宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究

李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义

宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究

李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义

(武汉理工大学 材料复合新技术国家重点实验室, 武汉 430070)

MgAl2O4透明陶瓷具有优异的光学性能, 但其较差的机械性能和成型过程中的水解问题限制了实际应用, 通过组成设计MgAlON四元尖晶石可以有效调节其综合性能。本研究采用凝胶注模成型、无压烧结和热等静压处理制备了一种具有宽光谱透过范围的新型Mg0.9Al2.08O3.97N0.03透明陶瓷, 系统比较其与MgAl2O4透明陶瓷的光学性能和机械性能, 分析了低应力下裂纹的缓慢扩展并预测使用寿命。研究表明:固相体积分数为50%的陶瓷浆料粘度最低, 为124 mPa·s, 满足凝胶注模成型的需求; 2 mm厚的Mg0.9Al2.08O3.97N0.03透明陶瓷样品在3.7 μm处的直线透过率达86.2%, 光学透过范围与MgAl2O4相比拟, 折射率和阿贝数略高于MgAl2O4; 同时, 该陶瓷具有和MgAl2O4相近的Weibull模数, 尽管裂纹缓慢扩展系数比MgAl2O4小, 但特征强度(210.6 MPa)和惰性强度(227.5 MPa)均高于MgAl2O4。包含少量N的MgAlON尖晶石较好地克服了陶瓷粉体的水解问题, 并在保持优越光学性能的前提下显著提高了透明陶瓷的机械性能。本研究为尖晶石型透明陶瓷的制备与性能的改善提供了新的途径。

透明陶瓷; 凝胶注模成型; 机械性能; 光学性能

MgAl2O4透明陶瓷是一种在0.3~5.5 μm波段具有重要应用的光学材料, 其光学透过范围在0.11~7 μm, 理论透过率可达到87%, 适用于红外窗口、条形码扫描仪及夜视系统等领域[1-4]。然而该材料的抗弯强度约为150 MPa, 断裂韧性通常低于2 MPa·m1/2[5], 迫切需要在保持优异光学性能的同时提升材料的机械性能。目前, 减少烧结助剂用量和细化晶粒尺寸是改善MgAl2O4透明陶瓷机械性能的主要手段[6-8], 但容易对材料的光学性能产生不利影响。另外, MgAl2O4粉体易产生水解行为, 难以通过水基凝胶注模成型制备高强度的大尺寸陶瓷[9-11]。如何获得综合性能优异且易于制备的尖晶石型透明陶瓷仍是亟待解决的问题。

MgAlON是一种四元尖晶石固溶体, 其中无序混合的O2–和N3–呈面心紧密堆积, Mg2+和Al3+分布于四面体和八面体空隙。MgAlON晶体结构复杂、组成变化范围宽, 可在较大范围内调控材料性能[12-13]。Liu等[14]采用无压烧结制备了Mg0.27Al2.58O3.73N0.27透明陶瓷, 发现该陶瓷的光学透过范围介于AlON和面蓝宝石之间。Zhang等[15]系统评价了该透明陶瓷的机械性能, 其显著优于MgAl2O4。Zong等[16]还发现Mg0.27Al2.58O3.73N0.27粉体不会发生水解, 适合用水基凝胶注模成型制备大尺寸、复杂形状的部件。Zong等[13]通过材料组成设计与调控, 制备出一种光学透过域与面蓝宝石相当的新型Mg0.55Al2.36O3.81N0.19透明陶瓷。上述研究表明, 随着MgAlON透明陶瓷中N含量降低和Mg含量上升, 陶瓷的光谱透过范围变宽, 且机械性能始终优于MgAl2O4, 同时还易于水基胶态成型。

本研究通过调控组成设计与晶体结构, 采用高温固相反应合成Mg0.9Al2.08O3.97N0.03陶瓷粉体, 通过凝胶注模成型、无压烧结结合热等静压处理制备透明陶瓷。研究陶瓷浆料的流变学性能, 评价Mg0.9Al2.08O3.97N0.03透明陶瓷的光学性能和机械性能, 进而分析该陶瓷的裂纹扩展情况和疲劳特性。

1 实验方法

以高纯度的-Al2O3、AlN和实验室自制的MgAl2O4为原料, 经过高温固相反应制得单相Mg0.9Al2.08O3.97N0.03粉体。然后通过水基凝胶注模成型制备陶瓷坯体, 具体过程如下: 以甲基丙烯酰胺(MAM, 98%, Ourchem Chem, 中国)作为单体,,ʹ-亚甲基双丙烯酸酰胺(MBAM, 97%, Alfa Aesar Chem, 美国)作为交联剂, 柠檬酸三铵(TAC, 97%, Alfa Aesar Chem, 美国)作为分散剂, 搅拌2 h制得固相体积分数为50%的浆料, 随后加入体积分数1%的引发剂过硫酸铵(APS, 98%, Alfa Aesar Chem, 美国)并真空搅拌除泡30 min, 加入体积分数0.25%的催化剂,,ʹ,ʹ-四甲基乙烯二胺(TEMED, 99%, Alfa Aesar Chem, 美国), 再把浆料注入到模具中使之固化成型获得陶瓷坯体。脱模后将坯体置于室温下干燥48 h, 冷等静压(200 MPa, 5 min)后在马弗炉中加热至630 ℃以排除有机物。将坯体在1.01×105Pa N2气氛下1675 ℃保温2 h, 所得陶瓷预烧体在180 MPa Ar气氛中1800 ℃热等静压烧结5 h,然后对样品进行切割、两面研磨和抛光, 备用。

使用X射线衍射仪(Model χ’Pert PRO of Panalytical, Almelo, 荷兰)对粉体和陶瓷的物相进行鉴定。通过旋转黏度计(Brookfield Viscometer, 美国)测试浆料的流变学性能, 剪切速率范围为0.01~ 56 s–1。用氧氮分析仪(TC600, Leco, 美国)和电感耦合等离子体原子发射光谱(ICP-AES Optima4300DV, PerkinElmer, 美国)确定粉体的实际组成; 使用扫描电子显微镜(Hitachi S-3400N,日本)观察坯体、陶瓷断口及刻蚀表面的形貌特征, 其中表面抛光的陶瓷样品在200 ℃的浓磷酸中刻蚀15 min。分别采用紫外–近红外分光光度计(Lambda750 S, PerkinElmer, 美国)和智能傅里叶红外光谱仪(Model Nexus, Thermo Nicolet Corporation, Madison, WI)测试透明陶瓷样品在200~2500 nm和2500~7000 nm范围的光学直线透过率; 通过椭圆偏振光谱仪(M-2000V, J.A. Woollam, 美国)测试样品在不同波长下的折射率。用维氏硬度计(Model 430 SVD, Wolpert, 中国)测试样品的维氏硬度、测试载荷9.8 N、保压时间15 s; 利用压痕法测试样品的断裂韧性; 使用弹性模量测试仪(GrindoSonic MK7, GrindoSonic, 比利时)测量样品的杨氏模量, 测试方法为脉冲激励法; 采用万能试验机(MTS810 100KN, MTS, 美国)测量陶瓷的抗弯强度, 测试方法为四点弯曲法[17](GB/T 6569-2006, 样品尺寸为3 mm×4 mm×35 mm)。利用热膨胀仪(DIL402SE, Netzsch, 德国)测定样品的热膨胀系数。

2 结果与讨论

2.1 Mg0.9Al2.08O3.97N0.03透明陶瓷的制备

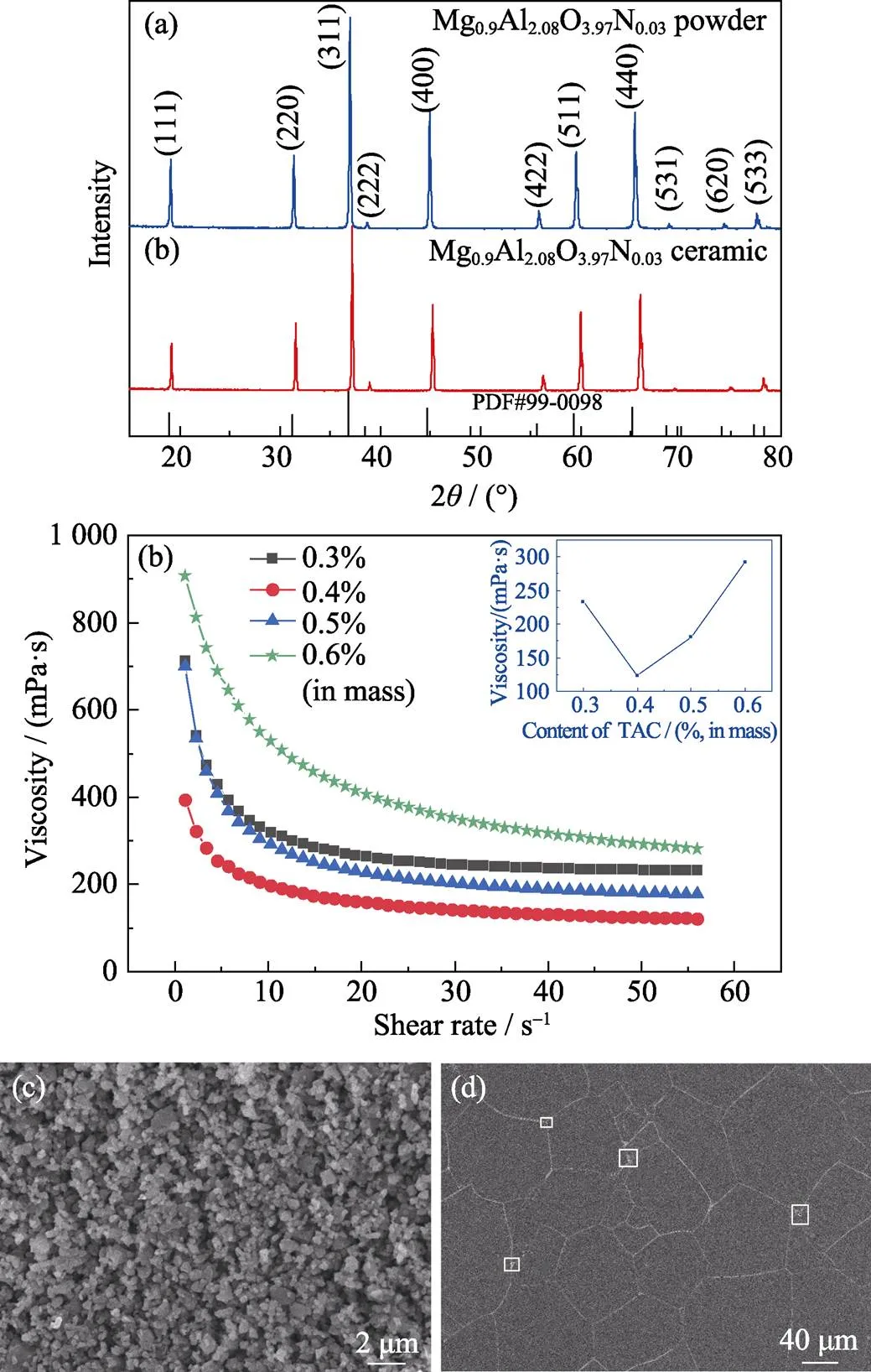

通过氧氮分析仪结合ICP-AES测定陶瓷粉体的实际组成为Mg0.9Al2.08O3.97N0.03, 与设计组成(Mg0.94Al2.05O3.98N0.02)差别不大, 差别主要来源于Mg、N的少量挥发[18]。图1(a)是所得粉体和陶瓷预烧体的XRD图谱, 从图中可以看到, 粉体和陶瓷的衍射峰位置均与尖晶石的PDF#99-0098标准卡片一一对应, 说明它们是由单一尖晶石相组成。

图1(b)显示了固相体积分数为50%时, 分散剂含量对浆料黏度的影响。在剪切速率50 s–1下, TAC质量分数为0.4%时, 浆料的黏度最低, 为124 mPa·s, 说明该浆料可满足水基凝胶注模成型制备陶瓷坯体的要求。

从图1(c)可以看到, 坯体中陶瓷颗粒堆积较紧密、分布较均匀, 粒径约为0.4 μm。图1(d)是热等静压烧结后样品的表面SEM照片, 平均晶粒尺寸约为100 μm、没有出现晶粒的异常长大, 但是残留少量的小气孔。

2.2 光学性能

图2(a)为Mg0.9Al2.08O3.97N0.03、MgAl2O4透明陶瓷、面蓝宝石[1]和Mg0.27Al2.58O3.73N0.27透明陶瓷[14]的光学透过谱。从插图中可以看到, 制备的样品表观透光性良好。2 mm厚的Mg0.9Al2.08O3.97N0.03陶瓷样品在3.7 μm处的透过率为86.2%, 在可见光波段样品的透过率略低于MgAl2O4透明陶瓷, 这是因为陶瓷中残留少量的小气孔(图1(d))。最终样品的光谱透过范围为0.2~6.7 μm, 与MgAl2O4透明陶瓷接近, 较面蓝宝石和Mg0.27Al2.58O3.73N0.27陶瓷更宽。在尖晶石晶体中, 随着Mg含量增大和N含量降低, 晶格振动频率降低, 声子吸收红移, 光谱透过范围变宽[13]。

图1 Mg0.9Al2.08O3.97N0.03陶瓷粉体、浆料、坯体以及透明陶瓷的表征

(a) XRD patterns of powder and ceramic; (b) Relationship between viscosity of slurry and contents of TAC; (c) Morphology of green body; (d) SEM image of etched surface of transparent ceramic

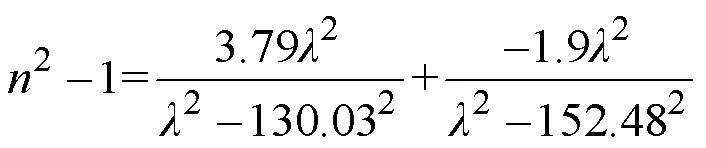

(a) In-line transmittance of Mg0.9Al2.08O3.97N0.03, MgAl2O4,-plane sapphire[1], Mg0.27Al2.58O3.73N0.27transparent ceramics[14]; (b) Refractive index of Mg0.9Al2.08O3.97N0.03, MgAl2O4transparent ceramics[19]

2.3 断裂强度的Weibull统计分析

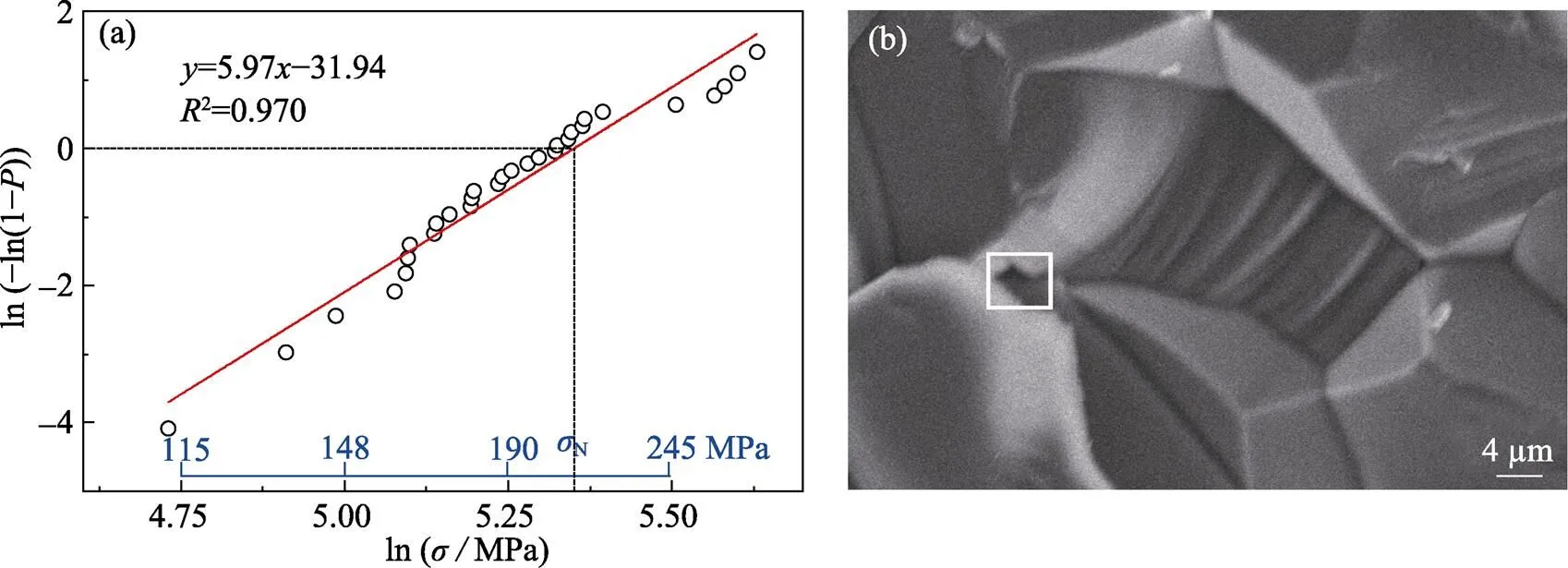

图3(a)是Mg0.9Al2.08O3.97N0.03透明陶瓷的两参数Weibull统计分布图, 可以看到对样品的实测强度线性拟合较好。从拟合结果可得, Mg0.9Al2.08O3.97N0.03透明陶瓷的Weibull模数为5.97±0.25, 特征强度为210.6 MPa。文献[25]报道了MgAl2O4透明陶瓷(平均晶粒尺寸约为5 μm, 下同)的Weibull模数为5±2, 特征强度为169 MPa; 而Mg0.27Al2.58O3.73N0.27透明陶瓷[15]的Weibull模数为4.5, 特征强度为255.54 MPa。本研究的材料特征强度介于MgAl2O4和Mg0.27Al2.58O3.73N0.27透明陶瓷之间, 但Weibull模数高于它们。这说明在相同载荷下, Mg0.9Al2.08O3.97N0.03陶瓷的断裂概率比MgAl2O4低。造成这三种材料特征强度和Weibull模数差异的原因可能来自于它们组成和显微结构的不同[26]。

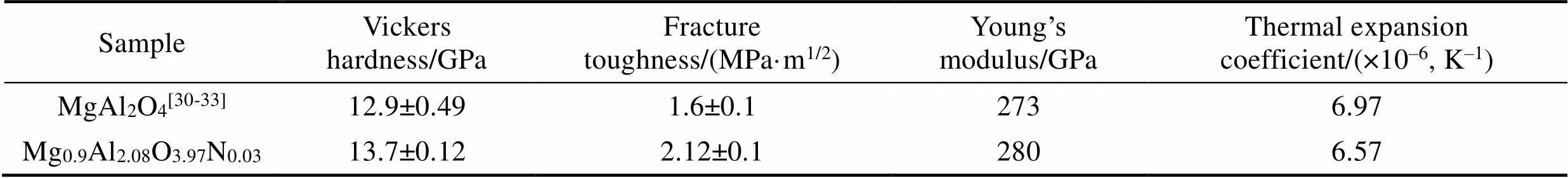

图3(b)是Mg0.9Al2.08O3.97N0.03陶瓷的断口形貌, 可以看出, 样品中存在明显的穿晶和沿晶混合断裂过程以及台阶式断层, 具备陶瓷的脆性断裂特征, 晶界处的小气孔可能是该材料的断裂源。

图3 Mg0.9Al2.08O3.97N0.03透明陶瓷的抗弯强度Weibull统计图(a)和断面SEM照片(b)

2.4 裂纹缓慢扩展

基于陶瓷材料在长时间、低应力下发生裂纹扩展的行为, 研究不同载荷速率下Mg0.9Al2.08O3.97N0.03透明陶瓷的四点抗弯强度。材料在低应力下微裂纹扩展对抗弯强度的影响可采用下式进行表征[28]:

在实际应用中, 陶瓷的使用寿命是一个非常重要的性能指标。将抗弯强度的Weibull统计结果和裂纹缓慢扩展相结合[27], 可得到表征陶瓷疲劳特性的关系式。

为了预测材料在不同使用时间下的实际强度和失效概率, 基于式(5)获得Mg0.9Al2.08O3.97N0.03和MgAl2O4透明陶瓷[27]的强度–概率–时间(Strength- probability-time, SPT)关系图。从图4(b)中可以看出, 材料的断裂概率为63.2%时, 随着使用时间从1 s延长到10 a, Mg0.9Al2.08O3.97N0.03透明陶瓷对应的承受应力从298 MPa降低到112 MPa。这说明随着材料使用时间延长, 裂纹缓慢扩展导致材料可承受的应力降低。当Mg0.9Al2.08O3.97N0.03和MgAl2O4透明陶瓷都使用10 a后, Mg0.9Al2.08O3.97N0.03在应力112 MPa下断裂概率为63.2%, 而MgAl2O4在该应力下的断裂概率超过99%。这是因为Mg0.9Al2.08O3.97N0.03透明陶瓷的惰性强度远大于MgAl2O4透明陶瓷, 不易在外应力冲击下破坏。因此在实际应用中, Mg0.9Al2.08O3.97N0.03透明陶瓷的使用寿命更长, 适用于更苛刻的工作环境。

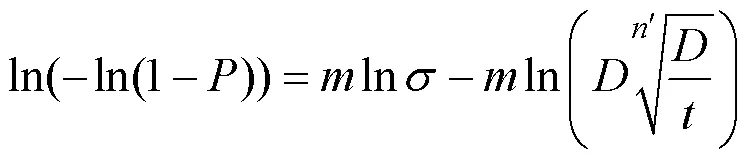

表1给出了Mg0.9Al2.08O3.97N0.03和MgAl2O4透明陶瓷的其它相关性能, 从表中可以看到, Mg0.9Al2.08O3.97N0.03透明陶瓷的硬度、断裂韧性和杨氏模量略高于MgAl2O4; 热膨胀系数略低于MgAl2O4透明陶瓷。这是因为两者组成和结构不同, 随着尖晶石晶体中Mg含量增大和N含量减少, 其四面体键的硬度和键力常数急剧下降, 而八面体键的硬度和键力常数几乎不变, 因此硬度、断裂韧性和杨氏模量降低[34]。

图4 Mg0.9Al2.08O3.97N0.03和MgAl2O4透明陶瓷[27]在不同载荷速率下的抗弯强度(a)与强度–概率–时间关系图(b)

Colorful figures are available on website

表1 Mg0.9Al2.08O3.97N0.03和MgAl2O4透明陶瓷的性能

3 结论

采用水基凝胶注模成型、无压预烧结合热等静压烧结制备了新型Mg0.9Al2.08O3.97N0.03透明陶瓷。所得浆料的固相量高、粘度低, 适合水基凝胶注模成型制备陶瓷坯体。2 mm厚的陶瓷样品在3.7 μm处的直线透过率达86.2%, 且具有与MgAl2O4透明陶瓷可比拟的光学透过域(0.2~6.7 μm)和略大的阿贝数。通过抗弯强度的Weibull统计以及裂纹缓慢扩展研究, 发现Mg0.9Al2.08O3.97N0.03透明陶瓷的Weibull模数、特征强度和惰性强度均大于MgAl2O4透明陶瓷, 但是裂纹缓慢扩展系数略小。另外, 较高的惰性强度使Mg0.9Al2.08O3.97N0.03透明陶瓷的使用寿命更长。

[1] RUBAT D M, KLEEBE H J, MÜLLER M M,. Fifty years of research and development coming to fruition; unraveling the complex interactions during processing of transparent magnesium aluminate (MgAl2O4) spinel., 2013, 96(11): 3341–3365.

[2] WAETZIG K, KRELL A, TRICE R. The effect of composition on the optical properties and hardness of transparent Al-rich MgO·Al2O3spinel ceramics., 2015, 99(3): 946–953.

[3] SANGHERA J, BAYYA S, VILLALOBOS G,. Transparent ceramics for high-energy laser systems., 2011, 33(3): 511–518.

[4] PAPPAS J M, DONG X Y. Porosity characterization of additively manufactured transparent MgAl2O4spinel by laser direct deposition., 2020, 46(5): 6745–6755.

[5] SALEM J A, SGLAVO V. Transparent armor ceramics as spacecraft windows., 2013, 96(1): 281–289.

[6] ROTHMAN A, KALABUKHOV S, SVERDLOV N,. The effect of grain size on the mechanical and optical properties of spark plasma sintering-processed magnesium aluminate spinel MgAl2O4., 2014, 11(1): 146–153.

[7] SOKOL M, KALABUKHOV S, SHNECK R,. Effect of grain size on the static and dynamic mechanical properties of magnesium aluminate spinel (MgAl2O4)., 2017, 37(10): 3417–3424.

[8] NECINA V, PABST W. Grain growth of MgAl2O4ceramics with LiF and NaF addition., 2021, 5(2): 100078.

[9] ZHANG H, WANG H, GU H,. Preparation of transparent MgO·1.8Al2O3spinel ceramics by aqueous gelcasting, presintering and hot isostatic pressing., 2018, 38(11): 4057–4063.

[10] YAN J, YAN W, CHEN Z,. A strategy for controlling microstructure and mechanical properties of microporous spinel (MgAl2O4) aggregates from magnesite and Al(OH)3., 2022, 896: 163088.

[11] ZHANG P, LIU P, SUN Y,. Microstructure and properties of transparent MgAl2O4ceramic fabricated by aqueous gelcasting., 2016, 657: 246–249.

[12] WILLEMS H X, WITH G D, METSELAAR R. Thermodynamics of AlON III: stabilization of AlON with MgO., 1993, 12(1): 43–49.

[13] ZONG X, WANG H, GU H,. A novel spinel-type Mg0.55Al2.36O3.81N0.19transparent ceramic with infrared transmittance range comparable to-plane sapphire., 2020, 178(15): 428–432.

[14] LIU X, WANG H, TU B T,. Highly transparent Mg0.27Al2.58O3.73N0.27ceramic prepared by pressureless sintering., 2014, 97(1): 63–66.

[15] ZHANG Z, WANG H, TU B T. Characterization and evaluation on mechanical property of Mg0.27Al2.58O3.73N0.27transparent ceramic., 2018, 33(9): 1006–1010.

[16] ZONG X, WANG H, GU H,. Highly transparent Mg0.27Al2.58O3.73N0.27ceramic fabricated by aqueous gelcasting, pressureless sintering, and post-HIP., 2019, 102(11): 6507–6516.

[17] GB/T 6569-2006, 精细陶瓷弯曲强度试验方法.

[18] GRANON A, GOEURIOT P, THEVENOT F,. Reactivity in the Al2O3-AlN-MgO system. The MgAlON spinel phase., 1994, 13(4): 365–370.

[19] KRELL A, HUTZLER T, KLIMKE J. Transmission physics and consequences for materials selection, manufacturing, and applications., 2009, 29(2): 207–221.

[20] WEMPLE S H, DIDOMENICO M J. Behavior of the electronic dielectric constant in covalent and ionic materials., 1971, 3(4):1338–1351.

[21] CAI B, KAINO T, SUGIHARA O. Sulfonyl-containing polymer and its alumina nanocomposite with high Abbe number and high refractive index., 2015, 5(5):1210–1216.

[22] KLEIN C A. Flexural strength of infrared-transmitting window materials: bimodal Weibull statistical analysis., 2011, 50(2): 1–10.

[23] DENG B, JIANG D, GONG J. Is a three-parameter Weibull function really necessary for the characterization of the statistical variation of the strength of brittle ceramics?, 2018, 38(4): 2234–2242.

[24] KHALILI A. Statistical properties of Weibull estimators., 1991, 26: 6741–6752.

[25] TOKARIEV O, SCHNETTER L, BECK T,. Grain size effect on the mechanical properties of transparent spinel ceramics., 2013, 33(4): 749–757.

[26] MALZBENDER J, STEINBRECH R W. Threshold fracture stress of thin ceramic components., 2008, 28(1): 247–252.

[27] TOKARIEV O, STEINBRECH R W, SCHNETTER L,. Micro- and macro-mechanical testing of transparent MgAl2O4spinel., 2012, 47: 4821–4826.

[28] CHOI S R. Slow crack growth analysis of brittle materials with finite thickness subjected to constant stress-rate flexural loading., 1999, 34: 3875–3882.

[29] RAMOS N D, CAMPOS T M, PAZ I S,. Microstructure characterization and SCG of newly engineered dental ceramics., 2016, 32(7): 870–878.

[30] EKATERINA N, KEYUR K, KIRA C,. Hall-Petch effect in binary and ternary alumina/zirconia/spinel composites., 2021, 11: 823–832.

[31] SENTHIL K, BISWAS P, JOHNSON R,. Transparent ceramics for ballistic armor applications., 2020, 11: 435–457.

[32] KRELL A, STRASSBURGER E, HUTZLER T,. Single and polycrystalline transparent ceramic armor with different crystal structure., 2013, 96(9): 2718–2721.

[33] IQBAL M J, ISMAIL B, RENTENBERGER C,. Modification of the physical properties of semiconducting MgAl2O4by doping with a binary mixture of Co and Zn ions., 2011, 46(12): 2271–2277.

[34] REN L, WANG H, TU B T,. Investigation on composition- dependent properties of Mg5xAl23−5xO27+5xN5−5x(0≤≤1): Part II. Mechanical propertiesfirst-principles calculations combined with bond valence models., 2021, 41(3): 4942–4950.

Preparation and Property of Mg0.9Al2.08O3.97N0.03Transparent Ceramic with Broad Optical Transmission Range

LI Wenjun, WANG Hao, TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi

(State Key Laboratory of Advanced Technology for Materials Synthesis and Processing, Wuhan University of Technology, Wuhan 430070, China)

MgAl2O4transparent ceramics possess excellent optical property, but their practical applications are somewhat restricted by the hydrolysis problem during the shaping process and limited mechanical property. Meanwhile, it has been demonstrated that the property of quaternary MgAlON spinel can be effectively adjustedvarying their composition. Accordingly, a novel Mg0.9Al2.08O3.97N0.03transparent ceramic with a broad transmittance range was prepared by combining aqueous gel-casting, pressureless sintering, and hot isostatic pressing treatment. Optical and mechanical property of this transparent ceramic were systematically investigated and compared with those of MgAl2O4transparent ceramic. Furthermore, the slow crack growth under low stress were analyzed, and the service life of transparent ceramic was predicted. It is shown that the viscosity of ceramic slurry with 50% (in volume) solid load was 124 mPa·s, which could meet the requirement of aqueous gel-casting. The in-line transmittance of 86.2% at 3.7 μm was obtained in the Mg0.9Al2.08O3.97N0.03transparent ceramic sample with thickness of 2 mm, and the optical transmittance range was comparable to that of MgAl2O4, with slightly higher refractive index and Abbé number. Further, this ceramic showed a Weibull modulus similar to MgAl2O4, and although its crack slow growth coefficient is lower than MgAl2O4,but both the characteristic strength (210.6 MPa) and inert strength (227.5 MPa) were much higher. Therefore, in the quaternary MgAlON spinel with low nitrogen content, the hydrolysis problem of ceramic powders could be well overcome, while the mechanical property of transparent ceramic was remarkably improved without degradation of optical property. This research provides a new pathway toward obtaining the novel spinel transparent ceramics with improved preparation and property.

transparent ceramics; aqueous gel-casting; mechanical property; optical property

1000-324X(2022)09-0969-07

10.15541/jim20210771

TQ174

A

2021-12-17;

2022-02-22;

2022-06-16

国家重点研发计划(2017YFB0310500); 国家自然科学基金(51472195); 三亚科教创新园开放基金(2020KF0018)

National Key Research and Development Program of China (2017YFB0310500); National Natural Science Foundation of China (51472195); Sanya Science and Education Innovation Park Open Fundation (2020KF0018)

李文俊(1996–), 男, 硕士研究生. E-mail: 15826911464@163.com

LI Wenjun (1996–), male, Master candidate. E-mail: 15826911464@163.com

王皓, 教授. E-mail: shswangh@whut.edu.cn

WANG Hao, professor. E-mail: shswangh@whut.edu.cn