Thermoelectric energy harvesting for internet of things devices using machine learning: A review

Tereza Kucova| Michal Prauzek| Jaromir Konecny|Darius Andriukaitis| Mindaugas Zilys | Radek Martinek

1VSB –Technical University of Ostrava, Ostrava,Czech Republic

2Kaunas University of Technology,Kaunas,Lithuania

Abstract Initiatives to minimise battery use,address sustainability,and reduce regular maintenance have driven the challenge to use alternative power sources to supply energy to devices deployed in Internet of Things (IoT) networks.As a key pillar of fifth generation (5G)and beyond 5G networks,IoT is estimated to reach 42 billion devices by the year 2025.Thermoelectric generators (TEGs) are solid state energy harvesters which reliably and renewably convert thermal energy into electrical energy.These devices are able to recover lost thermal energy,produce energy in extreme environments,generate electric power in remote areas,and power micro-sensors.Applying the state of the art,the authorspresent a comprehensive review of machine learning(ML)approaches applied in combination with TEG-powered IoT devices to manage and predict available energy.The application areas of TEG-driven IoT devices that exploit as a heat source the temperature differences found in the environment, biological structures, machines, and other technologies are summarised.Based on detailed research of the state of the art in TEG-powered devices,the authors investigated the research challenges,applied algorithms and application areas of this technology.The aims of the research were to devise new energy prediction and energy management systems based on ML methods,create supervised algorithms which better estimate incoming energy, and develop unsupervised and semi-supervised approaches which provide adaptive and dynamic operation.The review results indicate that TEGs are a suitable energy harvesting technology for low-power applications through their scalability, usability in ubiquitous temperature difference scenarios, and long operating lifetime.However,TEGs also have low energy efficiency(around 10%)and require a relatively constant heat source.

K E Y W O R D S adaptive systems, intelligent embedded systems, internet of things, machine learning, sensors

1 | INTRODUCTION

Energy harvesting has become a widely used alternative method of supplying power to sensors deployed in Internet of Things (IoT) networks.The deployment of energy harvesting has resulted from the effort to put into practice the notion of a Green IoT to minimise battery consumption, address sustainability, and reduce the need for regular maintenance [1].Common energy harvesting sources for Green IoT sensors are devices which harness energy from solar radiation, wind, mechanical movements or vibrations (electromagnetic, electrostatic, and piezoelectric), radio frequency (RF) signals [2], or differences in temperature [3].Selection of the alternative energy source to power an IoT sensor is dependent on where the sensor is deployed and the physical property the sensor is designed to detect.Selection of the correct source also affects sensor lifetime in terms of energy, power, and processing capabilities [4].Flow-based systems which collect energy from wind generators are used to detect wind speed[5]and monitor the conditions in wind energy conversion systems [6].Radio frequency energy harvesting systems [7] and solar radiation energy harvesting systems which use photo-voltaic panels(PV)[8] have proved themselves as suitable solutions for smart home IoT systems.Mechanical vibrations are a type of energy source which could be used with magneto-mechano-electric generators to power devices such as smart watches [9].

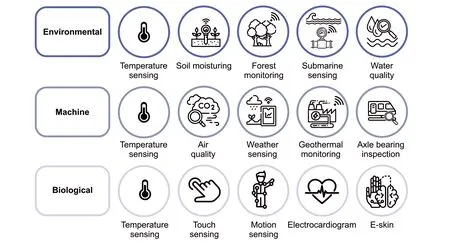

Figure 1 shows the wide range of applications of TEGpowered systems across different temperature sources.These applications encompass environmental, machine, and biological domains.The figure underscores the versatility and potential of TEG-based technologies in powering diverse applications in various temperature environments.

Thermoelectric generator (TEG) devices are suitable for powering wearable biomedical IoT nodes [10], machine parameters, location or environmental sensors [11].A combination of ambient energy sources can also be applied in hybrid energy harvesting systems, for example, piezoelectric transducers(PZT)and triboelectric nanogenerators(TENG),which are used to power autonomous wireless sensor nodes for data collection applications [12].

Energy harvesting schemes, including hybrid harvesters,have both advantages and drawbacks, and it is therefore difficult to find a general solution that is sufficiently versatile to cover the majority of use cases for IoT sensors [13].In this context, energy from temperature differentials is an attractive alternative energy source since thermal gradients are found frequently throughout our environments, often being a byproduct of other energies resulting from mechanical motion,electromagnetic dissipation, or chemical reactions [14].TEGpowered sensors are widely used in applications where the main power source is a battery, although these have limited lifetimes and must be replaced or recharged periodically [1].However, energy harvesting IoT sensors could exploit applications of machine learning(ML)to optimise power allocation during operation in unpredictable energy production conditions and energy-poor environments[15].The major utility of a TEG, therefore, is in heat recovery, surface cooling, and sensor applications[16].The article discusses our investigation of TEG-powered sensors which run in low-power applications and use the small temperature differences between the hot and cold sides of a TEG.Small temperature differentials take advantage of the small temperature differences naturally present in environments where IoT sensors are deployed and are able to produce sufficient energy for low power operations.

The review makes contributions in the following areas:

• Providing a comprehensive overview of the latest principles and materials employed in TEGs for IoT node energy harvesting solutions, including a detailed description of relevant energy harvesting topologies.

• Mapping the current trends in application areas involving diverse energy sources, such as environmental energy,technology power sources,and biological energy harvesting.

• Proposing research directions aimed at predicting the future harvested energy by TEGs and developing energy management strategies for IoT devices that have limited energy income and storage capabilities.

These contributions collectively enhance the understanding of TEGs in the context of IoT node energy harvesting and provide valuable insights for future research and development in this field.

F I G U R E 1 Typical thermoelectric generator applications powered by various temperature different sources.

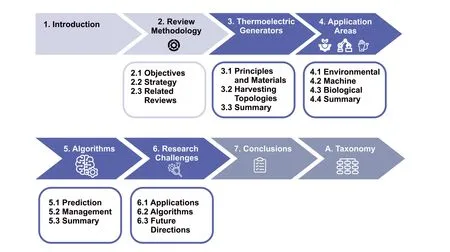

The article reviews the state of the art in TEG-powered sensors which operate from small temperature differentials(i.e., energy harvesting topologies, operation algorithms, and research challenges in this area).Figure 2 illustrates an outline of the article,which is organised as follows:Section 2 includes the review methodology.Section 3 describes the functioning principles of a TEG,the materials suitable for low temperature difference applications of TEGs,and the concepts of mikroTEG and nanoTEG.Section 3 also describes individual TEGpowered system topologies which differ in the battery types and additional power sources they may draw energy from;each topology is described, including application areas and general functioning principles.Section 4 outlines individual means of powering TEGs, for example, energy derived from environmental,machine/technological,or biological sources.Section 5,describes the control and predictive algorithms for TEGpowered systems to manage their energy consumption effectively.Section 6 suggests potential areas of research to investigate TEG-powered sensors operating from small temperature differentials.Section 7 concludes the article with a final summary.

2 | REVIEW METHODOLOGY

This section outlines the methodology employed to conduct the review.The Preferred Reporting Items for Systematic Reviews and Meta-Analyses(PRISMA)methodology was used to ensure transparency, rigour, and comprehensive reporting in the review process.The section provides details of the search engines used, search query compositions, and the selection criteria for referencing literature.Additionally, the section highlights the categorisation of reviewed articles and relevant surveys and outlines the strengths and weaknesses of TEGs deployed in energy harvesting systems.

2.1 | Review objectives

The review's general objective is to provide a guide for building a TEG-powered system for monitoring purposes, using stateof-the-art technologies and materials.The system is designed to support the implementation of ML techniques.This review encompasses the following list of objectives:

• Objective 1: Provide an overview of the currently used materials and future trends in constructing TEGs in relation to environmental impact, performance, and cost.Select suitable TEGs according to the application requirements,for example, voltage range or energy output.

• Objective 2: Explore integration options for TEGs in electronic circuits for the efficient use of generated energy.This objective involves mapping the technological possibilities of employing DC-DC converters, energy storage systems, supercapacitors, and secondary batteries.

• Objective 3: Map energy sources for TEGs and gather existing knowledge and experiences in using TEGs in various domains.The aim is to identify areas where TEGs have been successfully applied and discover additional potential applications.

• Objective 4: Identify ML methods suitable for compliance with energy constraints in conditions with limited energy and computational resources.

• Objective 5: Evaluate the energy generation potential of TEGs in different applications,specifically in the context of monitoring devices, and assess whether the generated energy is sufficient.Additionally, present the cost and reliability impact of implementing ML in the resulting application (e.g., IoT system).

F I G U R E 2 Scheme of the article: Thermoelectric generator principles and materials, DC-DC energy harvesting topologies, application areas, energy prediction and management algorithms.

2.2 | Review strategy

The number of published documents related to TEG-powered devices has shown a noticeable increase in recent years, as indicated in Table 1.Surprisingly,no reviews on this topic were published in 2018 and 2019.However, 2020 saw a significant shift, with three articles specifically addressing this subject published.The number of reviews subsequently continued to rise.In 2021, seven reviews were published, and this number surged to 13 in 2022.In 2023, only two reviews have thus far been identified, suggesting a slight decline.A similar pattern can be observed in the number of articles and conference papers published on this topic.

The process of conducting this review employed the PRISMA methodology.The PRISMA methodology and use of specific search engines, keywords, and selection criteria supports the reliability and ability to replicate this review process.PRISMA guidelines were followed to ensure transparency,rigour, and comprehensive reporting of the review process.

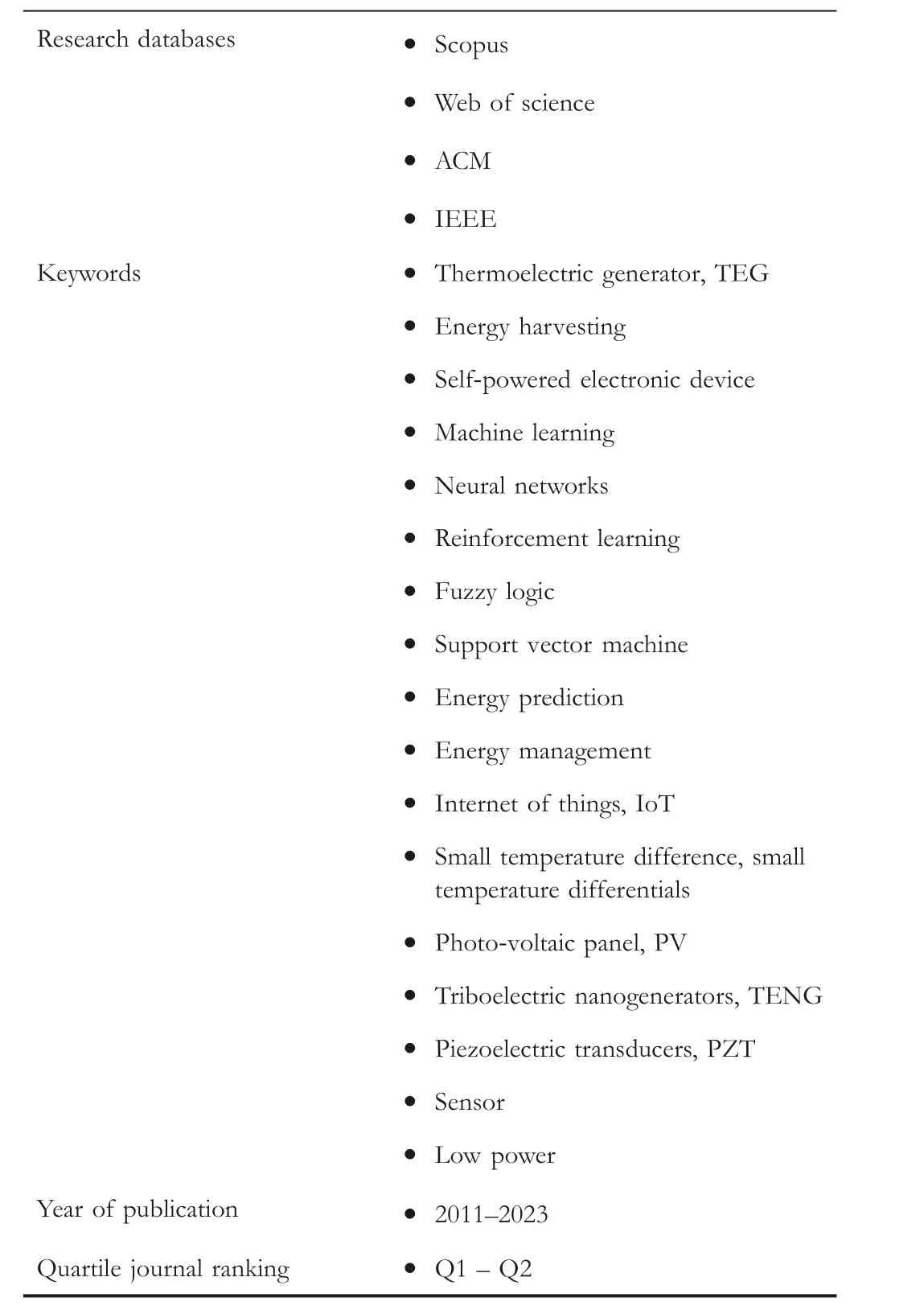

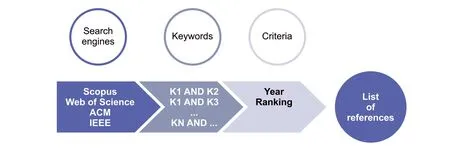

Figure 3 outlines the search engines used, search query compositions, and selection criteria for referencing literature.Table 2 provides a summary of the criteria for selecting the references used in this study.This review was created by searching research databases (Scopus, Web of Science, ACM,and IEEE) for reliable sources in from which relevant articles were selected according to the criteria listed in the table mentioned above.

The review methodology provided a systematic analytical approach for drawing conclusions and forming summaries.Analysis involved a comprehensive examination of thereviewed studies in a structured and unbiased manner to interpret their content and findings.This approach was useful in identifying common themes and trends across the selected relevant references and enabled a comprehensive and insightful understanding of presented topic.

T A B L E 1 Number of published documents on the topic of thermoelectric generator powered devices in recent years.

Identified by searching various keyword combinations, articles were selected according to several criteria, including the publication year and the quality and reputation of the journal.The selection process limited the articles to those publishedbetween 2011 and 2023, ensuring relevance and up-to-date information.The quartile journal ranking system was also used to rank journal articles according to the Q1 and Q2 quartiles for inclusion.For general principles and material descriptions,older publications prior to 2011 were referenced.For ML topics,the year of a study's publication was important in ensuring that references with recent advancements in the field were included for review.

T A B L E 2 Summary of inclusion criteria of the references used in this study.

F I G U R E 3 Illustration of the process of selecting references.

2.3 | Related reviews

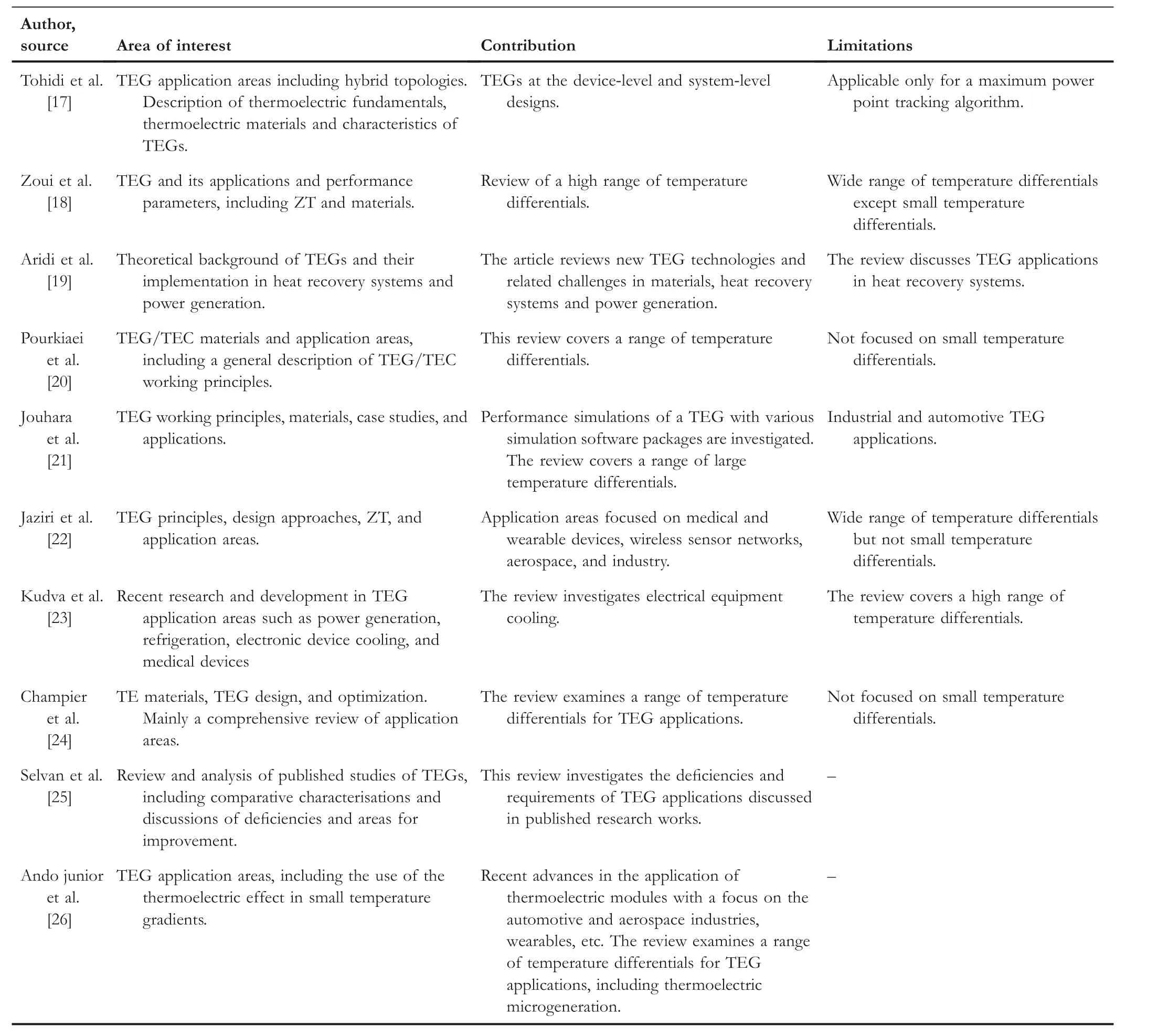

Table 3 provides an overview of relevant, recent surveys published on related topics and describes their main contributions.

These reviews explored TEG applications and reported a range of results.In ref.[19],a TEG applied in a heat recovery system was examined.In ref.[21], TEGs for industrial and automotive applications were studied with a range of large temperature differentials.In refs.[18,20,22–24,and 26],TEG applications were studied with a range of temperature differentials whereas our review directly examined small temperature differentials.In ref.[25], the authors reviewed published research works and discussed the deficiencies and requirements of TEG technologies.The authors of other comprehensive reviews[17,21,and 22]describe the principles,characteristics,and technologies of TEGs.Several reviews have examined the research trends and developments in TEG applications[18–20,24, and 25].The authors of ref.[26] discussed the currently most used materials in semiconductors and the workingprinciples of TEGs at low operating temperatures.The study in ref.[17] presented system-level designs which used maximum power point tracking algorithms.None of the reviews listed in Table 3 researched the use of algorithms with a TEG at low operating temperatures.Our article therefore mainly discusses the use of algorithms in this research area.Our article also reviews the state of the art in TEG-powered sensors which operate with small temperature differences (i.e., energy harvesting topologies, operation algorithms, and research challenges in this area).

T A B L E 3 Summary of available surveys of thermoelectric generator-powered devices: technologies, applications, modelling and materials.

3 | THERMOELECTRIC GENERATORS

This section presents the principle behind a TEG and describes the currently used materials to produce these devices.Individual topologies in which a separate TEG can be inserted to function in an energy harvesting unit to power an IoT sensor or other device are also described.The rest of this section is devoted to a technological summary, including the strengths and weaknesses of this type of electronic component.

3.1 | Principles and materials

A TEG is a device also known as a Seebeck or Peltier generator.These devices convert temperature differences(heat flux)into electrical energy [27].A TEG consists of two thermocouples made of two semiconductor materials with two primary junctions (n-type and p-type).The TEG structure contains thermocouples connected electrically in series and exploits the Seebeck effect to generate voltage and produce electrical energy.The voltage potential directly corresponds to temperature difference across the semiconductor [27].The Seebeck coefficient is a material characteristic whose value differs through the p-type and n-type materials which comprise a thermocouple.The p-type elements are doped to provide a number of positive charged carriers (holes) and a positive Seebeck coefficient.The n-type elements are doped to provide negative charged carriers (electrons) and a negative Seebeck coefficient [28].

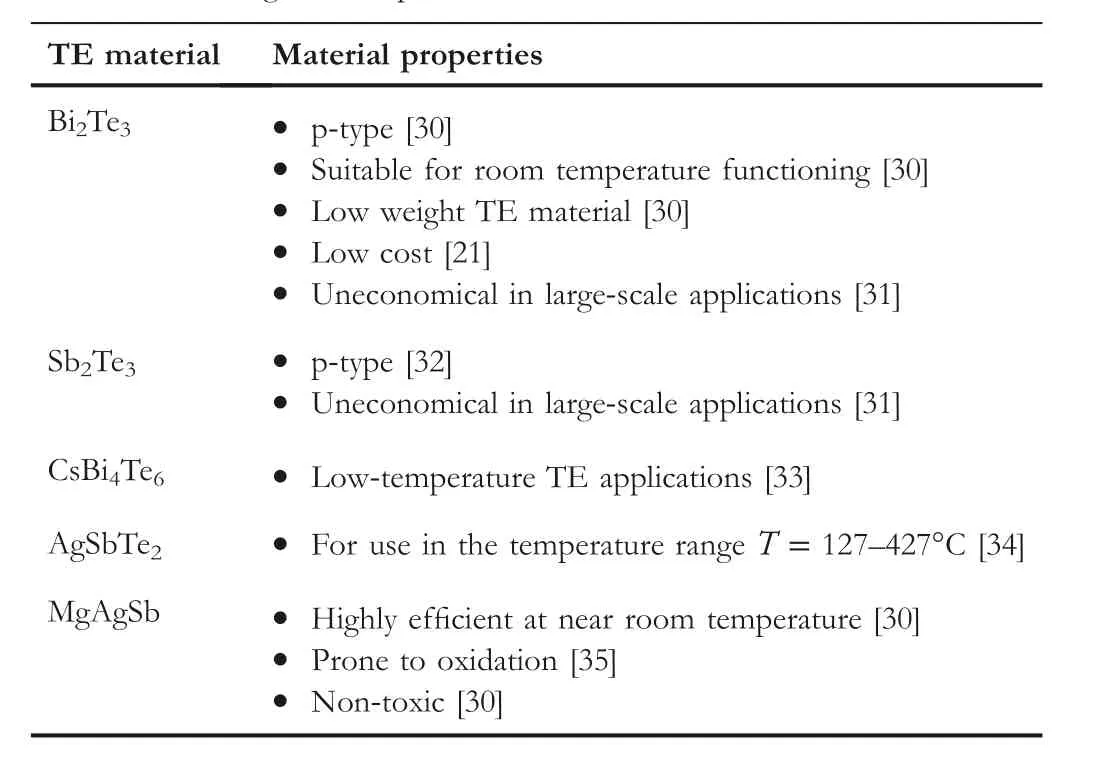

The development of TE materials suitable for TEGs which exploit small temperature differences is accelerating.Despite the findings of numerous studies, TE materials such as Bismuth Tellurium (Bi2Te3) and Antimony Tellurium (Sb2Te3)remain the most preferred in TEG designs [29].However,candidate materials such as Caesium Tetrabismuth Hexatelluride (CsBi4Te6), Silver Antimony Telluride (AgSbTe2),and Magnesium Silver Antimonide (MgAgSb) have been studied for their use at low operating temperatures [30].Table 4 lists the essential properties and attributes of widely used TE materials.

Bi2Te3is commonly used in combination with Sb2Te3,and both are specified for use in small-scale applications [30].Bi2Te3characterised by low weight[30],low cost[21],and high performance at near room temperature operation (approximately 19–29°C) is also suitable for operation at roomtemperature [33].AgSbTe2operates in the temperature range 127–427°C [34].MgAgSb is highly efficient at near room temperature and is non-toxic [30], but a disadvantage is its propensity to oxidise [35].For a compromise between cost reduction and electrical output performance, combinations of different TE materials can be selected [31].

T A B L E 4 List of material properties of thermocouple materials used in thermoelectric generator-powered sensors.

To mitigate adverse environmental effects,low-cost printed organic TEGs have been developed [36].The semiconductor materials used in these TEG variants are poly (3,4-ethylene dioxythiophene)polystyrene sulfonate(PEDOT:PSS)ink[36]or single wall carbon nanotube-based (SWCNT) ink [37].Thermoelectric generators made of organic-based materials have power outputs comparable to conventional TEGs [36].

For application in IoT networks, we are seeing a great demand for micro/nano scale energy sources which can deliver energy of just a few microwatts.A standard TEG is able to supply energy in this power range, however the size of the module may not be suitable for small wireless sensors, and therefore, miniaturisation of TEGs into micro-scale (micro-TEG) or nano-scale (nanoTEG) technology is required [38].

MicroTEGs are miniature versions of TEGs which,despite their small volumes, generate high output voltage [39].Their advantages over traditional TEGs are light weight and low cost.The output power of a microTEG is normally in the range of microwatts to milliwatts.MicroTEGs therefore are potentially useful in contemporary application areas such as consumer electronics, biomedical sensors, and the IoT[40].NanoTEGs are composed of nano-scale thermocouples(1 nm × 1 nm × 6 nm) which miniaturise the energy harvester [41].These devices can provide open circuit voltages of 4 mV and be used as harvesters in biomedical sensors[41] or wireless sensor networks to power nodes [42].

3.2 | Energy harvesting topologies

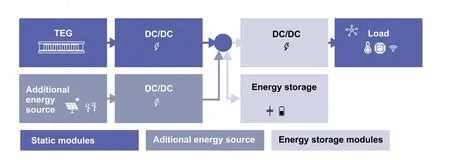

TEG-powered sensors come in a variety of configurations:standalone TEGs (fully autonomous or battery-supplemented topology) or TEGs in combination with other energy harvesting methods(hybrid TEG topology).The difference in construction of TEG-powered sensors is depicted in Figure 4.

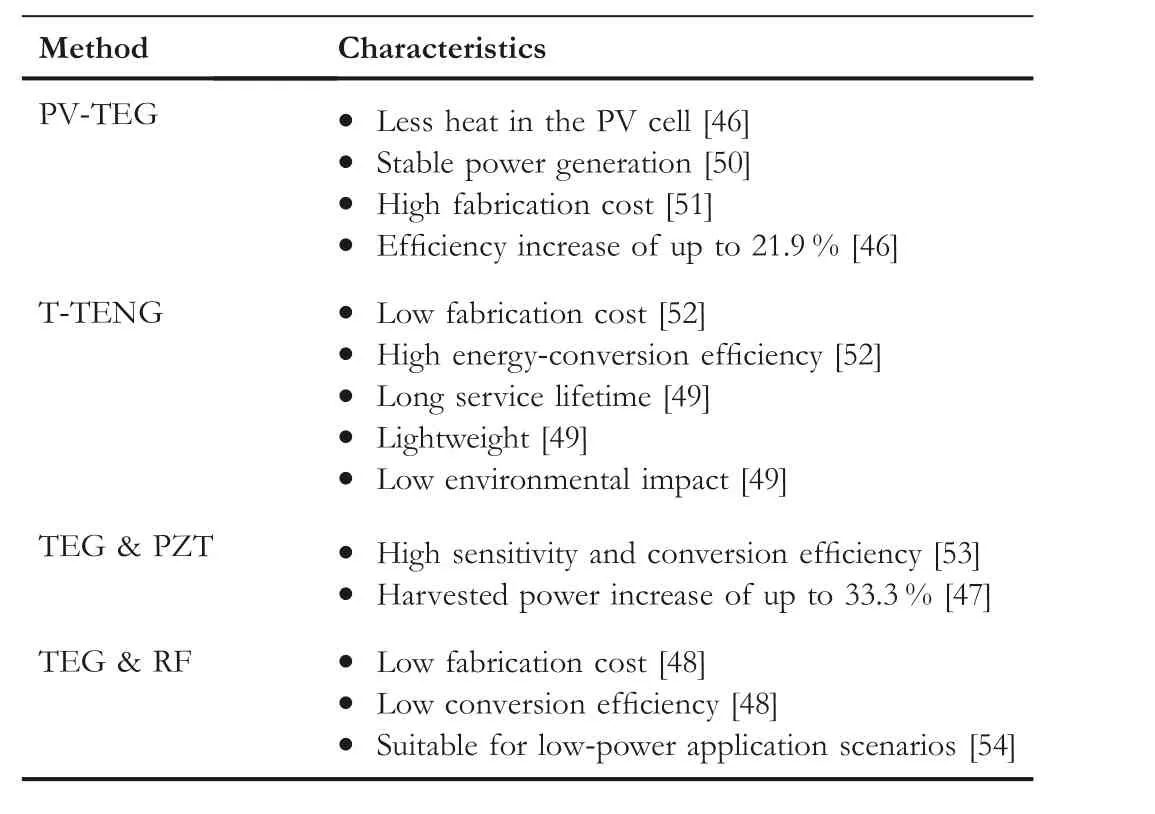

Autonomous topology provides a fully autonomous system based on a TEG without the use of batteries or other energy harvesting sources[43].The core components of autonomous topology are a TEG, DC-DC boost converter, energy storage elements, and microcontroller with a sensor system [44].The inclusion of other components depends on the sensor's detection purpose [3].The combination of a TEG and a primary and perhaps an additional secondary battery is the basis of a battery-supplemented TEG topology [21].The TEG energy harvesting system is used as a secondary power source to support the battery [22].Thermoelectric generators also support other energy harvesting methods to increase energy harvesting system efficiency by converting system waste heat into energy.The use of two energy harvesting methods is called a hybrid energy harvesting system.Hybrid energy harvesting systems use a combination of the TEG and one or more other energy sources, for example, PV [45, 46], PZT [47], RF signal generator [48], or TENG [49].

Each combination of energy harvesting sources can be used in monitoring applications according to the advantages and disadvantages listed in Table 5.A PV-TEG is a hybrid system which improves the overall energy harvesting system efficiency through the PV cell's efficient use of temperature and the TEG's conversion of the PV cell's waste heat into energy [55].Compared to a single PV harvesting method, the conversion efficiency of a PV-TEG is up to 21.9%greater[46].The added value of a PV-TEG is cooling delivered to the PV cells by the TEG [56].Hybrid PV-TEG systems have proved useful in a number of applications,for example,in monitoring environmental parameters in desert locations[57],as a primary power source for satellites on space platforms [58], and powering a synchronous reluctance motor for pumping applications[59].PV-TEG systems are suitable for applications which require greater thermal energy than electrical energy, for example, water heating [60].To maintain the temperature gradient in a TEG, various techniques enable the cool side of the TEG to be cooled or the temperature on the hot side to be increased.Two Fresnel lenses can be used as heating, one of them to concentrate sunlight on the PV cell and the other to concentrate sunlight on the hot side of the TEG[51].The high cost of PV-TEGs is due to the high price of TEGs.However,economic analysis suggests that the costs of investment into TEG modules are recovered in six years [51].

The triboelectric nanogenerator(TENG)is another energy harvesting method which can be used in combination with a TEG (called a T-TENG) to reuse heat [61].T-TENGs are promising methods for harvesting ambient mechanical energy[52].T-TENG hybrid energy harvesting topology is characterised by low fabrication cost, high energy-conversion efficiency [62], long service lifetime, low weight, and low environmental impact [49].The devices are suitable for use in self-powered IoT sensors [62].Hybrid TEG/PZT systems generate power [53] by converting vibrational energy through thermal excitation into electric energy.Compared to a single PZT harvesting method,this hybrid topology has up to 33.3%greater harvesting power [47], high sensitivity, and high conversion efficiency[53].Another combination of power sources uses RF signals and thermal energy.A rectenna harvests RF energy while the TEG harvests thermal energy[1].This hybrid method is able to produce more energy in ambient atmospheres where RF coverage and temperature gradients are available.Thisenergy harvesting topology operates well in low-power ranges and is low cost,but it has a low conversion efficiency[48].

T A B L E 5 Characteristics and properties of hybrid energy harvesting methods based on thermoelectric generators.

F I G U R E 4 Block diagram of thermoelectric generator(TEG)-powered topologies:autonomous topology(a TEG,DC-DC boost converter,energy storage elements, and load); battery-supplemented topology (the TEG energy harvesting system is used as a secondary power source to support the battery); hybrid topology (a combination of the TEG and one or more other energy sources).

3.3 | Technology summary

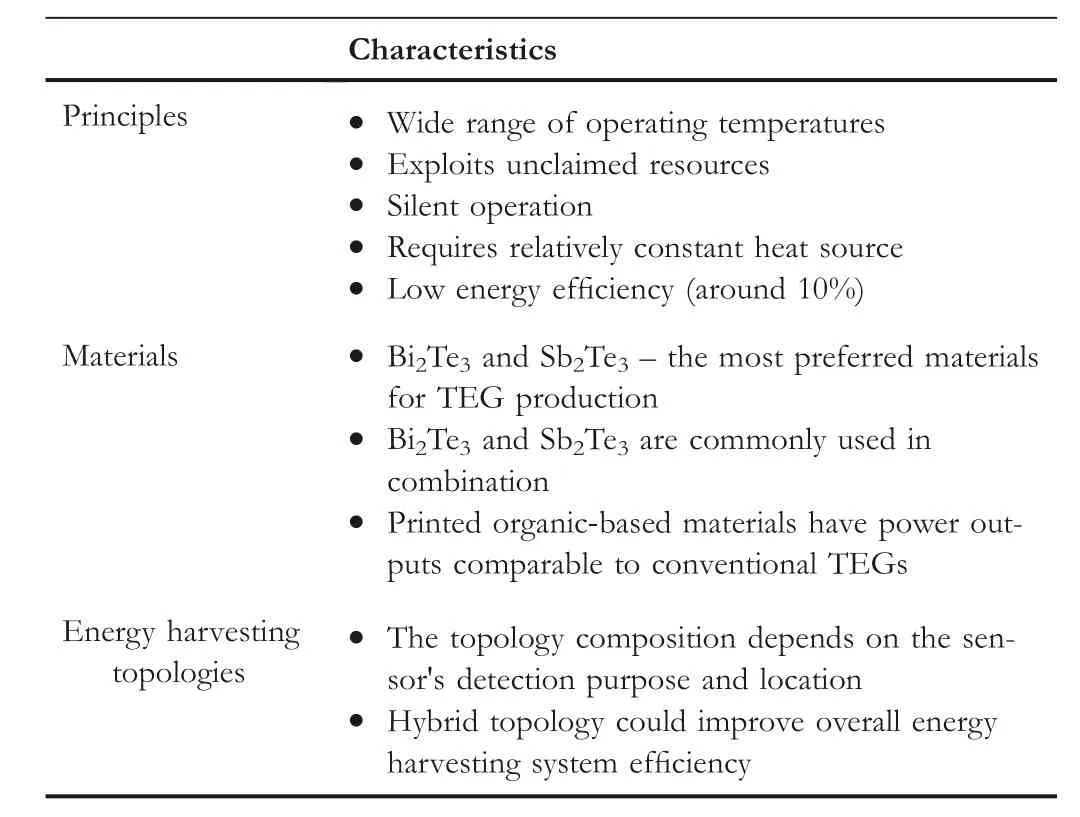

Table 6 highlights the strengths and weaknesses of the TEG used as an energy harvesting system and summarises the characteristics of TEG principles, materials, and topologies.

Thermoelectric generators are a suitable energy harvesting technology in low-power applications due to their scalability,usability with ubiquitous temperature difference scenarios,and long operating lifetime.The thermoelectric generator is a convenient energy harvesting system which can be easily exploited by IoT devices in numerous locations due to its wide range of operating temperatures.Its ingenuity lies in the use of unclaimed resources such as heat source,which could be a byproduct of primary energy production.Its advantage is also its silent operation.Nevertheless, the limitations of TEG energy production lies in requirement of relatively constant heat source and low energy efficiency which is around 10%.

The differing properties of thermocouple materials should be carefully evaluated for their suitability in specific applications.Commonly used thermocouple materials are Bi2Te3in combination with Sb2Te3, both suitable for use in small-scale applications with small temperature differentials.Correct selection of a suitable energy harvesting topology based on TEGs depends on the location,device sensing purpose,and size options of the final IoT device.Hybrid topology may offer the best solution since it can potentially improve overall energy harvesting system efficiency by using all the surrounding energy sources.

4 | APPLICATION AREAS

The capabilities and advantages of TEGs are applied in many research areas [22].Because their designs do not include the use of any toxic chemical products,TEGs are environmentallyfriendly devices.They do not have moving parts and operate silently[30].Thermoelectric generators are also not dependent on location, have long operating lifetimes, and are suitable for integration into flexible devices [63].

T A B L E 6 Characteristics of thermoelectric generator principles,materials, and topologies.

4.1 | Deriving power from the environment

Devices which harvest energy from temperature differences arising in the environment are ideal for deployment in remote areas [64].

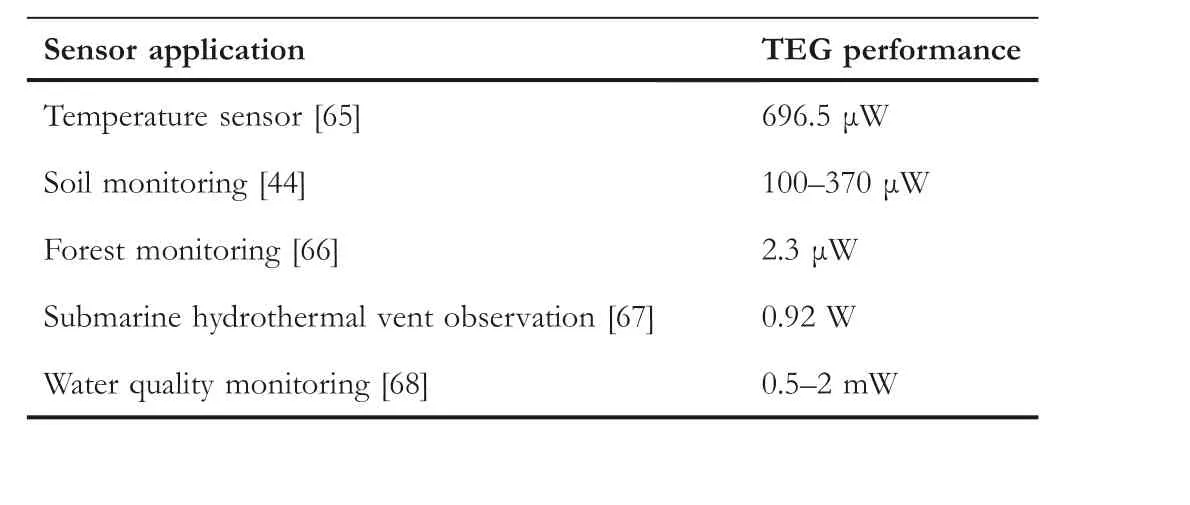

Table 7 lists TEG applications from recently published studies of TEG-powered sensors deployed in remote areas.TEG-powered sensors are usually deployed in such areas to obtain information about the ambient environment, for example,measurements of temperature or moisture[65]in soil[44], bodies of water [67] or forests [66].The devices must be energy autonomous, battery-free, and maintenance-free,therefore TEG energy harvesting systems are ideal for their cost effectiveness and lack of adverse environmental impact[8].

The temperature difference between air and shallow soil can be used as a temperature gradient by a TEG for energy harvesting [69].To produce energy from small temperature differences, a suitable soil depth is 30 cm [44].In deeper soil layers,the daily temperature fluctuations are minuscule,and at a depth of 1 m,temperature does not fluctuate over the course of a day [64].The power output of environment-monitoring devices which harvest thermal energy from temperature differences between air and soil is approximately in the range 2–370 μW.

TEG-powered IoT sensors also find use in aquatic environments to measure conditions on the seafloor or near submarine hydrothermal vents[67]or to detect water quality[68].In ref.[67], the study demonstrates that a TEG was able to power observation equipment for long-term monitoring of submarine hydrothermal vents.In this case, a temperature difference existed between the hydrothermal fluid and seawater, reaching approximately 25°C and supplying approximately 1 W of energy.Testing of the TEG indicated that the equipment could be used in shallow seas to a depth of 500 m.In ref.[70], the experiment uses the temperature difference between hydro-thermal fluid and seawater to provide energy for long-term seafloor observation systems which operated without batteries.In ref.[68],the study describes a TEG whichexploited low-temperature gradients between the surface of a water pipe and the ambient air to power a wireless water quality sensor.The TEG produced more than 0.5–2 mW from a temperature difference of approximately 1–2°C.

T A B L E 7 Thermoelectric generator performance of TEG-poweredsensors deployed in remote areas: temperature differences encountered in the environment.

4.2 | Deriving power from machines/technology

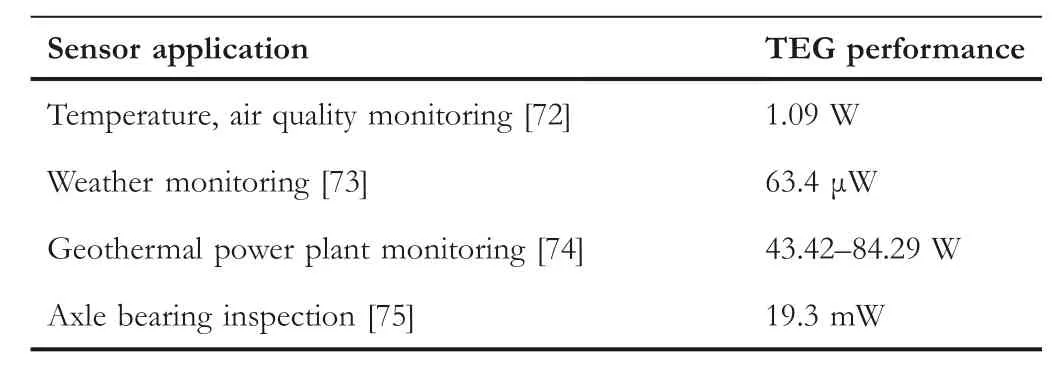

The conversion of waste heat into electrical energy can be used by TEGs to generate energy to power an IoT sensor.Waste thermal energy is a by-product of primary energy production.The large quantities of waste thermal energy and its apparent ubiquity provide ideal conditions for the use of TEGs in several applications to power IoT sensors [71].

Table 8 lists examples and applications of TEG-powered IoT sensors which convert waste heat into electrical energy.In ref.[74], the study discusses the integration of TEGs into geothermal power plants to harvest energy from waste heat and increase the electrical energy output or to power the plant's low energy consuming electrical equipment, such as lighting,sensors, instrumentation, and control systems.At a temperature difference of 41.98°C, the TEG produced 43.42 W.At a temperature difference of 60.6°C,the TEG produced 84.29 W.In ref.[72], the authors describe the use of a TEG to recover waste heat and drive a multi-functional monitoring system which checked the processing temperature of atmospheric pressure plasma jet and air quality in the surroundings.To operate the monitoring system continuously, the TEG had to produce 1.09 W of power[72].In ref.[73],the study describes the use of a TEG which produced an output power of 63.4 μW from a temperature difference of 30°C on a hot pipe to power a self-sufficient wireless weather sensor deployed in an IoT network.In ref.[75], the study reports on a TEG used to convert waste energy during heavy railroad vehicle operation at high speed.A temperature difference of 14.8°C between the surface of the axle bearing housing and the ambient air was converted into 19.3 mW of power.As yet,a system such as this is not widely applied,but it is suitable for real-time monitoring and axle bearing inspections or low power sensor nodes.

The simulation in [76] demonstrates the suitability of TEGs as energy harvesting devices in smart homes or smart buildings.In these structures, TEGs harvest energy from the temperature gradients between the two sides of the building envelope (outdoor and indoor climates).This could be implemented in areas with extreme climates where atemperature gradient is guaranteed.The study's simulation of a building application shows that the required temperature difference must reach 10°C to generate approximately 18 mW.Another study [77] describes the application of a 9 cm3TEG which generated approximately 5 mW power from a temperature difference of 6°C.

T A B L E 8 Thermoelectric generator performance ofthermoelectric-generator-powered sensors: temperature differences resulting from thermal energy produced by machines or technology.

In ref.[78], the study describes an experiment with a nanoTEG applied to a prototype exterior glass panel to generate energy from the temperature difference between the outdoor and indoor environments.At a temperature difference of around 25°C, the output power was approximately 34 W/m2.Another study [79] discusses the results of a simulated system which exploited the temperature difference between the roof and an air-conditioned space inside a building.The simulation showed that this approach could provide approximately 10 kWh/m2at a temperature difference of 21°C.Although the real-world functionality of these building envelope energy harvesting solutions were not proved in any practical experiments, the output powers in the simulations indicated the suitability of these systems to power sensors for monitoring parameters such as air temperature and humidity in buildings.

4.3 | Deriving power from biological systems

Temperature differences between biological structures and the ambient environment are also measurable.Because the human body contains a near-infinite supply of thermal energy, TEGs are suitable power sources for wearable sensors and electronics which monitor health [80].

Table 9 lists sensor applications which use TEGs powered by the temperature differences resulting from biological structures.Temperature differences occur between human skin and the ambient environment [85].Wearable sensors can measure numerous physiological signals in the human body,for example,blood pressure,heartbeat, body temperature,glucose level [86], movement or saturation of blood oxygen, and others.[87].In the world of TEG-powered wearable electronics,terms such as flexible TEG[88]or ultra-flexible TEG[81] have become widespread as TEGs have been adapted to fit the shapes of the human body.Ultra-flexible TEGs are assembled on cloth as wearable health and motion monitoring devices[81].Flexible TEGs are able to power long-term sensor systems which detect bio-signals such as joint movement and respiration [88].A μTEG design is also suitable for easywearing and has been deployed in a device only 1.9 mm×2.7 mm×400 μm in size to monitor respiration in real-time below the nostril and near the mouth [89].Wearable TEGs can supply power in the approximate range of 15 nW to 11 mW, which is sufficient to power miniaturised electronic health monitoring devices [84].

T A B L E 9 Thermoelectric generator performance of TEG-powered sensors: temperature differences created by biological structures.

In ref.[90], the study demonstrates the use of a TEGpowered wearable capable of producing approximately 2 μW of power while worn by a healthy person at room temperature(the temperature difference was approximately 15°C).In ref.[81],the authors present a wearable,ultra-flexible TEG sensor design for monitoring human temperature,touch,and motion.The device produced a large peak power output of 64.10 μW at a temperature difference of 33.24 K and was able to output a high voltage of 111.49 mV.The ultra-flexible TEG was integrated into a textile for potential use as wearable health or electronic skin for robots [81].Another TEG module design[82] was employed to optimise the power output of a flexible TEG for electrocardiograph monitoring.The power output of the flexible TEG was dependent on the temperature difference and the TEG's size.At a temperature difference of 35–75°C,the power output was 15 nW–11,4 mW.In ref.[83], the study investigates the use of a flexible TEG to power electronic skin(e-skin) that was sensitive to multiple sensations (flow, matter,temperature, humidity, and acceleration).The flexible TEG power output was approximately 2 mW at an environmental temperature of 20°C.In ref.[84],the authors applied a TEG to power a miniature accelerometer which detected human body motion.The TEG generated 38 μW of power at a temperature difference of approximately 20°C.

Now, an eagle with a King s heart in his breast is apt to be bold, and accordingly he instantly made up his mind to carry off the lovely damsel, feeling sure that having once seen her he could not live without her

4.4 | Application summary

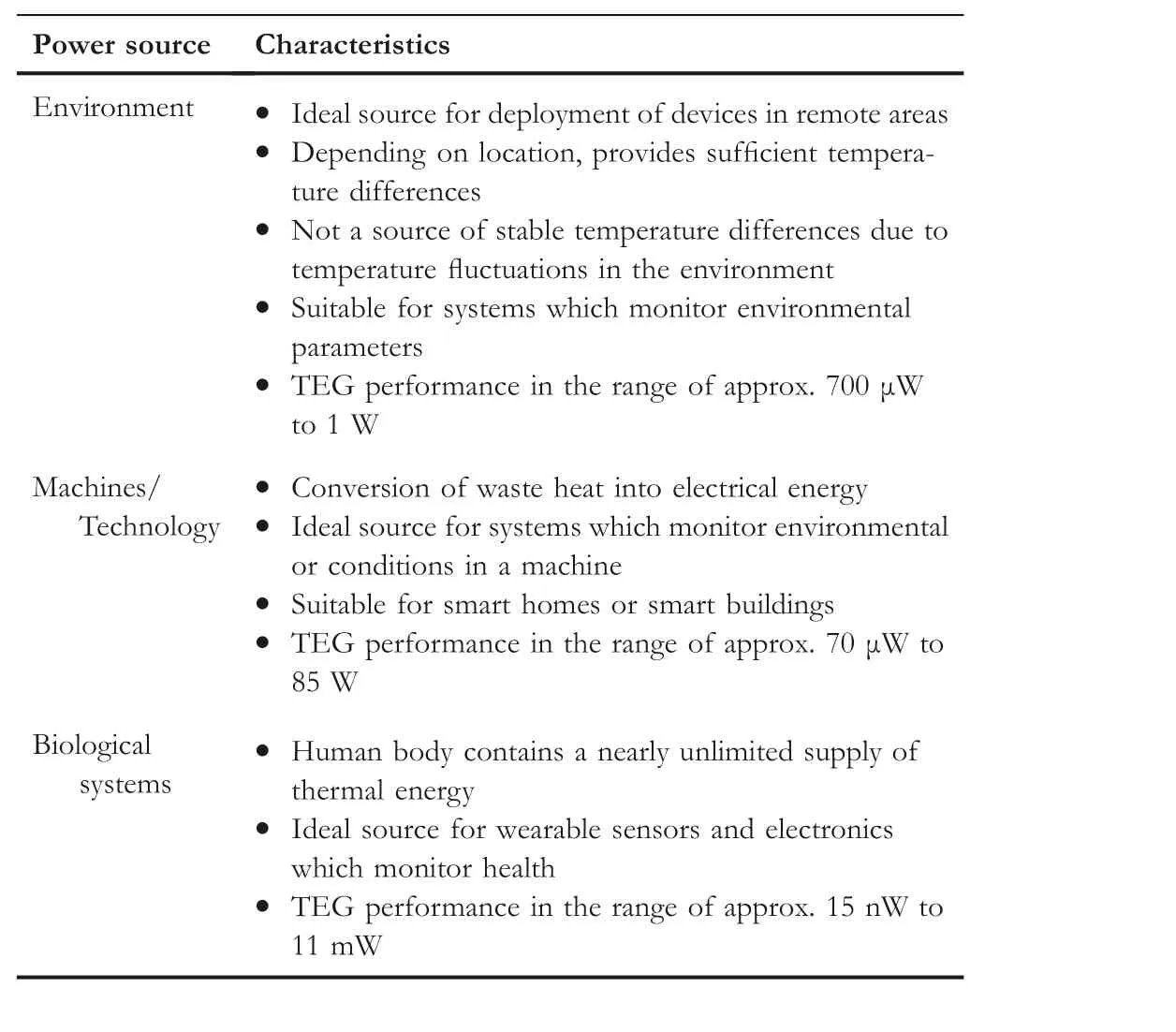

Table 10 highlights the strengths and weaknesses of energy harvesting sources suitable for generating power from a TEG.Energy can be harvested from temperature differences arising in the device's environment, waste energy from a machine/technology, or a biological structure such as the human body.

For monitoring systems deployed in remote areas, the ambient environment is a suitable source to generating power using a TEG,for example,air temperature in combination with soil temperature can provide the temperature differences sufficient for harvesting small amounts of energy.However,temperature fluctuations are a drawback and produce irregularity in the power supply output to a device.Energy harvesting systems based on ambient temperature differences can provide power in the range of approximately 700 μW to 1 W.

In smart homes and smart buildings, waste heat generated by a machine or technology can be converted into electrical energy with a TEG.These systems include monitoring devices which measure temperature, air quality, or the technical parameters of the machines in which the systems are deployed.Thermoelectric generators which derive power from machines/technologies can provide power in the range of approximately 70 μW to 85 W.

T A B L E 10 Characteristics of energy harvesting sources suitable for generating power from a thermoelectric generator.

The final application area is where power is derived from a biological system such as the human body, which is a nearly limitless source of thermal energy.The temperature difference between the human body and the ambient environment can be exploited by a TEG to power of wearable sensors and electronics for monitoring health.TEG-powered devices which use the human body as a heat source can provide a stable power source of approximately 15 nW to 11 mW.

5 | ALGORITHMS

Monitoring and prediction methods to evaluate the performance of energy harvesting while powering IoT sensors is essential.Energy management systems can benefit from predictive algorithms based on historical data to forecast parameters crucial to determining daily energy transactions [91].To predict energy performance,available energy must be managed to adapt the duty-cycle operation to the application scheme.

5.1 | Energy prediction

The stochastic nature of harvesting energy sources threatens power system stability and may result in the inability to balance power consumption and power production[92].The daily total energy predicted for the next day could be used as a supporting parameter to duty-cycle operation control, data collection, or communications with energy harvesting devices [64].To predict the power supplied by energy harvesters and to ensure a balance between the produced energy and system requirements, analytical equations can be applied to model the system [93] or implement statistical or ML algorithms [94].Because the prediction of TEG generated energy directly depends on temperature differentials, methods for predicting air temperature are suitable for application in this area.Air temperature also represents an essential climatic parameter in water resource management and other agro-hydrological/meteorological activities [95].To forecast air temperatures,neural networks(NN)and support vector machines(SVM)are widely implemented [96].

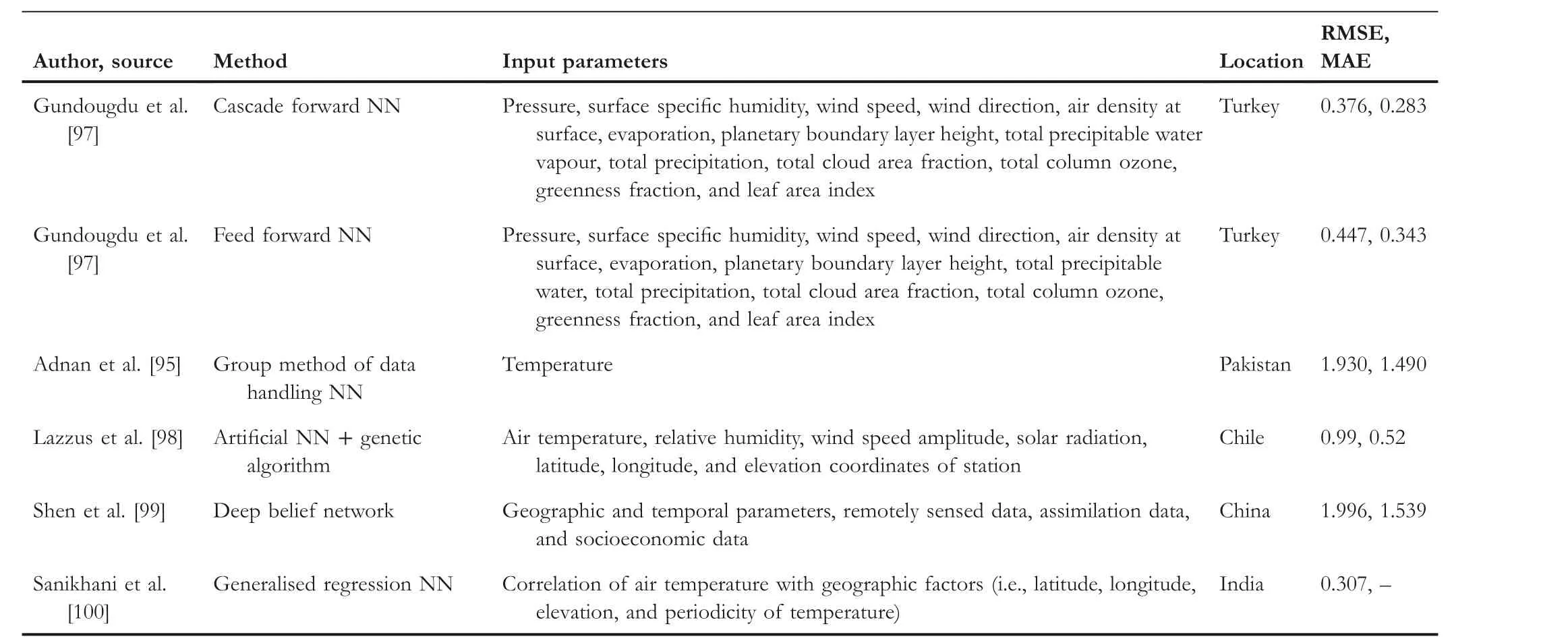

Table 11 lists several NN methods which have been tested in various locations with a variety of input parameters.RMSE and MAE are used as evaluation criteria to compare the performance of individual NN methods.In [97], the study analyses the performance of hourly predictions of ambient air temperature in a system using a Cascade Forward NN and a Feed Forward NN method.Measurements of 13 meteorological parameters provided the input data for the models.The results showed that the Cascade Forward NN model outperformed the Feed Forward NN model with a relatively lower RMSE and lower MAE; the Cascade Forward NN model's predictive ability was slightly better than the Feed Forward NN model.In ref.[99], the article describes a 5-layer Deep belief network structure which captured the complex, non-linear relationships between air temperature and a range of predictor variables.Compared to multiple linear regression, backpropagation NNs, and the random forest method, the Deep belief network model was better able to map non-linear relationships and achieved overall superior model performance[99].In ref.[100],the study demonstrates the application of the Generalised Regression NN model to temperature estimation without climate input data,instead using geographic factors as input parameters (i.e., latitude, longitude, altitude, periodicity,or monthly cycles).The temperature prediction capability of the Generalised Regression NN model exceeded the accuracy of multidimensional adaptive regression splines,random forest,extreme learning models,and the overall averaged results for all test sites [100].

NNs are also designed to directly predict the energy performance of energy harvesting devices.Artificial NNs can be used to design a prediction algorithm to forecast the output power according to the input parameters of a real-time environment monitoring system [102] or employ a sliding window data-level technique to accurately forecast output power [92].To set up the output characteristics of TEG-powered devices,a revised back propagation NN can be applied [103].

NNs are often combined with optimization methods.In ref.[104],the authors report that the combination of a Genetic algorithm and an NN model delivers highly accurate prediction of performance.In ref.[105], the study examines the combination of an NN and a multiverse optimization/genetic algorithm for the predicting output power, efficiency, and temperature.In ref.[98], the study discusses the combination of an artificial NN and a genetic algorithm for optimising the weighting update process and forecasting air temperature at intervals of 1,3,or 6 h ahead[98].Other combinations of NNs and ML approaches have also been tested.In ref.[106], the authors demonstrate the use of an Artificial NN combined with an adaptive neuro-fuzzy interface system to predict the thermal performance of a TEG system powered from waste heat;the system's prediction accuracy was greater than a setup which applies a coupled numerical approach.In ref.[107], thestudy presents a hybrid model composed of an NN and an echo state network.The system was used to generate power and predict energy consumption.The NN examined historical data and extracted meaningful patterns from which the echo state network could then learn temporal features.The output feature vector was then fed to fully connected layers for final forecasting.

T A B L E 11 Temperature prediction methods based on neural networks:description of input parameters,deployment location,and method performance.

Deep learning is a suitable method for predicting harvested energy from weather, wind, and solar energy data [108].Deep learning is often applied to obtain quick and accurate prediction of TEG performance.The deep NN approach uses the key parameters of a TEG device as input, and bases the training dataset on extracted features and finite element simulations [109].Artificial recurrent NN architecture in deep learning can also predict power generation; this technique is noteworthy for being able to manage complex problems with high non-linearity [110].However, the enormous computational,energy,and storage demands of deep NNs prohibit their deployment with resource-constrained energy-harvesting IoT sensors [111].

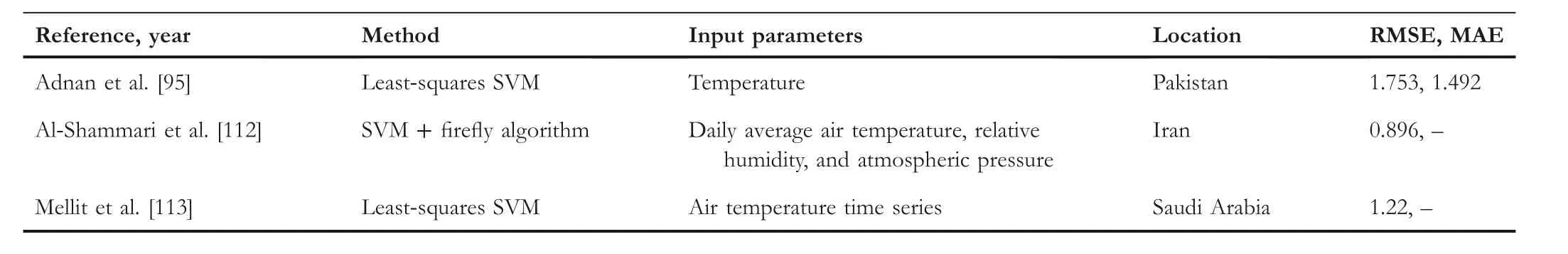

Compared to NNs, SVMs are more accurate and produce significantly better results [113], even with smaller training datasets [114].This method is suitable for both short-term[113] and long-term temperature forecasting [96].Table 12 lists several SVM methods which were tested at various locations with a range of input parameters.In ref.[95], the study demonstrates the air temperature prediction capability of a Least-Squares SVM.The Least-Squares SVM model was more accurate than an NN model, especially the Group method of data handling NN.In ref.[113], the study examines the suitability of the Least-Squares SVM method for short-term prediction of meteorological time series and reports significantly better results than Artificial NN architectures used for this purpose.The SVM method has also been compared to the dagging-based deep learning technique,which provides grid-side stability by predicting the overall current carrying potential of overhead transmission lines.This method outperforms the average prediction accuracy of SVM by 6.7% [115].

SVMs are not only combined with NNs,they are also often used in conjunction with optimization algorithms.In ref.[112],the authors examine the application of a firefly algorithm to an SVM to identify the optimal SVM parameters and thereby enhance the SVM's capabilities.This combination demonstrated greater efficiency, precision, and reliability than the combination of an SVM and an Artificial NN.

5.2 | Energy management

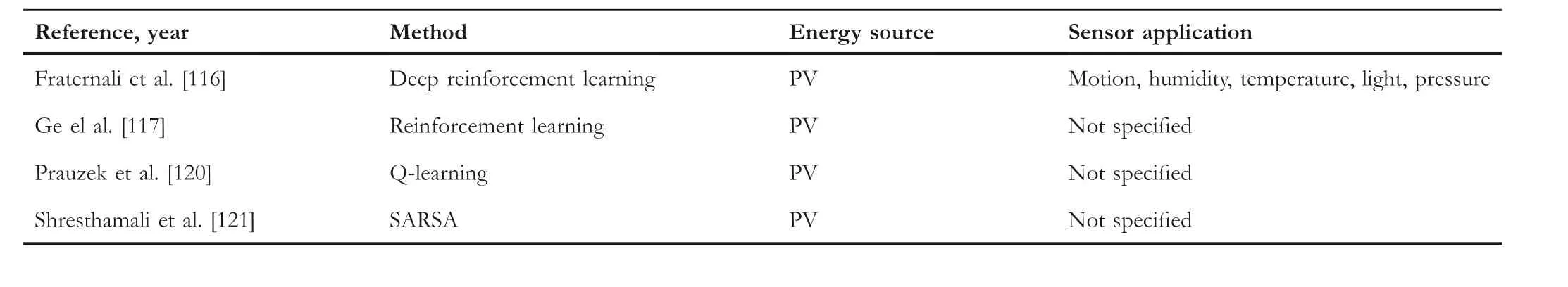

The quantity of available energy is a dynamic parameter which affects the operation of individual TEG-powered devices[17].An energy management system determines the device's operation at any time according to the available energy [116].Adaptive energy management is critical to controlling energy consumption and thus maintaining efficient system performance and sustainable operation[117].The main components of an energy management system include an energy policy,energy objectives and targets, monitoring, measurement, and analysis.These components set up and assist the device's energy production and consumption processes[118].Three types of strategy (rule-based, optimization-based, and learningbased) can be applied in energy management systems.[119].Key energy management techniques include fuzzy logic systems,NNs,and reinforcement learning[122].Table 13 lists several approaches suitable for energy management systems.Reinforcement learning based algorithms such as SARSA[121],Q-learning[120],and Deep Reinforcement Learning[116]can use historical data to manage energy production and consumption in sensors powered by energy harvesting.In ref.[117],the study explores reinforcement learning as suitable method for energy management by adjusting the duty cycle of each node in a wireless sensor network to achieve energy balance and prevent complete depletion in the node.In ref.[121], the authorspropose an adaptive power manager which uses SARSA learning to ensure near-optimal performance in solar energy harvesting sensor nodes and enhance battery performance without depletion or overcharging.In ref.[120],the study experiments with Qlearning in an environmental monitoring system which uses a wireless sensor network controller to achieve optimal data collection and transmission performance and thus minimise failure due to energy storage depletion.In ref.[123],the article describes an energy management algorithm based on a deep reinforcement learning framework.The algorithm was able to effectively distribute energy resources which were unreliable due to varying weather conditions affecting power generation (i.e.,sunny vs.cloudy days).In ref.[124],the study demonstrates the use of a deep reinforcement learning algorithm for energy management at a smart facility and minimising electricity costs while adapting to the characteristics of a decision-making problem.In ref.[116], the authors establish that deep reinforcement learning is able to learn environmental patterns over time and execute decisions to maximise the event detection rate of batteryless energy-harvesting sensor nodes under low energy conditions.The deep reinforcement learning approach proved its ability to decrease the load of a planner when faced with scenarios containing real-time restrictions[125].

T A B L E 12 Support vector machine approach used in temperature prediction: description of input parameters, deployment location, and method performance.

T A B L E 13 Reinforcement learning methods used for energy management in sensors powered by energy harvesting: description of method, energy harvesting source, and sensor application.

Reinforcement learning approaches can be combined with NNs to optimally manage scheduling under stochastic conditions [126].Neural networks approaches are widely used in conjunction with energy management algorithms for the ability to conveniently optimise energy consumption of a TEGpowered device in real-time [103].In ref.[127], the study examines an energy management technique based on an NN which ensured a continuous supply of electricity during periods of unreliable energy harvesting from an energy source which behaved erratically [127].In ref.[128], the authors attempt an experiment to eliminate the problems of discontinuous and unstable power generation through an NN energy management system which stores energy based on the difference between the energy generated and the energy required.

A fuzzy rules-based approach is another type of adaptive dynamic programming method.Fuzzy logic controllers are decision-making tools [129] and can be applied as power management systems to control and manage energy harvesting output [130].Besides controlling harvested energy, fuzzy logic controllers extend the lifetimes of energy harvesting devices[131].Because fuzzy logic is a rule-based algorithm, it can be combined with optimization-based algorithms to create a twostep energy management system [132].Genetic algorithms are able to optimise energy management strategies.For example,in[133], the study examines the deployment of a genetic algorithm to optimise self-consumption and satisfy real-time constraints while addressing unforeseen changes in device schedules and unpredictable variations in energy harvesting.

5.3 | Intelligent algorithms

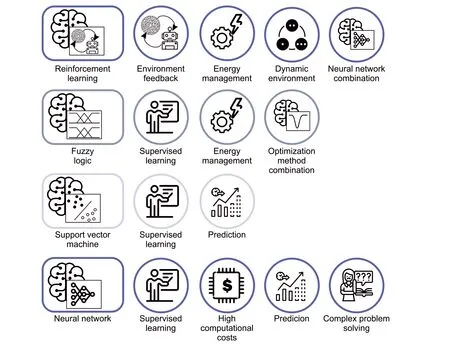

This section summarises the findings from our research of ML approaches which are suitable for energy prediction and deployment in energy management algorithms.The section highlights the suitability of various ML approaches, including reinforcement learning, fuzzy logic, and SVM, for energy management and prediction.Table 14 and Figure 5 summarise the characteristics of these ML approaches.

Reinforcement learning is a self-learning method suitable for deployment with energy management algorithms in dynamic environments.The method is not computationally intensive and is often combined with an NN to optimise and manage scheduling under stochastic conditions.Fuzzy logicbased algorithms lack self-learning abilities and are not suitable for adaptive energy management algorithms in dynamic environments, yet they are suitable for power management systems and are often deployed in combination with optimization algorithms.

SVMs are suitable for prediction and are more accurate than NN models.They are often applied in combination with optimization algorithms.It is also important to highlight that NNs are widely used in conjunction with energy management algorithms for their ability to conveniently optimise the energy consumption of a TEG-powered device in real-time.The drawbacks of NNs are high computational demands and lack of self-learning abilities, therefore they are unsuitable for deployment in energy management systems in dynamic environments.

In conclusion, reinforcement learning-based algorithms offer the benefits of low computational demands and selflearning skills, therefore they are suitable solutions for deployment with energy management algorithms in dynamicenvironments.SVMs are suitable for prediction,whereas fuzzy logic-based algorithms are more suited to use with power management systems.

T A B L E 14 List of findings of machine learning approaches suitable for energy prediction or energy management of TEG-powered Internet of Things devices.

F I G U R E 5 Features of machine learning approaches suitable for TEG-powered internet of things nodes.

6 | RESEARCH CHALLENGES

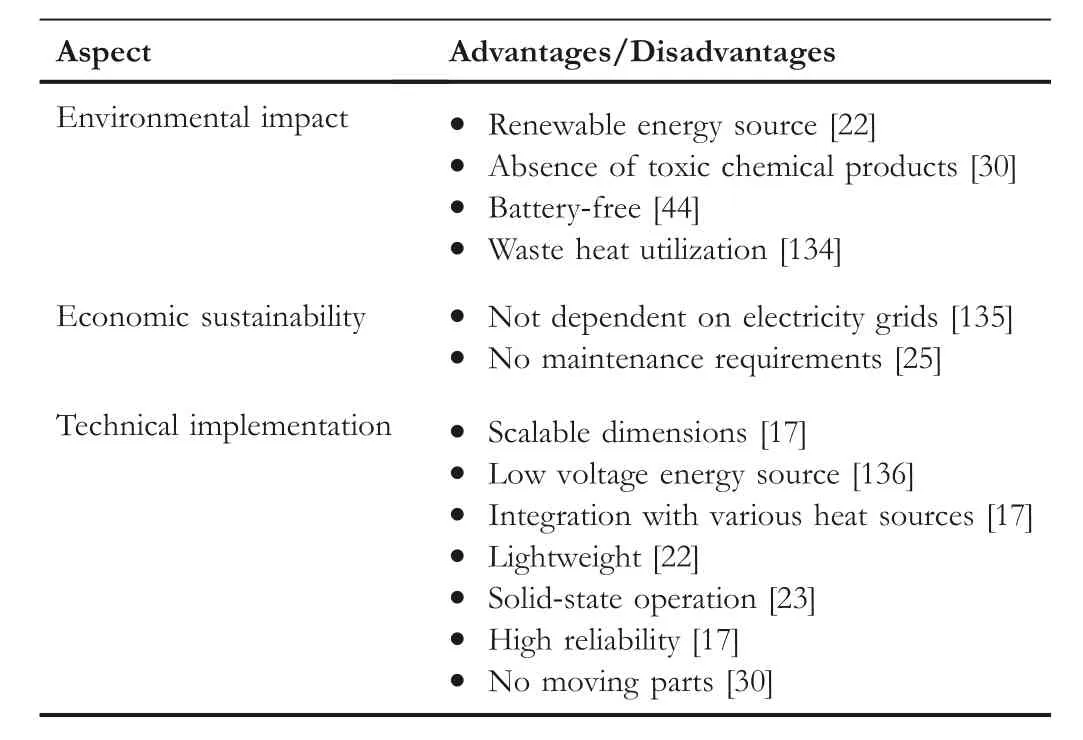

This section addresses the research challenges in IoT applications which use TEGs and discusses aspects such as environmental impact, economic sustainability, technical implementation, and the Industry 5.0 concept.The discussion also reviews the types of algorithm which can be deployed in conjunction with a TEG-powered device for the purpose of predicting generated energy or managing energy.The objective of balancing several attributes such as production cost, reliability, dimensions, and sustainability, which all affect the final design of a solution, is also examined.

6.1 | Applications

TEG-powered devices have several benefits regarding environmental impact, economic sustainability, technical implementation,and the Industry 5.0 concept.Thermoelectric generators are easy to implement in terms of dimensions [17],weight [22], and the absence of moving parts [30].Thermoelectric generators can be manufactured in many sizes and are therefore applicable in a wide range of industries [17].

Table 15 lists the individual benefits of the abovementioned aspects.The benefit to the environment in using TEG-powered devices is the absence of batteries or supercapacitors in the device's components[44].The materials used in batteries and supercapacitors are generally not environmentally friendly or cannot be mined or disposed of sustainably.Exclusion of batteries and supercapacitors in the designs of TEG-powered devices is therefore essential, and by eliminating the need for these components, the production of TEG-powered devices has lower energy requirements.In addition, TEG energy harvesting technologies do not necessitate external power sources and thus enable TEG-powered devices to operate independently [135].

Reduced energy consumption during the production of TEG-powered devices is more economically sustainable.The exclusion of battery and supercapacitor technology [44] from TEG devices eliminates the energy costs associated with the production of these components.Another economic benefit isthe move towards maintenance-free systems [25].TEGpowered devices need only simple maintenance if they do not contain a battery which requires replacement after a certain period[44].Another advantage of TEGs is their suitability for deployment in remote areas and the lack of any necessity to connect to a power grid [135].TEG-powered devices can therefore be deployed in environments such as forests,mountains, caves, and agricultural fields [44].TEG-powered devices do not need access to sunlight in the same manner as PV panels and can therefore be placed in environments which are exposed to minimal solar radiation.With TEGpowered devices, monitoring becomes available in areas which were previously limited by a lack of access to a regular power supply.However,if we assess only the economic aspect of using TEG technology to power sensor devices, TEGs are generally unprofitable power generators because of high acquisition costs and the relatively small amount of energy they produce [135].Nevertheless, the benefits of TEGs directly relate to the main pillars of Industry 5.0.Thermoelectric generator energy harvesting modules enable the implementation of devices which are in line with the Industry 5.0 concepts(that is, these devices assist workers in completing their tasks and deliver OHS benefits, more efficient use of time, and reduced physical demands.)

T A B L E 15 List of advantages and disadvantages of thermoelectric generators in terms of environmental impact, economic sustainability, and technical implementation.

In summary, with the ubiquity of temperature differentials available in the environment, the potential for TEG power generation is broad.TEG-powered devices are suitable solutions in any location where heat is transferred from a hot to cold medium,and therefore the opportunities for using TEGs in industrial or domestic applications are abundant.It is only a matter whether the inclusion of a TEG is worth the additional harvested energy.Although TEGs are characterised by low efficiency,the conversion of waste heat into energy can help in reducing environmental footprints.Another key characteristic and benefit of TEG-powered devices is low maintenance, but this is, however, offset by high fabrication costs based on the commercially available materials.Regardless of the high cost of TEGs and their low efficiency, TEGs are environmentally friendly solutions for converting waste heat into energy.For manufacturers, designers and developers, the challenge is to build TEGs composed of low-cost materials and using lowcost, automated manufacturing processes.Low-cost TEGs would ensure mass deployment in energy harvesting systems and consequently expand the range of application areas.

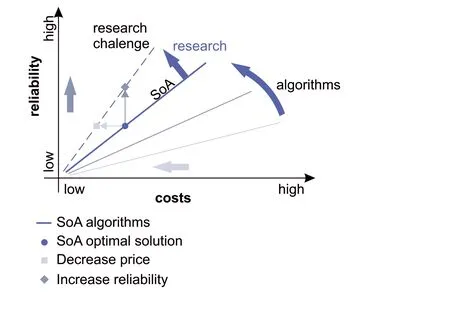

F I G U R E 6 Dependence of reliability on cost for optimal design and operation of a TEG-powered device.Algorithms are able to deliver anappropriate balance of reliability and cost.

6.2 | Algorithms

Power production by a TEG affects the balance of several attributes which must be considered to produce a suitable solution for a specific area of application.The main variables are reliability and cost, and their relationship is plotted in the chart in Figure 6.

For the optimal design and operation of a TEG-powered IoT device, cost and reliability must be balanced so that cost is as low as possible without compromising the device's reliability.However, reliability must be the maximum possible without too great an increase in the manufacturing cost.It is necessary to decide which of these attributes is more important in the solution.Algorithms provide potential solutions without limiting either of these attributes.Algorithms could be designed to deliver the appropriate balance of these two attributes and minimise the disadvantages of improving either without compromising the other.

TEG-powered devices raise several research challenges in the area of predictive and energy management algorithms.Various approaches have been applied to devices powered with different energy harvesting methods to achieve maintenancefree, autonomous systems which are reliable and customised to the area of application.For energy management in solar or wind-powered devices, NNs, fuzzy logic, and reinforcement learning algorithms have been deployed.For energy management in TEG-powered devices with similar working principles,none of these algorithms have as yet been applied.Duty cycle control is also a poorly researched area regarding TEGpowered devices, although a wide range of approaches could be applied.

Reinforcement learning methods are an especially suitable research area due to the satisfactory results obtained from energy management algorithms designed for sensors powered with PV panels.Q-learning has also demonstrated its capabilities in an environmental monitoring system which uses wireless sensor network controllers to achieve optimal data collection and transmission performance and to minimise the number of failures due to energy storage depletion.Another option in the design of reliable energy management systems is a combination of NN approaches and reinforcement learning.Deep reinforcement learning is suitable for energy management in TEG-powered IoT sensors for its ability to adapt to changes in the power produced by the TEG as a result of variable weather conditions (i.e., variable temperature differentials).Studies of deep reinforcement learning have shown its ability to adapt to varying weather conditions (i.e., sunny vs.cloudy days) which affect power generation.

6.3 | Future research directions

The review article identified various research challenges and potential future directions for the advancement of TEGpowered IoT devices.One key research challenge is addressing the limited investigation into energy management in TEGpowered devices which operate in a similar manner to solar or wind-powered devices.Another under-researched area is duty cycle control in TEG-powered devices, which presents a wide range of possible approaches.Notably, reinforcement learning methods offer promising avenues of research, given the satisfactory outcomes achieved by energy management algorithms designed for PV panel-powered sensors.

To tackle these challenges,future research can concentrate on developing cost-effective and efficient TEG-powered devices by exploring low-cost materials and temperature differentials.Additionally, employing ML algorithms holds promise for enhancing energy management and prediction in TEGpowered devices.Duty cycle control can benefit from reinforcement learning methods, while fuzzy logic, NN, deep learning, and SVM algorithms can be used for energy management and prediction.

Future research can also explore the potential applications of TEG-powered devices in emerging areas such as environmental sensors, wearable sensors, and health monitoring sensors.There is also space for investigating TEG-powered devices with improved sensing capabilities for machine/technology parameters.The review article emphasises the environmental friendliness of TEG-powered devices as they convert waste heat into electrical energy.Further research is required to address the challenges associated with energy management and prediction algorithms for TEG-powered devices, as well as to explore their potential in new application domains.

7 | CONCLUSION

This review article concludes by highlighting the research challenges and potential future directions in the area of energy management and energy prediction algorithms for TEGpowered devices.The review investigated the functioning principles, thermoelectric materials and topologies, including hybrid topologies, of TEG-powered devices, and presented a comprehensive summary of TEG-powered IoT devices that operate by generating power from small temperature differences.The review also described individual application areas of TEG-powered devices where low-power sensors can be deployed.Machine learning approaches and their suitability and potential use in energy prediction and energy management algorithms were outlined.However,the current research in the area of TEG-powered IoT devices indicates that these devices are still in the early stages of development and that further research is required to address the challenges in energy management and energy prediction algorithms deployed in TEGpowered devices.

One of the main research challenges is addressing the lack of energy management approaches for TEG-powered devices which have similar working principles to solar or windpowered devices.Duty cycle control is also a poorly researched area in relation to TEG-powered devices,although a wide range of approaches could be applied.Reinforcement learning methods are an especially suitable avenue of research due to the satisfactory results obtained from energy management algorithms designed for sensors powered with PV panels.Another potential avenue is addressing the lack of research on algorithms based on ML approaches for managing and predicting energy in TEG-powered devices.

The studies cited in this article may not be representative of all the research conducted in the field of TEG-powered devices and may only support the aims of this review.Additionally, the cited studies may have methodological limitations affecting the validity of their findings, for example, small sample sizes, lack of control groups, or inadequate statistical analyses.To ensure the validity of this review,several risk were addressed.First, the risk of bias was mitigated by including all research articles related to TEG-powered devices, thus avoiding the selective inclusion of studies which solely support the authors' arguments.Second, steps were taken to improve the generalisability of the findings by eliminating principles which cannot be transferred to other TEG-powered devices.Third,a representative group of articles was collected from high-ranked journals to enhance the overall quality of the review results.Finally,only recent studies were included for greater validity.In mitigating these risks, the review takes the necessary precautions to ensure the validity and robustness of its presented findings.

In conclusion, the review article highlights the potential of TEG-powered devices as environmentally friendly solutions for the conversion of waste heat into electrical energy.However, future research can address low-cost materials and temperature differentials to improve the costeffectiveness and efficiency of TEG-powered devices.The review also emphasises the need for further research into the challenges linked to energy management and energy prediction algorithms for TEG-powered devices and the potential of ML approaches in overcoming these challenges(Table A16).

ACKNOWLEDGEMENTS

This work was supported by the project SP2023/009,“Development of algorithms and systems for control, measurement and safety applications IX” of the Student Grant System, VSB-TU Ostrava.This work was also supproted by the project FW03010194 “Development of a System for Monitoring and Evaluation of Selected Risk Factors of Physical Workload in the Context of Industry 4.0″ of the Technology Agency of the Czech Republic.This work received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No.856670.This research received no external funding.

CONFLICT OF INTEREST STATEMENT

The authors declare no conflict of interest.

DATA AVAILABILITY STATEMENT

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

ORCID

Tereza Kucovahttps://orcid.org/0000-0002-7169-5116

Michal Prauzekhttps://orcid.org/0000-0003-1348-1328

Jaromir Konecnyhttps://orcid.org/0000-0002-0496-2915

Darius Andriukaitishttps://orcid.org/0000-0002-9862-8917

Radek Martinekhttps://orcid.org/0000-0003-2054-143X

APPENDIX A

A|References taxonomy

T A B L E A16 Taxonomy of references.

CAAI Transactions on Intelligence Technology2023年3期

CAAI Transactions on Intelligence Technology2023年3期

- CAAI Transactions on Intelligence Technology的其它文章

- Fault diagnosis of rolling bearings with noise signal based on modified kernel principal component analysis and DC-ResNet

- Anti‐noise diesel engine misfire diagnosis using a multi‐scale CNN‐LSTM neural network with denoising module

- Iteration dependent interval based open‐closed‐loop iterative learning control for time varying systems with vector relative degree

- An embedded vertical‐federated feature selection algorithm based on particle swarm optimisation

- An activated variable parameter gradient-based neural network for time-variant constrained quadratic programming and its applications

- Scale adaptive fitness evaluation‐based particle swarm optimisation for hyperparameter and architecture optimisation in neural networks and deep learning