set up. The water tank in the control group was not disinfected, and the water tank in the experimental group was disinfected with 0.1% povidone iodine. The disinfection method was spray disinfection, and the disinfection time was 3 min. After disinfection, drinking water was injected, and water samples were taken for testing after standing for 5 min. The method referred to the national standard GB/T 5750.12-2006[5].

Sampling around cows breasts

Twenty-four healthy China Holstein cows with similar parity (2 or 3 parity), milk yield (30-35 kg) and milk production days (80-120 d) were selected. Completely randomized experimental design was adopted, and a control group and an experimental group were set up. The control group was treated with iodine-free medicinal bath solution, while the experimental group was treated with 1.0% povidone iodine. The medicinal bath method included the steps of washing twice with warm water before milking, wiping dry with a disposable paper towel, immediately soaking the nipple in a medication bath cup for 10 s, and wiping dry with a disposable paper towel, and soaking the nipple in a medication bath cup for 10 s after milking.

After washing and drying the breasts of each cow with water, sampling was performed once, and another sample was then taken after giving a medicated bath and drying. Four samples were taken from each cow, one at the left front, one at the right front, one at the left rear, and one at the right rear nipple opening. A sterile test tube containing 10 ml of sterile physiological saline was taken, and a sterile cotton swab was dipped in the physiological saline, used for taking samples at the predetermined location, and placed in the test tube, which was then stored at a low temperature. The detection indicator was the aerobial plate count, and the method referred to the national standard GB 4789.2-2022[6].

Sampling of raw milk

After disinfecting milk cows breasts and wearing sterilized gloves, milk was extruded manually. The first three handfuls of milk from each milk chamber were discarded, and a sterilized 200 ml sampling bottle was used to collect a milk sample. Next, the bottle mouth was quickly disinfected on an alcohol lamp, followed by tightening the cover. A total of 14 samples were collected. Seven portions of raw milk were extruded and cooled to 4 ℃ for testing at 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, and 4.0 h, respectively. The remaining 7 portions of raw milk were extruded and kept at 4 ℃ for 2, 6, 12, 24, 48, 72, and 96 h before testing. The detection indicator was the aerobial plate count, and the method referred to the national standard GB 4789.2-2022.

Data statistics and analysis

Excel was used for preliminary statistical organization of the data, SPSS 19.0 for one-way analysis of variance, and LSD method for multiple comparisons. The results were expressed as "mean±standard deviation", with the significance level P<0.01 standing for that the difference was extremely significant, and P<0.05 standing for that the difference was significant.

Results and Analysis

Analysis of changes in aerobial plate count in drinking water

As can be seen from Table 1, the aerobial plate count in drinking water in the control group was 7 500 CFU/ml without disinfection, while that in drinking water in the experimental group was 1 400 CFU/ml with 0.1% povidone iodine disinfection. The difference between the control group and the experimental group was extremely significant (P<0.01).

Analysis of changes in aerobial plate count of dairy cows breasts before and after medicated bath

From Table 2, it can be seen that there was a significant change in the aerobial plate count before and after the use of the medicinal bath solution. The value in the control group decreased from 7 600 CFU/cm2 before medication to 1 600 CFU/cm2 after medication, achieving a bactericidal effect of 78.9%. The experimental group decreased from 7 100 CFU/cm2 before medication to 700 CFU/cm2 after medication, achieving a bactericidal effect of 90.1%.

Analysis of changes in aerobial plate count of the same raw milk cooled to 4 ℃ at different time

Table 3 shows that the aerobial plate count in the same raw milk had no significant difference from its initial aerobial plate count within 2 h (P>0.05). After 2 h, the aerobial plate count increased significantly (P<0.01), and there was a trend of increasing with time. After raw milk was extruded, the temperature should be decreased to 0-4 ℃ within 2 h, and the temperature should not exceed 4 ℃ during storage.

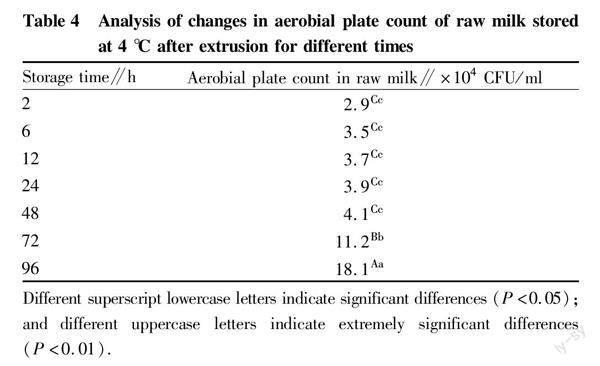

Analysis of changes in aerobial plate count of the same raw milk stored at the same temperature for different time

As can be seen from Table 4, compared with the initial aerobial plate count, no significant difference was found in raw milk stored at 4 ℃ for 48 h after extrusion (P>0.05). However, the aerobial plate count tended to increase with time, and the aerobial plate count increased significantly after 48 h (P<0.01).

Discussion and Conclusions

The microbial content in raw milk has a significant impact on the quality of both raw and commercial milk. Exploring the main factors affecting the aerobial plate count, strengthening monitoring of the aerobial plate count in raw milk and effectively controlling the aerobial plate count in raw milk are very important for producing high-quality dairy products[7]. The results of this study indicated that using disinfectants to disinfect drinking water tanks could significantly reduce the aerobial plate count in the water. Therefore, the water quality should comply with relevant national standards, and drinking water facilities such as water tanks (pools) should be cleaned and disinfected on time to avoid bacterial growth. There are many factors that affect the aerobial plate count in raw milk, among which the most concerned are the milking process, the hygiene of milking equipment, and the degree of disinfection[8]. Piepers et al.[9] analyzed the aerobial plate count in raw milk from 254 dairy farms in Belgium and their related factors, and found that there was a significant correlation between the aerobial plate count in raw milk and milking methods, farm farming level, and management level of cows in the dry period. It means that in actual production, appropriate production management methods can be adopted to control the aerobial plate count in raw milk, ensuring the microorganism quality and safety of raw milk. The use of medicated baths before and after milking can effectively reduce the aerobial plate count and have a significant bactericidal effect. Therefore, it is recommended to take a medicated bath on the nipples of cows before milking, and each cow should be wiped dry with a clean disinfected towel or multiple disposable tissues. During the milking process, if the milk cup falls out, it should be cleaned in a timely manner, and only after being clean and hygienic can the cup be filled. After milking, the nipples of cows should undergo a medicated bath after milking, and a medicinal bath solution that can form a protective film should be selected. To avoid contaminating raw milk with the first three handfuls of milk, the first three handfuls of milk should be discarded. In the storage process of raw milk, temperature management is a key factor in ensuring milk quality. Meng et al.[10] has shown through research that raw milk had a 2-hour antibacterial period at various temperatures (below 40 ℃). After extruding raw milk, as long as it falls to 4-6 ℃ during the antibacterial period and is stored at 4-6 ℃ for 24 h, it has little impact on its quality. Shi et al.[11] found that the aerobial plate count in fresh milk stored at 4 ℃ did not grow within 18 h. It indicates that 4 ℃ is an ideal storage temperature for milk, which can ensure that the aerobial plate count in milk does not increase for a considerable period of time. The result of this study showed that when raw milk was stored below 4 ℃, the growth of microorganisms was relatively slow. Therefore, after raw milk was extruded, the temperature should be reduced to 0-4 ℃ within 2 h, and the storage time should not exceed 48 h, which could effectively control the aerobial plate count in raw milk.

References

[1] SI BX, ZHANG YD, ZHENG N, et al. Research progress on freshness evaluation indices of raw milk[J]. Chinese Journal of Animal Nutrition, 2023, 35(6): 3499-3507. (in Chinese).

[2] LAN XY. Study on the microbial pollution status of fresh milk and its influencing factors in China[D]. Lanzhou: Gansu Agricultural University, 2018. (in Chinese).

[3] HE H, XIE JG, LIU WH, et al. Effects of different refrigeration modes on temperature,acidity and total number of bacteria in fresh milk[J]. China Dairy, 2022(9): 62-65. (in Chinese).

[4] GB 19301-2010 National food safety standard: Raw milk[S]. Ministry of Health of the Peoples Republic of China, 2010. (in Chinese).

[5] GB/T 5750.12-2006 Standard examination methods for drinking water—microbiological parameters[S]. Ministry of Health of the Peoples Republic of China, Standardization Administration of the Peoples Republic of China, 2007. (in Chinese).

[6] GB 4789.2-2022, National food safety standard food microbiological examination: Aerobic plate count[S]. National Health Commission of the Peoples Republic of China, China Food and Drug Administration, 2017. (in Chinese).

[7] ZHAO LS, WANG JQ, ZHENG N, et al. Main risk factor analysis for milk quality and safety VII. Somatic cell count & total bacterial count[J]. China Animal Husbandry and Veterinary Medicine, 2012, 39(7): 1-5. (in Chinese).

[8] ELMOSLEMANY AM, KEEFE GP, DOHOO IR, et al. Risk factors for bacteriological quality of bulk tank milk in Prince Edward Island dairy herds. Part 1: Overall risk factors[J]. J. Dairy Sci., 2009(92): 2634-2643.

[9] PIEPERS S, ZRIMkEK P, PASSCHYN P, et al. Manageable risk factors associated with bacterial and coliform counts in unpasteurized bulk milk in Flemish dairy herds[J]. Journal of Dairy Science, 2014, 97(6): 3409-3419.

[10] MENG MY, RUAN Z, LI BS. Research on the different store conditions influence the quality of raw milk[J]. China Dairy Industry, 2005(12): 49-51. (in Chinese).

[11] SHI CG, DONG P, WANG HY, et al. Survey of raw milks microbial growth in farms and analysis to involved factors[J]. China Dairy Industry, 2000(1): 32-35. (in Chinese).

Editor: Yingzhi GUANGProofreader: Xinxiu ZHU

Received: August 2, 2023Accepted: October 7, 2023

Supported by Hebei Province Phase III Modern Agricultural Industry Technology System Cow Innovation Team Building Project; The Fourth Batch of High-end Talent Project in Hebei Province; Hebei Provincial Science and Technology Innovation Leading Talents (21130243A).

Luman HUO (1991-), female, P. R. China, engineer, master, devoted to research about quality and safety monitoring of agricultural products.

Yi LI (1994-), male, P. R. China, engineer, devoted to research about quality and safety monitoring of agricultural products.

#These authors contributed equally to this work.

*Corresponding author.

- 农业生物技术(英文版)的其它文章

- Effects of Seed Dressing with Microbial Inoculum on Nutrient Composition and Biological Yield of Silage Corn

- Discussion on the Main Reasons for a Large Number of Père David’s Deer (Elaphurus davidianus) with Abnormal Antler Shedding

- Role and Effects of Eucommia ulmoides Leaves in the Growth Process of Livestock and Poultry

- A Study on the Interest Linkage Mechanism of the Taxus Industry Chain in Pengshui Miao and Tujia Autonomous County

- Therapeutic Effect and Mechanism of Jipei Dilong Ointment on Acute Soft Tissue Injury in Rats

- Integrated Green Prevention and Control Techniques for Kiwifruit Canker Disease in "Guichang" Kiwifruit in Xiuwen County, Guizhou Province