畜禽养殖粪水酸化贮存及氮素减损增效研究进展

张冬丽,张朋月,沈玉君,丁京涛

畜禽养殖粪水酸化贮存及氮素减损增效研究进展

张冬丽,张朋月,沈玉君,丁京涛※

(1. 农业农村部规划设计研究院农村能源与环保研究所,北京 100125;2. 农业农村部资源循环利用技术与模式综合性重点实验室,北京 100125)

畜禽粪水酸化贮存能够有效调控粪水贮存中微生物、环境与氮素间的作用关系,实现粪水氮素的减损增效,是一种具有广泛应用前景的关键技术。该研究系统综述了粪水酸化贮存中氮素的迁移转化机理,比较评价了常见酸化剂和不同酸化贮存工艺的应用效果,分析了酸化贮存技术对粪水氮素减损增效的影响。梳理总结得到:粪水酸化存储中氮素的迁移转化机制主要包括有机氮矿化、铵态氮固持、无机氮转化的抑制及硝化3个关键环节,可以依靠改变微生物作用和化学平衡状态实现氮素的减损;与其他酸化工艺相比,长期酸化工艺具有酸化效果更加稳定、应用范围较为广泛等优势;粪水酸化技术能够大幅降低NH3排放,以及部分N2O的排放,进而提高粪肥还田后土壤肥效,但不合理的酸化贮存技术及施用方式也会降低粪水肥效,甚至引起二次污染;未来应重点从氮素迁移转化路径的定量分析、复合酸化剂的开发、粪肥施用效果及风险的评估应对等方面进行深入研究。

酸;肥效;畜禽粪水;氮素减损

0 引 言

随着畜禽养殖业规模化的发展,粪水处理成为限制养殖场发展的重要因素[1],相对固体粪便而言,液态粪水处理难度大,更易导致环境污染。据统计,中国畜禽养殖粪污年产生量约30.5亿t,其中养殖过程产生的粪水量大、分散,更容易导致面源污染[2]。目前,贮存发酵被认为是一种实现养殖粪水无害化、资源化的处理方式,能够利用粪水中的氮、磷、钾等元素,同时对部分有害微生物进行灭活,既能促进物质循环又能提升废弃污染物的经济价值[3]。然而,在传统的粪水贮存发酵工艺中,容易产生氨气(NH3)、硫化氢(H2S)等臭气以及氧化亚氮(N2O)、甲烷(CH4)等温室气体,不仅造成粪肥产品肥效的降低,还会造成PM2.5浓度上升等一系列环境问题[4-6]。

近年来,随着畜禽粪水排放规模的进一步增大以及生态环境保护要求的持续提高,粪水酸化技术逐渐成为粪污臭气控制研究和应用的关键技术[7-9]。畜禽粪水酸化贮存技术能够通过改变粪水pH值,实现系统中NH4+和NH3间平衡关系的调节,进而减少粪水贮存及农田施用中氨气等气体排放,提高粪水贮存中养分固持率[10-12]。粪水酸化贮存技术已在国外得到较多的发展和应用,例如以浓硫酸酸化贮存粪水技术已在丹麦、瑞典等国普遍推广,丹麦有12%~20%的粪水采用酸化处理[13-14]。

在2021年8月全国畜牧总站印发的《规范畜禽粪污处理降低养分损失技术指导意见》中,粪水酸化技术已成为治理粪污氨挥发的主推技术,同时也被纳入《“十四五”全国畜禽粪肥利用种养结合建设规划》。但总体来看,中国对于粪水酸化贮存的研究尚处于起步阶段,有待进一步系统、深入研究。本文系统阐述了当前畜禽养殖粪水酸化贮存技术研究进展,并展望了其应用前景,以期为中国畜禽养殖粪水资源化、无害化利用技术研发应用提供理论和数据支撑。

1 粪水酸化贮存中的氮素迁移及其减损特征

1.1 粪水酸化贮存中的氮素迁移

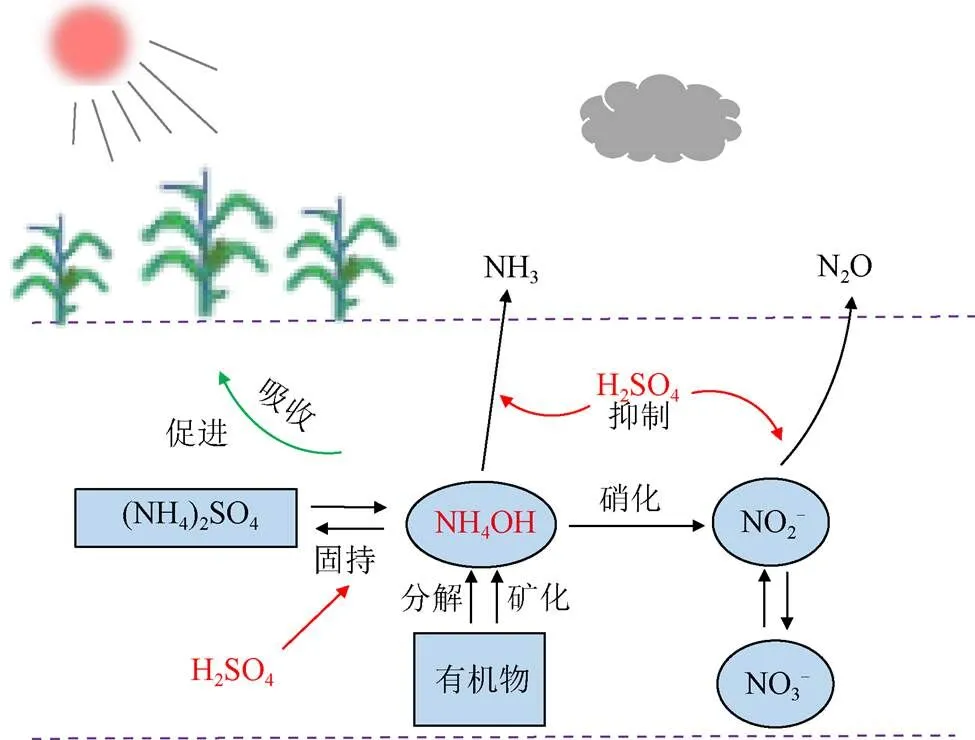

粪水是粪便与尿液的混合物,含有丰富的氮素等养分(见表1)[15-18],适宜在经过贮存发酵后还田进行资源化利用。然而,粪水中的尿酸、尿素以及未分解的蛋白质等氮素载体在好氧降解、水解或矿化作用下使粪水含有大量铵态氮,极易释放出NH3,造成氮素养分的损失,成为限制养殖粪水资源化利用的难点之一[19–22]。在粪水酸化贮存过程中,氮循环在很大程度上依赖复杂的化学生物作用。粪水中氮素的形态以有机氮和铵态氮为主,其总和占粪水中总氮质量分数的97%以上。因此,分析其氮素迁移机制,主要可以归纳为有机氮的矿化、铵态氮的固持、无机氮转化的抑制及硝化3个关键环节(见图1)。

表1 养殖粪水中主要物质含量

1)有机氮的矿化。向粪水中添加酸化剂后,少量硫酸分解了粪水底泥中部分大颗粒有机物,使之悬浮于粪水中提高了粪水中有机氮的含量。在酸性条件下,粪水中的有机氮通过好氧/厌氧微生物的矿化作用向铵态氮转化,另一部分有机氮则通过水解作用转化为氨基酸,并在脱氨基的作用下生成铵态氮[23-24]。2)铵态氮的固持。酸化工艺作用下,硫酸等酸化剂与铵态氮结合生成能够长期稳定固持的铵盐。3)无机氮转化的抑制及硝化。有研究表明[25-27],粪水酸化能够有效抑制粪水中微生物活性,通过浓硫酸酸化后粪水中耗氧率、硫酸盐还原率均明显降低,这可能是由于酸化粪水中含有高浓度的短链挥发性脂肪酸,它们作为细胞膜电位的解耦剂,抑制了微生物的代谢。因此,酸化抑制了有机氮向无机氮素的转化,微生物活性的降低使得粪水中存在一定量过剩的溶解氧,这部分溶解氧被硝化细菌利用,也使得粪水中硝态氮含量逐渐升高,亚硝态氮含量不断降低。

图1 畜禽养殖粪水酸化贮存及其氮素减损增效示意图

1.2 粪水酸化贮存的氮素减损路径

粪水酸化贮存中氮素的损失途径主要是NH3的产生和散逸。粪水为微生物提供了一种复杂的环境条件,不仅具有好氧微生物所需的环境,同时亦为厌氧微生物提供了所需的生存环境,因此,结合粪水酸化贮存中的氮素迁移机制的相关研究结论,粪水中氮素形态转化及氮素损失的调节,主要是通过改变微生物作用和化学平衡状态来实现。其分别对应了2种氮素减损的技术路径,一是添加酸化剂降低粪水pH值以改变粪水中NH4+与NH3的动态平衡,促进NH4+生成,以减少粪水中溶解NH3的排放;二是通过降低粪水pH值使微生物活性下降,降低粪水中有机物的矿化作用,进而减少NH3的产生及排放[28]。

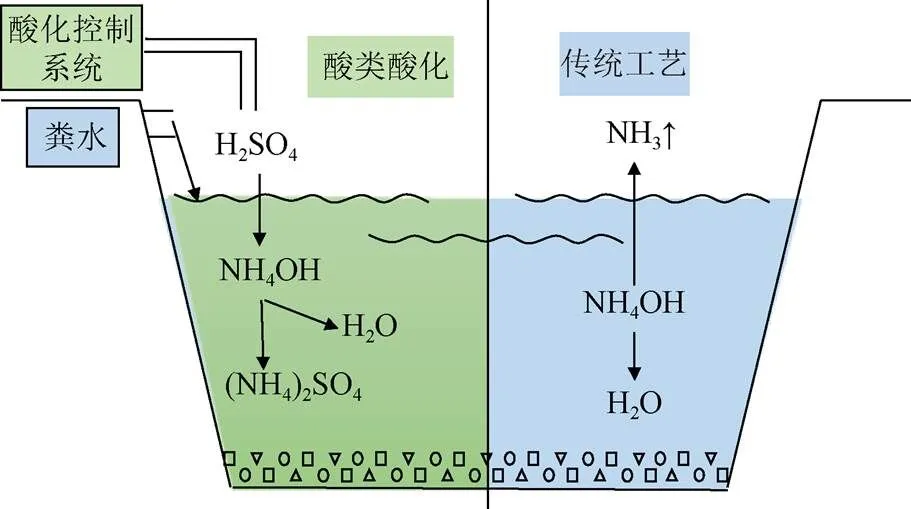

1.3 粪水酸化贮存与传统工艺的差异

与传统粪水贮存发酵工艺相比,粪水酸化贮存能够稳定固持粪水中的NH4+,体现了氮素减损的比较优势[29]。在传统养殖粪水贮存发酵工艺中,粪水一般是以自然静置贮存为主,表层粪水以好氧发酵为主,但深层粪水则以厌氧发酵为主。而在粪水酸化贮存发酵中,酸化后的粪水所提供的效应离子不会被降解及转化(易分解有机物及硝酸除外),能够稳定的固持粪水中的NH4+,使粪水中被固持的NH4+长期的贮存于粪水中(图2)。

图2 粪水酸化贮存与传统工艺对比示意图

综合已有研究[21-29],虽然酸化粪水一定程度上抑制了粪水中微生物对含氮有机物的矿化作用,但其也使氮素固持效率有了显著提高,进而减少氮素损失和氨气排放。酸化环境下一定量过剩溶解氧促进粪水中微生物的硝化作用,使粪水中硝态氮含量升高。总的来看,酸化技术使粪水贮存中总氮、铵态氮、硝态氮含量升高,氨气排放、亚硝态氮含量降低,故酸化粪水对提高粪水养分固持率,减少环境污染具有重要意义。

2 不同粪水酸化贮存工艺的比较评价

2.1 不同类型酸化剂

粪水酸化剂目前主要有3种类型[10,30]。第一种是强酸类,主要有浓H2SO4、HNO3和H3PO4等,其中浓H2SO4以其低廉的价格应用最广,强酸酸化剂用量少,但粪水酸化后pH稳定性差,且酸类具腐蚀性,对设备和安全操作要求较高,其作用方式为酸与粪水中的铵水反应生成相对更稳定的铵盐和水,降低了铵氮向氨气的转化。其中硫酸以价格便宜,用量少等优势可用于中国农村粪水的酸化。但其购置、存储、管理过程繁琐,故建议在农村地区推广以磷酸为主的酸化剂。

第二种是水解呈酸性的盐类,主要有明矾、过磷酸钙、氯化铝、硫酸铝等物质。此类酸化剂水解后一般生成碱性沉淀物与酸,酸与氨水反应生成铵盐和水,此类酸化剂酸化效果相对较稳定,但投加量相对酸类酸化剂较多,其应用经济效益及环境效益是该工艺的主要考量因素[9]。

第三种是易分解有机物,目前以葡萄糖和蔗糖研究较多[10,31]。这类物质主要是通过向粪水中投入大量的易分解有机物,促进微生物快速增长,待粪水中的溶解氧不足以供给微生物进行呼吸作用时,粪水中的厌氧微生物大量繁殖,厌氧的呼吸作用将有机物分解为乳酸,通过乳酸与氨水反应生成乳酸铵和水。在粪水贮存后期,随着易分解有机物的厌氧降解,粪水中的有机酸会逐渐转化为甲烷,失去酸化效果。此方法投入量较大,成本偏高,会产生酸性臭气,并吸引蛾蠓等飞虫,引发二次污染,实际应用较少。

2.2 不同类型酸化方式

按照酸化场所,粪水酸化方式主要有养殖舍内长期酸化、贮存池中长期酸化和施用时短期酸化3种方式[10,32-33]。粪水酸化施用方式对酸化存储过程中氮素损失量影响显著[34-35]。

1)养殖舍内长期酸化是指粪水在养殖舍内酸化后,随粪沟流入酸化处理罐,再添加酸化剂,进行酸化,同时增加曝气并不断搅拌以减少酸化过程中气泡的产生,酸化后的粪水一部分回流至养殖舍,一部分进入粪水储罐或粪水贮藏池。此方法的优点在于粪水酸化后有利于进行固液分离,同时收集的粪水能够在贮存及施用过程中的各个阶段均能起到减少NH3的挥发作用,进入贮存设施的粪水一般不再进行酸化,进入养殖舍收集系统的粪水会注入新的粪水,并再次进入酸化系统酸化,如此循环可使酸化效果更稳定,此种酸化技术目前应用最广;2)贮存池中长期酸化是指粪水在贮存池中进行酸化,向贮存池中投入酸化剂并辅以不断搅拌。此方法在酸化过程中会产生大量的气泡,增加管理风险,另外,如果贮存时间较长,为了防止氨挥发作用增强,需要根据情况再次酸化;3)施用时短期酸化是指在粪水农田施用之前,向施肥罐车中添加酸化剂,通过罐车搅拌机混合均匀进行酸化,主要降低粪水还田施用阶段NH3的挥发,提高氮素利用率[36]。

3 酸化贮存对粪水氮素减损增效影响

3.1 对氨气排放的影响

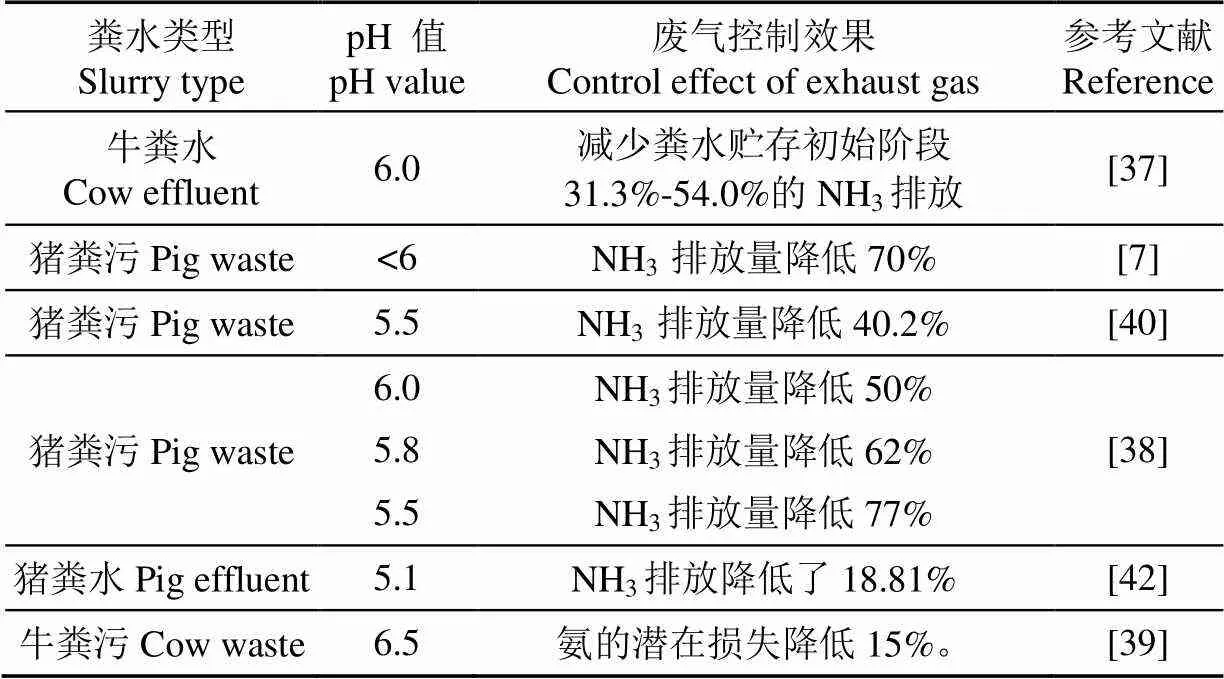

粪水酸化能够有效抑制粪水的碱性环境以及其中的微生物活性[25],同时灭活粪水中部分有害微生物及致病菌[17],从而通过化学生物作用降低NH3的排放。研究表明粪水酸化可以降低15%~77%的NH3排放(见表2),其中沈玉君等[37]研究成果表明酸化牛粪水至pH值为6.0可减少粪水贮存初始阶段31.3%~54.0%的氨气排放;DAI[38]等利用硫酸(H2SO4)酸化技术,可减少猪场污水和牛粪水50%以上的NH3排放。

酸化贮存对粪水氮素减损效果与酸化剂用量和酸化剂类型等因素密切相关[39]。郜斌斌等[12,40]的研究亦表明粪水酸化可大幅降低粪水中的NH3排放,同时NH3的排放随酸化pH的降低而不断降低;REGUEIRO等[41]研究发现在粪水中添加明矾也能起到类似的的减排效果,同时也能促进磷(P)的增溶、提效,但其作用效果弱于常见强酸酸化剂。然而,目前大部分酸化粪水的pH值通常会控制在5.1以上,以使粪水酸化后酸碱度能够逐渐恢复至中性或弱碱性。主要原因是当酸化pH值过低时,可能会导致粪水长期贮存后仍呈酸性,不利于后期的还田利用,也增加了酸化工艺成本[42]。

表2 粪水酸化后氨气排放情况

3.2 对N2O气体排放的影响

粪水酸化贮存中,N2O主要来自氮素降解过程的反硝化阶段,已有研究[37]表明,酸化会抑制粪水中有机物的降解,故理论而言酸化后的粪水在贮存中含氮有机物的降解率会下降,导致粪水中的铵氮生成量下降,且酸化剂的加入会降低铵氮向硝氮的转化率,从而进一步降低硝氮向N2O的转化,故酸化粪水理论上也会显著抑制粪水中N2O的排放量[43-46]。HUSTED以及WANG等学者[39-40]的研究均表明,粪水酸化会显著降低酸化粪水贮存期间CH4、N2O等温室气体的排放量,虽然在粪水酸化阶段排放量会显著升高,主要是由于酸化阶段搅拌扰动粪水导致的,并非添加酸化剂导致的。此外,李路路等[42,47]的研究表明酸化粪水会抑制N2O的排放,同时李路路还发现酸化沼液会提升2.59倍,但酸化沼液对CO2的排放量计划无影响。综上酸化粪水可以有效降低粪水贮存期间温室气体的排放。

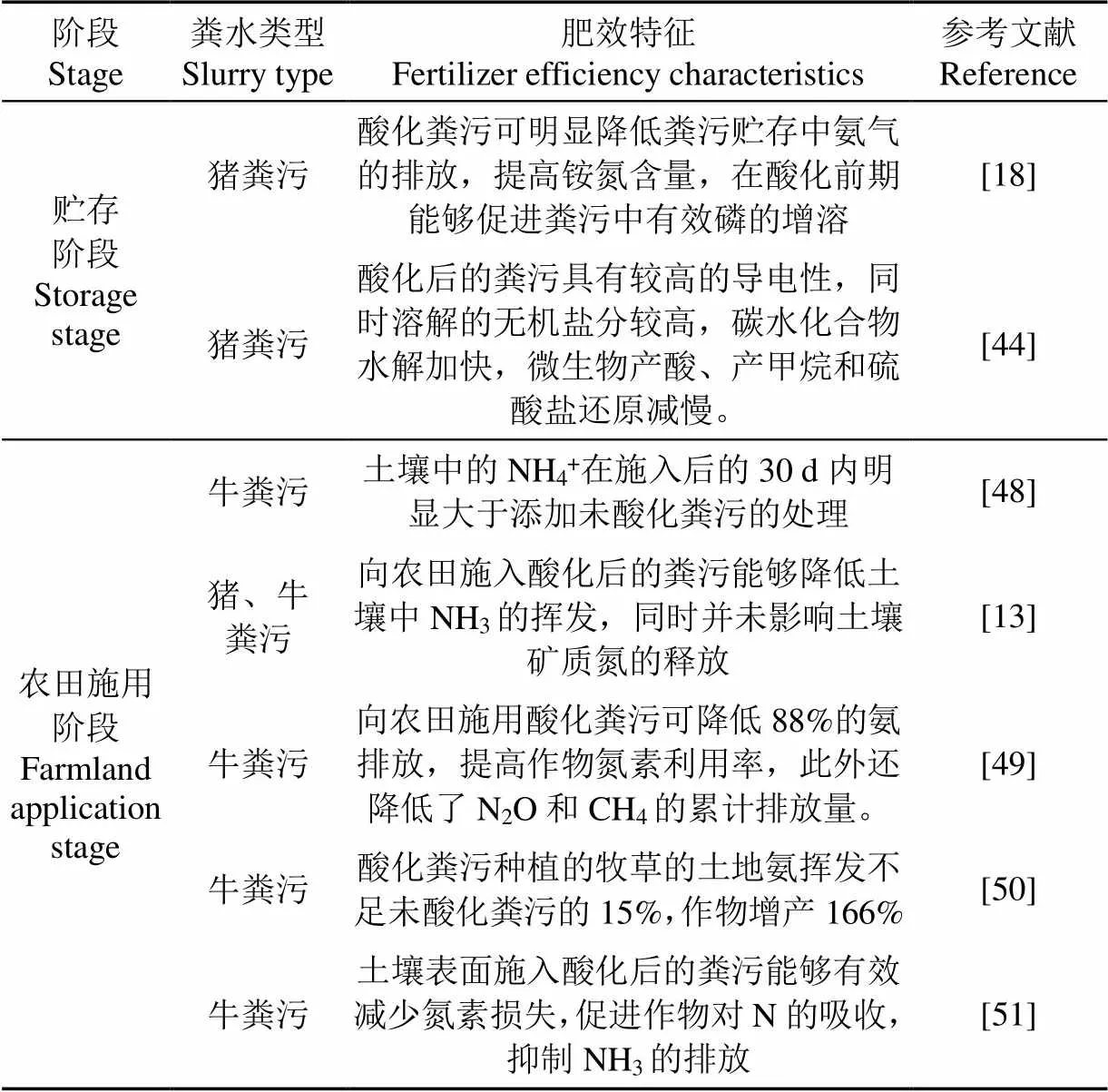

3.3 对粪肥还田后土壤肥效的影响

国内外已有研究发现,粪水酸化后还田可以提高土壤中N、P等有效态养分含量,对作物生长具有重要意义(见表3)。酸化粪污不仅可以降低贮存期粪污中氨气的排放[28],提高粪水中无机盐成分,在酸化粪污施用到农田后也能够有效提高作物产量。FANGUEIRO等[48]通过向具有高有机质含量的石灰性壤土和低有机质含量的酸性砂土中施入酸化的粪污,土壤中的NH4+在施入后的30 d内明显大于添加未酸化粪污的处理,可以看出施入酸化处理的粪污可以使土壤中的N以NH4+的形式停留在土壤中,降低土壤中NH3挥发的损失。SØRENSEN[13,49]等的研究也表明向农田施入酸化后的粪污能够明显降低土壤中NH3的挥发,同时其表明施入酸化的粪污的农田中CH4的累积排放量也显著下降,FROST等[50]的研究表明施入酸化粪污的土壤相对施入未酸化粪污的土壤其氨挥发损失降低了85%,提高了黑麦草对NH4+的利用率,同时也明显提升了该土壤上种植黑麦草的干物质产量,同样,也有研究[51]表明土壤表面施入酸化后的粪污能够有效减少土壤N损失,促进作物对N的吸收。FANGUEIRO等[52]最新研究再次表明在燕麦播种0 和8 d后的土壤表面单独施用酸化猪粪水或与尿素联合使用均能有效降低NH3-N的排放,尿素和酸化猪粪水联合应用还进一步提高了尿素的使用效率。

表3 粪污酸化贮存及施用肥效特征

3.4 对农田环境的影响

酸化后的粪水还田后可以提高土壤肥效,但不合理的酸化贮存技术及施用方式会降低粪水肥效,甚至引起二次污染[53-56]。主要原因是粪水中有大量以铵氮为主的盐分,向粪水添加酸化剂会使铵盐形态更加稳定,虽然降低了氨气排放,但却增加了粪水盐分含量,盐含量升高是粪水酸化还田的难点之一。

正如COCOLO等[57]研究表明,酸化后粪水固液分离出的干物质含量降低了10%~50%,这主要是由于粪污中部分固体物质在酸性条件下以无机盐的形式溶出。HJORTH等[58]发现粪水中的无机沉淀物在酸性条件下溶解,使可溶性磷和可溶性钙、镁含量增加,粪水电导率增加。

另外,也有研究者发现不科学的酸化还田技术会带来土壤酸化问题,如FANGUEIRO等[59]将粪污酸化至pH值为5.5短期存放后进行试验,研究结果表明长期施用酸化后的粪污可能会导致土壤pH值降低。

HJORTH等[58]也发现类似现象,使用浓硫酸作为酸化剂会使土壤pH值降低。对于酸化粪水还田引起的盐分过高问题,现有研究尚未提供系统解决方案[60-61]。而对于土壤酸化问题,部分学者研究提出延长粪水贮存时间等缓解路径。如丁京涛等[62-64]发现随着储存时间的推移,还田前的粪污将呈中性乃至碱性,不足以对农田pH及其土壤肥效产生影响。因此科学的粪水酸化还田技术可有效减少粪水酸化对土壤的副作用。同时,结合中国农村环境和农田自然禀赋情况以及粪水酸化存储技术特征,分析认为中国农村地区应采取养殖舍内长期酸化的酸化工艺,待酸化粪水存储足够长时间后还田利用。

4 结论与展望

粪水酸化贮存技术是一种成本低、操作简单的粪水资源化利用技术,能够有效减少粪水贮存及农田施用过程NH3的挥发损失,提高粪水肥效,同时粪水酸化贮存还田可有效减少养分流失,对促进中国种养循环、发展生态农业具有重要的意义。目前,欧美等发达国家对粪水酸化贮存及施用技术的研究较多,在国内仍处于初始探究阶段,相关机理与技术研究存在许多不足。尤其是粪水酸化存储过程中NH3和N2O排放规律尚不清楚,粪水酸化存储过程NH3和温室气体产排微生物驱动机制和协同减排的系统研究相对缺乏,科学经济的酸化技术工艺、应用标准研究依然不足。

因此,针对现有研究中存在的不足,未来应重点从以下几方面深入研究:1)采用同位素示踪等新型生化手段,结合定量PCR技术,探明粪水存储过程中含氮气体的产排规律,摸清粪水存储过程中的氮素迁移转化路径;2)以复合酸化剂等作为研发重点,系统研究不同酸化剂、酸化方式对粪水的酸化效果,筛选出成本低、效果好的酸化剂,明确不同酸化剂、pH、贮存时间、贮存方式对粪水养分含量的影响效果及作用机制,进而确定科学合理的酸化技术工艺;3)研究酸化后粪水的农田施用效果及环境风险,分析酸化粪水施用后对土壤理化性质、土壤生物群落及酶活性、农作物生长及产量、养分淋溶损失、氨气及温室气体排放等变化特性,制定粪水酸化还田技术标准,规范粪水还田方式与施用量,减少环境风险;4)在明确酸化机理及工艺参数的基础上,开展适用于中小型养殖场的粪水酸化贮存装备研发,同时要充分考虑相关酸化设备与设施的耐腐蚀性能,强化国内酸化贮存技术的推广应用。

[1] 周海宾,丁京涛,孟海波,等.中国畜禽粪污资源化利用技术应用调研与发展分析[J]. 农业工程学报,2022,38(9):237-246. ZHOU Haibin, DING jingtao, MENG Haibo, et al. Survey and development analysis of resource utilization technology of livestock and poultry wastes in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(9): 237-246. (in Chinese with English Abstract)

[2] 农业农村部关于贯彻实施《中华人民共和国固体废物污染环境防治法》的意见[Z]. [2022-03-28].

[3] HRISTOV A N. Technical note: Contribution of ammonia emitted from livestock to atmospheric fine particulate matter (PM2.5) in the United States[J]. Journal of Dairy Science, 2011, 94(6): 3130-3136.

[4] PETERSEN S O, HUTCHINGS N J, HAFNER S D, et al. Ammonia abatement by slurry acidification: A pilot-scale study of three finishing pig production periods[J]. Agriculture, Ecosystems & Environment, 2016, 216: 258-268.

[5] CALVET S, HUNT J, MISSELBROOK T H. Low frequency aeration of pig slurry affects slurry characteristics and emissions of greenhouse gases and ammonia[J]. Biosystems Engineering, 2017, 159: 121-132.

[6] GIOELLI F, DINUCCIO E, CUK D, et al. Acidification with sulfur of the separated solid fraction of raw and co-digested pig slurry: Effect on greenhouse gas and ammonia emissions during storage[J]. Animal Production Science, 2016, 56(3): 343.

[7] KAI P, PEDERSEN P, JENSEN J E, et al. A whole-farm assessment of the efficacy of slurry acidification in reducing ammonia emissions[J]. European Journal of Agronomy, 2008, 28(2): 148-154.

[8] BUCHEN-TSCHISKALE C, WELL R, FLESSA H. Tracing nitrogen transformations during spring development of winter wheat induced by 15N labeled cattle slurry applied with different techniques[J]. Science of the Total Environment, 2023, 871: 162061.

[9] OVERMEYER V, TRIMBORN M, CLEMENS J, et al. Acidification of slurry to reduce ammonia and methane emissions: Deployment of a retrofittable system in fattening pig barns[J]. Journal of Environmental Management, 2023, 331: 117263.

[10] FANGUEIRO D, HJORTH M, GIOELLI F. Acidification of animal slurry: A review[J]. Journal of Environmental Management, 2015, 149: 46-56.

[11] SOMMER S G, ZHANG G Q, BANNINK A, et al. Algorithms determining ammonia emission from buildings housing cattle and pigs and from manure stores[J]. Advances in Agronomy: Elsevier, 2006, 89:261-335.

[12] 郜斌斌,王选,常瑞雪,等. 黏土矿物和化学添加剂对牛粪堆肥过程氮素固持的影响[J]. 农业工程学报,2018,34(20):250-257. SHAO Binbin, WANG Xuan, CHANG Ruixue, et al. Effects of clay and chemical additives on nitrogen retention during cow manure composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(20):250-257. (in Chinese with English Abstract)

[13] SØRENSEN P, ERIKSEN J. Effects of slurry acidification with sulphuric acid combined with aeration on the turnover and plant availability of nitrogen[J]. Agriculture, Ecosystems & Environment, 2009, 131(3/4): 240-246.

[14] BORUSIEWICZ A , BARWICKI J. Slurry management on family farms using acidification system to reduce ammonia emissions[J]. Environment Protection Engineering, 2016, 19:423-438.

[15] 孙迪,杨仁杰,李梦婷,等. 春秋季对近红外光谱模型预测奶牛场粪水氮磷含量结果的影响[J].农业工程学报,2020,36(10):197-205. SUN Di, YANG Renjie, LI Mengting, et al. Influences of spring and autumn on the nitrogen and phosphorus contents of the slurry predicted by near-infrared spectrum model on dairy farms[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(10):197-205. (in Chinese with English Abstract)

[16] 张帅,陆鹏,陈硕,等.京郊畜禽粪污氮磷含量特征及影响因素分析[J]. 农业工程学报,2018,34(8):244-251. ZHANG Shuai, LU Peng, CHEN Shuo, et al. Characteristics of nitrogen and phosphorus content and analysis of its influencing factors in feces and wastewater of livestock farms in Beijing suburb[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(8):244-251. (in Chinese with English Abstract)

[17] 黄丹丹. 猪场沼液贮存中的气体排放研究[D]. 杭州:浙江大学,2013. HUANG Dandan. Gas Emissions from Anaerobically- Digested Pig Slurry during Storage[D]. Hangzhou: Zhejiang University, 2013.(in Chinese with English abstract)

[18] 韩静磊,贺德春,王志良,等.规模化养殖场废水中抗生素种类及残留特征研究[J]. 广州化学,2012,37(1):27-31. HAN Jinglei, HE Dechun, WANG Zhiliang, et al. Research of variety and residual characteristics of antibiotics of wastewater in industrial raising farm[J]. Guangzhou Chemistry, 2012, 37(1): 27-31.

[19] 祝其丽,李清,胡启春,等.猪场清粪方式调查与沼气工程适用性分析[J]. 中国沼气,2011,29(1):26-47. ZHU Qili, LI Qing, HU Qichun, et al. Investigation and analysis of animal manure collection methods on pig farms and their applicability to the anaerobic digestion[J]. China Biogas, 2011, 29(1): 26-47. (in Chinese with English abstract)

[20] 王娜. 环境中磺胺类抗生素及其抗性基因的污染特征及风险研究[D]. 南京:南京大学,2014. WANG Na. Pollution Characteristics and Risk of Sulfonamides Antibiotics and Their Resistance Genes in the Environment[D]. Nanjing: Nanjing University, 2014.

[21] 王霜,邓良伟,王兰,等. 猪场粪污中重金属和抗生素的研究现状[J]. 中国沼气,2016,34(4):25-33. WANG Shuang, DENG Liangwei, WANG Lan, et al. The heavy metals and antibiotics in swine manure: A Review[J]. China Biogas, 2016, 34(4): 25-33. (in Chinese with English abstract)

[22] 郑苇,刘淑玲,靳俊平. 不同清粪工艺下猪、牛、鸡养殖场粪水和污水厌氧消化技术探讨[J]. 环境卫生工程,2017,25(5):58-63. ZHENG Wei, LIU Shuling, JIN Junping. Anaerobic digestion technology of fecal water and wastewater from pig, cattle and chicken farms with different manure collection[J]. Environmental Sanitation Engineering, 2017, 25(5): 58-63.

[23] OTTOSEN L D M, POULSEN H V, NIELSEN D A, et al. Observations on microbial activity in acidified pig slurry[J]. Biosystems Engineering, 2009, 102(3): 291-297.

[24] 薛晶晶,李彦明,常瑞雪,等. 厨余与园林废物共堆肥过程氮素转化及损失[J].农业工程学报,2021,37(10):192-197. XUE Jingjing, LI Yanming, CHANG Ruixue, et al. Nitrogen transformation and loss during co-composting of kitchen and garden wastes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(10): 192-197. (in Chinese with English abstract)

[25] 徐同宝,李吕木,甄长丰,等.不同微生物对猪粪堆肥过程及其养分状况的影响[J].农业工程学报,2008,24(11):217-221. XU Tongbao, LI Lyumu, ZHEN Changfeng, et al. Effects of different microorganism consortiums on composting process of pig manures and their nutrient status[J]. Transactions of the Chinese Society of Agricultural Engineering, 2008, 24(11):217-221.(in Chinese with English abstract)

[26] 陈文旭,刘逸飞,蒋思楠,等.微生物菌剂对厨余垃圾堆肥温室气体减排的影响[J]. 农业工程学报,2022,38(23):181-187. CHEN Wenxu, LIU Yifei, JIANG Sinan, et al. Mitigation effects of microbial agents on greenhouse gas emissions from kitchen waste composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(23): 181-187. (in Chinese with English abstract)

[27] 刘娟,沈玉君,罗文海,等. 盐含量对餐厨垃圾好氧堆肥腐殖化过程及微生物演变的影响[J]. 农业工程学报,2022,38(19):190-201. LIU Juan, SHEN Yujun, LUO Wenhai, et al. Effects of salt content on the humification and microbial community succession of food waste aerobic composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022,38(19): 190-201. (in Chinese with English abstract)

[28] THIERMANN I, LATACZ U. Incentivising ammonia emission abatement through in-house slurry acidification: Evidence from a discrete choice experiment in Germany[J]. Journal of Cleaner Production, 2022, 345: 131158.

[29] WAGNE C, NYORD T, VESTERGAARD A V, et al. Acidification effects on in situ ammonia emissions and cereal yields depending on slurry type and application method[J]. Agriculture, 2021, 11(11): 1053. https://doi.org/10.3390/ agriculture11111053.

[30] DALBY F R, GULDBERG L B, FEILBERG A, et al. Reducing greenhouse gas emissions from pig slurry by acidification with organic and inorganic acids[J]. Plos One, 2022, 17(5): e0267693.

[31] 史风梅,徐洪涛,卢玢宇,等. 温度对养殖废水厌氧发酵初期产酸的影响及其原因分析[J]. 农业工程学报,2018,34(增刊1):42-47. SHI Fengmei, XU Hongtao, LU Binyu, et al. Effects of temperature on production of volatile fatty acids in mesophilic anaerobic fermentation of swine wastewater and its cause analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(Supp.1): 42-47. (in Chinese with English abstract)

[32] FANGUEIRO D, PEREIRA J, BICHANA A, et al. Effects of cattle-slurry treatment by acidification and separation on nitrogen dynamics and global warming potential after surface application to an acidic soil[J]. Journal of Environmental Management, 2015, 162: 1-8.

[33] LEMES YM, GARCIA P, NYORD T, et al. Full-scale investigation of methane and ammonia mitigation by early single-dose slurry storage acidification[J/OL]. ACS Agricultural Science & Technology, 2022. https://doi.org/10.1021/ acsagscitech.2c00172

[34] OVERMEYER V, KUBE A, CLUEMENS J, et al. One-time acidification of slurry: What is the most effective acid and treatment strategy?[J]. Agronomy, 2021, 11(7): 1319.

[35] REGUEIRO I, GOMEZ B, LUBECK M, etal. Bio-acidification of animal slurry: Efficiency, stability and the mechanisms involved[J]. Bioresource Technology Reports, 2022, 19: 101135.

[36] NIGHTINGALE J, CARTER L, SINNCLAIR C J, et al. Assessing the influence of pig slurry pH on the degradation of selected antibiotic compounds[J]. Chemosphere, 2022, 290: 133191.

[37] 张朋月,丁京涛,沈玉君,等. 牛粪水酸化贮存过程中氮形态转化的特性研究[J]. 农业工程学报,2020,36(8):212-218. ZHANG Pengyue, DING Jingtao, MENG Haibo, et al. Characteristics of nitrogen transformation in the process of acidification and storage of cow slurry[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(8): 212-218. (in Chinese with English abstract)

[38] DAI X R, BLANES-VIDAL V. Emissions of ammonia, carbon dioxide, and hydrogen sulfide from swine wastewater during and after acidification treatment: Effect of pH, mixing and aeration[J]. Journal of Environmental Management, 2013, 115: 147-154.

[39] HUSTED S, JENSEN L S, JORGENSEN S S. Reducing ammonia loss from cattle slurry by the used of acidifying additives: The role of the buffer system[J]. Journal of the Science of Food and Agriculture, 1991, 57: 335-349.

[40] WANG K, HUANG D, YING H, et al. Effects of acidification during storage on emissions of methane, ammonia, and hydrogen sulfide from digested pig slurry[J]. Biosystems Engineering, 2014, 122: 23-30.

[41] REGUEIRO I, COUTINHO J, FANGUEIRO D. Alternatives to sulfuric acid for slurry acidification: Impact on slurry composition and ammonia emissions during storage[J]. Journal of Cleaner Production, 2016, 131: 296-307.

[42] 李路路. 粪污存储过程中温室气体和氨气排放特征与减排研究[D]. 北京:中国农业大学,2016. LI Lulu. Study on the Characteristic and Reduction for Greenhouse Gases and Ammonia Emissions during the Storage of Manure and Wastewater[D]. Beijing:China Agricultural University, 2016.

[43] ÓLAFSDÓTTIR S S, JENSEN C D, LYMPERATOU A, et al. Effects of different treatments of manure on mitigating methane emissions during storage and preserving the methane potential for anaerobic digestion[J]. Journal of Environmental Management, 2023, 325: 116456.

[44] WANG Y, LIANG L, LIU J, et al. Impact of anaerobic digestion on reactive nitrogen gas emissions from dairy slurry storage[J]. Journal of Environmental Management, 2022, 316: 115306.

[45] TEN M, NYORD T, PETERS G M, et al. A life cycle perspective of slurry acidification strategies under different nitrogen regulations[J]. Journal of Cleaner Production, 2016, 127: 591-599.

[46] PEREIRA J L S, PERDIGAO A, TAVARES A, et al. Effects of the sddition of different additives before mechanical separation of pig slurry on composition and gaseous emissions[J]. Agronomy, 2022, 12(7): 1618.

[47] PEDERSEN J, FEILBERG A, NYORD T. Effect of storage and field acidification on emissions of NH3, NMVOC, and odour from field applied slurry in winter conditions[J]. Journal of Environmental Management, 2022, 310: 114756.

[48] FANGUEIRO D, SURGY S, FRAGA I, et al. Acidification of animal slurry affects the nitrogen dynamics after soil application[J]. Geoderma, 2016, 281: 30-38.

[49] OWUSU, M Y, POLASTRE A, et al. Gaseous emissions and modification of slurry composition during storage and after field application: Effect of slurry additives and mechanical separation[J]. Journal of Environmental Management, 2017, 200:416-422.

[50] FROST J P, STEVENS R J, LAUGHLIN R J. Effect of separation and acidification of cattle slurry on ammonia volatilization and on the efficiency of slurry nitrogen for herbage production[J]. The Journal of Agricultural Science, 1990, 115(1): 49-56.

[51] FANGUEIRO D, PEREIRA J L S, MACEDO S, et al. Surface application of acidified cattle slurry compared to slurry injection: Impact on NH3, N2O, CO2and CH4emissions and crop uptake[J]. Geoderma, 2017, 306: 160-166.

[52] SILVA A A, FANGUEIRO D, CARVALHO M. Slurry acidification as a solution to minimize ammonia emissions from the combined application of animal manure and synthetic fertilizer in no-tillage[J]. Agronomy, 2022, 12(2): 265.

[53] 徐鹏翔,沈玉君,丁京涛,等.规模化奶牛场粪污全量贮存及肥料化还田工艺设计[J]. 农业工程学报,2020,36(21):260-265. XU Pengxiang, SHEN Yujun, DING Jingtao, et al. Technological design of slurry manure storage and returning to farmland for fertilization on large-scale dairy farm[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(21): 260-265. (in Chinese with English abstract)

[54] PRADO J, RIBEIRO H, ALVARENGA P, et al. A step towards the production of manure-based fertilizers: Disclosing the effects of animal species and slurry treatment on their nutrients content and availability[J]. Journal of Cleaner Production, 2022, 337: 130369.

[55] 徐鹏翔,沈玉君,丁京涛,等.规模化养猪场粪污全量收集及贮存工艺设计[J].农业工程学报,2020,36(9):255-262. XU Pengxiang, SHEN Yujun, DING Jingtao, et al. Slurry manure collection and design of storage system on scaled pig farms[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(9): 255-262. (in Chinese with English abstract)

[56] BEYERS M, DUAN Y F, JENSEN L S, et al. Effect of natural and regulatory conditions on the environmental impacts of pig slurry acidification across different regions in Europe: A life cycle assessment[J]. Journal of Cleaner Production, 2022, 368: 133072.

[57] COCOLO G, HJORTH M, ZAREBSKA A, et al. Effect of acidification on solid-liquid separation of pig slurry[J/OL]. Biosystems Engineering, 2016, 143: 20-27.

[58] HJORTH M, COCOLO G, JONASSEN K, et al. Continuous in-house acidification affecting animal slurry composition[J]. Biosystems Engineering, 2015, 132: 56-60.

[59] FANGUEIRO D, SURGY S, FRAGA I, et al. Band application of treated cattle slurry as an alternative to slurry injection: Implications for gaseous emissions, soil quality, and plant growth[J]. Agriculture, Ecosystems & Environment, 2015, 211: 102-111.

[60] SICA P, KOPP C, MÜLLER-STÖVERO D S, et al. Acidification and alkalinization pretreatments of biowastes and their effect on P solubility and dynamics when placed in soil[J]. Journal of Environmental Management, 2023, 333: 117447.

[61] 李梦婷,孙迪,牟美睿,等.天津规模化奶牛场粪水运移中氮磷含量变化特征[J]. 农业工程学报,2020,36(20):27-33. LI Mengting, SUN Di, MU Meirui, et al. Variation characteristics and rules of nitrogen and phosphorus contents throughout the slurry movement from scaled dairy farms in Tianjin[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(20): 27-33. (in Chinese with English abstract)

[62] 丁京涛,张朋月,赵立欣,等. 养殖粪水长期贮存过程理化特性变化规律[J]. 农业工程学报,2020,36(14):220-225. DING Jingtao, ZHANG Pengyue, ZHAO Lixin, et al. Change rule of physical and chemical properties of slurry in the process of long-term storage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(14): 220-225. (in Chinese with English abstract)

[63] 马艳茹,沈玉君,丁京涛,等. 粪水酸化储存还田应用效果[J]. 农业工程学报,2020,36(15):245-251. MA Yanru, SHEN Yujun, DING Jingtao, et al. Application effect of the acidification storage of animal slurry returning to field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(15): 245-251. (in Chinese with English abstract)

[64] 王祥润,张朋月,沈玉君,等. 连续施用酸化粪水对土壤养分淋溶及重金属累积的影响[J]. 农业工程学报,2022,38(7):245-256. WANG Xiangrun, ZHANG Pengyue, SHEN Yujun, et al. Effects of manure acidification on the soil nutrient leaching and accumulation of heavy metals in the continuous administration[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(7): 245-256. (in Chinese with English abstract)

Progress in the mechanism for the promotion of nitrogen loss reduction during the acidification storage of animal slurry

ZHANG Dongli, ZHANG Pengyue, SHEN Yujun, DING Jingtao※

(1.,,100125,; 2.,,100125,)

Acidification storage of animal slurry is one of the key technologies to effectively regulate the relationship between microorganisms, environment, and nitrogen for the high reduction of nitrogen loss and efficiency in animal slurry. This review aims to systematically investigate the nitrogen migration and transformation during the acidified storage of animal slurry in recent years. Three acidifiers were used, including the strong acid, hydrolyzed acidic salt, and easily decomposed organic matter. Three types of acidizing storage were then selected, namely long-term, medium, and long-term acidizing in the storage pool and short-term acidizing in the application. Finally, the economic cost and application effectiveness were comparatively evaluated in this case. More importantly, a systematic analysis was performed on the reduction of nitrogen losses and enhancement of fertilizer effectiveness, according to the technical route in the acidification storage. Furthermore, future research directions were addressed to identify the shortcomings of existing technologies for the acidified storage of animal slurry. Specifically, the nitrogen migration and transformation in the acidification storage process of animal slurry were divided into organic nitrogen mineralization, ammonium nitrogen fixation, inhibition of inorganic nitrogen conversion, and nitrification. Two reasons were attributed to reducing the nitrogen loss in the acidification storage of animal slurry. The addition of acidifiers was one way to change the dynamic balance of NH4+and NH3by lowering the pH of animal slurry, in order to promote the formation of NH4+while reducing the emission of dissolved NH3in animal slurry. The microbial activity decreased with the decreasing pH and mineralization of organic matter in animal slurry, thus reducing the production and emission of NH3. The acidification storage of animal slurry reduced the NH3emissions by 15%-77%. The degradation rate of nitrogenous organic compounds decreased with the addition of acidifiers, leading to the lower production of ammonium nitrogen. And the conversion rate of ammonium nitrogen to nitrate nitrogen was also reduced, thus further reducing the conversion of nitrate nitrogen to N2O. To sum up, the nitrogen losses were reduced to alter the microbial action and chemical equilibrium state. In addition, the long-term acidizing process presented more stable acidizing and a wider application range during the application, compared with the medium and long-term acidizing in the storage pool and the short-term acidizing. The acidification storage of animal slurry can be expected to stabilize and retain NH4+in the animal slurry. Therefore, acidification and returning to the field can improve the content of effective nutrients (such as N and P) in the soil for the high efficiency of soil fertility. However, the low efficiency of manure fertility and the secondary pollution can also be found in the unreasonable acidification storage and application in practice. It is a high demand for the quantitative analysis of nitrogen migration and transformation pathways in the process of fecal water storage, the complex acidifiers, and the post-acidification animal slurry in agricultural fields. The assessment and response to environmental risks can be launched for the research and development of acidification storage equipment in the future.

acids; fertilizer efficiency; animal slurry; nitrogen loss reduction

2022-11-05

2022-03-30

农业农村部规划设计研究院自主研发项目:废弃物肥料化利用创新团队(CXTD-2021-11);青年拔尖人才支持计划(SQ2022QB00354);典型畜禽养殖场不同类型粪水资源价值与安全性综合评估技术(21327304D)

张冬丽,博士,工程师,研究方向为农业废弃物资源化利用技术研发。Email:dongliustb@126.com

丁京涛,高级工程师,研究方向为农业废弃物资源化利用与环境保护技术研发。Email:dingjingtao@163.com

10.11975/j.issn.1002-6819.202211070

S21;X713

A

1002-6819(2023)-08-0012-08

张冬丽,张朋月,沈玉君,等. 畜禽养殖粪水酸化贮存及氮素减损增效研究进展[J]. 农业工程学报,2023,39(8):12-19. doi:10.11975/j.issn.1002-6819.202211070 http://www.tcsae.org

ZHANG Dongli, ZHANG Pengyue, SHEN Yujun, et al. Progress in the mechanism for the promotion of nitrogen loss reduction during the acidification storage of animal slurry[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(8): 12-19. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.202211070 http://www.tcsae.org