Contrast Test of Precision Electric Mist Duster and Electric Sprayer

Xianliang ZHU, Dengke YIN, Lingli WANG

1. Qingdao Agricultural Technology Extension Center, Qingdao 266071, China; 2. Provincial Agricultural High-tech Zone Management Committee of Qingdao West coast, Qingdao 266500, China; 3. Agricultural and Rural Bureau of Laoshan District, Qingdao 266100, China

Abstract [Objectives] The paper was to compare and verify the operation performance of precision electric mist duster and electric sprayer, and to select the optimum plant protection equipment suitable for greenhouse application. [Methods] Agents were sprayed by precision electric mist duster and electric sprayer to control tomato downy mildew in greenhouse, and the control effect and pesticide utilization rate were compared. [Results] Compared with electric sprayer, precision electric mist duster improved the pesticide utilization rate by 31.7%, improved the spray efficiency by 20 times, and increased the control effect by 13.2%. [Conclusions] The study provides technical support for the popularization and application of precision electric mist duster in greenhouse and other facilities cultivation.

Key words Plant protection machinery; Precision electric powder grinder; Electric sprayer; Efficiency; Utilization rate; Efficacy

1 Introduction

At present, the general development trend of plant protection machinery at home and abroad is efficient, economic, green and safe. Greenhouse and other facilities cultivation should also adopt the corresponding pesticide application technology against diseases and insect pests, which can not only reduce the application amount of pesticides and save production costs, but also greatly reduce pesticide residues in agricultural products and ensure the production of pollution-free and green agricultural products[1-3]. However, conventional electric sprayer is often used to control diseases and insect pests in greenhouses and other protected areas. The prevention and control method will: sharply increase the humidity in the greenhouse; aggravate the germination, infection and reproduction of pathogenic fungi and bacteria in the greenhouse; provide conditions for the occurrence of diseases and insect pests; induce some diseases and insect pests and; accelerate the spread of diseases and insect pests, leading to rapid spread of diseases and insect pests and causing serious economic losses. Meanwhile, the method easily leads to poisoning of pesticide operator due to high labor intensity of application[4-6]. In order to solve the problem of disease and pest control in facility cultivation, precision electric mist duster is introduced relying on the project ofIntroductionofEfficientGreenhousePlantProtectionMachineryandTools, and the contrast trial between precision electric mist duster and electric sprayer was carried out, in order to provide technical support for the popularization and application of precision electric mist duster in greenhouse cultivation[7-9].

2 Materials and methods

2.1 MaterialsPrecision electric mist duster, backpack sprayer, water sensitive paper, 50% dimethomorph WP (micro powder).

2.2 MethodsPrecision electric mist duster was used for micro powder spray and conventional electric sprayer was used for mist spray.

2.3 Experimental design

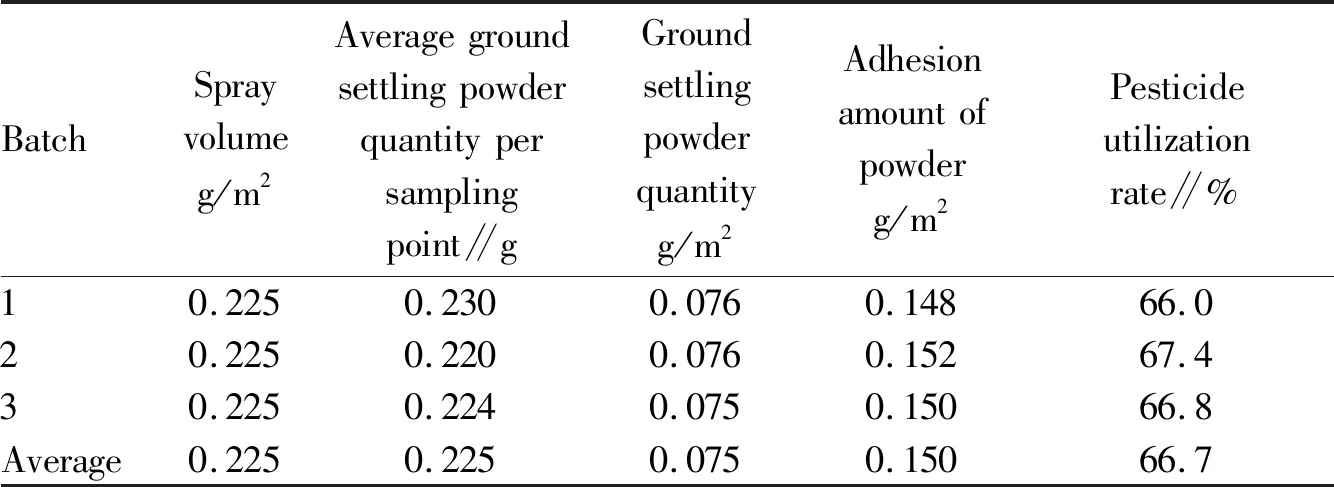

2.3.1Pesticide utilization rate test. (i) Utilization rate test of micro powder spray. In the experimental area of tomato cultivation, 5 sampling points were randomly selected in the cultivation row, and 3 m2of each sampling point was covered with white paper. The dosage was calculated according to grow plants and greenhouse size. The pesticide spray equipments and machines were prepared, and pesticides were sprayed according to operation requirements. After the powder was completely settled, the dust attached to 5 pieces of white paper was collected, weighed, and recorded in the table. The total ground settling powder quantity in the greenhouse was converted, and the utilization rate of micro powder was calculated.

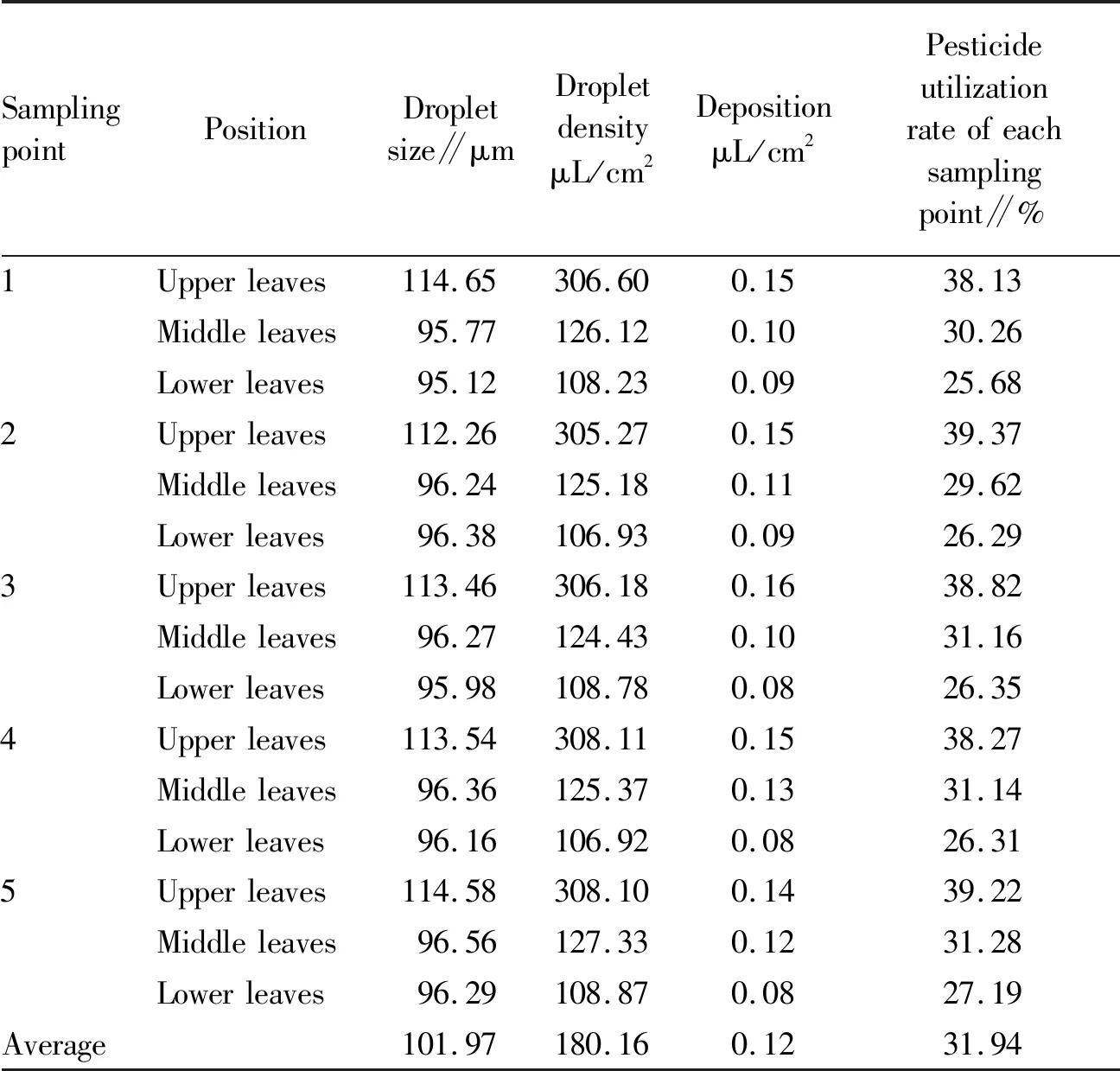

Pesticide utilization rate refers to the proportion of the volume of pesticide deposited on the target per unit area to the total volume of pesticides sprayed, that is, deposition rate.

Pesticide utilization rate (%)=(The volume of pesticide deposited on crops/Total spray volume)×100

(1)

(ii) Utilization rate test of mist spray. In the tomato cultivation experiment area, 5 sampling points were randomly selected according to the 5-point sampling method, and one tomato seedling was selected at each sampling site. A piece of water-sensitive paper was placed on the upper, middle and lower leaves of each tomato plant respectively to test adhesion density and deposition distribution of droplets at different positions of tomato. After the test, the droplet test cards were collected, scanned by the droplet scanning device, and analyzed by Deposit Scan software to get droplet diameter and other related parameters. The droplet density and liquid deposition in the upper, middle and lower leaves of tomato were monitored, and the pesticide utilization rate was calculated.

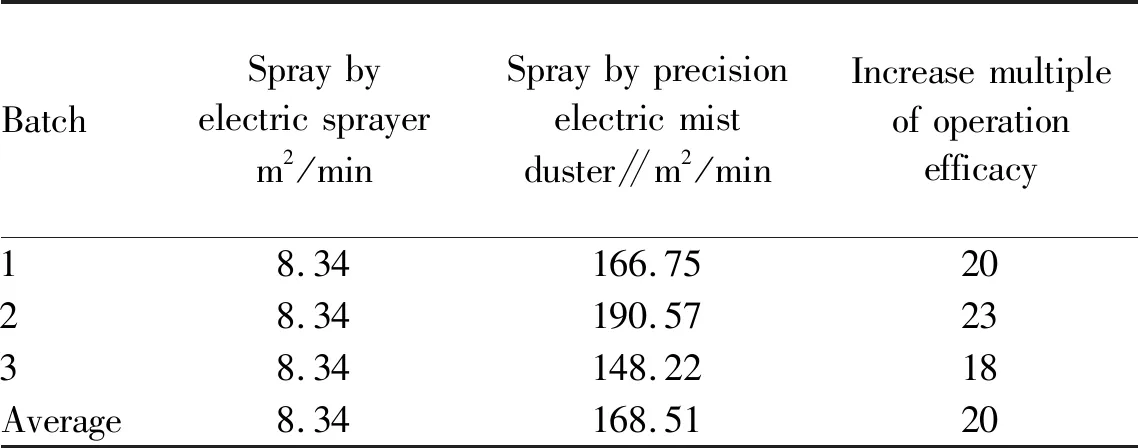

2.3.2Contrast test of spray efficiency. Two contrast tomato cultivation greenhouses were selected, and the agents sprayed by precision electric mist duster and electric sprayer respectively. The completion time of spray was recorded and the efficiency of spray was calculated.

2.3.3Efficacy contrast test. (i) 50% dimethomorph WP (micro powder) was provided by Institute of Vegetables and Flowers, Chinese Academy of Agricultural Sciences.

(ii) Tomato and downy mildew were targets of the test.

(iii) Two chemical treatments were designed in the test, including 50% dimethomorph WP (micro powder) sprayed by precision electric mist duster at the dose of 0.03 g/m2, and 50% dimethomorph WP sprayed by electric sprayer at the dose of 0.03 g/m2. The agents were diluted 1 000 times, and sprayed once every 7 d for consecutive 3 times. Those sprayed with water were severed as the blank control. The disease condition of each point was investigated before spray, and the incidence was investigated at 7 d post spray for consecutive 4 times. According to the 5-point sampling method, 5 sampling plots were randomly selected, and 3 plants were randomly selected from each sampling plot and labeled. All leaves of each plant were investigated. Chemical injury was investigated in the last survey.

According to GB/T 17980.26-2000, the control effect was calculated, and the degree of chemical injury of each sample point was recorded.

The classification criteria of tomato downy mildew were as follows: level 0, there was no lesions; level 1, the lesion area accounted for less than 5% of the whole leaf area; level 3, the lesion area accounted for 6%-10% of the whole leaf area; level 5, the lesion area accounted for 11%-25% of the whole leaf area; level 7, the lesion area accounted for 26%-50% of the whole leaf area; level 9, the lesion area accounted for more than 50% of the whole leaf area.

Disease index=[∑(Number of diseased leaves at each level×The value of the representative level)/(Number of total leaves surveyed×9)]×100%

(2)

Control effect (%)=[1- (CK0×PT1)/(CK1×PT0)]×100

(3)

whereCK0stands for the disease index of control area before spray;CK1stands for the disease index of control area after spray;PT0stands for the disease index of treatment area before spray;PT1stands for the disease index of treatment area after spray.

3 Results and analysis

The pesticide utilization rates of precision electric mist duster and electric sprayer are shown in Tables 1-2. The effective utilization rate of pesticide sprayed by precision electric mist duster reached 66.7%, while that sprayed by electric sprayer was only 31.94%.

Table 1 Pesticide utilization rate of micro powder spray

The spray efficiency of micro powder spray and mist spray was compared (Table 3). The efficiency of micro powder spray by precision electric mist duster was 166.75 m2/min, 20 times higher than that by conventional mist spray.

Table 2 Pesticide utilization rate of mist spray

Table 3 Comparison of spray efficiency of micro powder spray and mist spray

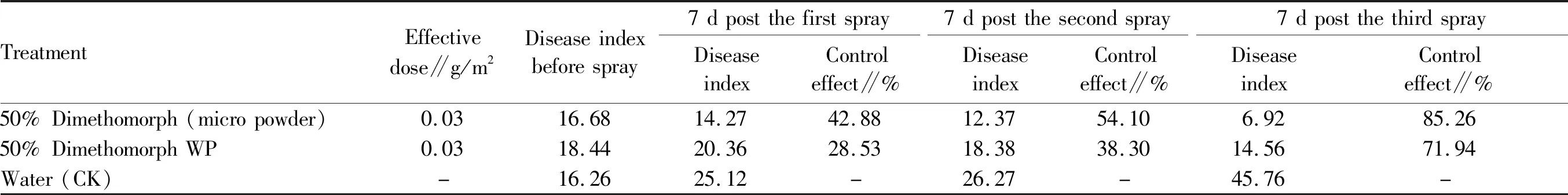

The field control effects of micro powder spray and mist spray on tomato downy mildew are shown in Table 4. The control effects of the agent sprayed by precision electric mist duster on tomato downy mildew was 85.26%, which was higher than that sprayed by electric sprayer (71.94%), and the control effect was increased by 13.2%, indicating that precision electric mist duster could be used to control tomato downy mildew. The average control effect of the agent sprayed by precision electric mist duster on tomato downy mildew was 42.88% at 7 d post the first spray, 54.10% at 7 d post the second spray, and 85.26% at 7d post the third spray, higher than that sprayed by electric sprayer in the corresponding survey period.

Table 4 Comparison of field control effects of micro powder spray and mist spray on tomato downy mildew

4 Conclusions and discussion

Precision electric mist duster is a kind of special plant protection machinery for facility cultivation in protected area, with long range, accurate powder control and good dispersion. Mist duster can adjust the amount of powder and air force, and powders are misty after spray, with static electricity. After spray, agents are evenly distributed in the upper, middle and lower leaves of crops, which have good control effect on diseases and basically meet the requirements of precise application of pesticides in greenhouse. In addition, there is no need to enter the ridge during the operation, and the agents are dispersed and evenly distributed throughout the shed, but do not increase the humidity of the shed. It can be used flexibly in sunny days, cloudy days, rainy days and haze days. The powder particles are charged, which are easily adhered to the front and back side of leaves, with high drug utilization rate and good prevention and control effect. The operation by precision electric mist duster reduces the application amount of pesticide and lowers the pollution to the environment and vegetables.

Through the test, compared with the electric sprayer, precision electric mist duster improved the pesticide utilization rate by 31.7%, improved the spray efficiency by 20 times, and increased the control effect by 13.2%. From the perspective of control effect, spraying agents by precision electric mist duster could effectively control the occurrence of downy mildew tomato, and the control effect was as high as 85.24% after three times of spray, with no newly infected downy mildew spots on the leaves. Taking pesticide utilization rate, operation efficiency and control effect into consideration, it is more economical and effective to spray agents by precision electric mist duster than by electric sprayer, and it also conforms to the requirements of green production. It is suggested to popularize the spraying machine step by step on the basis of further experiment and demonstration.

- 植物病虫害研究(英文版)的其它文章

- Grafting and Seedling Cultivation Technique of Bitter Gourd for Disease Prevention in Hainan

- Key Technical Points of Wheat Moisture-resistant Strain Sowing and Management of Promoting Seedlings from Weak to Strong in Daiyue District

- Rodent Damage and Control Methods in Hami Grassland of Xinjiang

- Identification of Resistance of Powdery Mildew and Stripe Rust of Winter Wheat Strains in Xinjiang

- Study on Toxicity of 9 Biocontrol Microbial Products to Adult Population of Tobacco Beetle, Lasioderrma serricorne (Fabricius)

- Screening of Chemical Agents for Controlling Spodoptera frugiperda in Corn Fields of Panmao Township, Yunnan Province