Zr靶功率对(WMoTaNb)ZrxN薄膜微观组织及性能的影响

曹丽娜,邵文婷,陈建,王富强,武上焜,杨巍,要玉宏,刘江南

Zr靶功率对(WMoTaNb)ZrN薄膜微观组织及性能的影响

曹丽娜,邵文婷,陈建,王富强,武上焜,杨巍,要玉宏,刘江南

(西安工业大学 材料与化工学院,西安 710021)

提高(WMoTaNb)ZrN薄膜的硬度与弹性模量、膜基结合力、摩擦磨损及抗烧蚀性能。采用反应磁控溅射技术,通过对Zr靶功率的调控,在单晶Si和M2高速钢基体上制备不同Zr含量的(WMoTaNb)ZrN薄膜。采用FESEM对薄膜的表面及截面形貌进行观察,利用XRD对薄膜的物相组成进行分析,采用纳米压痕仪、划痕仪和摩擦磨损试验机分别对薄膜的硬度、膜基结合力及摩擦磨损性能进行表征,通过氧–乙炔烧蚀试验对薄膜的抗烧蚀性能进行测定。(WMoTaNb)ZrN薄膜主要由FCC和BCC固溶体结构组成,Zr元素引入后,薄膜FCC(200)晶面衍射峰消失,FCC(111)与(311)晶面衍射峰强度增强。随着Zr靶功率的增加,薄膜中Zr元素含量逐渐增加,薄膜的硬度与弹性模量先增大、后减小,膜基结合力呈现不规律变化,薄膜的抗烧蚀性能逐渐提升。薄膜的摩擦系数随着Zr靶功率的增加而增大,但维持在0.65~0.95。当Zr靶功率为40 W时,制备的薄膜硬度、弹性模量及膜基结合力均达到最大,分别为27.9 GPa、291.3 GPa、84 N,此时薄膜的磨痕深度最小为227 nm。Zr靶功率为40 W时制备的薄膜硬度、弹性模量、膜基结合力、摩擦磨损与抗烧蚀性能最佳。

反应磁控溅射;(WMoTaNb)ZrN薄膜;硬度;膜基结合力;摩擦学性能;抗烧蚀性能

随着高初速远程弹丸的投入使用,火炮身管的寿命问题已成为制约火炮发展的关键性因素[1-2]。因此,提高火炮身管服役寿命是火炮工程领域亟待解决的军事问题。提高火炮身管寿命的方法主要有:改变火药成分即在火药中加入缓蚀剂、改变弹带结构或对弹带表面进行改性处理、改变身管材料成分或身管内膛改性等[3-5]。目前,改善身管寿命最有效的方法是在身管内膛涂覆一层具有耐磨损、抗烧蚀性能的涂层。国内外广泛使用的身管减磨延寿涂层为电镀Cr涂层,但其存在热应力裂纹、附着力差、环境污染严重等顽疾[3,6-8]。因此,急需寻找能够满足身管服役环境的新涂层材料。

难熔高熵合金是高熵合金[9-11]的一种,由化学元素周期表ⅣB、ⅤB、ⅥB副族中3种及3种以上元素组成[12-14],具有高硬度、耐磨损及优异的高温稳定性。2010年,美国空军研究室Senkov等[15]通过电弧熔炼炉制备出W-Nb-Mo-Ta和W-Nb-Mo-Ta-V难熔高熵合金,发现其硬度优于任何单一元素。Hung等[16]采用磁控溅射法制备了V-Nb-Mo-Ta-W涂层,发现涂层中Cr、B元素的引入提高了薄膜的抗氧化和防腐蚀性能。Feng等[17]采用直流磁控溅射制备了CrTaNbMoVN薄膜,发现N=20%时,沉积的薄膜具有最高硬度(21.6 GPa),且耐磨性能优异。Kim等[18]利用直流磁控溅射法制备了NbMoTaW RHEA薄膜,发现其硬度高达12 GPa。虽然研究者们对WMoTaNb系难熔高熵合金薄膜进行了大量的试验研究,但Zr元素对难熔高熵合金薄膜微观组织和性能的影响规律尚不清楚。

依据二元合金相图[19-20],Zr与Ta、Nb完全互溶,与Mo、W不完全互溶,可在一定程度上促进薄膜的固溶强化,进而提高薄膜的硬度、摩擦磨损等性能。此外,Zr作为难熔金属元素,可在一定程度上提高薄膜的抗烧蚀性能。因此,本文以WMoTaNb靶和Zr靶为溅射源,采用反应磁控溅射技术,通过调控Zr靶功率在单晶Si和M2高速钢基体上制备出一系列(WMoTaNb)ZrN薄膜,研究Zr元素的引入及Zr靶功率对 (WMoTaNb)ZrN薄膜微观组织和性能的影响规律,为火炮身管减磨延寿涂层的制备提供理论依据和试验支撑。

1 试验

1.1 薄膜制备

试验采用VTC-600-2HD双靶磁控溅射仪,以Ar和N2为工作气体,以WMoTaNb靶和Zr靶为溅射源,靶材尺寸均为50 mm×3 mm。其中,WMoTaNb高熵合金靶连接射频电源,Zr靶(纯度≥99.9%)连接直流电源。以单晶Si片和M2高速钢为基体,Si片主要用于薄膜微观组织和硬度测试,高速钢基体用于薄膜摩擦磨损和烧蚀等性能测试。试验前对靶材进行溅射清洗1 h,清洗完毕后,用酒精清洗且烘干的单晶Si片和M2高速钢放入真空腔室中进行等离子体轰击清洗20 min,后调整沉积工艺参数进行溅射镀膜。具体沉积工艺参数见表1。

表1 (WMoTaNb)ZrN薄膜沉积工艺参数

Tab.1 (WMoTaNb)ZrxN film deposition process parameters

1.2 薄膜微观组织与性能表征

采用JSM-7000F型场发射扫描电子显微镜(FESEM)对薄膜表面及截面形貌进行观察,利用配套能谱仪(EDS)对薄膜中元素含量及元素分布进行表征。采用D2 PHASER型X射线衍射仪(XRD)分析薄膜的相组成,Cu Kα射线(波长为0.151 4 nm),扫描步长为0.09°,扫描角度为20°~100°。采用Agilent G20型纳米压痕仪对薄膜的硬度及弹性模量进行测定,每个试样测试6个点,取其平均值作为薄膜硬度与弹性模量值,最大压入深度约为薄膜厚度的1/10。采用WS-2005型划痕仪对薄膜的膜基结合力进行测试,试验载荷为150 N,加载速率为75 N/min。使用HT-1000型高温摩擦磨损实验机对薄膜的室温摩擦磨损性能进行测试,对磨球选用6 mm的GCr15轴承钢球,试验载荷为2 N,摩擦半径为2 mm,摩擦时间为20 min,圆盘转速为232 r/min。采用Zygo newview 8200型白光干涉仪对磨痕宽度及深度进行分析。利用氧–乙炔烧蚀试验对薄膜的抗烧蚀性能进行测定,单次烧蚀0.5 s,共烧蚀8次。利用VEGA3- SBH扫描电子显微镜(SEM)对烧蚀形貌进行观察。

2 结果与分析

2.1 微观组织与成分分析

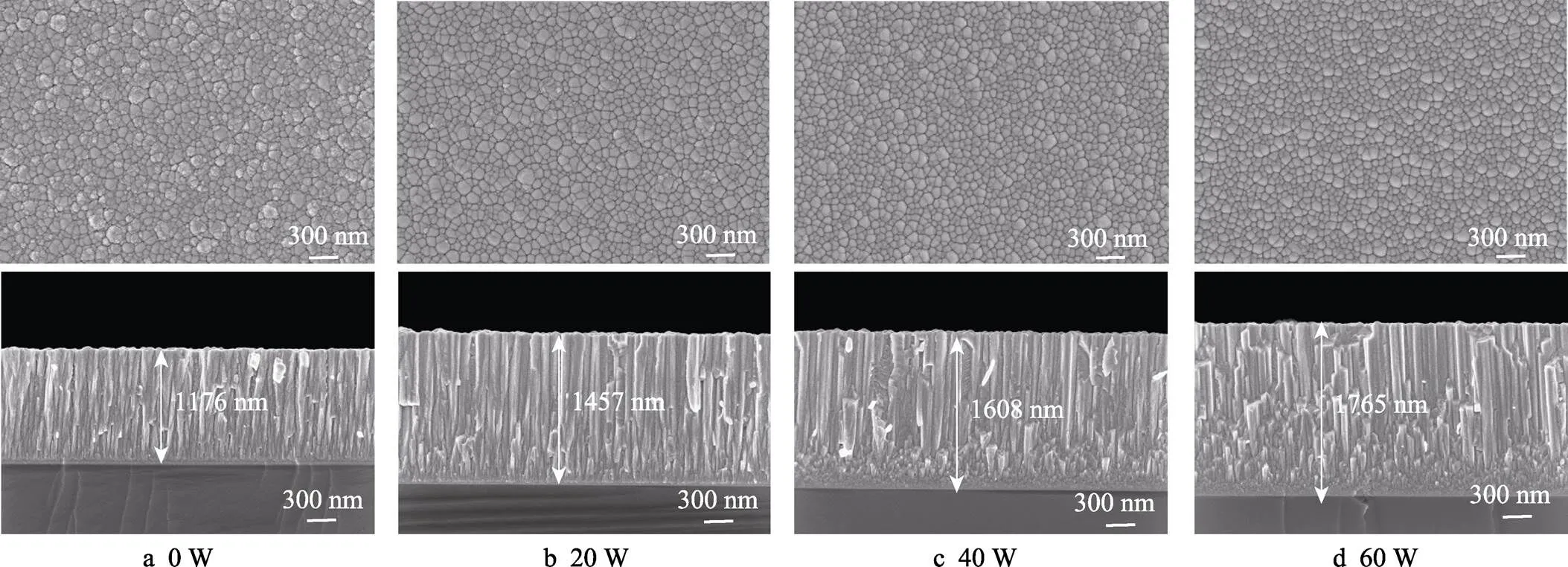

图1为不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜的表面及截面形貌。当Zr靶功率为0 W时,薄膜表面团簇颗粒呈“菜花”状,颗粒尺寸不一,从几纳米到几十纳米(见图1a)。随着Zr靶功率的增加,薄膜表面团簇颗粒变得光滑平整,团簇颗粒尺寸减小(见图1b—d),说明Zr靶功率的增加有利于细化晶粒。由截面形貌可以看出,薄膜以层岛结合方式生长[21-22],这是生长初期薄膜与基体晶格常数不匹配及内应力随着沉积时间增加而增大共同作用所致。膜基晶格常数不同使薄膜在生长初期以层状方式进行沉积,随着沉积时间的持续增长,薄膜沉积到一定厚度时,会产生内应力过大现象。此时,薄膜转变为岛状生长,以减小这部分应变能[23]。因此,薄膜的截面形貌表现为近基体部分为致密层,远基体部分为柱状结构。当Zr靶功率增加至40 W时,薄膜柱状结构底部呈现“三角锥”形态,薄膜更加致密[24-25]。随着Zr靶功率的增加,薄膜厚度逐渐增加,这是由于Zr靶功率的增大提高了Zr粒子的溅射能量与溅射速率,进而增加了薄膜的沉积速率。

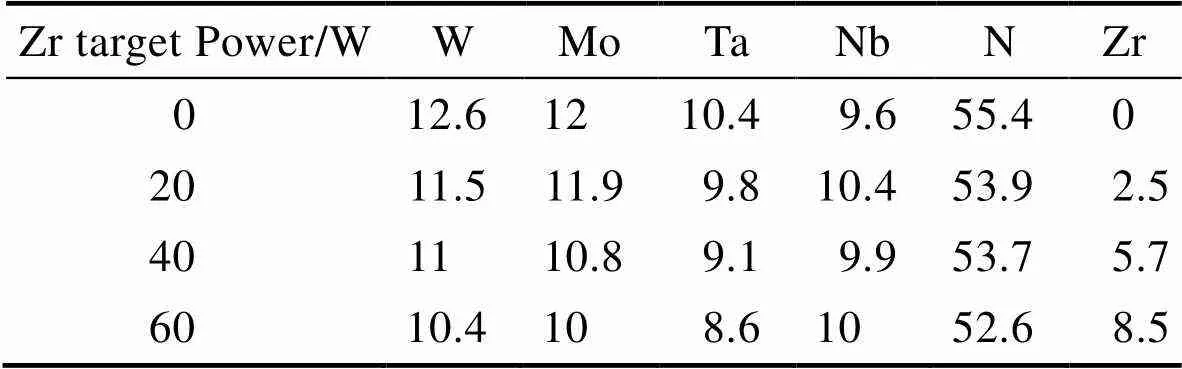

不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜中各元素含量见表2。由表2可知,薄膜中N元素的含量最高。这是因为N为反应元素,在靶材粒子溅射沉积过程中,与W、Mo、Ta、Nb元素反应,生成固溶体,因而以较高含量存在薄膜中。随着Zr靶功率的增大,薄膜中Zr元素含量逐渐增加,W、Mo、Ta、N元素含量相对降低。这是因为EDS表征的是元素的相对含量,一种元素含量的增多必然伴随着其他元素含量的减少。此外,高能量Zr粒子在腔体中的碰撞过程也会影响其他粒子的沉积。当Zr靶功率为60 W时,薄膜中的Zr元素含量最高,为8.5%(原子分数),且与厚度相一致。随Zr靶功率的增大,Nb元素含量总体为增加趋势,但呈不规律变化。

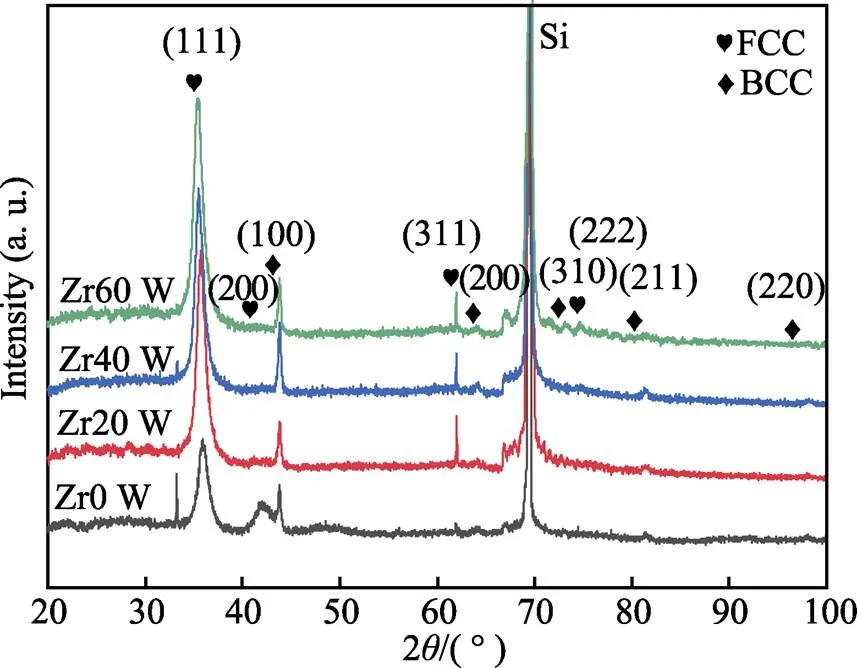

图2为不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜的XRD图谱。由图2可知,薄膜主要由FCC和BCC固溶体结构组成,且所有试样均在2为66.9°~ 71°范围内出现了Si基体的衍射峰,这是由于X射线扫到Si基体所致。Zr元素的引入使FCC(200)晶面的衍射峰消失,BCC(111)及FCC(311)晶面的衍射峰强度呈现先增加、后减小的变化趋势,这是由于Zr元素的引入使其产生晶格畸变所致。当Zr靶功率为40 W时,BCC相的衍射峰强度最大,而FCC相的衍射峰相对较弱,说明Zr元素引入产生的晶格畸变可改变薄膜的生长取向。

图1 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜的表面及截面形貌

表2 不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜中各元素含量

Tab.2 Elements content of (WMoTaNb)ZrxN films prepared at different Zr target power at.%

图2 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜XRD图谱

2.2 力学性能分析

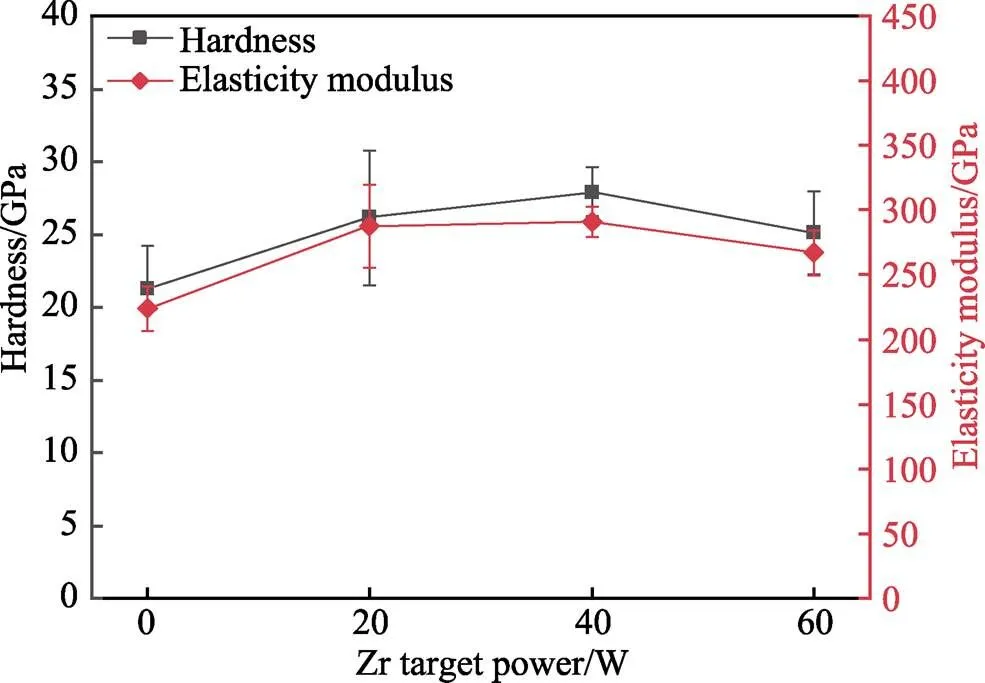

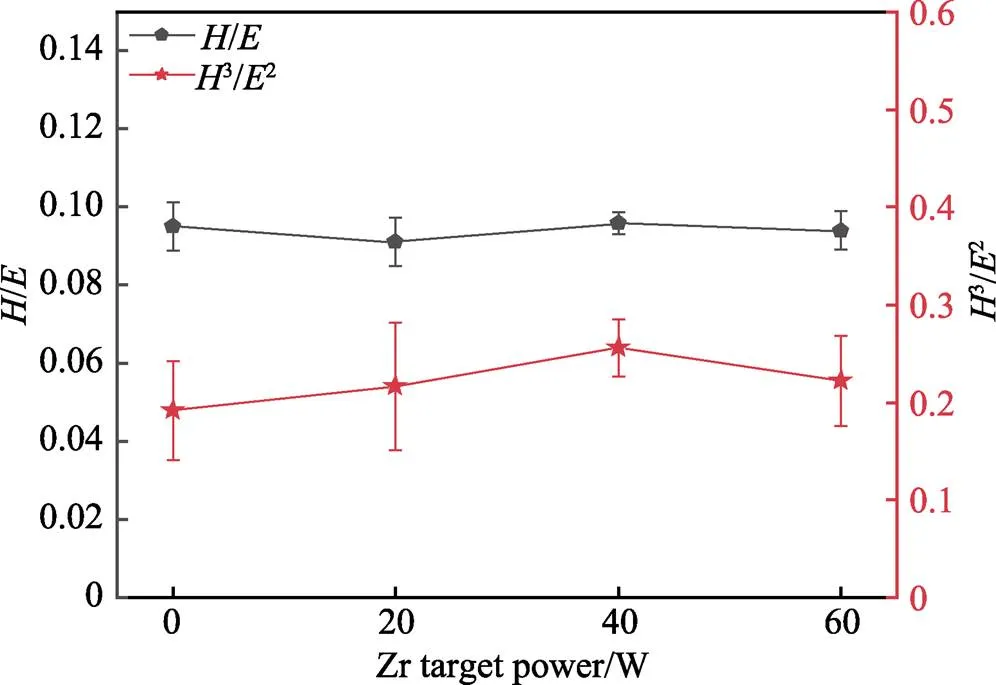

不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜的硬度及弹性模量如图3所示。由图3可知,随着Zr靶功率的增加,薄膜硬度及弹性模量均呈先增大、后减小的变化趋势。当Zr靶功率为40 W时,制备的薄膜硬度及弹性模量最大,分别为27.9、291.3 GPa,较无Zr掺杂时分别提高了6.6、67.3 GPa,说明适量Zr元素的引入有利于提高薄膜的硬度及弹性模量。这是由于Zr元素的引入使得薄膜生长取向发生改变,薄膜中BCC相衍射峰强度的增加,以及FCC相衍射峰强度的降低均有利于提高薄膜硬度。此外,薄膜表面团簇颗粒尺寸减小、致密度增加,使得薄膜中团簇界面增多,起到了界面强化的作用。因此,可以通过调整靶材功率对薄膜的形貌及结构进行调控,进而获得目标硬度的薄膜材料。对薄膜硬度及弹性模量比值的计算结果如图4所示。/、3/2与硬度变化规律均具有较好的一致性,当Zr靶功率为40 W时,/、3/2最大。

不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜的膜基结合力如图5所示。由图5可知,薄膜膜基结合力随Zr靶功率的增大呈不规律变化,但均大于60 N,优于传统硬质薄膜与电镀Cr层。当Zr靶功率为0 W时,薄膜膜基结合力为76 N;增加Zr靶功率至20 W,薄膜膜基结合力减小至71 N。这是由于Zr元素的引入增加了W、Mo、Ta、Nb等靶材原子的碰撞几率,使其到达基体表面成膜时粒子能量较低,与基体的吸附作用减弱所致。增大Zr靶功率至40 W,Zr原子的溅射能量增加量远远高于碰撞过程中的能量消耗,故粒子与基体的吸附作用增强,使得薄膜的膜基结合力增加至83.5 N。继续增大Zr靶功率至60 W,Zr原子粒子能量过高对薄膜生长表面带来的冲击,使得薄膜表面晶格产生畸变而使应力增加,此时本征应力导致薄膜膜基结合力下降。

图3 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜的硬度及弹性模量

图4 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜的H/E、H3/E2

图5 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜膜基结合力

2.3 摩擦学性能分析

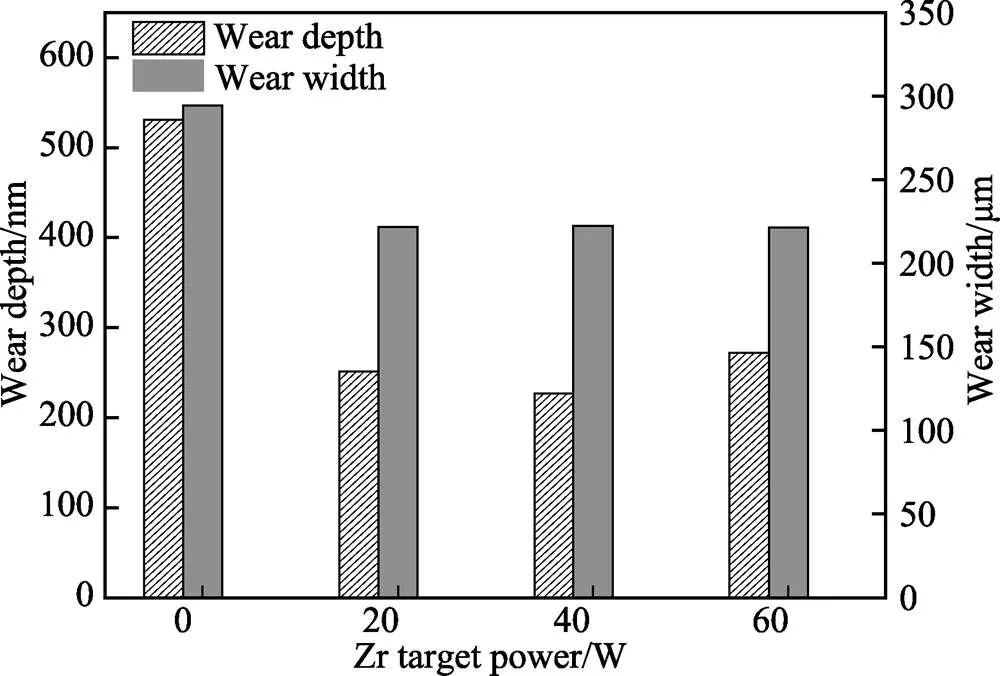

不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜的摩擦因数曲线如图6所示。由图6可知,磨损前期,薄膜摩擦因数曲线波动较大。这是因为磨损前期薄膜表面颗粒大小不一,粗糙度较大。随着磨损时间的增加,表面大颗粒被磨掉,摩擦曲线波动相对平稳。随着Zr靶功率的增大,薄膜的摩擦因数逐渐增大,但摩擦因数曲线变得相对平滑,磨痕宽度及深度减小(如图7所示)。这是由于Zr元素的引入能够细化晶粒,使薄膜表面团簇颗粒减小,粗糙度减小,进而使得薄膜摩擦因数曲线变得相对平滑。同时,硬度的提高可使薄膜的耐磨性得到提升,进而促使薄膜磨痕宽度和深度减小。当Zr靶功率由20 W增加至60 W,薄膜的磨痕宽度基本不变,但磨痕深度呈先减小、后增大的变化规律,与薄膜硬度呈负相关。当Zr靶功率为40 W时,制备的薄膜磨痕深度最小,说明此时薄膜的摩擦磨损性能最好,与/、3/2一致[26]。

图6 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜的摩擦系数曲线

图7 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜磨痕宽度及深度

2.4 抗烧蚀性能分析

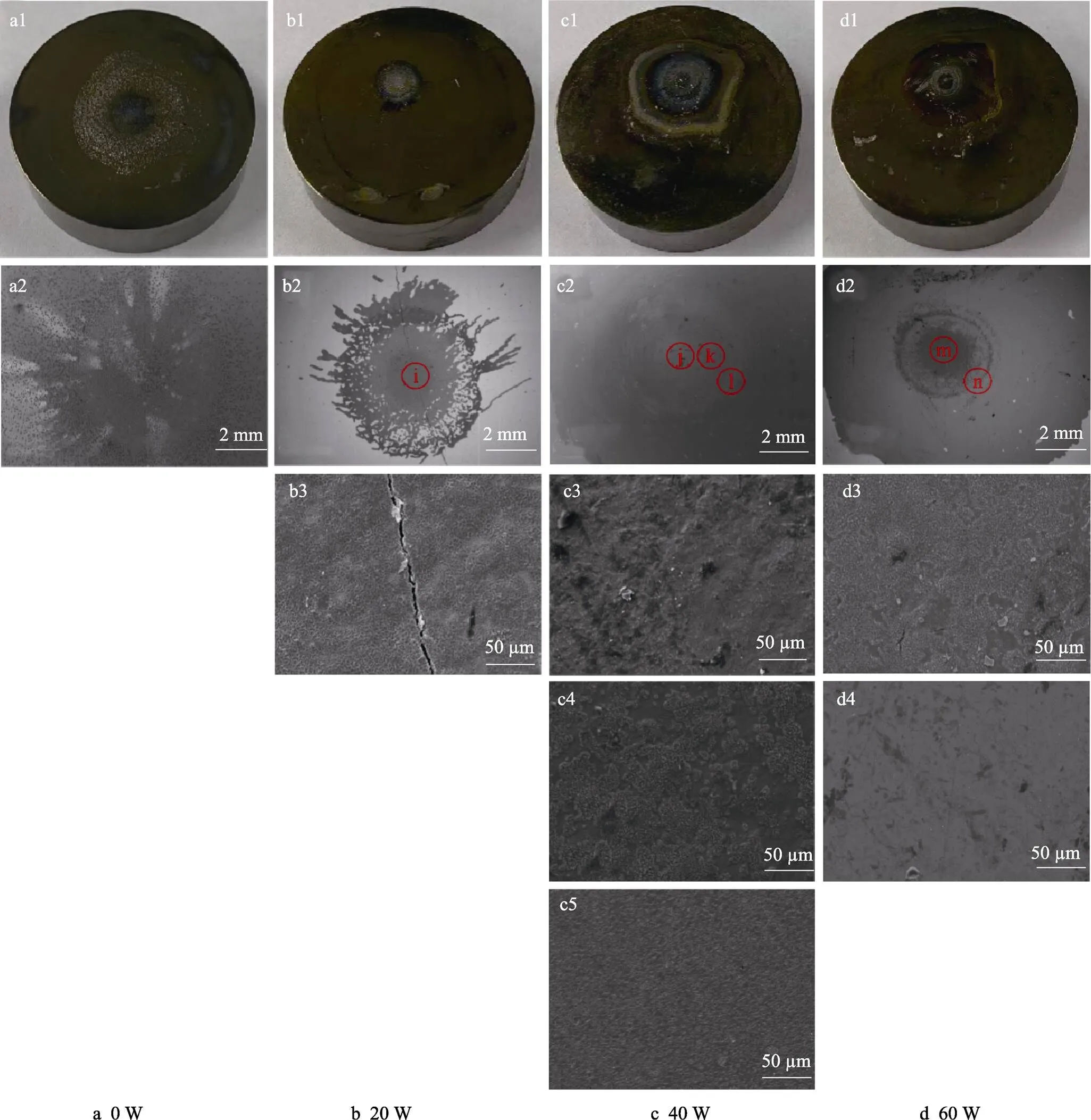

不同Zr靶功率下制备的(WMoTaNb)ZrN薄膜在氧–乙炔环境中烧蚀8次后的宏观及SEM形貌如图8所示。由图8a1—d1可知,样品烧蚀中心区域的烧蚀现象最为严重。随着Zr靶功率增加,制备的薄膜烧蚀面积及向外扩散的方式出现差异(见图8a2—d2)。无Zr元素掺杂时,薄膜烧蚀区域呈点蚀状,烧蚀区域周围薄膜开裂并剥落(见图8a1、a2)。当Zr靶功率为20 W时,制备的薄膜烧蚀区域最小、无脱落现象,但有裂纹贯穿烧蚀区域(见图8b3),这是因为薄膜烧蚀前后在高温与室温的多次冷热循环条件下产生的过大应力导致的。此外,氧–乙炔烧蚀过程中会产生C元素,C元素在高温作用下会通过薄膜表面的微裂纹进入薄膜深处,然后与高速钢基体反应,产生渗碳体,渗碳体的存在会使基底及膜层材料脆化,进而容易形成裂纹[3]。Zr靶功率为40 W时,制备的薄膜经氧–乙炔烧蚀后,烧蚀中心出现杂质(见图8c3),烧蚀中心外围由于受热不均匀,出现烧蚀颗粒(见图8c4)和冷凝液体(见图8c5)2种形态,烧蚀边缘熔融态液体以一定方向进行冷却(见图8c5)。Zr靶功率为60 W时,制备的(WMoTaNb)ZrN薄膜烧蚀区域明显缩小(见图8d1),烧蚀中心出现了烧蚀颗粒及微裂纹(见图8d3),烧蚀边缘薄膜未出现明显变化(见图8d4),薄膜抗烧蚀性能较好。Zr元素的引入能够提高薄膜的抗烧蚀性能,(WMoTaNb)ZrN薄膜的抗烧蚀性能随着Zr靶功率的增大而提升。当Zr靶功率为40 W即薄膜中的Zr元素的原子分数为5.7%时,薄膜的抗烧蚀性能最为优异。

图8 不同Zr靶功率下制备的(WMoTaNb)ZrxN薄膜烧蚀宏观及SEM形貌

Fig.8AblationmacroandSEMprofile of the (WMoTaNb)ZrNfilms preparedatdifferentZrtargetpower

3 结论

本文采用反应磁控溅射方法在单晶Si和M2高速钢基体上制备了(WMoTaNb)ZrN薄膜,研究了Zr靶溅射功率对(WMoTaNb)ZrN薄膜微观组织和性能的影响规律,得出以下结论:

1)Zr元素的引入能够细化薄膜表面的团簇颗粒,促使薄膜致密化。

2)(WMoTaNb)ZrN薄膜主要由FCC和BCC固溶体结构组成,Zr元素的引入能够改变薄膜的生长取向。

3)当Zr靶功率为40 W时,薄膜硬度、弹性模量及膜基结合力均达到最大,分别为27.9、291.3 GPa和84 N。

4)Zr元素的引入可有效提高薄膜的抗烧蚀性能。

[1] 胡士廉, 吕彦, 胡俊, 等. 高强韧厚壁炮钢材料的发展[J]. 兵器材料科学与工程, 2018, 41(6): 108-112.

HU Shi-lian, LÜ Yan, HU Jun, et al. Progress in High Strength and Toughness of Steel Material for Thick-Wall Cannon[J]. Ordnance Material Science and Engineering, 2018, 41(6): 108-112.

[2] 吕彦, 胡俊, 任泽宁, 等. 大口径厚壁火炮身管用钢的性能与发展[J]. 兵器材料科学与工程, 2013, 36(2): 142-146.

LV Yan, HU Jun, REN Ze-ning, et al. Progress in Steel Used for Large-Calibre Thick-Wall Gun Barrel[J]. Ordnance Material Science and Engineering, 2013, 36(2): 142-146.

[3] 胡明. 不同制备方法的火炮身管材料Cr涂层性能研究[D]. 太原: 中北大学, 2019.

HU Ming. Research on the Properties of Cr Coatings Prepared by Three Methods on the Surface of Gun Barrel Material[D]. Taiyuan: North University of China, 2019.

[4] 邹志强, 吴斌. 弹带喷涂技术[J]. 四川兵工学报, 2013, 34(12): 116-118.

ZOU Zhi-qiang, WU Bin. Technology of Sprayed Rotating Band[J]. Journal of Sichuan Ordnance, 2013, 34(12): 116-118.

[5] 郭策安, 周峰, 胡明, 等. CrNi3MoVA钢表面磁控溅射Ta涂层的摩擦磨损性能[J]. 材料导报, 2018, 32(18): 3213-3216.

GUO Ce-an, ZHOU Feng, HU Ming, et al. Performance of Friction and Wear of Magnetron Sputtered Ta Coating on CrNi3MoVA Steel[J]. Materials Review, 2018, 32(18): 3213-3216.

[6] 张健, 郭策安, 卢旭东, 等. 炮钢表面电弧离子镀NiCoCrAlYSi涂层的高温氧化行为[J]. 材料热处理学报, 2015, 36(6): 197-201.

ZHANG Jian, GUO Ce-an, LU Xu-dong, et al. High Temperature Oxidation Behavior of Arc Ion Plated NiCoCrAlYSi Coating on Gun Steel[J]. Transactions of Materials and Heat Treatment, 2015, 36(6): 197-201.

[7] 郭策安, 张健, 尚光明, 等. 炮钢表面电火花沉积Cr涂层的性能研究[J]. 沈阳理工大学学报, 2013, 32(2): 76-80.

GUO Ce-an, ZHANG Jian, SHANG Guang-ming, et al. Performance of Electrospark Deposited Cr Coating on Gun Steel[J]. Journal of Shenyang Ligong University, 2013, 32(2): 76-80.

[8] 陈志诚, 周洁, 何雪芹. 电镀项目环境影响评价工程分析技术要点[J]. 环境与发展, 2020, 32(8): 40-41.

CHEN Zhi-cheng, ZHOU Jie, HE Xue-qin. Technical Points of Environmental Impact Assessment of Electroplating Project[J]. Environment and Development, 2020, 32(8): 40-41.

[9] YEH J W, CHEN S K, LIN S J, et al. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303.

[10] HUANG Ping-kang, YEH J W. Effects of Nitrogen Content on Structure and Mechanical Properties of Multi-Element (AlCrNbSiTiV)N Coating[J]. Surface and Coatings Technology, 2009, 203(13): 1891-1896.

[11] 赵腾雄, 康蓉, 李培友. 高熵合金薄膜涂层研究进展[J]. 铸造技术, 2017, 38(4): 746-748.

ZHAO Teng-xiong, KANG Rong, LI Pei-you. Research Progress of High Entropy Alloy in Thin Film Coating[J]. Foundry Technology, 2017, 38(4): 746-748.

[12] 刘张全, 乔珺威. 难熔高熵合金的研究进展[J]. 中国材料进展, 2019, 38(8): 768-774.

LIU Zhang-quan, QIAO Jun-wei. Research Progress of Refractory High-Entropy Alloys[J]. Materials China, 2019, 38(8): 768-774.

[13] 张晗, 艾云龙, 陈卫华, 等. 难熔高熵合金研究进展[J]. 功能材料, 2021, 52(4): 4062-4070.

ZHANG Han, AI Yun-long, CHEN Wei-hua, et al. Research Progress of Refractory High-Entropy Alloys[J]. Journal of Functional Materials, 2021, 52(4): 4062-4070.

[14] FENG Bo-jun, WIDOM M. Elastic Stability and Lattice Distortion of Refractory High Entropy Alloys[J]. Materials Chemistry and Physics, 2018, 210: 309-314.

[15] SENKOV O N, WILKS G B, MIRACLE D B, et al. Refractory High-Entropy Alloys[J]. Intermetallics, 2010, 18(9): 1758-1765.

[16] HUNG S B, WANG C J, CHEN Yen-yu, et al. Thermal and Corrosion Properties of V-Nb-Mo-Ta-W and V-Nb- Mo-Ta-W-Cr-B High Entropy Alloy Coatings[J]. Surface and Coatings Technology, 2019, 375: 802-809.

[17] FENG Xing-guo, ZHANG Kai-feng, ZHENG Yu-gang, et al. Chemical State, Structure and Mechanical Properties of Multi-Element (CrTaNbMoV)NFilms by Reactive Magnetron Sputtering[J]. Materials Chemistry and Physics, 2020, 239: 121991.

[18] KIM H, NAM S, ROH A, et al. Mechanical and Electrical Properties of NbMoTaW Refractory High-Entropy Alloy Thin Films[J]. International Journal of Refractory Metals and Hard Materials, 2019, 80: 286-291.

[19] 徐丽丽, 徐勇, 许荣福, 等. 基于Ti-Nb-Zr三元系合金的相图优化[J]. 山东科学, 2021, 34(1): 35-42.

XU Li-li, XU Yong, XU Rong-fu, et al. Optimization of Phase Diagram Based on Ti-Nb-Zr Ternary System Alloy[J]. Shandong Science, 2021, 34(1): 35-42.

[20] ZHOU Peng, PENG Ying-biao, DU Yong, et al. Thermodynamic Modeling of the C-W-Zr System[J]. International Journal of Refractory Metals and Hard Materials, 2015, 50: 274-281.

[21] 徐滨士, 朱绍华. 表面工程的理论与技术[M]. 北京: 国防工业出版社, 1999.

XU Bin-shi, ZHU Shao-hua. Theories and Technologies on Surface Engineering[M]. Beijing: National Defense Industry Press, 1999.

[22] 吴自勤, 王兵. 薄膜生长[M]. 北京: 科学出版社, 2001.

WU Zi-qin, WANG Bing. Film Growth[M]. Beijing: Science Press, 2001.

[23] 方英翠, 沈杰, 解志强. 真空镀膜原理与技术[M]. 北京: 科学出版社, 2013.

FANG Ying-cui, SHEN Jie, XIE Zhi-qiang. Vacuum Coating Principles and Techniques[M]. Bbeijing: Science Press, 2013.

[24] 晁云峰. 磁控溅射沉积系统设计及SiC-A1薄膜的摩擦特性研究[D]. 郑州: 郑州大学, 2015.

CHAO Yun-feng. Design on Deposition System and Tribological Properties Ofrf Magnetron Sputtered SiC-Al Coatings[D]. Zhengzhou: Zhengzhou University, 2015.

[25] 姚寿山, 李戈扬, 胡文彬. 表面科学与技术[M]. 北京: 机械工业出版社, 2005.

YAO Shou-shan, LI Ge-yang, HU Wen-bin. Surface Science and Technology[M]. Beijing: China Machine Press, 2005.

[26] LEYLAND A, MATTHEWS A. On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour[J]. Wear, 2000, 246(1-2): 1-11.

Effect of Zr Target Power on Microstructure and Performance of (WMoTaNb) ZrN Films

,,,,,,

(School of Materials Science and Chemical Engineering, Xi'an Technological University, Xi'an 710021, China)

As a physical vapor deposition method, magnetron sputtering technology can improve the surface performance of matrix without changing the substrate material. Besides, the deposition rate of the magnetron sputtering becomes faster and the film prepared by magnetron sputtering is uniformly dense and has high adhesion force. In this paper, reaction magnetron sputtering technology were used to prepare a series of (WMoTaNb)ZrN films by changing Zr target power and this paper aimed to study the effect of Zr target power on the microstructure and performance of (WMoTaNb)ZrN films.

The WMoTaNb alloy and Zr metal target were used to prepare film that the sizes were both Φ50 mm×3 mm, and the single crystal Si slice and M2 high-speed steel were used as substrate materials. The target power of WMoTaNb was 200 W, and the target power of Zr were 0 W, 20 W, 40 W, 60 W, respectively. The substrate bias and temperature were –200 V and 300 ℃ respectively. The deposition time of film was 180 min and the flow ratio of argon to nitrogen was 6:2. In this study, the surface and cross-section morphology of films were observed by FESEM and the content and distribution of elements in the films were characterized by the matching energy spectrometer. The phase composition of (WMoTaNb)ZrN films were analyzed by XRD. The nanometer indentation, scratch trainer and friction wear tester were used to characterize the hardness, film-substrate adhesion and friction wear properties of the films, respectively. The white light interferometer was used to detect the width and depth of grinding to value the wear resistance performance further. The ablation resistance of the films was determined by oxygen-acetylene ablation test and the ablation morphology were observed by SEM.

A series of (WMoTaNb)ZrN films were prepared successfully by adjusting Zr target power. And it was found that the (WMoTaNb)ZrN films were mainly composed of FCC and BCC solid solvent structures and the diffraction peak of the FCC(200) crystal plane of the thin film disappears, and the intensities of the diffraction peak of the FCC (111) and (311) crystal planes increases after the introduction of Zr elements. With the increase of Zr target power, the content of Zr elements in the film increased gradually. When the Zr target power was increased to 60 W, the Zr element content in the film was increased to 8.5%. The hardness and elastic modulus of (WMoTaNb)ZrN films increased firstly and then decreased with the increase of Zr target power, but the film-substrate cohesion of (WMoTaNb)ZrN films changed irregularlyand the ablation resistance of the film gradually improved. Both the ablation resistance performance and friction coefficient were sustainably improved with the increase of Zr target power, but the friction coefficient was still maintained between 0.65 and 0.95, which were normal for nitride films. When the Zr target power was 40W, the hardness, elastic modulus and film-substrate cohesion of the prepared film reached the maximum, which were 27.9 GPa, 291.3 GPa, and 84 N, respectively. At this time, the minimum wear scar depth of the film was 227 nm.

In a word, the film has the best hardness, elasticity modulus, binding force, frictional wear and ablation resistance when the Zr target power was 40 W.

reaction magnetron sputtering; (WMoTaNb)ZrN films; hardness; film-substrate adhesion; tribology performance; ablation resistance performance

2021-10-28;

2022-03-21

CAO Li-na (1996-), Female, Postgraduate, Research focus: surface modification of metal material and coating

邵文婷(1988—),女,博士,副教授,主要研究方向为金属表面改性及涂层。

SHAO Wen-ting (1988-), Female, Doctor, Associate professor, Research focus: surface modification of metal material and coating.

曹丽娜, 邵文婷, 陈建, 等. Zr靶功率对(WMoTaNb)ZrN薄膜微观组织及性能的影响[J]. 表面技术, 2022, 51(9): 160-167.

TG174

A

1001-3660(2022)09-0160-08

10.16490/j.cnki.issn.1001-3660.2022.09.000

2021–10–28;

2022–03–21

曹丽娜(1996—),女,硕士研究生,主要研究方向为金属表面改性及涂层。

CAO Li-na, SHAO Wen-ting, CHEN Jian, et al. Effect of Zr Target Power on Microstructure and Performance of (WMoTaNb)ZrN Films[J]. Surface Technology, 2022, 51(9): 160-167.

责任编辑:刘世忠