Classification of Preparation Methods and Wearability of Smart Textiles

FANG Jialu(方佳璐), DU Jianxia(杜剑侠)

School of Fashion, Beijing Institute of Fashion Technology, Beijing 100029, China

Abstract: In recent years, smart textiles have attracted the attention of scholars from all walks of life, but there is an imbalance between functionality and usability, which affects their marketization process. Firstly, five representative smart textiles are introduced and their respective wearability is described around preparation methods. Secondly, it is concluded that the preparation methods of smart textiles can be divided into two categories: fiber methods and finishing methods. The fiber methods refer to making smart fibers into smart textiles. Textiles made by fiber methods are breathable and feel good in the hand, but the mechanical properties are influenced by the production equipment, and the process cost is high. The finishing methods refer to the functional finishing of ordinary textiles. Although the finishing method is simple and convenient, it may reduce the comfort of the textile. Finally, applications and new research in various fields of smart textiles are presented with promising prospects. It is anticipated that this review will serve as a theoretical basis for future research and development of smart textiles. Researchers are expected to create new technologies to overcome the tension between functionality and usability, as well as to increase user comfort and convenience.

Key words: smart textiles; classification of preparation method; wearability; functionality; fabric comfort

Introduction

With the continuous development of society, ordinary textiles can no longer satisfy people’s pursuit of high-quality living standards. Textiles’ function is no longer restricted to protecting the body at birth but has evolved to serve the person, giving comfort and convenience. Therefore, smart textiles have attracted much attention, and their prospects are unlimited. Brand companies have also committed to the research and development of smart textiles. Existing commercial products include smart sports bras that monitor heart rate[1-2], jackets that can touch and remotely control devices such as mobile phones and computers[3], skin clothing that changes color depending on the intensity of ultraviolet rays[4], and electrocardiographic clothing that monitors physiological signals[5].

Smart textiles must be capable of detecting changes in the external environment, giving prompt feedback, and making adjustments automatically. However, they should have good wearing performance and appearance style, such as no harm to the human body, breathability and moisture permeability, soft and wear-resistant[6]. At present, the research and evaluation of smart textiles are still in the exploratory stage, and the functionality and wearability of existing products are still uneven. In prior research and development, some wearing properties, including feel, breathability, and mechanical capabilities, may have been compromised to accomplish the functionality of smart textiles. For example, the existing electronic smart textiles cannot get rid of the rigid connection, resulting in insufficient flexibility. Furthermore, the implanted sensor area’s tensile and flexural strength is inadequate, resulting in brittleness and discomfort of the textiles during usage[7].

Currently, the testing and evaluation of smart textiles are mostly from the perspective of functionality. For example, Xiaoetal.[8]introduced the testing methods for the special properties of smart textiles, such as phase-change thermoregulation textiles, shape memory textiles, and color-changing textiles, and evaluated the currently existing evaluation methods. Xiaoetal.[9]introduced and analyzed the existing methods for evaluating the temperature regulating the ability of smart thermoregulation textiles, and provided the testing ideas of thermoregulation textiles. Ohetal.[10]studied and evaluated the moisture transfer performance of waterproof and breathable textiles with different pore sizes and distributions at low temperatures. Liuetal.[11]did a study on the functional evaluation methods of electronic smart textiles, providing valuable ideas for developing standards for electronic smart textiles. From the perspective of wearing performance, Zhangetal.[12]used fabric touch tester(FTT) to get the ranking of hand feel comprehensive index in the order of tencel fabric, cotton fabric, and nylon/cotton blend fabric. Atalie and Rotich[13]used Kawaba-ta’s evaluating system(KES) to test and found that cotton fiber parameters significantly influenced surface friction and roughness performance. Cai[14]also studied that the yarn fineness of cotton shirting fabric can affect the fabrics’ softness, wrinkle resistance, elasticity, warmth, coolness, and flatness. Yin and Sun[15]tested the relevant indexes of cotton/wool blended fabrics with different blending ratios and found that 80/20 cotton/wool blended ratio fabrics had the best hand feel.

In conclusion, there are corresponding evaluation indicators for thermal-humidity comfort and mechanical properties, such as thermal resistance, moisture resistance, breaking strength, and compression work. Nevertheless, there is no corresponding standard for contact comfort. In addition, the current evaluation of textiles’ mechanical and contact properties is mostly for normal textiles but not for smart textiles. Due to the lack of evaluation of the wearing performance of smart textiles, smart textiles preparation methods are classified. The wearing performance of smart textiles under different categories of preparation methods is discussed to find better preparation methods to provide a better user experience.

1 Main Types of Smart Textiles

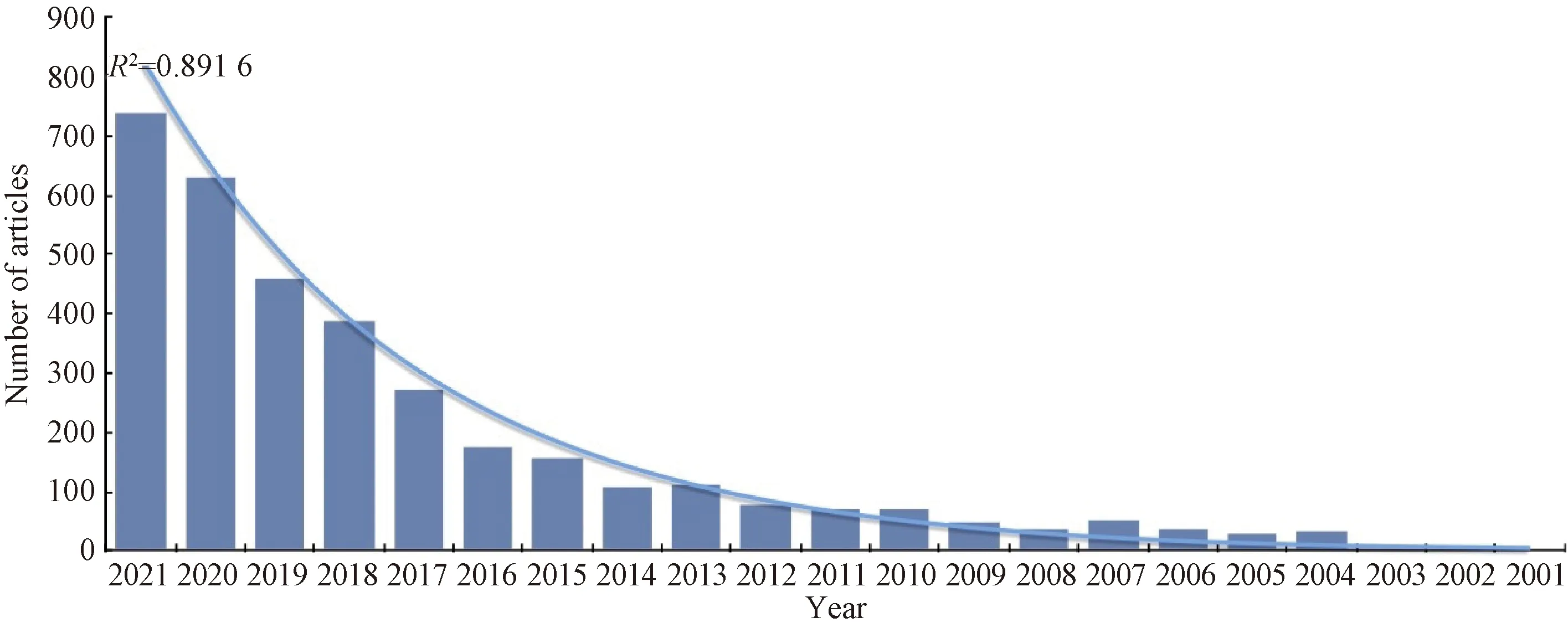

Smart textiles are a cross-discipline that integrates textiles, electronics, chemistry, biology, medicine, materials, and other disciplines. It imitates living systems and can self-regulate to adapt to changes in the external environment[16]. Nowadays, scholars have developed a very wide range of smart textiles. To visualize the growth trend of the research literature in the field of smart textiles, the number of publications is fitted to an exponential function andR-squared(R2) is used to reflect the degree of fit. The closer theR2is to 1, the faster the number of articles grows. Using the Web of Science Citation Index database, a search of the keywords “smart textile” and “smart fabric” yielded 3 511 articles from 2001 to 2021, and the number of studies has been increasing exponentially withR2of 0.891 6 in recent years shown in Fig. 1.

Fig. 1 Statistics of the number of documents from 2001 to 2021

Smart textiles are often prepared from smart materials. Smart materials include phase change materials(PCMs), shape memory polyurethane(SMPU), thermoplastic polyurethanes(TPU), polytetrafluo-roethylene(PTFE), thermotropic material(TM), photochromic material(PM), electronic components,etc. Among the many types of smart textiles, we focus on five main types of smart textiles[17-22], which are shown in Fig. 2.

Fig. 2 Technical routes and types of smart textiles: (a) smart thermoregulation textiles; (b) smart color-changing textiles; (c) shape memory textiles; (d) waterproof and breathable textiles; (e) electronic smart textiles

2 Smart Thermoregulation Textiles

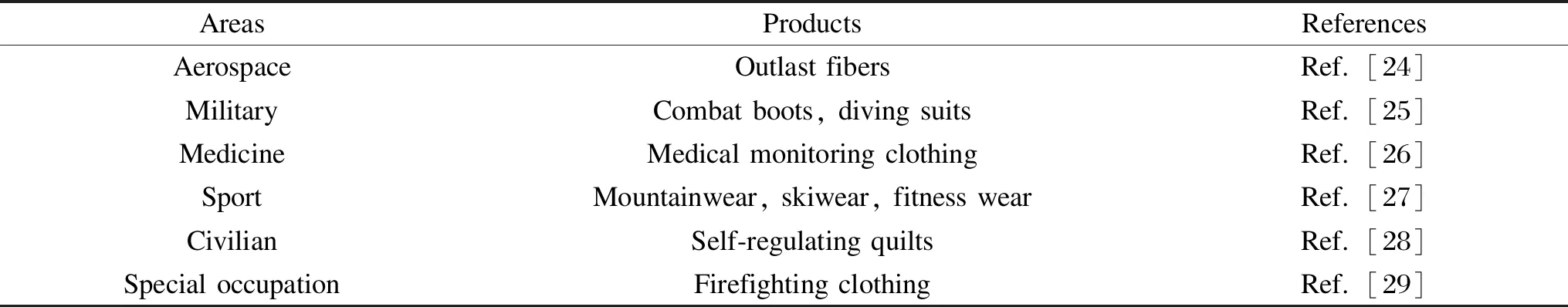

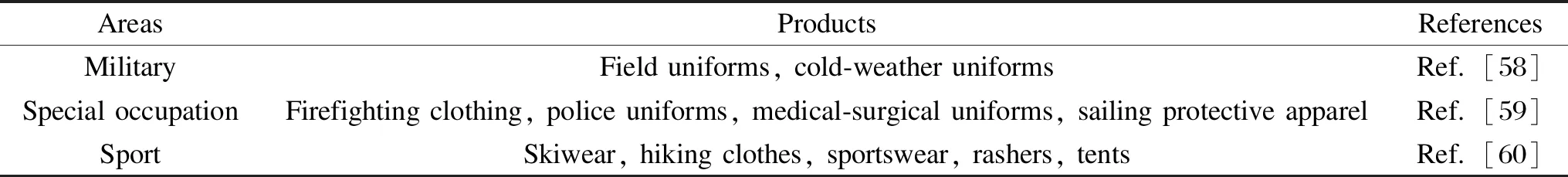

When the external temperature changes, the inside of smart thermoregulation textiles will undergo physical, chemical, or structural changes to absorb or release energy so that the wearer can maintain a comfortable temperature[23]. Table 1 shows the areas of application for smart thermoregulation textiles.

There are many different types of smart thermoregulation materials, such as the currently popular radiation thermoregulation materials, semiconductor thermoregulation materials, and phase change materials. Thermoregulation textiles may be created using PCMs to alter the phase state, which is a hot topic in the study. PCMs can be divided into inorganic and organic phases. Inorganic PCMs include crystalline hydrates, metals, and alloys, while organic PCMs include paraffin, fatty acids, and polyols. Organic phase change materials have a higher enthalpy value than inorganic materials. Their phase-change conversion temperature is closer to body temperature, making them more suitable for thermoregulation textiles. However, PCMs are limited in practical applications due to their corrosiveness, unstable storage environment, and difficulty in combining with the base fabric[30]. Microcapsule technology can encapsulate PCMs to solve the above problems.

Melamine-formaldehyde resin (MFR) and urea-formaldehyde resin (UF) are the primary materials for microcapsules. The microcapsules made of MFR and UF have better overall performance but are brittle, easy to break, and contain formaldehyde, which is harmful to human health. Carbamide resin and polyurethane resin are prepared without the addition of formaldehyde. However, it is difficult to achieve the desired effect in the thermoregulation function. Due to its high chemical stability and reasonable price, polyacrylate is the direction of research on phase change microencapsulated wall materials[31]. So, the current research on microcapsule phase change textiles is more extensive.

AreasProductsReferencesAerospaceOutlast fibersRef. [24]MilitaryCombat boots, diving suitsRef. [25]MedicineMedical monitoring clothingRef. [26]SportMountainwear, skiwear, fitness wearRef. [27]CivilianSelf-regulating quiltsRef. [28]Special occupationFirefighting clothingRef. [29]

The preparation methods of phase-change temperature-regulating textiles are mainly divided into two categories: fiber methods and finishing methods[32].

In the fiber methods, PCMs, or PCM microcapsules are processed into phase change fibers by hollow fibers filling method or spinning method and then woven into corresponding textiles. Zhangetal.[33]used PCM microcapsules to produce acrylic chloride fibers with a PCM of 30% through solution spinning, which has good spinnability and thermal stability, but poor mechanical properties. Yanetal.[34]concluded that the addition of microcapsules reduced the spinnability of the spinning solution and yields fibers with lower breaking strength and elongation.

The finishing methods are to directly coat or pad ordinary textiles to obtain temperature-regulating textiles. Shietal.[35]used a coating process to finish the phase change microcapsules on the spunbond/meltblown/spunbond (SMS) to obtain phase-change thermoregulation textiles, which showed an increase in fabric breaking strength and elongation at break. However, the microcapsules are attached to the fabric’s surface and in the gaps to block the pores of the fabric, resulting in a decrease in the air permeability. Caoetal.[36]used the coating method and the padding method to respectively finish the PCM finishing liquid on the cotton fabric and found that the coating finishing has stronger heat storage and thermoregulation function than the padding finishing, but the fabric is thicker, with a poorer hand feel and application. Liuetal.[37]also compared the effects of the padding method and the coating method on the wearability of denim, and found that the coating finishing was stiffer than the padding finishing cloth sample, with the moisture permeability and the air permeability being worse.

In summary, the mechanical properties of phase-change fibers prepared by the fiber methods have not yet reached the requirements for use, so the finishing methods have become the first choice. The wearing comfort and durability of the textile obtained by the coating method are lower than that of the padding method. However, the textile obtained by the padding method needs to be improved in terms of thermoregulation functionality. Therefore, the balance of functionality, comfort, and mechanics to maximize benefits is a key issue that needs to be addressed in application and development.

3 Smart Color-Changing Textiles

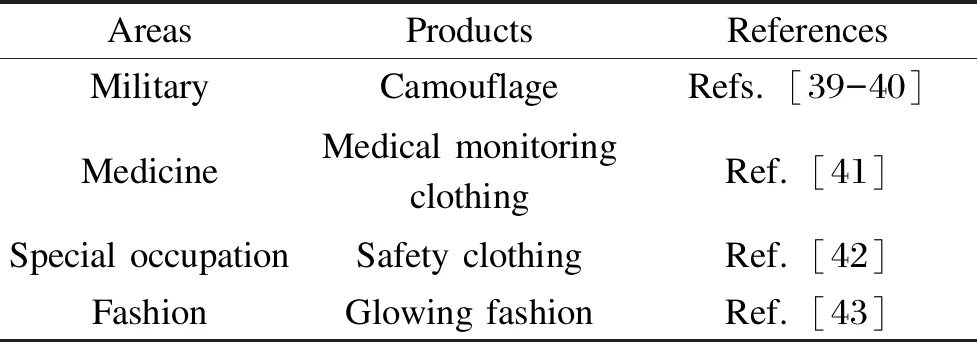

Color-changing textiles can show different colors as the environment changes. According to the principle of discoloration, it can be divided into photosensitive discoloration, heat-sensitive discoloration, moisture-sensitive discoloration, electrochromic, and acid-base discoloration textiles[38]. Table 2 shows the areas of application for smart color-changing textiles.

Table 2 Areas of application for smart color-changing textiles

Preparing smart color-changing textiles can also be divided into the same two categories as in section 2 above. The first category is weaving textiles using color-changing fibers, which are fiber methods. The other is the functional finishing of textiles, which are finishing methods. The specific ways in which each of the two categories is covered are described in more details below.

The finishing methods include dyeing, printing, coating, padding method, and dipping method. The dyeing method is to first make color-changing materials into dyes, and then dye fibers, yarns, or fabrics. Leeetal.[44]treated the photochromic dye on the fabric to obtain a photochromic fabric, the color change effect of the fabric was weakened. The printing method requires a large number of binders to attach the color-changing material to the surface of the fabric. Chenetal.[45]found that color-changing textiles prepared by the traditional printing method were stiffer to the touch due to the large number of micron-sized pigment particles gathered on the surface, and had poor breathability and rubbing color fastness. Chen and Liu[46]claimed the coating method lost the feel and breathability of the fabric, but its rub resistance and wash fastness are better than the printing method. Wu[47]used the padding method to produce a fabric with good breathability, moisture permeability, and a soft feel, however, microcapsules encapsulating color-changing materials could not be used in the padding method as the padding process caused extrusion and fracture of the microcapsules. Liuetal.[48]concluded that the dipping method was simple and easy to use and also suitable for microencapsulation finishing and that fabrics finished by dipping retain the softness of the original fabric. However, Yang[49]found that the colorfastness to washing and abrasion resistance of the discolored textile obtained by the dipping method was not ideal.

The durability and colorfastness of many domestic color-changing textiles are not ideal. The hand feel and breathability of the textiles obtained by the finishing methods are affected to a certain extent. Color-changing fiber manufacturing technology includes melt spinning, solution spinning, and graft polymerization. Compared with the finishing methods, the color-changing textiles made by the fiber methods have better hand feel, air permeability, washing resistance, abrasion resistance, and durability of the color-changing function. In addition, they are energy-saving and environmentally friendly.

4 Shape Memory Textiles

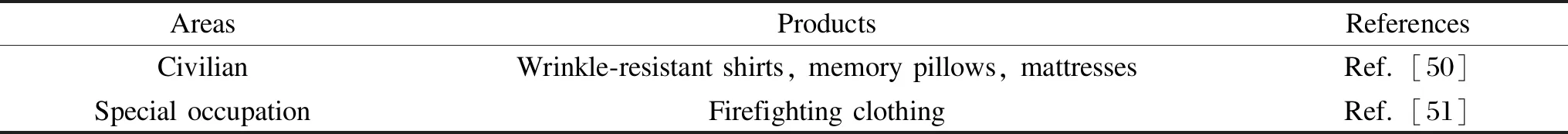

Shape memory textiles temporarily deform under certain special conditions and reversibly return to their original shape under external stimulation (generally including heat, light, humidity, magnetic field, pH value,etc.). Table 3 shows the areas of application for shape memory textiles.

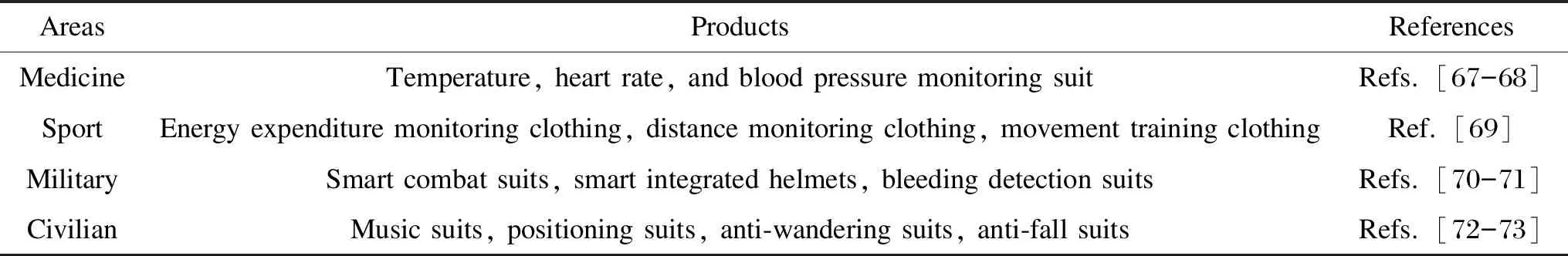

Table 3 Areas of application for shape memory textiles

Shape memory textiles are prepared in the same way as section 2 above and are summarized into two methods: finishing methods and fiber methods. Standard finishing methods include shape memory polymer finishing, collagen finishing and grafting, embedding, and resin finishing; fiber methods refer to weaving textiles with shape memory fibers, and fiber preparation technologies include electrostatic spinning, wet spinning, and melt spinning[52].

Liuetal.[53]adopted the finishing methods on cotton fabrics and used the KES to analyze the fabric style before and after shape memory finishing. They found that the friction factor of the finished fabric increased slightly, the smoothness was slightly worse, and the bulkiness decreased. In addition, different shape memory finishing agents will also have different effects on the wearability of the fabric. For example, in terms of mechanical properties, Hu[54]used SMPU finishing agent and SiO2/SMPU composite finishing agent to finish the printed cotton fabric. It was found that the pure SMPU finishing agent would reduce the breaking strength of the fabric. The composite finishing agent could not only improve the breaking strength of the fabric but also improve the color fastness of the fabric.

In the fiber methods, Liu and Hu[55]mentioned that the Hong Kong Polytechnic University used SMPU to spin shape memory fibers through the traditional wet spinning process, which had higher breaking strength and breaking elongation. In contrast, the mechanical properties of shape memory fibers produced by melt spinning need to be further improved. Then, Huetal.[56]successfully prepared a shape memory fiber by the melt spinning method and applied it for a patent. The textile woven from the fiber has good comfort. Wangetal.[57]summarized the method of preparing shape memory micro-nano fibers by electrospinning technology, which prepared fibers with small diameter, good flexibility, large specific surface area, high porosity, and excellent mechanical properties of nanofiber membranes. Therefore, it shows potential application value in drug-controlled release, biomedicine, smart textiles, and wound dressings.

In the finishing methods, the choice of shape memory finishing agent is significant to the fabric style and wearability. Moreover, the continuous improvement of fiber preparation technology brings better wear performance under the condition of ensuring functionality, offering the possibility of more applications in more fields.

5 Waterproof and Breathable Textiles

Waterproof and breathable textiles mean liquid water molecules (including rain, snow, dew, and frost) cannot pass through the textiles. In contrast, gaseous water molecules (water vapour formed by sweat) emitted by the human body can be transmitted to the outside world. They will not accumulate and condense between the body surface and the textiles, thereby keeping the human body dry and warm and realizing the unity of the textile’s waterproof function and thermal and wet comfort. Table 4 shows the areas of application for waterproof and breathable textiles.

Table 4 Areas of application for waterproof and breathable textiles

The most common waterproof and breathable textiles can be divided into high-density, coated, and laminated textiles. High-density textile is formed through the fiber methods. Coated textile and laminated textile are formed through the finishing methods.

High-density textile[61]is generally woven with superfine fibers. The yarn density of the textile is high, while the gap is so small that water droplets are not allowed to pass through, which achieves the waterproof function. The fibers’ moisture-absorbing capacity and capillary effect, together with the voids in the fibers can absorb, transfer, and release water vapor to achieve a moisture-permeable function. High-density waterproof and breathable textiles have good breathability, moisture permeability, and softness, but the textile is less resistant to tearing and abrasion.

The coating agent with waterproof and breathable function is uniformly coated on the base cloth to form a coated textile.

Natural rubber, synthetic rubber, silicone, polyacrylate, and polyvinyl chloride, which were originally used as coating agents, have good waterproofing properties but poor breathability and moisture permeability, so they are gradually being replaced by PTFE and TPU[62]. However, TPU hardens below 0 ℃ and its moisture permeability is greatly reduced, so it cannot be used to make cold-proof clothing. In addition, cross-linking after the coating is required to improve abrasion, water, and solvent resistance, but cross-linking can affect the feel of the textile. Different coating technologies also have an impact on the performance of waterproof and breathable textiles. Chen[63]found that dry-coated textiles feel soft and flexible, but the moisture permeability and water pressure resistance of the textiles were poor; the textiles processed by wet coating had excellent appearance and hand feel, and better breathability and elasticity than the dry coating, but the process was complicated and led to environmental pollution.

The laminated textile is obtained by combining the waterproof and breathable film with the textile. Laminating technology is the main development direction of waterproof and breathable textiles widely used in outdoor clothing[64]. According to the waterproof and moisture permeability mechanism, laminate films can be divided into three types: hydrophobic microporous film, non-porous hydrophilic film, and the film formed by the combination of the above two films[65]. The microporous film realizes waterproof and moisture permeability through the difference in the diameter of raindrops and water vapor molecules. Its moisture permeability, water pressure resistance, wind resistance, and warmth retention are good, but its durability is not high. Long-term use will lead to the expansion of pores due to stretching and thus losing the waterproof function, or because of dirt blocked pores and thus losing the moisture permeability function. The non-porous film waterproof and breathable textile achieves the waterproof effect through the hydrophilic characteristics of the molecule, and the non-porous makes it have long-lasting waterproof and windproof properties. However, its moisture and air permeability are relatively low, and the comfort is poor. The hydrophilic and microporous composite waterproof and breathable textile can improve the waterproofness of the microporous film and overcome the shortcomings of the short durability of the microporous structure.

6 Electronic Smart Textiles

In a narrow sense, smart textiles refer to electronic smart textiles[66]. It is based on textiles with sensors, communications, artificial intelligence, and other high-tech means to collect signals and give feedback. Table 5 shows the areas of application for electronic smart textiles.

Table 5 Areas of application for electronic smart textiles

Packaging and coating methods are types of finishing methods, whereas weaving and embroidery methods are types of fiber methods.

The packaging method[74]was first applied to integrating sensors and wearable devices, which was a simple process to directly add sensors into smart clothes or textiles mechanically. However, during the long period of continuous monitoring, the sensor and the textile will slide due to the motion amplitude and other factors, making the product’s stability and accuracy limited. At the same time, some sensor materials are hard, which limits stretchability and reduces comfort. So the future of the packaging method depends on whether electronics can be miniaturized. The requirements for electronic smart textiles made by the packaging method include good stretchability, lightweight, high comfort, good electrical conductivity, good functionality, durability, abrasion resistance, and reasonable cost.

The coating method[75]is to attach smart materials to the textile by coating, dipping, printing,etc. The production process is simple and easy, and the textile also has the advantages of a large area and low cost, but the adhesion strength between the material and the base textile will decrease with the number of washes and frictions, and the durability is difficult to guarantee. In addition, the uniformity of the coating is difficult to control, and the stretch performance is also poor, which will affect the feel and wearability of the textile.

The weaving method[76]first prepares electronic smart fibers by electrospinning, or by filling microchips into the yarn structure, and then spins the fibers into yarn to make electronic smart textiles. This method is costly, and the process is lengthy. Moreover, the yarn’s mechanical properties and the textile’s washability are yet to be studied. However, textiles offer better hand feel, comfort, and durability.

In addition, smart yarns can be sewn onto textiles by embroidery[77]. However, this technique is not suitable for mass production, and the fibers are fragile and not wear-resistant.

Making the rigid electronic components comfortably combined with the skin is the most significant technical challenge of electronic smart textiles[78]. Liuetal.[11]explored the evaluation method for the wearability of electronic smart textiles. In addition to the hand feel and comfort, if the textile is embedded in rigid electronic components, its mechanical properties should be considered, including bending and tearing strength. Furthermore, electronic components in direct contact with the skin need to consider their heavy metal content.

7 General Approach and New Develop-ment of Textile Intelligence

In summary, the pathways to textile intelligence are generally divided into two broad categories:fiber methods and finishing methods. Because the fiber methods are technically through the blending or interweaving of fibers to eventually form textiles, they have unique advantages in hand feel, breathability, washability, and other functions. However, they often have complex processes, high equipment requirements, and excessive costs. The finishing methods are simple, but the adhesion between the finishing agent and the base textile will weaken with washing and friction. The functionality cannot be sustained, and further exploration is needed in handling and breathability. Although both pathways have advantages and disadvantages, preparation techniques and new applications are being continuously explored and studied, and researchers are gradually making some progress[79].

7.1 Optimization of wearing performance

Wearing performance is the essential element for the development of textiles. The performances of the smart textiles mentioned above are optimized in the following section.

For example, in response to the problem mentioned in section 2 that the mechanical properties of thermoregulation fibers prepared by the fiber methods are insufficient, but the comfort and durability of thermoregulation textiles obtained by the finishing methods are reduced, Wuetal.[17]produced fibers by cryospinning and then integrated temperature-controlled PCMs coated with polydimethylsiloxane (PDMS) into the fiber microstructure to obtain thermoregulation fibers with mechanical and durability properties that met the requirements. In summary, this method combines the fiber methods with the finishing methods, replacing the previous direct combination of phase change materials and fibers (leading to wear, leakage, and non-durability of PCMs) and the coaxial electrostatic spinning method (leading to insufficient mechanical properties), integrating the advantages of the fiber methods to obtain better textile feel as well as durability. The finishing methods to obtain better textile mechanical properties can provide new ideas for optimizing the durable and mechanical properties of future smart textiles.

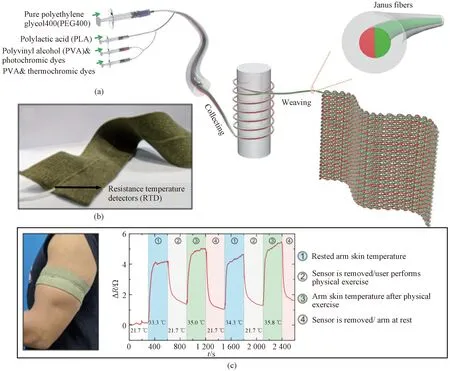

As mentioned in section 3, the main problem with smart color-changing textiles is that their durability and color fastness are not satisfactory. Weietal.[80]used microfluidic spinning technology (MST) to produce Janus fibers, and the preparation process was shown in Fig. 3(a). After 60 ultraviolet/infrared radiation (UV/IR) stimulations and 50 washes, the combined color change of the textile was only from 0.42% to 4.71%, indicating the durability of the color-changing properties with good colorfastness performance. The MST can prepare new and efficient nano-fiber microarrays with lower energy consumption than melt spinning, higher safety performance than electrostatic spinning. Moreover, it can produce structurally elastic and well-arranged fibers, but as the technology is just in its infancy, there are still many shortcomings and defects in its application. It is expected that MST will continue to advance and be applied to smart textile production in the future.

Fig. 3 Performance optimization of smart textiles: (a) schematic diagram of the Janus fibers preparation process; (b) physical view of the flexible sensor; (c) test procedure and results for flexible sensors

For the limitations of the mechanical properties of shape memory textiles in section 4, Muetal.[81]improved the properties of the matrix material by transforming shape memory polymers (SMPs) into shape memory polymer composites (SMPCs) to obtain better mechanical properties. However, the shape memory effect would be reduced, so there is still a long way to go in the research of balancing functionality and mechanics. Improving performance through the compounding of materials so that several components complement each other and create synergies still offers new ideas for continuous improvement.

In response to the lack of hand feel of the waterproof and breathable textiles obtained by the coating method in section 5, Jin[82]optimized and developed a nylon/polyester linen grey taslon fabric with both wearability and functionality, taking into account the waterproof and breathable properties, the hand feel and cost of the finished product, by dipping and rolling the polyester fabric at a rolling temperature of 175 ℃, a pressure of 80 kg, two times, and a coating dry glue weight of 30 g/m2to 35 g/m2. The solution can be used as a template for the industrial production of water and moisture permeable fabrics.

As mentioned in section 6, previous electronic smart textiles were often realized by the finishing methods (e.g., encapsulation, coating), where the textile only acted as a carrier for electronic components without inherent electronic functionality, which also led to limitations in terms of lightness, softness, and washability of the electronic smart textiles. Lugodaetal.[83]used the fiber methods to integrate flexible sensors into textile yarns, effectively improving the softness and increasing the usability of the electronic smart textiles, as shown in Figs. 3(b) and 3(c). However, the electronic smart textiles lost 14% of their functionality in terms of measurement sensitivity due to the inability of the sensor to come into direct contact with the skin, and further research is necessary to balance functionality and comfort.

In summary, researchers have continued to study the performance of fabrics, providing good ideas, including the integration of the advantages of various methods, the application of new technologies, and the compounding of materials. Nevertheless, due to the limitations of current technology, the imbalance between performance and functionality is still relatively obvious; that is, when improving performance, a certain amount of functional effectiveness is lost. At the same time, the existing smart textiles are mostly optimized from the perspective of mechanical and durable properties, and research on hand feel properties is still very limited. It is expected that the intersection of multidisciplinary knowledge will lead to the joint development of the mechanical, durable, and hand properties of textiles in the future, while gradually reducing the imbalance between usability and functionality, then better-combining intelligence and comfort to achieve a human-centered effect.

7.2 Diversity of functions

Nowadays, smart textiles are developing towards combining smart, functional materials to achieve multifunctional products. For example, Yietal.[84]combined thermoregulation properties with waterproof and breathable properties to prepare a nanofiber membrane with excellent mechanical properties using the electrostatic spinning method with carbon nanotubes. Tanetal.[85]combined antibacterial function with shape memory function to prepare an antibacterial shape memory fiber. Gu[86]compounded color-changing function with shape memory function to prepare a medical color-changing textile with shape memory function. Chen[87]developed a composite finishing agent that was both flame retardant, waterproof, and breathable, and then applied it to polyester fabrics to form flame retardant, waterproof, and breathable fabrics. People’s demand for textiles is gradually increasing. Because single-functional products cannot meet all of their needs, the transition from intelligent textiles to multi-functional composites has become an inevitable trend. As also mentioned in section 7.1, the compounding of materials not only leads to functional diversification but also allows several components to complement each other, creating synergies and thus improving performance. Therefore, the development of high-value-added textiles with multiple functions will be the future trend of smart textiles.

7.3 Safety, environmental friendliness and energy efficiency

As people become more environmentally and health-conscious, the ecological safety of textiles is becoming more and more critical. The residues of finishing agents used in the production of textiles are harmful to human skin and can cause cancer in severe cases when the residues on textiles reach a certain level. Therefore, Liuetal.[18]chose non-toxic chlorophenol red (CPR)-fatty acid particles dispersed in polymer films to form non-toxic thermochromic films. The choice of spinning solvent could also impact the ecological safety of textiles in the fiber methods. In response to the current situation where fluorine-free waterproof and breathable nanofiber membranes are usually prepared by toxic solvent-based electrostatic spinning, Zhouetal.[21]developed environmentally friendly fluorine-free nanofiber membranes with waterproof and breathable textile protection. In summary, the types of finishing agents and spinning solvents should be strictly screened and controlled during the production of smart textiles to ensure their safety of the textiles.

In addition, the current social situation of energy crisis and environmental pollution has led to energy-saving becoming a major requirement for the concept of green ecology. Muleetal.[88]have proposed polypyrrole (PPy)-based flexible and wearable triboelectric nanogenerators (TENGs), which effectively converted mechanical energy into electrical energy with good electrical output performance and robustness. Qiuetal.[89]developed smart textiles that could generate electricity from the mechanical movements of the human body, enabling sustainable powering of wearable electronics in a clean, safe, and efficient manner. Chenetal.[90]combined solar cells made of lightweight polymer fibers with fiber-based frictional electric nanogenerators to develop micro-cable power textiles that could simultaneously harvest the energy of sunlight and mechanical motion. As the concept of green safety continues to grow, smart textiles should also be developed towards greening in the future. It aims to achieve safety for the human body and friendliness to the natural environment and consider factors such as energy consumption and cost to promote the market of smart textiles.

8 Conclusions

Smart textiles have shown many possibilities in different fields and now show great potential in the consumer market. Initially, smart textiles were mainly used in military and aerospace applications. With the advancement of technology, more and more kinds of smart textiles are being used in the fields of health monitoring, sports and fashion. In response to the requirements of wearing comfort, smart textiles need to be safe, low cost, soft, breathable, comfortable and durable. Textile wearability improvement is an inevitable technical breakthrough point to achieve faster industrialization and marketization of smart textiles. The researchers have developed new production methods in order to achieve these properties.

At present, the preparation route of smart textiles can be widely divided into fiber and finishing methods. In summary, it seems that textiles made by fiber methods are breathable and have a good feeling, but durability is affected by the production equipment and the cost of the process is high. The finishing methods are less costly, simpler, and faster, but the fabric is thicker and less comfortable.

Taking the preparation method as the entry point, the methods for wearability improvement include the integration of the advantages of various methods, the application of new technologies, and the compounding of materials. Future smart textiles can show more kinds of functions and optimize their performance in breathability, softness, safety, and durability to better balance technological innovation, artistic design, and wearable comfort, bringing comfort and convenience to consumers.

Journal of Donghua University(English Edition)2022年4期

Journal of Donghua University(English Edition)2022年4期

- Journal of Donghua University(English Edition)的其它文章

- Computer-Based Estimation of Spine Loading during Self-Contained Breathing Apparatus Carriage

- Click-Through Rate Prediction Network Based on User Behavior Sequences and Feature Interactions

- Predictive Model of Live Shopping Interest Degree Based on Eye Movement Characteristics and Deep Factorization Machine

- Object Grasping Detection Based on Residual Convolutional Neural Network

- Time Delay Identification in Dynamical Systems Based on Interpretable Machine Learning

- Online Clothing Recommendation and Style Compatibility Learning Based on Joint Semantic Feature Fusion