Development and performance evaluation of a high temperature resistant,internal rigid,and external flexible plugging agent for waterbased drilling fluids

Zhe Xu ,Jinsheng Sun ,b,* ,Li Li ,Kihe Lv ,Jingping Liu ,** ,Zhiwen Di ,Xinf Zhng ,Zonglun Wng

a School of Petroleum Engineering,China University of Petroleum (East China),Qingdao,266580,China

b CNPC Engineering Technology R&D Company Limited,Changping,10206,China

c Oil & Gas Technology Research Institute of Changqing Oilfield Company,Xi'an,710000,China

Keywords: Internal rigidity External flexibility Plugging agent Filter loss reduction Plugging performance

ABSTRACT During the drilling process for oil and gas production,a larger number of drilling fluids invade the formation,causing severe formation damage and wellbore collapsing,which seriously hinders the efficient production of deep oil and gas.Although several plugging agents have been developed for efficient fracture sealing in recent years,the development of high-performance plugging agents with selfadaptive ability and high-temperature resistance remain a challenge.Herein,we report the synthesis of an internal rigid and external flexible plugging agent PANS by reversed-phase emulsion polymerization with nano-silica as the rigid core and poly (acrylamide-co-N-vinylpyrrolidone) as a flexible shell.The plugging agent has a median particle size of 10.5 μm and can self-adapt to seal the microfractures and fractures in the formation,leading to an effective reduction in the filtration loss of bentonite waterbased drilling fluid under both low temperature and low pressure(LTLP)and high temperature and high pressure (HTHP) conditions.In addition,compared with the neat nano-silica (500 nm),the sealing efficiency of PANS toward 100-120 mesh sand bed was increased by 71.4% after hot rolling at 180°C.

1.Introduction

With the rapid growth in demand for oil and gas and the yearon-year increase in domestic oil and gas dependence,there is an urgent need for us to accelerate the efficiency of oil and gas exploration and development [1].China's deep oil and gas resources are abundant,and the production of deep oil and gas from the reservoir to the surface must be established through drilling,of which drilling fluid plays critical roles,e.g.,carrying and suspending drilling bits,cooling the drilling bits,and maintaining the wellbore stability [2,3].However,the development of microfractures and fractures in deep formations and subsequent penetration of drilling fluid along the micro-fractures and fractures into the deep part of the formation are prone to cause downhole complications and accidents,such as well wall collapse,leakage,stuck drilling,and reservoir injury,which seriously restrict the process of deep oil and gas exploration and development [4-6].Therefore,there is a need to develop a plugging agent that effectively stops drilling fluids from entering microfractures and fractures in the formation.

There are many types of inorganic plugging agents,such as silica,calcium carbonate,etc.,which are commonly used in drilling.In addition,it also includes graphite,zinc oxide,titanium oxide,various iron complexes,and silicon synthetic materials.Inorganic plugging agents generally have the advantages of good temperature resistance and strength,but a single inorganic plugging material cannot form a stable plugging layer,and often needs to be compounded with other materials or modified to achieve a good plugging effect [7-9].Su et al.invaded sand beds with a depth of 2.5 cm by compounding lignin fibres,elastomeric materials and calcium carbonate for 10-20 purposes [10].By modifying the surface of silica,Ma et al.showed a good sealing performance for low permeability reservoirs at 170°C,with a sealing efficiency of 78.25%[11].Polymer plugging agent is mainly based on polyacrylamide and its copolymer with other monomers as a glue-forming agent,using its rheological properties to seal the strata,with good sealing effects [12-14].Jia et al.obtained polymer gels using acrylamide,metal ion crosslinkers,and polyethyleneimine crosslinking,which are resistant to temperatures up to 150°C [15].Yan et al.used acrylamide(AM)and N,N-methylene-bis-acrylamide(MBA)as raw materials to synthesise a delayed cross-linked polyacrylamide gel plugging agent that is resistant to 150°C[16].Li et al.used styrene(ST),AM,2-acrylamido-2-methylpropanesulfonic acid (AMPS) and dimethyldiallylammonium chloride(DMDAAC)as raw materials to synthesise polymeric nanospheres with a double cross-linked structure,which could retain about half of their original size after high temperature treatment at 150°C -200°C [17].The polymer plugging agent can adapt itself to the size and shape of the leaky channel,but it is not strong enough to form a plugging layer with a generally poor pressure-bearing capacity.

Currently,the combination of inorganic materials such as nanosilica and calcium carbonate with polymers increases the strength of plugging agents,and the combination of fibers and rubber with polymers increases the toughness of plugging agents has become the development trend of plugging agents [18-20].James et al.developed a composite plugging agent with synthetic fibers and polymers,which can resist temperatures up to 120°C and can effectively prevent fluids from entering the formation[21].Lecolier et al.prepared an organic/inorganic nanocomposite gel,which can reduce the permeability of rocks and has a good plugging effect under a high temperature of 120°C [22].Sun et al.synthesized a composite plugging material with quartz sand and bitumen,which could effectively seal the fractures by bridging and deformation filling,with a pressure-bearing capacity of >3.5 MPa at 80°C [23].Sadeghalvaad et al.synthesized a nanocomposite material with TiO2and AM,which improved the plugging performance by 64.0%at room temperature [24].Pan et al.used elastic rubber granules and partially hydrolyzed polyacrylamide (HPAM) to form a plugging agent.When the number of rubber granules was 5.0%and the amount of HPAM was 0.5%,the pressure could be up to 12.2 MPa after sealing 1-4 mm pores at room temperature [25].Zhang synthesized a composite granular plugging agent with bentonite,AM,AMPS,and acrylic acid (AA).After aging at 150°C,it still has good toughness and can bear pressure up to 8 MPa[26].Zhang et al.developed a new high-temperature-resistant fiber-reinforced gel consisting of flexible fibers,AM,AMPS,and butyl methacrylate(BMA),which can seal highly permeable layers up to 7 MPa under a high temperature of 140°C,and up to 5 MPa after sealing wide fracture leaky channels[27].Xu et al.prepared an external flexible and internal rigid plugging agent with crosslinked pAM and pAMPS as the shell and calcium carbonate as the core,which improved the blocking performance by 75.0% after aging at 120°C [28].Liu et al.prepared an organic/inorganic composite plugging agent using AM and nano-silica as raw materials.The plugging agent reduced the filtration loss of water-based drilling fluid by 88.3% after aging at 150°C,and its plugging performance was better than that of crosslinked acrylamide microspheres and nano-silica [29].

However,the above-mentioned plugging agents have either poorly self-adaptive ability or insufficient temperature resistance.Therefore,in this work,a novel plugging agent PANS with the combined self-adaptive ability and high-temperature resistance is prepared,which consists of nano-silica as a rigid core and copolymers as a flexible shell.Filtration and blocking performance analyses revealed that PANS can reduce filtration loss and seal pores and fractures at the same time,providing alternative technical support for oil and gas drilling in deep strata.

2.Experiments

2.1.Materials

White oil (5#),acrylamide (AM,99 wt%),N-vinylpyrrolidone(NVP,99 wt%),N,N-methylene-bis-acrylamide (MBA,wt%),nanosilica(99 wt%,500 nm),span 80(Span80,99 wt%)and ammonium persulphate (APS,99 wt%) were purchased from Sinopharm Chemical Reagent Co.Sodium bentonite for drilling fluid was purchased from Huai'an County Tengfei Bentonite Development Co.

2.2.Preparation of PANS

PANS was prepared by reverse phase emulsion polymerization.The synthesis process includes three critical steps:(1)preparation of the oil phase,(2) preparation of the aqueous phase,and (3) emulsification and cross-linking reaction.In the first step,a certain amount of emulsifier Span 80 was added to white oil,and then the mixture was stirred vigorously.In the second step,nano-silica was dispersed in deionized water by sonication for 10min.Then,reaction monomers (i.e.,AM and NVP) and cross-linking agents (i.e.,MBA)were charged and stirred until fully dissolved.In the third step,the as-prepared aqueous phase was slowly dropwise to the oil phase and emulsified at room temperature for 30min.Finally,the reaction was initiated by adding the APS initiator at 70°C under stirring for 5 h.

2.3.Characterization of PANS

Solid samples of PANS were obtained by repeated washing of the PANS emulsion with acetone and anhydrous ethanol,followed by centrifugation and then drying at 105°C using a drying oven.The IR spectra were measured at room temperature in the frequency range 400-4000 cm-1with a resolution of 4 cm-1using a Shimadzu IRTrancer-100 infrared spectrometer.The sample was prepared based on the KBr pellet method.

The thermal stability was determined using a TGA 550 thermogravimetric analyzer (Mettler-Toledo,USA) under a nitrogen protection atmosphere at a temperature range of 40°C-800°C and a heating rate of 10°C∙min-1.The particle size and microscopic morphology were evaluated with the aid of a Mastersizer 3000 laser particle size analyzer(Malvern,UK)and an EVO LS15 scanning electron microscope (Zeiss,Germany).

2.4.Performance evaluation

2.4.1.Rheological andfiltration properties

Different concentrations of PANS were added to 4% prehydrated sodium bentonite-based drilling fluid.The mixtures were stirred at high speed for 20min to obtain a homogeneous suspension system and hot-rolled at a pre-designed temperature for 16 h to determine the rheological and filtration properties.

The rheological and filtration performance were measured according to the standard of the American Petroleum Institute (API)[30,31].Specifically,the rheological properties of bentonite-based drilling fluid containing different amounts of samples,such as apparent viscosity(AV),plastic viscosity(PV),and yield point(YP),were tested with ZNN-D6 six-speed rotary viscometer (Qingdao Haitongda special instrument Co.,Ltd.,China).The API filtration of bentonite-based drilling fluid containing samples at 25°C and 100 psi ± 5 psi was tested by an SD medium pressure filtration instrument(Qingdao Tongchun Oil Instrument Co.,Ltd.).JM-2 high temperature and high-pressure filtration instrument (Qingdao Tongchun Oil Instrument Co.,Ltd.) was used to test the high temperature and high pressure (HTHP) filtration of bentonite-based drilling fluid containing samples at different hot rolling temperatures and 500 psi ±5 psi pressure.

2.4.2.Blocking performance

The intrusion depth of the drilling fluid was measured in an FA.BX visual medium pressure sand bed plugging instrument(Qingdao Tongchun Oil Instrument Co.,Ltd.)containing 350 cm3of quartz sand in the cylinder.The drilling fluid,which had been hot rolled and cooled to room temperature,was poured into the cylinder,pressurized by 0.69 MPa,and tested for 30min.The depth of intrusion of the drilling fluid was recorded.The permeability of the sand bed was changed by controlling the mesh of quartz sand in the experiment.

Five artificially created cores with 25 mm in diameter,50 mm in length,and similar permeability were taken.The cores were sealed with water,1% PANS dispersion,2% PANS dispersion,3% PANS dispersion,and 3%nano-silica dispersion by LDY50-180A core flow tester(Jiangsu Hongbo Machinery Manufacturing Co.,Ltd.)at room temperature and 2 MPa surrounding pressure.

A natural core of 25 mm in diameter and 50 mm in length was firstly repelled with water,and the NMR spectrum of water was recorded by using a Macro MR12-150H-VTHP NMR analyzer (Suzhou Niumag Analytical Instruments Co.,Ltd.).Then,the core was fully dried and repelled with 3% PANS aqueous solution to obtain the NMR spectrum of PANS.

Take 3 cups of 400 mL base drilling fluid,add 3%PANS to one of the cups and 3%nano-silica in one of the cups,stir at high speed for 20 min,add to the aging tank respectively,place them at 180°C for 16 h,and then prepare mud cake by SD type medium pressure filter loss instrument,as shown in Fig.1.The mud cake was dried after washing off the surface with water to remove the virtual mud cake,then a small piece was taken and glued onto the conductive adhesive,sprayed with gold,and observed by electron scanning microscope for its microscopic morphology.

Fig.1.Comparison of filter cake morphology between base drilling fluid and 3%PANS base drilling fluid after hot rolling at 180 °C for 16 h((a)Base drilling fluid mud cake,(b)3%PANS base drilling fluid cake,(c) 3% nano-silica base drilling fluid cake.

3.Results and discussion

3.1.Characterization of PANS

3.1.1.Chemical structure

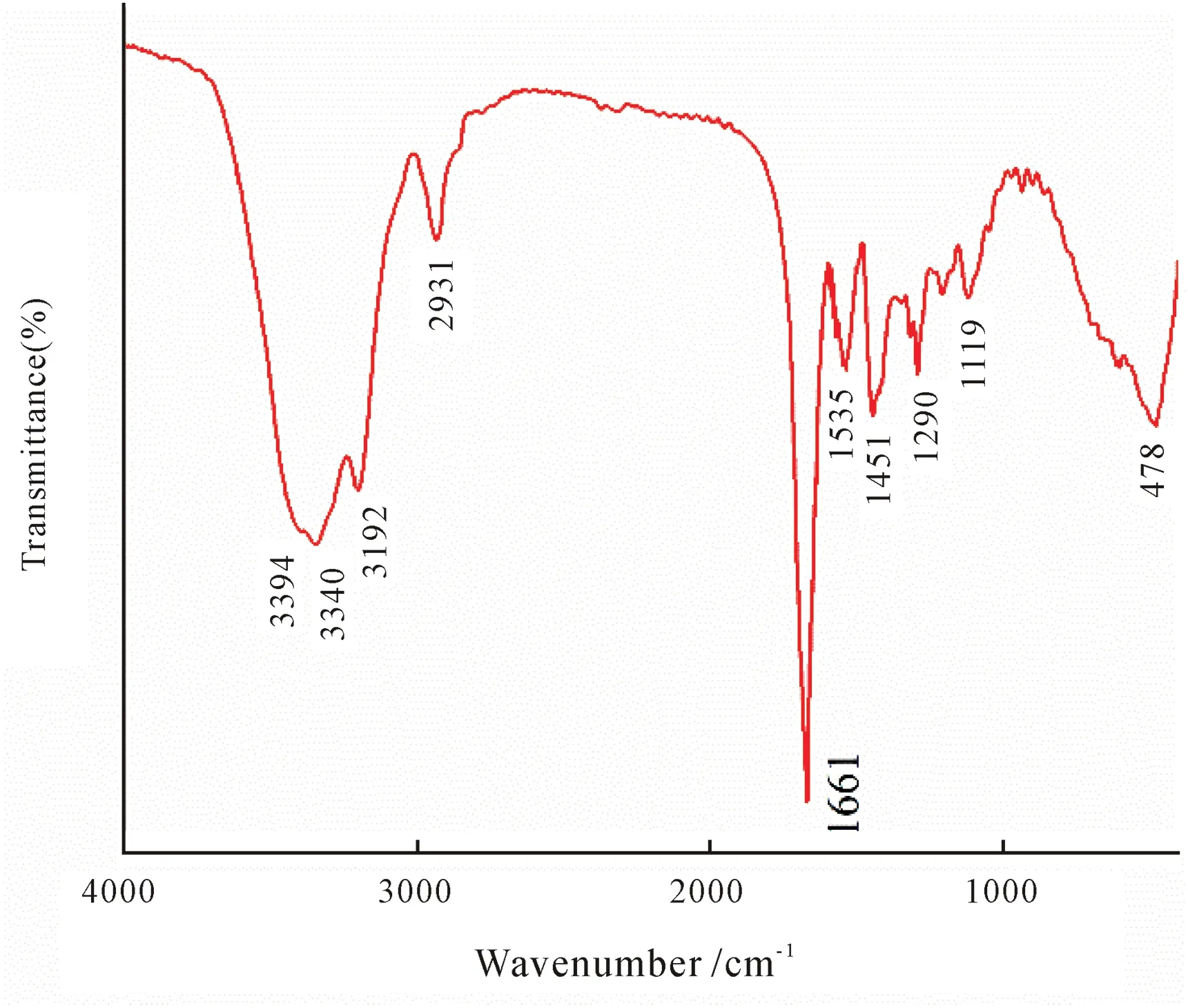

The infrared spectrum can be used to analyze the functional groups contained in the polymer and thus determine whether the synthesized material is the target product [32,33].The infrared spectrum of PANS is shown in Fig.2.The main characteristic peaks in AM appear at 3192 cm-1and 3340 cm-1for the symmetric and antisymmetric stretching vibration absorption peaks of -NH2and 1661 cm-1for the carbonyl(C=O) stretching vibration absorption peak[34,35].3394 cm-1is the N-H stretching vibration absorption peak in MBA.An absorption peak of a five-membered ring in NVP appears at 1451 cm-1,1290 cm-1is the -C-N-stretching vibration absorption peak,and there is no bending vibration absorption peak of N-H between 1655 cm-1and 1590 cm-1,indicating that the vinyl group of NVP was polymerized and the ring-opening reaction did not occur.478 cm-1is the Si-O-Si bending vibration absorption peak[36].Hence,the characteristic peaks of PANS indicate that all specific functional monomers have been successfully incorporated during the polymerization.

Fig.2.Infrared spectrum of PANS.

3.1.2.Thermal stability

The temperature of the reservoir is high at around 200°C.Some polymers can be thermally degraded at such high temperatures,causing the molecular chain to break,resulting in the polymer losing its original properties.If the polymer shell of PANS is thermally degraded,its capacity will be significantly reduced and the plugging effect will be damaged.Therefore,the thermogravimetric analysis (TGA) is conducted to understand the thermal stability of PANS.The TGA and DTG curve of PANS is shown in Fig.3.

Fig.3.TGA and DTG curve of PANS.

As can be seen in Fig.3,the thermal weight loss of PANS can be divided into three stages.The first stage is between 40°C and 230°C,with the maximum weight loss occurring at 69°C,and the sample retention at 230°C is 90.7%.The main cause of weight loss in this stage is the volatilization of bound water.Therefore,the sample can be useful in this temperature range.The second stage of weight loss is mainly caused by the thermal decomposition of the amide group.In this stage,the weight loss mainly occurred in the range of 230°C-330°C,and the retention of the sample at 330°C is 69.5%.According to the TGA-DTG curve,the maximum weight loss occurred at 301°C.The third stage is caused by the start of the breakage and decomposition of the main and side chains of the sample molecule.The decomposition temperature mainly ranged from 330°C to 494.3°C and the maximum weight loss rate occurred at 378.3°C.After 494.3°C,the thermal weight loss rate of the sample essentially equilibrated,leaving the rigid material,i.e.,nano-silica.The thermal stability analysis of PANS showed that no significant thermal decomposition occurred until the temperature reached 230°C,indicating that PANS has good thermal stability,which meets the temperature-resistant requirement in the reservoir.

3.1.3.Particle size and micromorphology

The particle size distribution curve of PANS determined by the laser particle size analyzer is shown in Fig.4(a).The experimental results show that the median particle size of PANS is 10.5 μm.Fig.4(b) shows an SEM photograph of the PANS with a magnification of 3000x.It can be seen that the PANS particles are spherelike and the particle size is consistent with the results obtained by the laser particle size analyzer.

3.2.PANS performance evaluation

3.2.1.Rheological andfilter loss properties

Fig.5 shows the influence of PANS content on the rheological and filtration properties of the base slurry and PANS-containing drilling fluids before and after 16 h of hot rolling at 120°C.As the PANS constent increased,the apparent viscosity,plastic viscosity,and yield point of the drilling fluid increased slightly.When the PANS content was 3%,the apparent viscosity of the drilling fluid was 10.5 mPa∙s and the API filtration loss was 8 mL after hot rolling at 120°C.The high temperature and high-pressure filtration loss was 28 mL,indicating that the plugging agent PANS has good plugging performance.

Fig.5.Comparison of the rheological and filtration properties of base drilling fluids and PANS base drilling fluids after hot rolling at 120 °C for 16 h.(a)Apparent viscosity,(b)Plastic viscosity,(c) Yield Point,(d) Filtration volume.

3.2.2.Temperature resistance

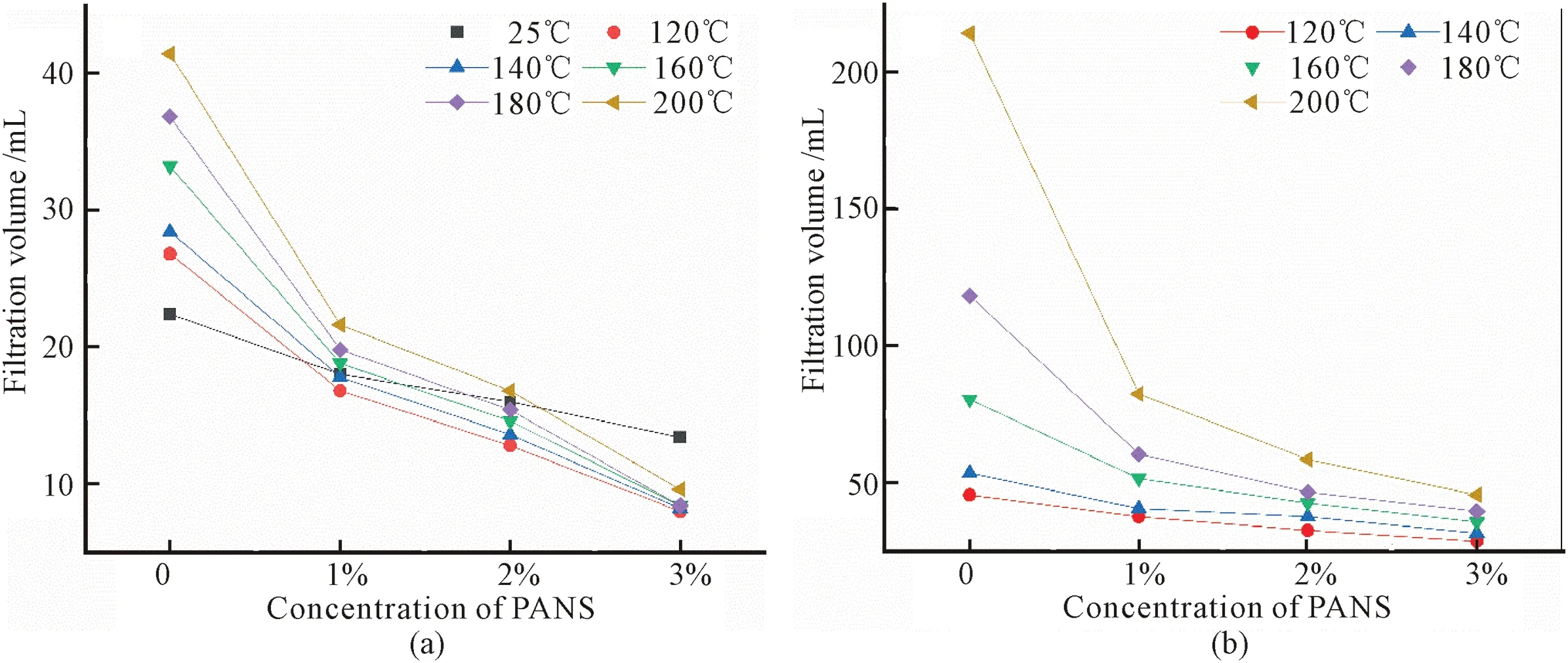

Fig.6 shows the variation of API and HTHP filtration loss of drilling fluids with different PANS concentrations before and after hot rolling at different temperatures.It can be seen that with a gradual increase in the hot rolling temperature,the API filtration loss of the base slurry gradually increased,and when the hot rolling temperature reached 180°C,the API filtration loss increased from 22.4 mL to 36.88 mL,and the HTHP filtration loss was as high as 118.0 mL.After the addition of PANS,the API filtration loss before hot rolling(i.e.,25°C)gradually decreased with an increase in PANS concentration.When the addition amount was 3%,the API filtration loss decreased from 22.4 mL to 13.4 mL,achieving a reduction rate of 40.1%,indicating that the PANS had a superior ability to seal the pores of the mud cake.After hot-rolling at different temperatures of 120,140,160,180,and 200°C,PANS showed an excellent sealing effect as well.After hot rolling at 180°C,when the concentrations of PANS were 1%and 3%,the reduction rates of API filtration loss were 46.1%and 77.1%,and the reduction rates of HTHP filtration loss were 49.1% and 66.9% respectively.The filtration performance is gradually enhanced as the concentration of blocking agent PANS increases.

Fig.6.Variation infiltration loss of base drilling fluids and PANS-base drilling fluids at different hot roll temperatures.(a) API filtration loss,(b) HTHP filtration loss.

3.2.3.Blocking performance

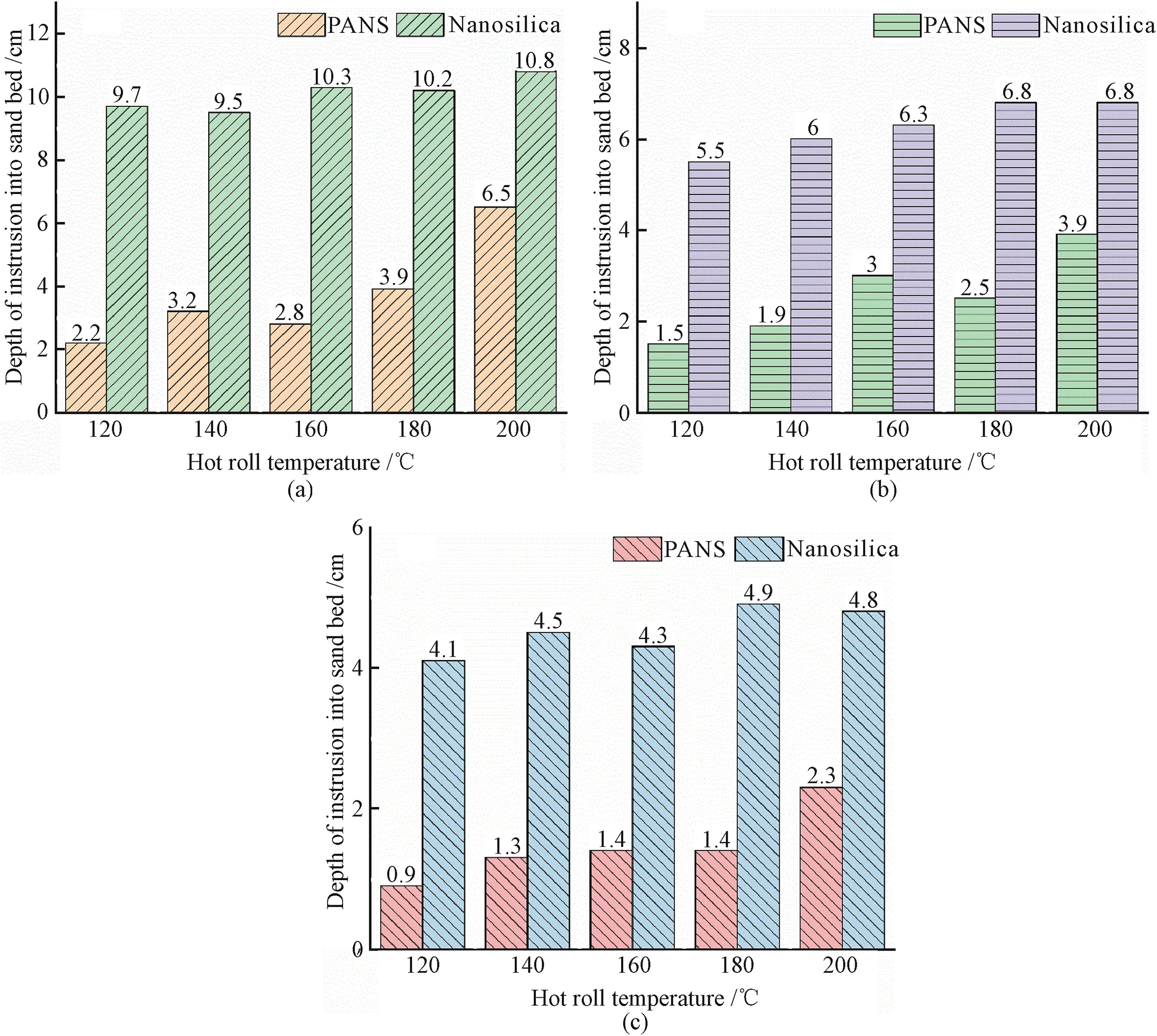

3.2.3.1.Sand-bed plugging performance.Fig.7 shows the variation of the intrusion depth of sand bed filled with different meshes of quartz sand by drilling fluids containing 3% PANS and 3% nanosilica after 16 h aging at different temperatures.It can be seen that as the aging temperature increases,the intrusion depth of the sand bed increases slightly,and the overall sealing effect of the drilling fluid containing 3% PANS is better than that of the drilling fluid containing nano-silica.As can be seen from Fig.7(c),the intrusion depth of the drilling fluid containing nano-silica in the 100-120 mesh sand bed after aging at 180°C was 4.9 cm,while the intrusion depth of the drilling fluid containing PANS was only 1.4 cm.The plugging efficiency was improved by 71.4%,indicating that the plugging agent has better plugging performance.

Fig.7.Comparison of sand bed intrusion depth between drilling fluids containing PANS and drilling fluids containing nano-silica after hot rolling for 16 h at different temperatures(a: 60-80 mesh,b: 80-100 mesh,c: 100-120 mesh).

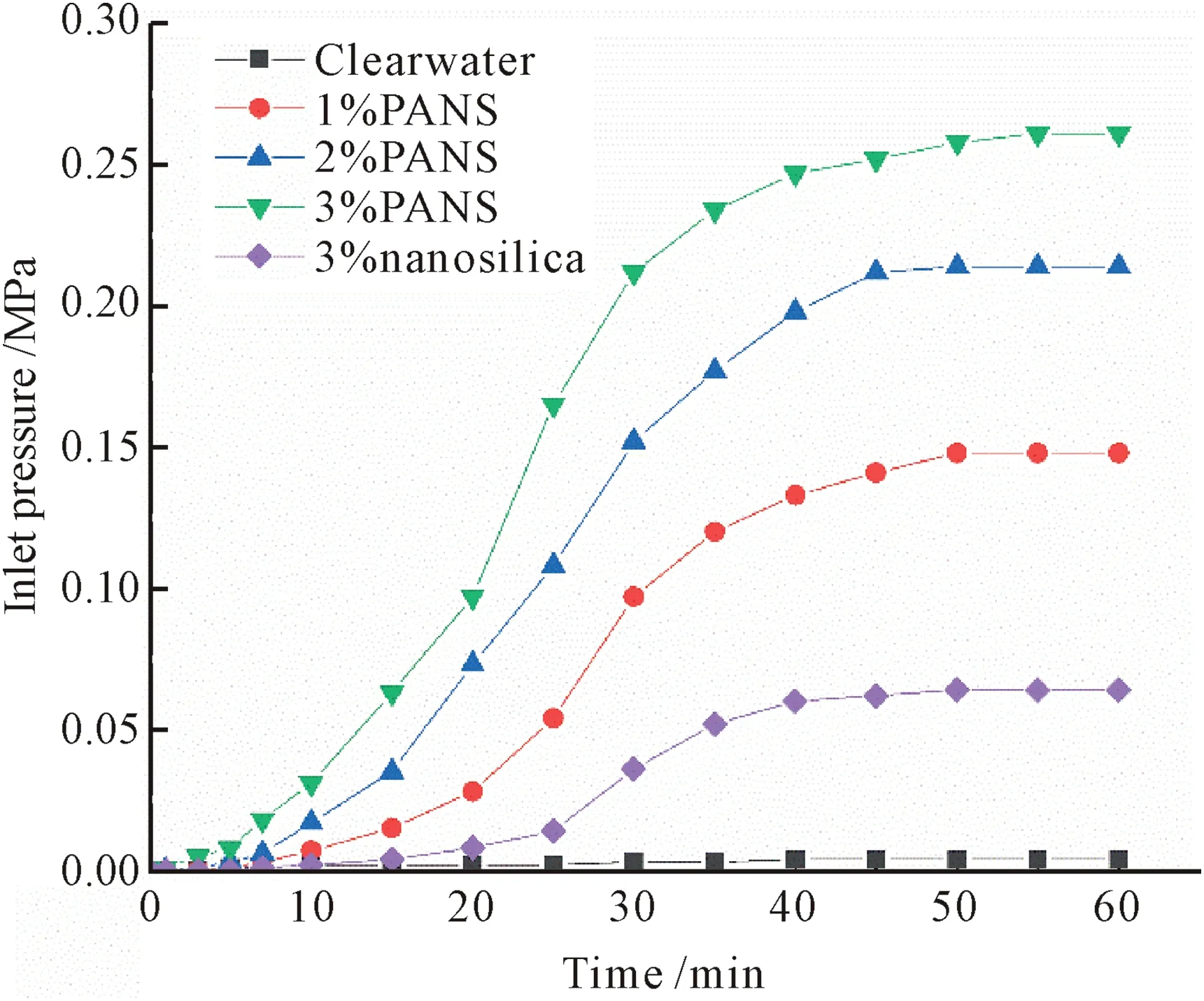

3.2.3.2.Microfracture sealing performance.The sealing effect of PANS on rock microfractures was evaluated using an LDY50-180A core flow meter.The higher the inlet pressure,the better the sealing effect is.Fig.8 shows the variation of the inlet pressure with time.

Fig.8.Comparison of clear water,different concentrations of PANS suspensions,and silica nanodispersions for sealing microfractures in cores.

As can be seen from Fig.8,the clear water reaches equilibrium at an inlet pressure of 0.004 MPa,and the 3% nano-silica (500 nm)reaches equilibrium at an inlet pressure of 0.064 MPa,while the 1%PANS solution reaches equilibrium at an inlet pressure of 0.148 MPa.As the concentration of PANS increases,the inlet pressure required to reach equilibrium becomes greater.When the concentration reached 3%,the inlet pressure reached 0.261 MPa,which was four times higher than the inlet pressure of 3% nanosilica,indicating the remarkable blocking effect.

3.2.3.3.Pore sealing performance.Using the NMR phenomenon of hydrogen nuclei,the water saturation of a core can be calculated by measuring the NMR magnetic field strength and thus converting the hydrogen nuclei content of the core.The NMR transverse relaxation timeT2is proportional to the pore size[37-40],and the signal amplitude is proportional to the amount of fluid in the corresponding pore size.Therefore,the change in transverse relaxation timeT2can be measured to obtain the distribution of fluid in pores of different sizes,and the volume of the pore after being sealed by the sealant can be deduced.The same rock sample was subjected to NMR analysis after being repelled by water and a liquid containing 3% PANS.The corresponding relaxation time and amplitude are shown in Fig.9,which indicates the pore size in the rock sample and fluid content in the pore,respectively.

Fig.9.Comparison of clear water and PANS suspensions for sealing core pores.

As can be seen from Fig.9,the NMR curves of the core samples after the water repellent showed a triple-peaked distribution in the range of 0.01 ms-382.75 ms with three peaks at 0.06 ms,3.08 ms,and 44.49 ms.The peak amplitudes at 3.08 ms and 44.49 ms are much higher than those at 0.06 ms,indicating an uneven distribution of larger pores within the rock.In addition,the amplitude of the NMR curve of the PANS suspension-replaced core sample is much lower compared to that of the water-replaced core sample.

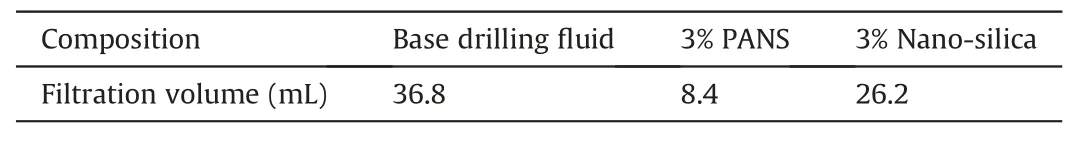

3.2.4.Microscopic appearance of the mud cake

Analysis of the surface morphology of deposited mud cake can provide direct evidence of the filtration and sealing performance[41].Table 1 shows the API filtration loss volumes of base drilling fluid,3% PANS base drilling fluid and 3% nano-silica base drilling fluid after aging at 180°C for 16 h.Fig.10 shows the microscopic morphology of the mud cake after aging the base drilling fluid,PANS,and nano-silica at 180°C for 16 h.As can be seen in Fig.10(a),there are a large number of micro-cracks on the surface of the mud cake before plugging,which can be used as a seepage channel for the drilling fluid filtrate.As can be seen in Fig.10(b),the surface of the mud cake after PANS plugging is free of micro-cracks and the surface of the mud cake becomes smooth.The low permeable surface of the mud cake can effectively seal the cracks and thus stop the filtrate intrusion.However,as can be seen in Fig.10(c),the surface pores of the mud cake after the nano-silica cladding are relatively large,which also contributes to the larger volume of filtration loss from the drilling fluid.In conclusion,PANS can effectively reduce the filtration loss volume of drilling fluid than nano-silica,and the mud cake formed is denser.

Fig.10.Comparison of the microscopic morphology of the filter cake of base drilling fluid and 3% PANS base drilling fluid after hot rolling at 180°C for 16 h.(a) microstructure of base drilling fluid mud cake;(b) microstructure of 3% PANS base drilling fluid cake;(c) micromorphology of 3% nano-silica based drilling fluid cake.

3.3.Analysis of the PANS blocking principle

Table 1 Comparison of API filtration loss volume of base drilling fluid,3%PANS base drilling fluid,and 3% nano-silica base drilling fluid after hot rolling at 180°C for 16 h

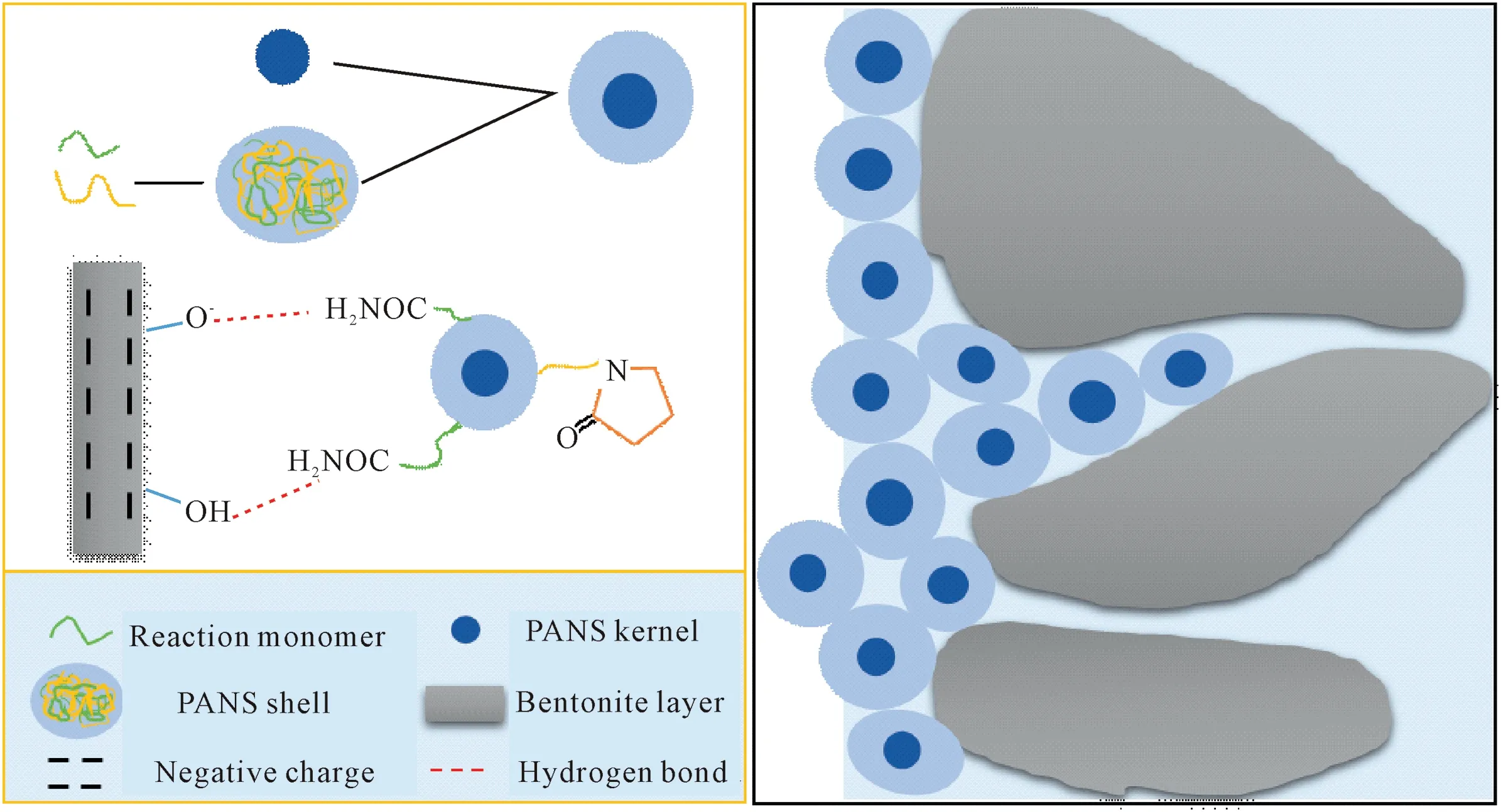

Clay is mainly composed of clay minerals (aqueous aluminosilicates),and the amount of charge carried on its surface varies with the pH of the medium [42,43].The pH of the drilling fluid is generally greater than 7.Under neutral or alkaline conditions,the Al-OH on the end faces of the clay crystals reacts with OH-to form Al-O-[44].As shown in Fig.11,PANS carries an amide group(-CONH2),which readily forms hydrogen bonds with hydroxyl and oxygen atoms[45,46].Under the action of hydrogen bonding,PANS shows strong adsorption on the clay layer.The outer shell of PANS is a polymer with certain elasticity,which can self-adapt to the size and shape of microfractures and fractures in the formation,and the inner core is nano-silica,which can play a good pressure-bearing effect.Therefore,when the PANS enters the fracture,it can form a dense sealing layer,leading to reducing the amount of filtration loss and achieving the purpose of formation protection.

Fig.11.Visual model of the blocking effect of PANS.

4.Conclusions

In this study,a temperature-resistant,internal rigid,and external flexible plugging agent PANS with a median particle size of 10.5 μm was prepared.When the dosage is 3%,PANS can effectively reduce the filtration of drilling fluid after hot rolling at 180°C,and the plugging efficiency of 100-120 mesh sand bed is increased by 71.4% compared with the same dosage of nano-silica (500 nm).PANS incorporates the strength of a rigid sealer with the strong self-adaptability of a flexible sealer.In addition,it shows superior temperature resistance up to 180°C,meeting the deep reservoir application.Based on the above findings,it is critically important for the rational design of the chemical structure of the plugging agent.Our developed PANS with an internal rigid core and external flexible shell may find huge promise in the high-performance drilling fluids for deep reservoir application.

Acknowledgements

This research was financially supported by the Natural Science Foundation of China (Grants 51904328).

- Petroleum的其它文章

- Super gas wet and gas wet rock surface: State of the art evaluation through contact angle analysis

- Petroleum system analysis-conjoined 3D-static reservoir modeling in a 3-way and 4-way dip closure setting: Insights into petroleum geology of fluvio-marine deposits at BED-2 Field (Western Desert,Egypt)

- Anti-drilling ability of Ziliujing conglomerate formation in Western Sichuan Basin of China

- Production optimization under waterflooding with long short-term memory and metaheuristic algorithm

- Investigation of replacing tracer flooding analysis by capacitance resistance model to estimate interwell connectivity

- Experimental study on sand production and coupling response of silty hydrate reservoir with different contents of fine clay during depressurization