Research on strategic risk identification method of equipment system development based on system dynamics

WANG Xinfeng,WANG Tao,ZHOU Xin,and WANG Yanfeng

College of Systems Engineering,National University of Defense Technology,Changsha 410073,China

Abstract: Strategic management of equipment system development must attach importance to effective strategic risk management.Aiming at the identification of strategic risk of equipment system development,firstly,the source of strategic risk of equipment system development is analyzed and classified.Based on this,a causal loop diagram of strategic risk of equipment system development based on system dynamics is established.The system dynamics analysis software Vensim PLE is used to carry out the risk influencing factors analysis,risk consequences analysis,risk feedback loop identification and corresponding pre-control measures,and achieves a good risk identification effect.

Keywords: equipment system development strategy management,strategic risk management,risk identification,system dynamics,loop diagram of causality.

1.Introduction

The strategic management of equipment development is an important part of the military strategic management.The strategic management of equipment development is the process of introducing strategic management theories and methods into the field of equipment development,making scientific plans for equipment development from a global and strategic perspective,and carrying out a series of activities such as forecasting,decision-making,planning,implementation and evaluation for the formulation and implementation of equipment development strategies [1,2].Modern high-tech warfare is the confrontation between equipment systems,and the development of equipment has changed from the past equipment platforms to focus on the overall capability of equipment systems.Therefore,the strategic management of equipment system development has become the development trend and main content of the current strategic management of equipment development.In the process of strategic management of equipment system development,there are many problems,such as complex and multi-dimensional management objects,multiple stakeholders,long cycle span,great difficulty in predicting changes in internal and external strategic environment,and difficult process adjustment.There are inevitably strategic risks,that is,the conditions necessary to achieve strategic objectives are insufficient or non-existent,which cannot guarantee the realization of strategic objectives.To ensure the realization of strategic objectives and the smooth implementation of the strategic management process,strategic risk management must be carried out.Strategic risk management is an effective combination of strategic management and risk management,and has become an important branch of strategic management [3-7].

To carry out strategic risk management of equipment system development,first of all,we must carry out strategic risk identification of equipment system development,which is the foundation and the most initial link of strategic risk management,and directly determines the success or failure of risk management.Risk identification is to find,identify and describe the potential risk matters that may have an impact on the target,analyze the source of risk,the cause of risk,the scope and nature of the impact of risk consequences and the corresponding current control measures.Common methods for risk identification include brainstorming method,Delphi method,checklist method,fault tree method,scenario analysis method,work breakdown structure (WBS) method,analytic hierarchy process (AHP) method,etc.The above methods can be summarized into two types.One is the expert interview method represented by brainstorming method,Delphi method,etc.The other is the analysis method represented by checklist method,fault tree method,scenario analysis method,WBS method,AHP method,etc [8-16].The expert interview method is mainly through the interview,the expert’s professional theoretical knowledge and research information is integrated,to find the possible risk factors.The analysis method is mainly through the decomposition,refinement and analysis of the project,to sort out and classify risk factors.The advantage of the expert interview method is that it can quantitatively analyze the risks when the knowledge about the project data is relatively lacking,but its disadvantage is that the experts have strong subjectivity,which may cause potential risks to be ignored.The advantage of the analysis method is that other project management processes,such as cost management process,also need to carry out work decomposition,and the risk identification process can share the decomposition results with other project management processes.The disadvantage is that when dealing with complex or large-scale engineering projects,the decomposition process is too complex,which needs more time and effort.

The strategic management process of equipment system development is a typical complex system with high uncertainty of risk factors,and most of them are difficult to quantify scientifically.For example,it is difficult to achieve good results by using expert interview and analysis methods.Therefore,based on the initial analysis and classification of the risk sources of equipment system development strategy,this paper establishes a causal loop diagram of equipment system development strategy risk based on system dynamics.System dynamics analysis software Vensim PLE is used to analyze the risk influencing factors,risk consequences,risk feedback loop identification and corresponding pre-control measures,and good risk identification results are achieved.

2.Risk classification of equipment system development strategy

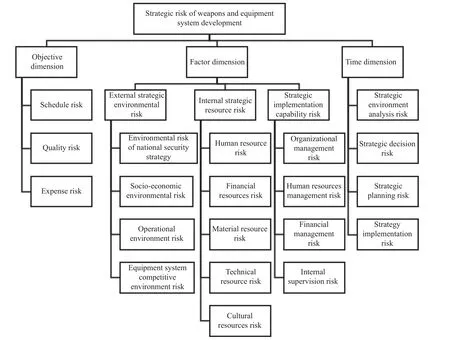

In order to facilitate the research and management of risks,people often classify risks.Based on the needs of strategic risk management of equipment system development,this paper classifies strategic risks from objective dimension,factor dimension and time dimension respectively.

2.1 Objective dimension

The ultimate goal of strategic management of equipment system development is to achieve strategic objectives.Strategic objectives can be basically described from three aspects,namely progress goals,quality goals and expenses (investment or cost) goals.The realization of these three goals is uncertain,so there are schedule risk,quality risk and expense risk in the strategic management objective dimension of equipment system development.

2.2 Factor dimension

According to the theory of strategic management,strategic management is to achieve the match between the strategic planning and design and the internal and external strategic environment,and the risk is formed because the strategic planning and design cannot match the internal and external strategic environment [14-16].Similarly,for the strategic management of equipment system development,the realization of its strategic objectives requires the matching of strategic planning and design with internal and external strategic environment.If there is deviation in the matching between the two,it is likely that the strategic objectives cannot be achieved and strategic risks are formed.

The external strategic environment of equipment system mainly includes national security strategic environment,socio-economic environment,combat environment,equipment system competition environment,etc.Internal strategic environment can be reflected by internal strategic resources and strategic implementation ability.Internal strategic resources include both tangible assets and intangible assets,mainly human resources,capital,material,technology,information,culture and other resources.Strategy implementation ability is a necessary key factor to achieve strategic goals,mainly including organization and management ability,human resource management ability,financial management ability,project organization ability,and internal supervision ability.The mismatch between strategic planning and strategic environment can specifically include the mismatch between strategic planning and external strategic environment,the mismatch between strategic planning and internal strategic environment,the mismatch between strategic planning and strategic implementation capability,the mismatch between strategic implementation capability and external strategic environment,the mismatch between strategic implementation capability and internal strategic resources,and the mismatch between external deployment environment and internal strategic resources.Each mismatch will lead to deviation in the realization of strategic objectives,which will lead to the generation of strategic risks.The formation mechanism diagram of strategic risk factors for equipment system development is shown in Fig.1.

Fig.1 Formation mechanism of strategic risk factors of equipment system development

Therefore,the strategic risk factors of equipment system development can be divided into external strategic environment risk,internal strategic resource risk and strategic implementation ability risk.External strategic environmental risks mainly include national security strategic environmental risks,socio-economic environmental risks,operational environmental risks,and equipment system competition environment risks.Internal strategic resource risks mainly include human resources risks,capital resources risks,material resources risks,technological resources risks,and cultural resources risks.Strategic implementation capability risk mainly includes organized management risk,human resource management risk,financial management risk,project organization risk,and internal supervision risk.

2.3 Time dimension

Time dimension corresponds to the whole life cycle of equipment system development strategy management process.Generally speaking,its strategic management mainly includes four key stages: strategic environment analysis,strategic decision-making,strategic planning and strategic implementation [17,18].At each stage,there is the possibility of strategic risk.The tasks of the strategic environment analysis stage mainly include the external strategic environment analysis and the internal strategic environment analysis.The purpose of the external strategic environment analysis is to understand the external threats and development opportunities of the equipment system development.The purpose of the internal strategic environment analysis is to recognize the internal strengths and weaknesses of the equipment system development and lay the foundation for strategic decisionmaking.The strategic decision-making stage is a process of selecting and establishing major issues such as equipment system development goals,development approaches,and development priorities based on strategic environment analysis and clear strategic needs.Strategic decision-making is a process of establishing development goals and directions.The strategic planning stage is a process of decomposing and refining the strategic objectives and tasks on the basis of strategic decisions,optimizing the allocation of strategic resources with the planning plan as the leading role,defining development measures,methods and steps,and forming policy documents such as development plans,plans or schemes.The task of the strategy implementation stage is mainly to inspect,supervise,guide and regulate the implementation process of the strategic planning through the improvement of the equipment system development organization system and mechanism,so as to ensure the implementation of the strategic decision-making and planning.

In the four stages,risk analysis is carried out in advance to understand the possible strategic risks,and necessary management and control measures are taken to reduce these risks or control them at an acceptable level,which can increase the possibility that the strategic objectives can be completed according to the budget and schedule.

Based on the above discussion,the risk classification diagram of equipment system development strategy is established,as shown in Fig.2.

Fig.2 Strategic risk classification of equipment system development

3.Identification of strategic risk factors based on system dynamics

System dynamics is a method proposed by Dr.Forrest of Massachusetts Institute of Technology in the 1960s to study the dynamic behavior of systems.Its research purpose is to reveal the information flow and feedback characteristics of complex systems such as socio-economic systems and ecosystems [19-22].The advantages of using system dynamics to carry out risk identification are as follows [23-30]: first,the dynamic relationship between risk factors can be intuitively expressed through the risk causality diagram;second,when there are risk factors that are not easy to be accurately quantified,the research can continue within the parameter tolerance of the system dynamics model.As the strategic management cycle of equipment system development is long,there are many participants,and the uncertainty of internal and external environment is high,the use of system dynamics method to build a model can make up for the shortcomings of traditional methods and provide more perfect countermeasures and suggestions for strategic risk management.

Among many system dynamics simulation software,Vensim PLE software is the most widely used in the academic world with its efficient operation function and simple and understandable operating system [31-33].When Vensim PLE is used,the system dynamics model can be established accurately and quickly by building and inputting the system dynamics equation without programming,thus realizing the simulation of the research system.This paper applies Vensim PLE v8.1 software to identify the strategic risk factors of equipment system development.

3.1 Establishment of the causality loop diagram of strategic risk of equipment system development

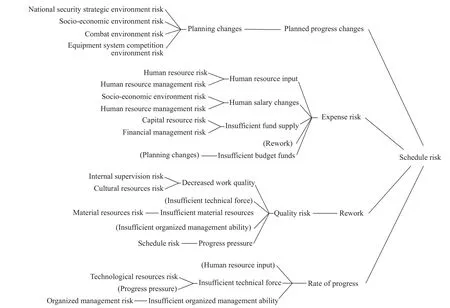

According to the risk classification diagram of the equipment system development strategy,from the objective dimension,the equipment system development strategy risk is divided into three risk subsystems: schedule risk,quality risk,and cost risk.The causal relationship between three risk subsystems and other factors including external strategic environmental risk (including national security strategic environmental risk,socio-economic environmental risk,operational environmental risk and equipment system competition environmental risk),internal strategic resource risk (including human resource risk,capital resource risk,material resource risk,technical resource risk and cultural resource risk),strategic implementation capability risk (including organizational management risk,human resource management risk,financial management risk and internal supervision risk)is analyzed.Use Vensim PLE software to establish the action path of each subsystem and its corresponding risk factors,and build the causal loop diagram of equipment system development strategy risk as shown in Fig.3.

Fig.3 Loop diagram of causality of strategic risk of equipment system development

In the causal loop diagram,the causal chain is used to reflect the causal relationship of different factor variables.It is indicated by an arrow symbol that shows the result and the tail of the arrow shows the cause.The causal chain has two different polarities,positive and negative,which are respectively represented by “+”and “-” symbols.If the causal chain is positive,it means that the variables in the system are positively related,that is,the dependent variable will change in the same direction with the change of the independent variable;for a negative causal chain,the opposite is true.Based on the causal chain function of Vensim PLE software,specific risk identification can be carried out for the three risk subsystems of the equipment system of systems development strategy,that is,the top-level risks to be analyzed can be selected and analyzed layer by layer according to the logical direction from top to bottom,so as to identify the key risk influencing factors under the subsystem,and clarify the causal relationship between the risk factors according to the tree diagram.In addition,the feedback function in Vensim PLE software can also be used to obtain the risk causal chain under different risk cycles,so as to conduct more in-depth research and analysis on the interaction and dynamic impact between different risks.

3.2 Impact analysis of schedule,cost and quality risk factors

Based on the causal loop diagram of equipment system of systems development strategic risk,the impact diagram of schedule risk factors can be obtained by using the result tree function of Vensim PLE software,as shown in Fig.4.It can be clearly seen from Fig.4 that the main factors cause schedule risk.The more factors cause schedule risk,the greater the possibility of schedule risk.In the quantitative or qualitative analysis of schedule risk,we mainly analyze the size and probability of these main factors to analyze the size of schedule risk.Similarly,the influencing factors of cost and quality risk are shown in Fig.5 and Fig.6.

Fig.4 Influencing factors of progression risk

Fig.5 Influencing factors of expense risk

Fig.6 Influencing factors of quality risk

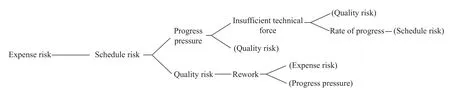

3.3 Identification of consequences resulting from schedule,cost and quality risks

Using the result tree function of Vensim PLE software,the schedule risk result tree as shown in Fig.7 is obtained.The consequences caused by schedule risk can be clearly analyzed through Fig.8,mainly including quality risk,progress speed,cost risk and schedule pressure.The more consequences caused by schedule risk,the greater the potential loss caused by this risk.When schedule risks occur in the construction process,pay enough attention to the consequences in the figure to avoid secondary risks.Similarly,the influencing factors of expense and quality risk can be shown in Fig.8 and Fig.9.

Fig.7 Identification of the consequences of schedule risk

Fig.8 Identification of the consequences of expense risk

Fig.9 Identification of the consequences of quality risk

3.4 Identification and control analysis of feedback loop of schedule,cost and quality risk

When the causal chain constitutes a closed channel,the feedback loop will also be generated with positive and negative polarity.Based on the causal loop diagram and the “Loops” function of Vensim PLE software,the causal chain related to schedule risk can be identified as follows:

From the above causal chain,we can see that with the increase of the risk of the equipment system development strategy progress,the pressure of the strategy implementation progress increases,which may directly lead to the increase of the quality risk,and may also require more technical input,leading to the quality risk.The quality decline may lead to rework,which will lead to the increase of the schedule risk and cost risk,and the cost risk will also indirectly lead to the increase of the schedule risk.The above causal chains are all positive feedback loops,indicating that when schedule risk occurs,the schedule risk is further increased through the self reinforcement effect of a large number of positive feedback loops.

It can be seen from the above causal loop of schedule risk that the control method adopted to reduce schedule risk is mainly to mitigate and reduce the schedule pressure caused by schedule risk,which can be implemented in two ways: first,by increasing internal supervision,technology,material,organizational management and other resources,the quality will not decline,and the rework and cost will be avoided,so as to reduce the schedule risk.Second,by increasing technical force,reduce the risk of technical resources brought by progress pressure,avoid the quality risk and the increase of rework quantity brought by the lack of technical force,so as to reduce schedule risk.

It is also possible to identify and analyze the impact of risk factors brought by the feedback loop of expense risk and quality risk,which will not be discussed in detail in this paper.

4.Conclusions

Aiming at the strategic risk identification of equipment system of systems development,this paper points out the shortcomings of the application of traditional risk identification methods,and then studies and proposes a method for identifying the strategic risk of equipment system of systems development based on system dynamics.This method first analyzes and classifies the sources of the strategic risk of equipment system of systems development,and then establishes a causal loop diagram of the strategic risk of equipment system of systems development based on system dynamics.The risk impact factor analysis,risk consequence analysis,risk feedback loop identification and corresponding control measures research are carried out.The research results show that this method has the following advantages compared with the traditional risk identification methods: first,as the strategic risk identification has the risk factors that cannot be accurately quantified,the relationship between risk factors can be intuitively expressed through the risk causality diagram to identify risk factors;second,through the analysis of the feedback loop,we can find some hidden risks that cannot be found by other identification methods.

The next step is to convert the risk causal loop diagram into the system stock flow diagram,determine the boundary risk factors and assign weights,and establish a quantitative risk analysis model for the equipment system development strategy based on system dynamics.This model can effectively support the risk analysis,risk evaluation,risk control and other research work after risk identification.

Journal of Systems Engineering and Electronics2023年5期

Journal of Systems Engineering and Electronics2023年5期

- Journal of Systems Engineering and Electronics的其它文章

- A spawning particle filter for defocused moving target detection in GNSS-based passive radar

- Cuckoo search algorithm-based optimal deployment method of heterogeneous multistatic radar for barrier coverage

- Radar fast long-time coherent integration via TR-SKT and robust sparse FRFT

- Robust dual-channel correlation algorithm for complex weak target detection with wideband radar

- Deep convolutional neural network for meteorology target detection in airborne weather radar images

- Super-resolution parameter estimation of monopulse radar by wide-narrowband joint processing