High sensitivity dual core photonic crystal fiber sensor for simultaneous detection of two samples

Pibin Bing(邴丕彬) Guifang Wu(武桂芳) Qing Liu(刘庆) Zhongyang Li(李忠洋)Lian Tan(谭联) Hongtao Zhang(张红涛) and Jianquan Yao(姚建铨)

1College of Electric Power,North China University of Water Resources and Electric Power,Zhengzhou 450045,China

2College of Precision Instrument and Opto-Electronics Engineering,Institute of Laser and Opto-Electronics,Tianjin University,Tianjin 300072,China

Keywords: photonic crystal fiber,surface plasma resonance,sensor

1. Introduction

Optical fiber sensors have attracted widespread attention because of their small size, strong anti-electromagnetic interference ability,high sensitivity,and suitability for harsh environments. In modern times, surface plasma resonance (SPR)technology has the peculiarities of analytical biosensors because it provides label-free and real-time monitoring.[1–3]The PCF based on SPR technology is a crucial platform for designing biosensors because of its attractive characteristics such as flexible and controllable dispersion,high sensitivity,and high birefringence effect. With the rapid development of sensors,the designs of biosensors based on SPR-PCF technology have received extensive attention from professionals in the fields of environmental testing,water quality detection,medical testing and so on.[4–6]For instance,a D-type SPR-PCF sensor with a maximal sensitivity of 46000 nm/RIU was reported by Rifatet al.in 2017.[7]Kuar and Singh proposed a PCF biosensor based on TiN metal coating. TiN has the advantages of chemical stability and high conductivity, so it can be used as plasmamaterial. The high wavelength sensitivity of 10000 nm/RIU has been achieved in the refractive index range of 1.385–1.40.[8]Moreover,a variety of multi-core optical fiber sensors including dual-core sensors are also proposed.[9–13]For example,Paul reported a dual-core sensor that can achieve a sensitivity of up to 9000 nm/RIU.[14]With the rapid development of clinical diagnosis,drug screening and environmental monitoring,the traditional single parameter SPR sensor cannot satisfy the demands of multi-parameter detection applications. Furthermore,multi-channel and high-throughput sensors have attracted extensive attention of researchers. In the past decade,multi-channel SPR sensors have been a research hotspot in the sensing field.[15,16]In 2016,Azzam presented a multi-channel PCF sensor with sensitivity up to 2400 nm/RIU which has four microfluid channels with gold coating and analyzed four different propagating modes.[17]Yasli reported a multi-channel detection sensor, a metal-coated medium composed of silver and gold, which can obtain sensitivities of 3083 nm/RIU and 2500 nm/RIU in 2020.[18]In the same year,a dual-sample synchronous detection PCF sensor was proposed by Binget al.,with dual-channel wavelength sensitivity of 11600 nm/RIU and 10600 nm/RIU,respectively, and the refractive index detection range is 1.33–1.40.[19]The dual channel PCF sensor can detect a single sample or two samples synchronously.Compared with the single channel PCF sensor, it reduces the steps of emptying, filling and multiple cleaning of the samples. In practical application,the dual channel PCF sensor can also detect two different parameters of the same sample by covering different sensing media in different channels.For example,the temperature and pH of the sample can be measured simultaneously. A thermo optic material can be coated on the metal film surface of channel A for temperature detection. A layer of pH sol gel is deposited on the metal film surface of channel B to detect the change of pH.[15,20]In short,the dual channel PCF sensor can detect two samples or two parameters at the same time. This paper mainly studies the performance of the sensor when two samples are detected synchronously.Dual-channel PCF sensors are expected to be developed in the fields of medical detection,organic chemical sensing and bioengineering detection.

This article proposes a dual-core D-channel PCF sensor that can detect two samples simultaneously,which effectively solves the problems of coating difficulty and low wavelength sensitivity. Through spectral sensitivity analysis, the maximum sensitivity of the dual-channel sensor is 21300 nm/RIU,which achieves the highest sensitivity of the dual-sample synchronous detection sensor.

2. Theory and method

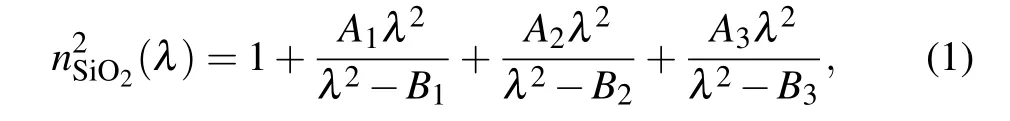

The structure of the high-sensitivity dual-core PCF sensor is presented in Fig.1. The outermost layer increases a circular perfect matching layer(PML)with a thickness of 3µm to absorb radiation power. Four layers of small air holes are arranged radially from the inside to the outside of the center of the substrate, with the first layer of small air holes closest to the center of the substrate and arranged in an outward order.To form the two cores C1and C2, the two small air holes in the third layer of air holes are omitted. The D-shaped air hole channel A is provided above the central air hole of the optical fiber, and a D-shaped air hole channel B is arranged below.A gold nanolayer of equal thickness is deposited on the plane of channel A and channel B.The diameter of all the small air holes of the optical fiber isd1=0.4Λand the spacing between adjacent small air holes isΛ=2µm. The simultaneous measurement of the refractive indexes of both samples is achieved by filling channels A and B with two samples with refractive indexes ofNAandNB, respectively. The diameters of channels A and B aredD=5.29Λ. The distance between the Dshaped channel and the central air hole isH=6.2µm.Gold is selected as plasma-material because it has good stability and strong chemical inertness.Gold nanolayers with a thickness oftg=40 nm are plated on the polished planes of both the A and B channels. SiO2is chosen as the background material, and when the wavelength changes,the specific refractive index of the SiO2can be obtained by the Sellmeier equation[21]

whereλis the wavelength of the incident light,A1,A2,andA3are respectively equal to 0.6961663, 0.4079426, 0.8974794,B1,B2, andB3are respectively equal to 4.67914826×10−3µm2, 1.35120631×10−2µm2, 97.9340025 µm2, and the more accurate value of the dielectric constant of gold can be expressed by the Drude model.[22]

Fig.1. Optical fiber structure diagram.

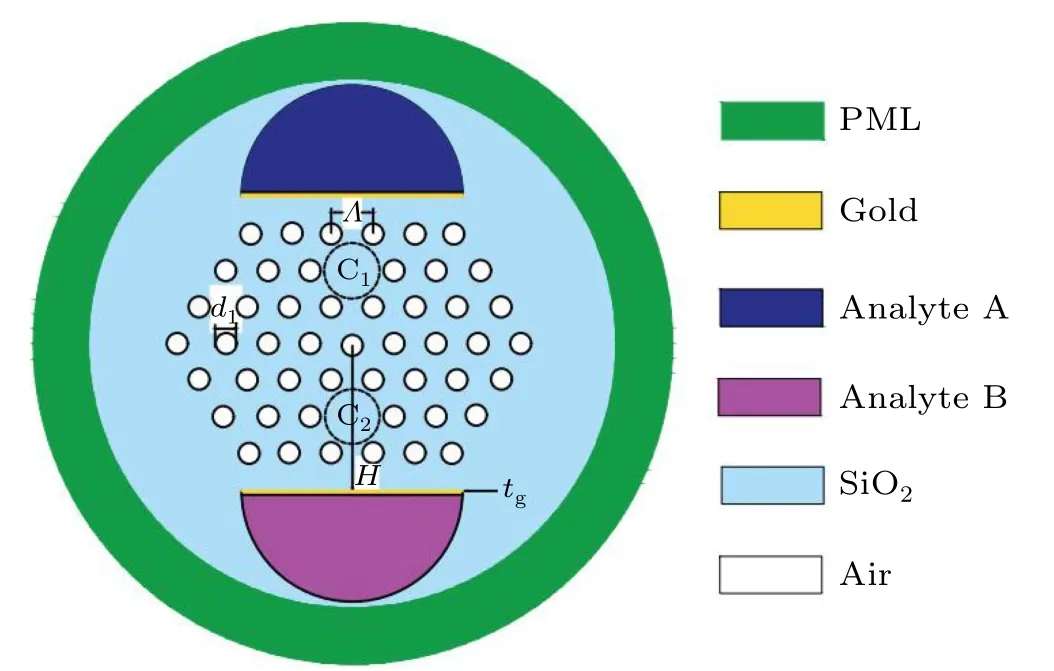

Fig. 2. (a) The loss spectra of core mode and SPP mode at different wavelengths. (b)The four electric field distribution maps correspond to points A,B,C,and D,respectively.

Theoretically,to achieve the phase matching between the SPP mode and the core mode, the real part of the refractive indexes (Re(neff)) of the two modes must be equal. Figure 2 describes Re(neff) and loss spectrum of the two modes whenNA=1.33,NB=1.40,andNA=1.33,NB=1.41,and the electric field distribution at points A, B, C, and D. Point A in Fig. 2(a) indicates that whenNA= 1.33,NB= 1.40,λ=750 nm,the value of Re(neff)in SPP mode is greater than the value of Re(neff) in core mode, and the fiber core energy is continuously transferred to the metal nanolayer,and the loss slowly increases.Whenλ=822 nm,the loss reaches the maximum,that is point B in Fig.2(a),and the Re(neff)value of the SPP mode and the Re(neff) value of the core mode will be equal, and a phase match occurs between them. Most of the fiber core energy is absorbed by the gold nanolayer. When the incident wavelength continuously increases, Re(neff) in SPP mode is smaller than Re(neff)in core mode. At this time,the SPR effect continues to weaken,and energy begins to transfer from the gold nanolayer to the core, resulting in the SPR effect,and the loss continues to decrease. From the electric field distribution diagram of point D in Fig.2(b), point D is also a phase-matching point, and the entire optical field is enclosed in the core. Besides, plasma can be observed on the metal coating of polished plane of the D-channel.

3. Results and discussion

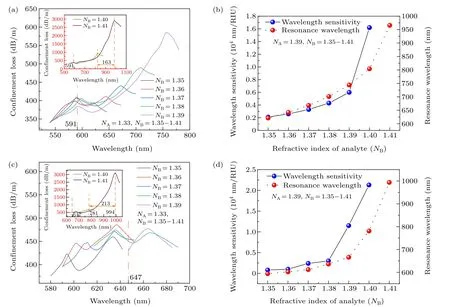

The amplitude detection method adopts light incident at a single wavelength, and samples with different refractive indexes have various losses at this wavelength. The corresponding samples can be detected by measuring the transmitted light power of the sensor. The confinement loss is able to be accurately calculated by the following formula:[23]

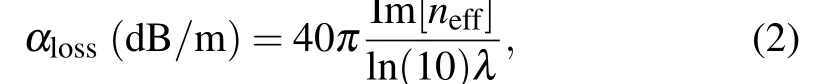

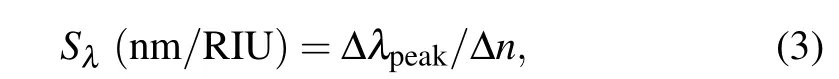

where the refractive index is expressed inneff, andλis the wavelength of incident light.[24]When samples with refractive indexes ofNAandNBare respectively filled into channel A and channel B,the SPR effect will occur on the gold nanolayer in channels A and B.Therefore,both resonance peaks appear on the spectrum by the simulation experiments. As can be seen from Fig. 3(a), the refractive indexNA=1.33 of sample in channel A remains unchanged,and the resonance wavelength always remains around 591 nm when the loss curve of channel A reaches its peak. Therefore, the wavelength sensitivity of sample B at different refractive indexes can be obtained according to the offset of the resonant peak of channel B.

Similarly,the refractive indexNAof the sample in channel A is 1.39,and the refractive indexNBvaries within the range of 1.35–1.41.The peak value of the loss curve in channel A always varies around 647 nm. As the difference value betweenNAandNBincreases, the resonance wavelength spacing between A and B also increases, and the ability to distinguish the two samples is enhanced. Therefore, the channels A and B can detect the refractive index simultaneously, and the two channels are independent of each other.

Fig. 3. (a) When NA =1.33, NB =1.35–1.41, the resonance peak spectrum of the sensor under different refractive index NB. (b) When refractive index NB =1.35 increases to NB =1.41, the sensitivity and resonance wavelength change with the change of NB. (c) When NA =1.39, NB =1.35–1.41, the resonance peak spectrum of the sensor under different refractive index NB. (d)When refractive index NB=1.35 increases to NB=1.41,the sensitivity and resonance wavelength change with the change of NB.

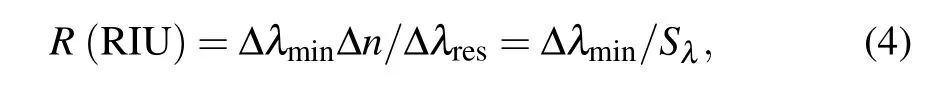

Sensitivity and minimum resolution are both indicators to measure whether the refractive index sensor is excellent, and the wavelength sensitivity in this article is measured by the spectral detection method,and the formula is as follows:[25]

where ∆λpeakrefers to the shift of the resonance peak on the spectrum,and the change in refractive index is represented by∆n. Figure 3(b)demonstrates that the sensor’s sensitivity also changes when theNBvalue increases from 1.35 to 1.41. It is clear from the loss spectrum that 621 nm,643 nm,672 nm,709 nm,757 nm,822 nm,and 985 nm are the resonance wavelengths corresponding to differentNBrefractive indexes. The proposed sensor demonstrates resonant wavelength shifts of 22 nm, 29 nm, 37 nm, 48 nm, 65 nm, and 163 nm, and corresponding refractive indexes are 1.35,1.36,1.37,1.38,1.39,and 1.40, respectively. When the refractive indexNA=1.33,NB=1.35–1.41,according to Eq.(3),the sensor can obtain the upmost wavelength sensitivity of 16300 nm/RIU.Figure 3(d)demonstrates that whenNA=1.39 and the value ofNBincreases from 1.35 to 1.41, the sensor’s sensitivity will also change. It can be concluded from the loss spectrum that 594 nm, 602 nm, 612 nm, 636 nm, 666 nm, 781 nm, and 994 nm are the resonance wavelengths corresponding to differentNBrefractive indexes. Furthermore, we must note that channels A and B are symmetric and they have equivalent effects. When the refractive indexNA=1.39,NBchanges in the range of 1.35–1.41,the sensitivity value is the same as that ofNB=1.39 andNAchanges in the range of 1.35–1.41, which can reach 21300 nm/RIU.

The resolution of sensor refers to the most minor change in the measurement parameters of the sample that the system can detect. The smaller the value of the minimum resolution,the better sensor’s performance,and it is customary to use the following formula to express resolution:[26]

where ∆nand ∆λminare the change in refractive index and the minimum resolution of the spectrum respectively. According to the Eq. (4), it is clear that the greater the resonance wavelength shift is,the lower the sensor resolution is,hence,a small change in the refractive index of the sample can be detected accurately. Assuming that ∆λmin=0.1 nm is the minimum resolution unit of the spectrometer,the resolution of the sensor is 4.695×10−6,which indicates that the sensor can detect small refractive index changes of the order of 10−6,and this result is better than the result reported in Refs. [27–29]. In summary,since the wavelength sensitivity and resolution are better than the same kind of sensor for dual sample synchronous detection,it will become an ideal sensor for sample detection such as medical testing, organic chemical sensing, and biological sensing.

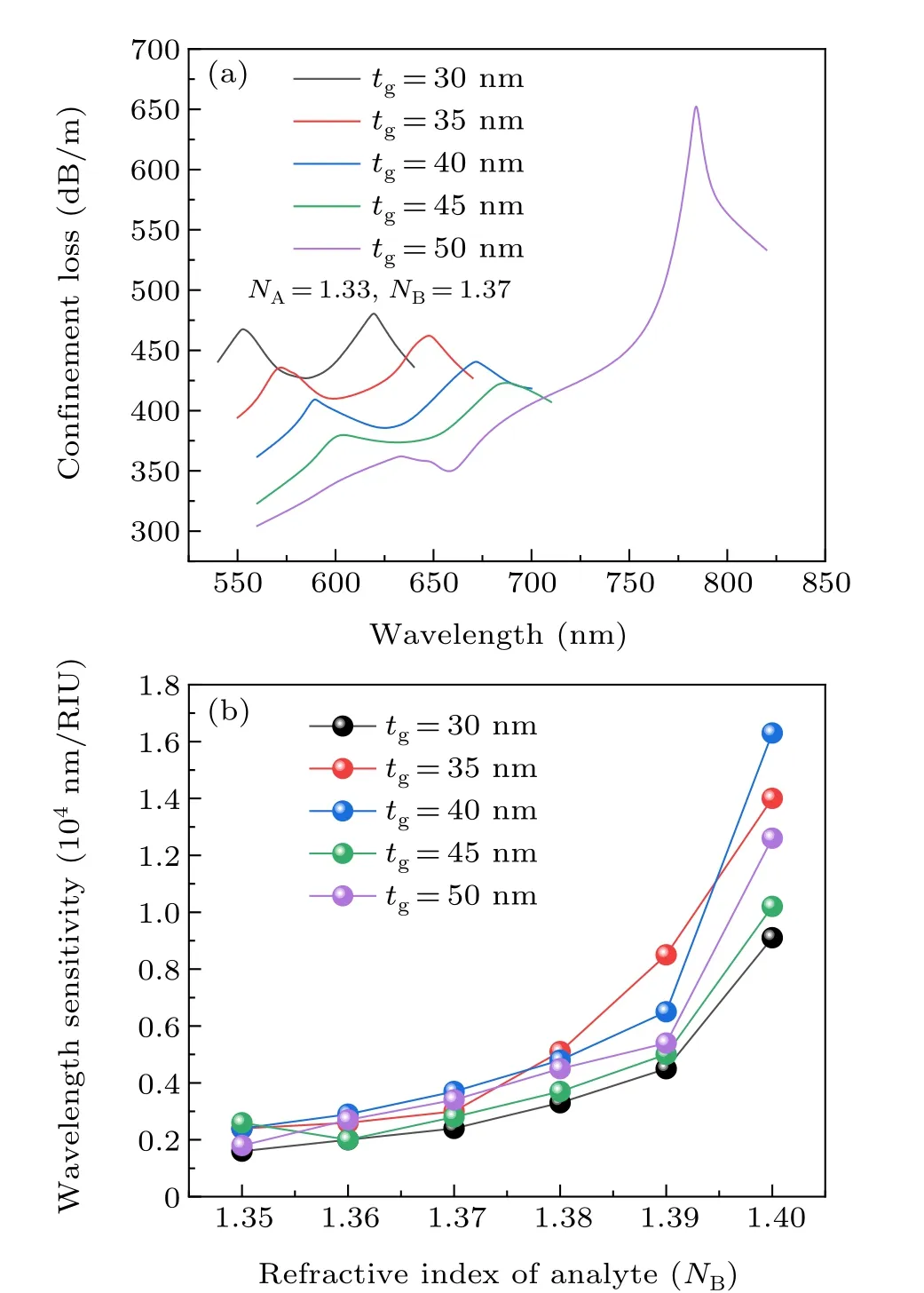

This paper studies the effect of structural parameters(gold nanolayer thicknesstg,central air hole radiusr,vertical distanceH)on the sensitivity and loss of the sensor when the refractive indexNA=1.33,NB=1.37. Different parameters also affect wavelength sensitivity,and the results are shown in the figures. After many simulation experiments,we obtain the best parameters for the proposed fiber structure.

Fig. 4. (a) The loss spectrum of sensor with different thickness of gold nanolayer. (b) The change of wavelength sensitivity with different gold nanolayer thicknesses.

Gold has good stability and strong chemical inertness,so it has good application value in SPR. Therefore, the optical fiber chooses gold as the coating material to produce the SPR effect, and the position of the resonant peak and the wavelength sensitivity will change with the different thickness of gold nanolayer. If the gold nanolayer is excessively thick, it will weaken the penetration of the evanescent field, thereby reducing the sensitivity and confinement loss. If the gold nanolayer becomes thin,the plasma wave will be damped and strongly suppressed. Figure 4(a)demonstrates the core mode loss spectrum at different gold nanolayer thicknesses. When the thickness of the gold nanolayer increases from 30 nm to 50 nm, the loss peak gradually redshifts. As shown in the Fig. 4(b), the sensitivity increases nonlinearly when the gold nanolayer thicknesstgremains unchanged and the refractive indexNBincreases. Whentg=40 nm, the maximum wavelength sensitivity of the sensor is 16300 nm/RIU.

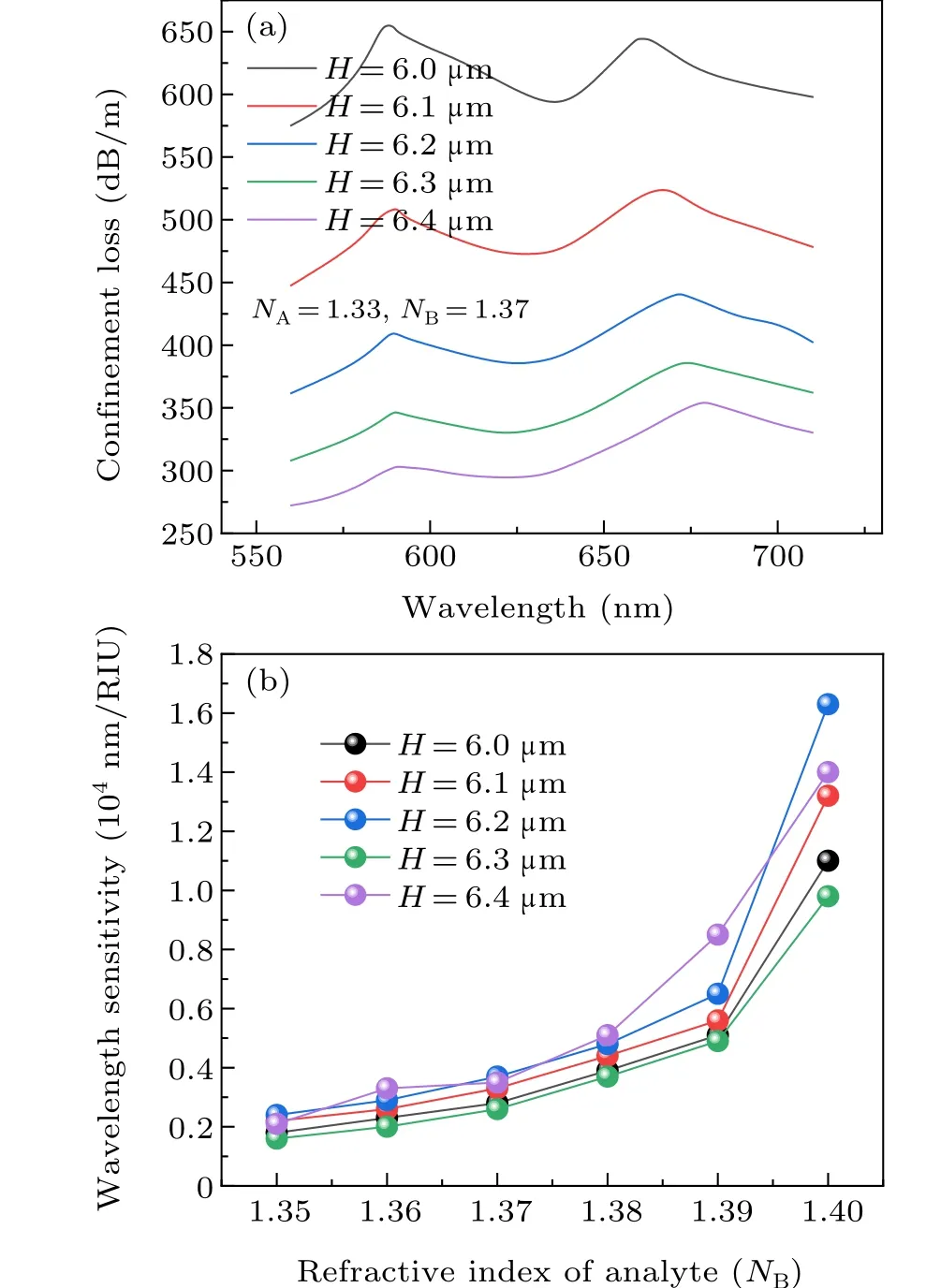

This paper anatomizes the effect of the vertical distanceHfrom channel D to the central air hole on wavelength sensitivity and confinement loss,and the change of confinement loss is shown in the Fig.5(a). WhenH=6.0µm,the peak loss is the maximum value of 652.1 dB/m. WhenH=6.4µm,the peak loss is the minimum value of 303 dB/m.Figure 5(a)shows that the loss intensity continues to decrease as the vertical distanceHincreases. Due to the large vertical distanceH, the energy leaking into the gold nanolayer is reduced,thus weakening the resonance strength. Figure 5(b)demonstrates the effect of different vertical distances on wavelength sensitivity. WhenHis constant,the sensitivity value increases with the increase in the refractive index.Due to the offset of resonance wavelength∆λpeakdoes not increase linearly with the increase of vertical distance,the wavelength sensitivity does not increase linearly,but we can still obtain an optimal value of vertical distanceHby simulation. WhenH=6.2 µm, the wavelength sensitivity of channel B reaches the maximum. Therefore,the sensor chooses the vertical distanceH=6.2 µm as the optimal parameter.

Fig.5. (a)The confinement loss varies with the vertical distance H. (b)The vertical distance H varies with wavelength sensitivity.

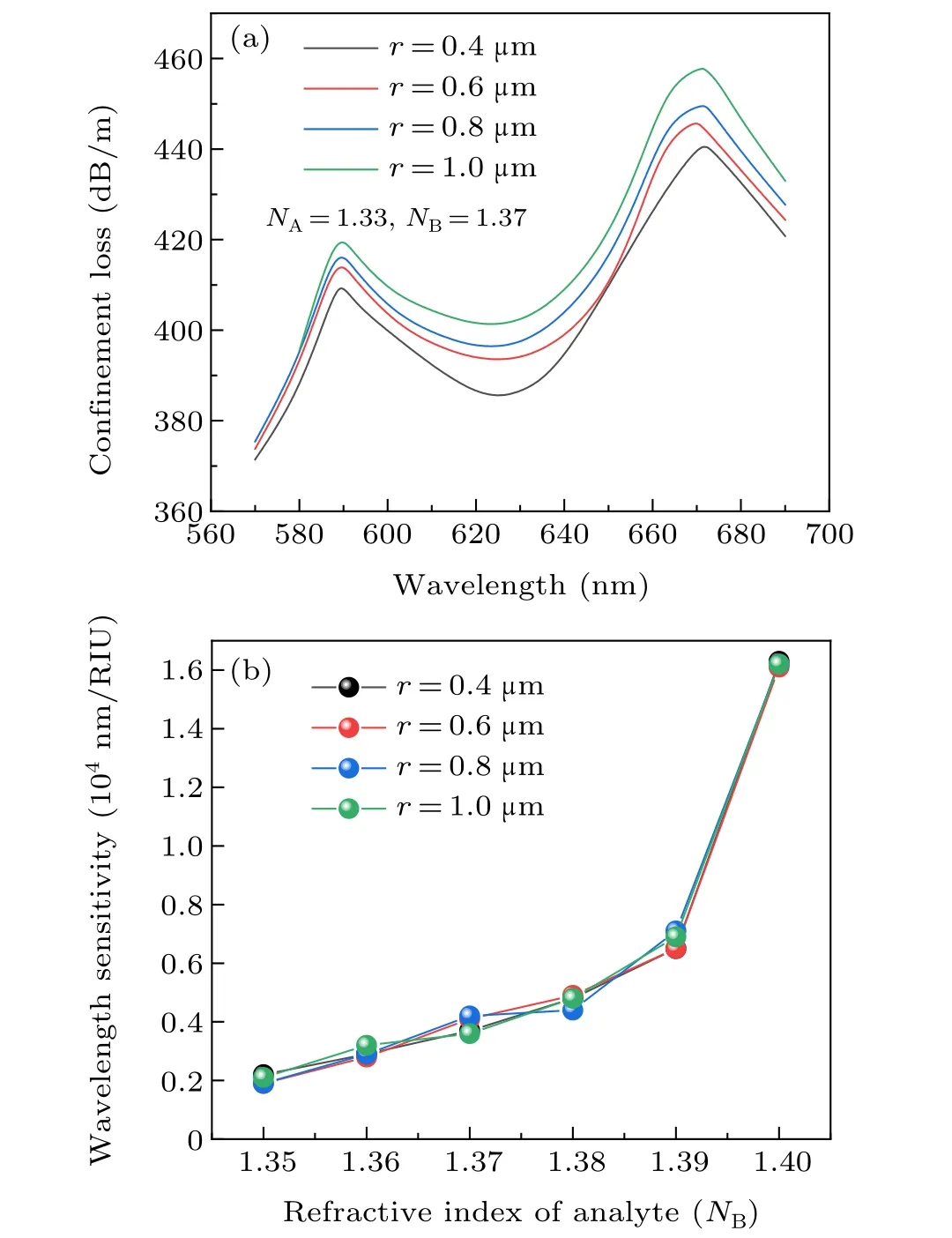

Figure 6(a) displays the loss curves of the core mode when the radiusrof central air hole changes. The fiber loss increases with the increase of radiusr. The reason is that the larger central air hole is more conducive to concentrating the mode field energy of the core, thus effectively improving the coupling strength between the core mode and the SPP mode,and increasing the peak loss. As seen from Fig. 6(b), the changes of the central air hole radius have little effect on the sensitivity. The wavelength sensitivity at the radius of the central air holer=0.4 µm is higher than that at the radius of the central air holer=1.0 µm. In short, the sensor has the utmost performance when the radius of the central air hole isr=0.4µm.

Fig.6. (a)The loss spectrum of sensor with different central air hole radius.(b)The change of wavelength sensitivity as the radius of the central air hole increases.

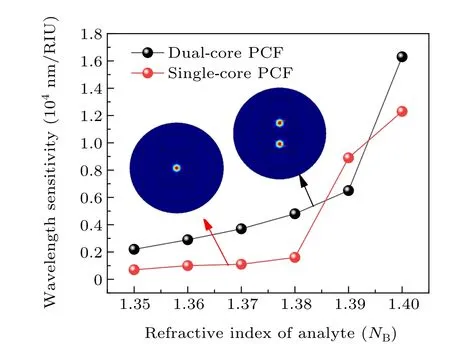

Since the fiber core of the single-core PCF sensor is far away from the sample channel, the evanescent field faces a longer transmission distance, and more free electrons in the gold nanolayer are required to form the SPR effect. The evanescent field may disappear before reaching the metal surface, and the free electrons are not effectively excited.[30–32]This paper proposes a dual-core PCF sensor that can effectively solve the above problems. A fiber core is arranged on the upper and lower sides of the central air hole,respectively.It not only guarantees the high-quality transmission of incoming energy,but the evanescent field is also closer to the metal surface of the sample channel. Figure 7 is a comparison diagram of the wavelength sensitivity values of single-core PCF and dual-core PCF, the maximum wavelength sensitivity of single-core PCF is 12300 nm/RIU,while dual-core PCF is up to 16300 nm/RIU.Besides,the dual-core PCF proposed in this paper can also manufacture polarization modulators or polarization couplers based on the coupling effect between the two cores,which is more widely used than single-core PCF.

Fig. 7. Wavelength sensitivity of single-core PCF and dual-core PCF when NB=1.35–1.40.

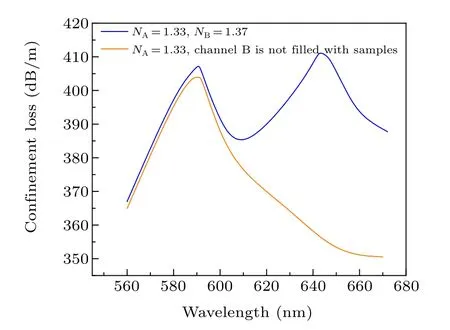

The dual channel PCF sensor can detect a single sample or two samples synchronously. Compared with the single channel PCF sensor, it reduces the steps of emptying, filling and multiple cleaning of the samples.Figure 8 shows the influences of channel B filled and unfilled with samples on the resonance wavelength.The blue curve shows the loss change in the sample-filled A and B channels withNA=1.33 andNB=1.36.The orange curve shows the change of optical fiber loss when D-type large air channel A is filled with sample with refractive indexNA=1.33 and channel B is not filled with sample.Because the gold film thickness of channel A and the vertical distance from the fiber core do not change,the intensity of optical coupling to the surface of gold and the sample does not change significantly,and the resonance wavelength remains at 591 nm. Therefore,when we detect a single sample,only one D-shaped channel needs to be coated,which reduces the complexity of coating operation,upgrades the detection efficiency,and makes the application range of the sensor more extensive.

Fig. 8. The influences of channel B filled and unfilled with samples on resonance wavelength.

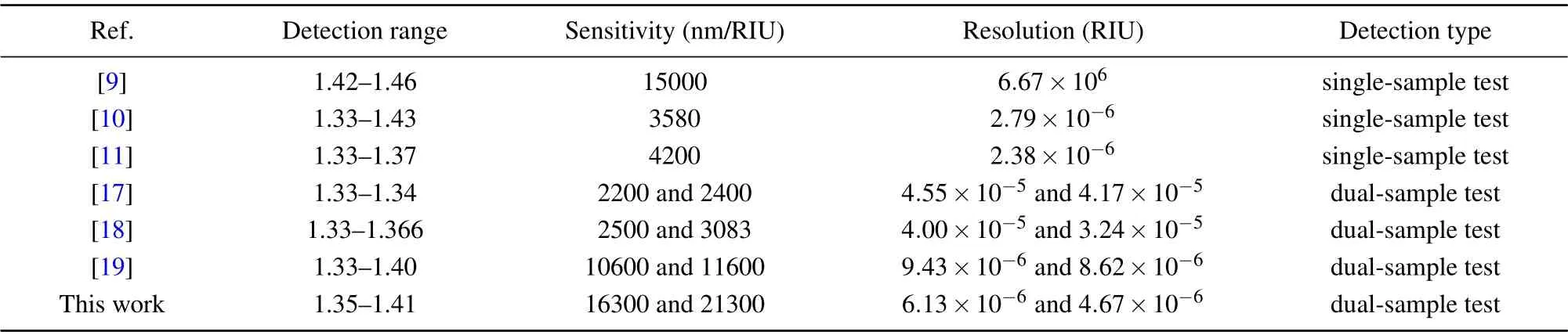

The critical performance of this sensor is shown in Table 1. The performance of the sensor provided is better than the previously reported SPR-PCF sensor. Currently, our reported sensor has higher wavelength sensitivity than that of similar dual-sample synchronous detection of PCF sensors.All in all, the sensor has outstanding performance in terms of wavelength sensitivity, detection range and resolution, as shown in the table.

Table 1. The important performance of the proposed sensor is compared with other similar sensors.

In the specific manufacturing process of the PCF sensor,two solid glass rods are selected as two fiber cores based on the number of fiber cores and cladding layers of D-shaped PCF.During stretching,the inert gas is introduced into the capillary glass tube to adjust its internal air pressure,and the two core Dshaped PCF is obtained by controlling the tensile velocity.Flat polishing is performed along the D-plane side to dip the fiber directly into the sample or drop the sample onto the D-polished side of the fiber.[7,19]Magnetron sputtering technology is used to reduce the coating difficulty and avoid microfluidic filling.This method is easy to implement and it not only ensures uniformity of the coating but also reduces the scrapping rate of D-type PCFs.

4. Conclusion

This article proposes a dual-core D-channel PCF sensor that can detect two samples simultaneously,which effectively solves the problems of coating difficulty and low wavelength sensitivity. The dual-core PCF has demonstrated outstanding performance in various application fields, such as polarizing beam splitters, polarizing filters and sensors for detecting refractive index. In practical application, the dual channel PCF sensor can detect two different samples and two different parameters of the same sample, which is realized by covering different sensing media in different channels. Furthermore,the influence of parameters such as the vertical distanceH,the central air hole radiusrand thickness of the gold nanolayertgon the sensor performance are also analyzed to obtain the best parameters of the proposed structure. The optical fiber sensor can detect the refractive index of two samples simultaneously with a maximum sensitivity of 21300 nm/RIU.To the best of our knowledge,the sensitivity achieved in this work is the highest sensitivity with the dual sample synchronous detection sensors. Due to the simple manufacturing process,the sensor is a strong competitor for refractive index detection in the biochemical field.

Acknowledgments

Project supported by the National Natural Science Foundation of China (Grant No. 61601183 and 31671580),the Key Technologies Research and Development Program of Henan Province, China (Grant No. 202102210390 and 222102210242),and Young Backbone Teachers in University of Henan Province,China(Grant No.2020GGJS099).

- Chinese Physics B的其它文章

- Magnetic properties of oxides and silicon single crystals

- Non-universal Fermi polaron in quasi two-dimensional quantum gases

- Purification in entanglement distribution with deep quantum neural network

- New insight into the mechanism of DNA polymerase I revealed by single-molecule FRET studies of Klenow fragment

- A 4×4 metal-semiconductor-metal rectangular deep-ultraviolet detector array of Ga2O3 photoconductor with high photo response

- Wake-up effect in Hf0.4Zr0.6O2 ferroelectric thin-film capacitors under a cycling electric field