Performance Comparisons of Five Different SPF Mouse Transport Containers

Yuanyuan YANG, Dong WU, Xiaolin LI, Ning LI, Yun Teng, Ling’en LI

Abstract [Objectives] This study aimed at providing gist for selecting qualified transport containers by comparing the performance of common SPF mouse transport containers at home and abroad, and laying a foundation for subsequent improvement of transport containers.

[Methods] In this study, 5 different transport containers were selected, and their microbial filtration performance, ventilation, sterilization method and flux, and other related design and construction were analyzed.

[Results] The results showed all 5 SPF mouse transport containers can provide enough air for the survival of mouse and protect them from bacterial infections. Transport container B and D are superior to others on one-time sterilization flux and deformation degree after autoclaving. Furthermore, taking into account the related design and construction of these transport containers, such as viewing window and carrying handle, the result of comprehensive comparison is that the transport container D>A>E>C>B.

[Conclusions] In summary, the 5 SPF transport containers tested in this study can all satisfy the basic demand of SPF mouse transportation, but each transport container has its own advantages and disadvantages on storage space, deformation degree after autoclaving and other aspects. Thus, SPF mouse transport containers should be selected by different demand.

Key words SPF mice; Transport container; Filtering capability; Ventilation; Related design and construction

With the rapid development of biological sciences, the demand for laboratory animals at home and abroad has become higher and higher in recent years. Laboratory mice have become preferred laboratory animals in various research fields due to their advantages of easy feeding, high reproduction rate, small individual differences and low cost. In 2018, the usage quality of laboratory mice in Germany was 1.54 million, while the usage quality of laboratory mice in mainland China in 2015 reached 7.03 million [1-2] .

Laboratory mice of the specific pathogen free (SPF) grade are raised in a barrier facility, where microorganisms and parasites are strictly controlled. Transportation is a necessary link between production and use, so the quality of transport container is closely related to the safety of SPF mice and barrier facilities.

According to the requirements of DB32-T967-2006 Laboratory Animal Cage Plastic Cage and Laboratory Animal Science Association (LASA) for SPF laboratory animal transport container, transport container should be able to be sterilized in a suitable way, and should be capable of effectively filtering the incoming air, and should maintaining leakproofness during transportation. Based on the above, the transport container could effectively prevent animals from being contaminated during transportation, so as to ensure the original microbial status of animals [3-4] . Meanwhile, the transport container need to maintain a certain permeability to ensure that the animals in them can breathe normally and avoid death due to the lack of air circulation.

In this study, five kinds of SPF mouse transport containers commonly used at home and abroad were selected and compared in terms of design requirements, disinfection methods, microbial filtration performance, animal survival, etc. , so as to provide reference for the selection of SPF mouse transport container and lay a foundation for the improvement of SPF mouse transport containers.

Materials and Methods

Experimental materials

Information of transport containers

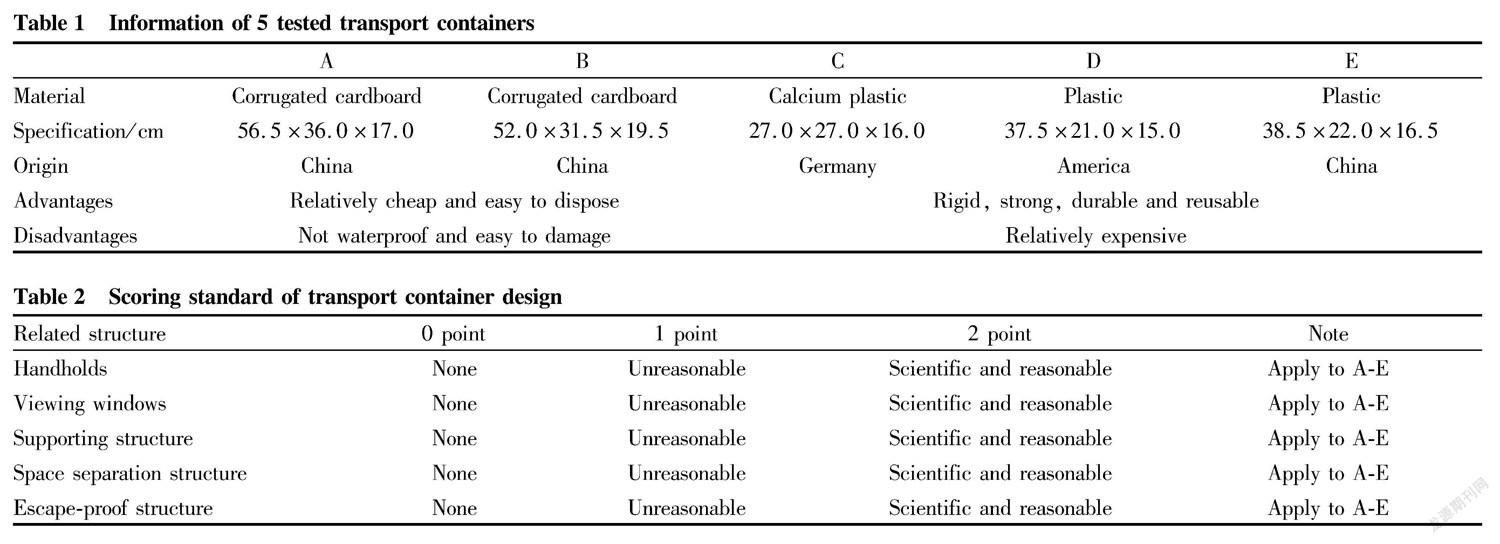

In this study, five kinds of SPF mice transport containers commonly used at home and abroad were selected, and relevant information is shown in Table 1.

Animals

450 SPF female C57BL/6JGpt mice, 6 weeks old, weighing (18±2) g, were provided by GemPharmatech Co., Ltd. [SCXK (Su) 2018-0008].

Other materials

TSA plates and contact plates (size: 55 mm) were purchased from Shanghai Comagal Microbial Technology Co., Ltd. Transgenic mouse feed for Co 60 irradiation tests was purchased from Jiangsu Xietong Pharmaceutical Bio-engineering Co., Ltd. Wood shavings were purchased from Pizhou Xiaohe Technology Development Co., Ltd.

Comparison of structural design requirements

According to the design requirements of DB32-T967-2006 Laboratory Animal Cage Plastic Cage, GB14925-2010 Laboratory Animal Requirements of Environment and Housing Facilities and Laboratory Animal Science Association (LASA) for SPF laboratory animal transport container, the scoring standard of transport container structure design (as shown in Table 2) was formulated, and the five kinds of transport containers were compared and scored from the structural design [3-5] .

Autoclaving test

After autoclaving the five kinds of transport containers (121 ℃ for 20 min, drying for 20 min), the single autoclave flux of different transport containers (which is steam autoclave volume/transport container volume) and the degree of deformation of those transport containers after autoclaving were compared.

Comparison of microbial filtration performance

After the transport containers were sterilized by autoclaving and entered animal facilities, nine transport containers were randomly selected from each kind to detect the number of bacteria in the air in the transport containers [6] .

Detection of sedimentated bacteria in transport containers

TSA dishes were placed in the containers, while the number of dish varied with the size of the bottom area of the transport containers. Transport containers A-B were large transport container, in which two TSA dishes were placed, while C-E were small transport container that held one TSA plate. The transport containers were sealed, and the transport containers were placed in a normal environment for static storage.

On the 0 th , 3 rd , and 6 th d, three transport containers were taken out from each kind of containers, and after ethanol spray disinfection was performed on the outside, the transport containers were moved into biological safety cabinets and opened to take out the TSA dishes. Three blank TSA dishes were added at each time point as a negative control. At the same time, on the 0 th , 3 rd , and 6 th d, three TSA plates were placed for 30 min in a normal environment where the transport containers were placed as a positive control. The TSA dishes were placed in incubators at 37 ℃ for 48 h , and the number of colonies were observed and counted. For the samples on day 0, the transport containers containing the dishes needed to be placed in a normal environment for 30 min and then taken out for culture.

Detection of contact dishes in transport container

On the 0 th , 3 rd , and 6 th d, after taking out the dishes in the transport containers from the biological safety cabinets, three contact dishes were used in each transport container to detect the inner surface microbial. Point 1# was the inside bottom surface of each transport container; and points 2# and 3# were the vents on the inner side wall. Negative control and positive control were added at each time point, which were blank contact dishes and dishes inoculated with Escherichia coli respectively.

Comparison of animal conditions

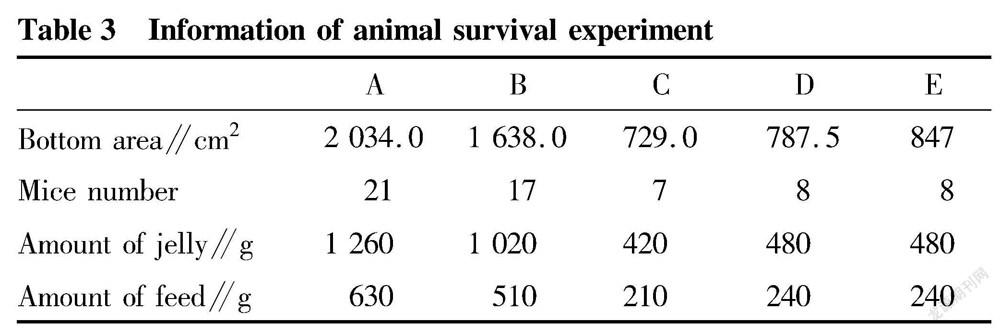

Six sterilized transport containers were randomly select from each kind in animal facilities. According to the LASA standard, enough shavings bedding were put into the transport container, and the number of C57BL/6JGpt living in different transport container was calculated according to the minimum bottom area of 96 cm 2 for each animal. The numbers of animal in the five kinds of transport container are shown in Table 3 [3] . Meanwhile, each mouse was provided with diet and drinking water according to 5 g of feed and 10 g of jelly per day [7-8] . The initial state of the mice was observed and recorded, and the transport container was sealed.

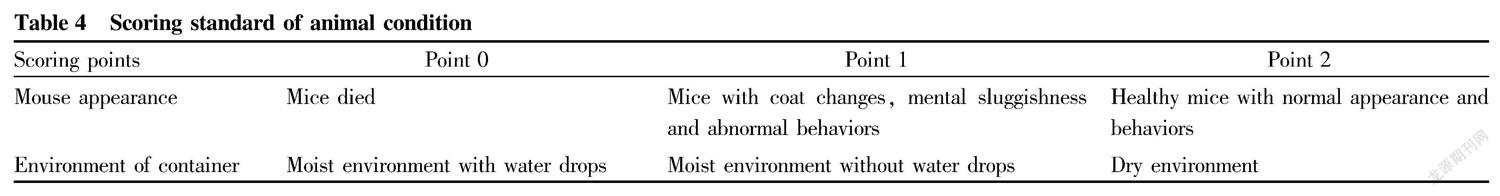

The transport container containing the mice was placed in a room with an air-conditioning control system maintained at a temperature of 20-26 ℃ and a humidity in the range of 40%-70%. During the experiment, the status of the mice in the transport container were observed and judged twice a day (9:00 and 18:00) through the viewing windows of transport containers or listening to the movement in the transport containers. For example, if the mice were in an abnormal state or there was abnormal sound in the transport containers, the experiment should be stopped immediately, and corresponding measures should be taken according to the actual situation. On the 2 nd , 4 th , and 6 th d, two of each kind of transport containers were taken, and the transport containers were opened to observe the status of the mice and the environment in the transport containers, and the condition of the animals was scored according to Table 4.

Results

Comparison of structural design

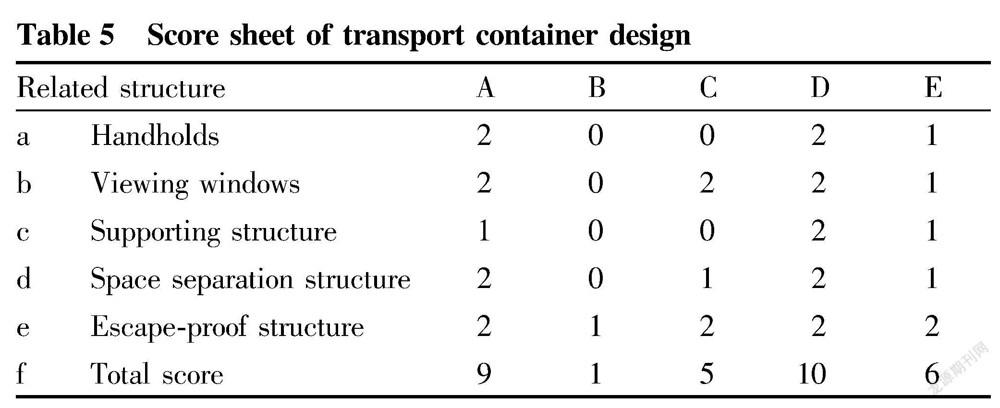

The structural details of the five kinds of transport containers are shown in Fig. 1, and the scoring results of the designs are shown in Table 5. Transport container B (1 point) had no handholds, viewing windows, supporting structures and space separation structures, and the escape-proof metal mesh had poor flatness which could scratch people and mice easily at spliced positions. Transport container C (5 points) had no handholds, supporting structures and space separation structures. Transport container E (6 points) had all structural designs, but most of the designs are unreasonable, such as poor diaphaneity of the viewing windows, etc. To achieve space separation, transport container A (9 points) have to use an additional metal cage, which increased the complexity of the operation and the weight of the transport container. The design of all aspects of transport container D (10 points) was relatively scientific and reasonable.

Comparison in autoclaving test

Items entering animal facilities should be sterilized, and the preferred method of sterilization is autoclaving. The autoclaving test results showed that all five kinds of transport containers can withstand high temperature and high pressure, but there would be different degrees of deformation, and the degrees of deformation after autoclaving ranked as A>B=C=E>D. In addition, due to different sizes of various transport containers, the autocalving flux of the same volume of sterilizer was different. The one-time aotuclaving flux of transport container B is 300, which are made of corrugated board that can be folded, while that in unfoldable transport containers A and C were 28 and 76 respectively. The one-time aotuclaving flux of transport containers D and E was 140.

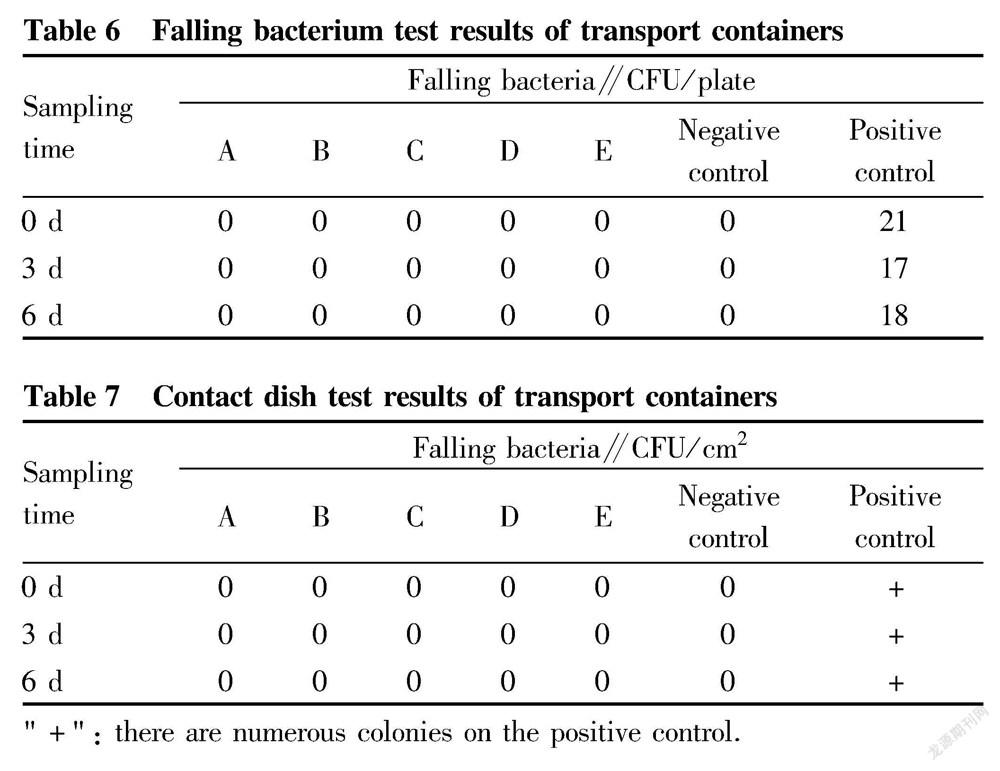

Comparison of microbial filtration performance

The packaged transport containers were placed in the ordinary environment for 6 d, and the content of bacteria in air and inner surface were continuously monitored. The results are shown in Table 6 and Table 7. No bacteria and mold were detected in the all kinds of transport containers, indicating that the filter membranes of all transport containers could effectively filter external microorganisms, which meet the requirements of SPF transport containers.

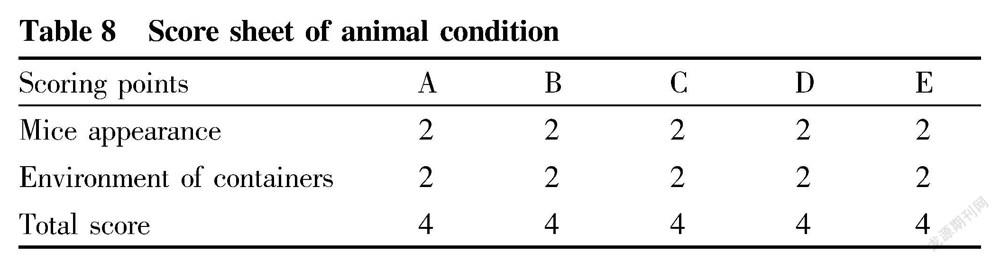

Animal survival test

During the test period, the mental state and activities of the animals in each kind of transport containers were normal, there were remaining jelly and feed, and the environment was relatively dry. The above indicated that the air permeability of the filter membrane of each kind of transport containers could meet the life needs of mice.

Discussion

The commonly used transport container materials in China include corrugated board, calcium-plastic board and plastic. Among them, corrugated board transport containers are widely used for short-distance transportation due to their low cost. Plastic transport container are moisture-resistant and stable, so they are often used for long-distance and air transportation. The properties of calcium-plastic board transportation containers are between corrugated board and plastic transport containers, and can be used for medium and long-distance transportation.

The most basic performance requirements of the SPF mice transport containers are as follows: ① the materials should be safe and non-toxic; ② they could seal and maintain isolation between the inside and outside environment of the transport containers; ③ the filter membranes of the viewing windows should effectively filter the microorganisms in the outside air; ④ they should have good ventilation which can provide enough air for the survival of animals. Zhang et al. [6] tested the bacterial filtration performance of IVC cages and two kinds of transport containers, and the results showed that two kinds of sealed transport containers cannot filter all kinds of bacteria and molds, which means the two transport containers do not meet the requirements of the SPF grade. The five kinds of transport containers selected in this study were sealed and placed in the normal environment for 6 d, and no bacteria or mold was detected, indicating that the sealing property of all transport containers and the filtration performance of the filter membranes were up to the standard, indicating that they could protect SPF mice from being polluted by microorganisms in the external environment during the transport process.

The condition of animals in transport containers will be affected by various factors such as the activity area, diet and water, the ventilation of the transport containers, and the ambient temperature and humidity. In this study, referring to the LASA standard [4] , according to the body weight of mice and the bottom area of each mouse of 96 cm 2, different numbers of mice were placed in the transport containers of different sizes, and different amounts of feed and jelly were placed according to the number of mice to ensure that the daily survival needs of each mouse were met. The transport containers were placed in an environment with constant temperature and humidity, and the different states of mice and inside environment after a period of time could represent the ventilation of the transport containers. The results of the animal survival test showed that the mice could live normally for at least 6 days in all five kinds of sealed transport containers (the maximum time in the experimental design was 6 d), and the environment in the transport containers was still relatively dry, which all indicating that the air permeability of the filter membranes of all five kinds of transport containers could meet the basic life needs of mice in them. Combined with the results of microbial filtration performance test and animal survival test, all above were shown that the five kinds of transport containers all could meet the basic needs of SPF mice for transport.

Additionally, laboratory animal manufacturers also need to consider the sterilization methods and the storage space requirement of the transport containers when they use transport containers. Autoclave sterilization is the preferred method for items entering in SPF facilities [9] . The five transport containers selected in this study could all be sterilized by autoclaving, but the degree of deformation and the one-time autoclaving flux of different transport containers were different. The autoclaving flux of the two plastic transport containers was same, but the high-pressure deformation degree of transport container D was lower than transport container E. Among other three kinds of transport containers, the autoclaving flux of transport container B was much higher than those of transport containers A and C, and the deformation degree of transport container B was also lower. In addition, the low autoclaving flux also means it need more space to store the same number of transport container. For large laboratory animal manufacturers, the autoclaving flux of transport containers and the space required for storage inside and outside animal facilities are also the important selection criteria. Combining the autoclaving flux and the high-pressure deformation degree, the best plastic transport container is transport container D, and the best corrugated board transport container is transport container B.

In addition to the basic performance and the sterilization methods of transport container, following parts will be designed according to the actual needs of users [4] : handholds, viewing windows, supporting structures, space separation structures, and escape-proof structures. Handholds are convenient for personnel to carry out handling operations, and can ensure that the fingers will not poke the filter membranes of the viewing windows to cause damage. Viewing windows are convenient for personnel to observe the mice in transport containers without opening the containers. Supporting structures are designed to ensure that when the transport containers are stacked, there is a certain gap between adjacent transport containers, which is conducive to the circulation of air. Space separation structures can allow the transport containers be divided into several parts, and mice of different strains or genders can be placed in different part, which allow to make full use of the space. Escape-proof structures are wire mesh or plastic mesh used in transport containers, which can prevent mice from escaping. After comprehensively comparing the above points, transport container D had the highest score, because they included all designs and the relevant designs were scientific and reasonable. Transport container A needs to use an additional metal cage to achieve space separation, which is a defect. Transport container E had defects in several structures, such as many barriers under the handhold which is inconvenient to seal the transport container, and the viewing windows having low transparency which made it impossible to observe mice. The transport container C has a risk of slipping when being stacked. Transport container B had the lowest score, they don’t have viewing windows, handholds, supporting structures and space separation structures which would bring some inconvenience to the transportation work.

To sum up, the five kinds of transport containers tested in this study can meet the basic needs of SPF mice transportation. Among them, transport container D are the best choice in terms of various performances, but the cost of plastic transport container is higher. Transport container B are more convenient for altoclaving and storage, and can meet the basic needs of large-scale laboratory animal manufacturers, but there are obvious defects in some structural designs. Transport container A have a more comprehensive design, but require more space for autoclaving and storage. When choosing transport container, you can refer to the above points and make corresponding choices based on your own needs and characteristics. In addition, this paper also provides a reference for the subsequent improvement of SPF mice transport containers by comparing the performance of the five kinds of SPF mice transport container commonly used at home and abroad.

References

[1] Federal Ministry of Food and Agriculture (BMEL). Available online at: https://www.bmel.de/DE/themen/tiere/tierschutz/versuchstierzahlen2018.html.

[2] WANG XL, GONG W, HE ZM, et al. Investigation on the current situation of laboratory animal usage on China mainland[J]. Laboratory animal science, 2017, 34(6): 42-48. (in Chinese).

[3] DB32/T967-2006, Laboratory animal cage plastic cage[S]. (in Chinese).

[4] Laboratory Animal Science Association. Guidance on the transport of laboratory animals[R]. UK, 2005.

[5] GB 14925-2010, Laboratory animal requirements of environment and housing facilities[S]. (in Chinese).

[6] ZHANG HQ, ZHAO T, FAN FL, et al. Comparison of microbial pollution during transfer of laboratory animals between production workshops using different transport boxes[J]. Chinese journal of comparative medicine, 2012, 22(2): 18-21. (in Chinese).

[7] https://www.clearh2o.com/animal-research-products/faq/hydrogel-faq/.

[8] KATHLEEN R PRITCHETT-CORNING, AURLIE GIROD, GLORIA AVELLANEDA, et al. Handbook of clinical signs in rodents and rabbits[M]. Charles River Laboratory, 2011.

[9] GE BL, XING JS, WANG CY, et al. The comparison of using effect for four kinds of SPF animal transport box[J]. Laboratory animal science, 2013, 30(3): 41-45. (in Chinese).

Editor: Yingzhi GUANG Proofreader: Xinxiu ZHU

- 农业生物技术(英文版)的其它文章

- Molecular Cloning and Bioinformatics Analysis of crp Gene in Vibrio alginolyticus

- Breeding Technology of Sunflower Inbred Lines with Four Generations in One Year

- Artificial Plant Seeds and Their Application

- Breeding of a Water-saving Drought-resistant Two-line Hybrid Rice Variety Wanliangyou 1008

- Development of Landscaping and Selection of Contemporary Landscaping Plants

- The Register and Characteristics of Chinese Key Protected Wild Plants in Dabie Mountains National Nature Preserve, Hubei Province