Strain insensitive vector curvature sensor based on triple-core fiber Mach-Zehnder interferometer

ZHANG Shao-Xian

(Editorial Board of Journal of Engineering of Heilongjiang University, Heilongjiang University,Harbin 150080, China)

Abstract:Strain insensitive vector curvature sensor based on triple-core fiber(TCF)Mach-Zehnder interferometer(MZI)is designed and verified.The interferometer is formed with a piece of triple-core fiber between two standard single mode fibers by using fusion splicing.Because the three cores of the TCF are distributed in a straight line at the same plane, the parameters of the two side cores are changed when the fiber is bended.Therefore, the interferometer can be used for vector curvature measurement.Experimental results show that the wavelength shift moves toward the shorter wavelength with the increase of curvature, and the maximum curvature sensitivity at the curvature direction of 0° is-29 nm·(m-1)-1 and moves toward the longer wavelength with the increase of curvature, and the maximum curvature sensitivity at the curvature direction of 180° is 41.09 nm·(m-1)-1.The strain response does not change significantly with the increase of strain.The sensor can realize strain insensitive vector curvature measurement.

Key words:curvature sensor;interferometer;triple-core fiber(TCF)

The optical fiber curvature sensors are widely used in the field of mechanical, aerospace engineering, and structural health monitoring due to their advantages such as small size, remote monitoring ability and immunity to electromagnetic interference[1-4].Nowadays, the curvature sensors with many kinds of forms based on optical fibers has been proposed[2-15].In the variety of vector curvature sensors, the most common one is based on the fiber grating structure.Normally, they designed axial asymmetrical fiber such as eccentric core fiber(ECF)[2,5].multi-core fiber[6-8].D-shaped cladding fiber[9].holey fibers[10].photonic crystal fiber[11-13]and CO2laser[14-15]or inscribing asymmetrical refractive index gratings with femtosecond laser[16]to write long period fiber gratings(LPG)or fiber Bragg gratings(FBG)used in realizing vector curvature measurement.In general, the vector curvature sensors based on FBG or LPG has small size but high cost due to the production need laser setup and the curvature sensitivities are not significant.In-fiber interferometers were favored by many researcher because of its small size, low cost and simple processing.The fiber interferometers based on the core-cladding mode interference in single mode fibers(SMF)or eccentric core fiber(ECF)was also common for curvature sensing[17-20].In these interferometers, the special structure such as asymmetrical tapers[17].lateral-offset fusion splice junctions[18-19]or swell or micro notches[19-20]were used to realize the choice of the directional curvature of the fiber.The multi-mode fiber based fiber interferometer were also referred[21-22].However, the process of the multi-mode interference is relatively complicated and the cladding-mode is sensitive to the change of external refractive index.Such the advantage of the interferometer-based curvature sensors are easy fabricated and have relative high sensitivities.

In this paper, we propose a Mach-Zehnder interferometer(MZI)based on triple-core fiber(TCF)for vector curvature measurement.The MZI is consist of a piece of TCF and two ends are link to two pieces of standard SMFs.Especially, we suggested the vector curvature sensor based on TCF fiber that the three core-modes vary with curvature affects the curvature sensing.It is different from the being MZI based on SMF vector curvature sensors in which only three core modes change with curvature and the cladding mode is absorbed.And the vector curvature sensor, which is aforesaid, has high sensitivities and simple processing.

1 Sensor fabrication and principle

The schematic configuration of the MZI based on TCF is shown in Fig.1(a).The cross-section image of the TCF is displayed in Fig.1(b).Here the diameter of the fiber is 125 μm.The three cores have the same diameter 8 μm, one located in the middle of the fiber, and the other two being an eccentric core with 23.7 μm offset from the fiber center.The two sides of the TCF were fusion spliced between two standard SMFs by using a commercial fiber fusion splicer(Fujikura, FSM-60S)and keep the middle core of the TCF connected to SMF.The duration time and power of the arc discharge were set to be “2000 ms” and “standard minus 23 bit”, respectively.

Fig.1 (a)Schematic configuration of the TCF based MZI.(b)Cross-section image of the triple-core fiber

First, we tapered on the TCF and the distance of the two tappers are 40 cm.The light launched into the middle core of the TCF from the SMF, which was coupled in the first taper and the mode of three core was interfered between two tapers.And then a part of the light was transmitted from the SMF at the other end.As a result, a MZI based on TCF is realized.

According to the interference theory, the electric vector of three waves based on TCF areE1,E2,E3, respectively.Therefore, the total intensity of the three beams after interference can be expressed as

I=a2+b2+c2+2abcosφ1+

2bccosφ2+2accosφ3

(1)

Where,a,b,care the amplitude of the three beams, respectively.φ1,φ2,φ3are the phase difference between any two cores, respectively.

(2)

m=1,2,3,λis operation wavelength,Lis the length of TCF and Δneffis the effective refractive index(RI)difference between any two core modes.Due to the elastic-optical effect with the curvature of the fiber, the effective RI was changed.In the experiment, the effective RI of the outer core of the fiber increases with the curvature, while the inside is decreased in the two side cores and the can be described as[23]

(3)

i=1, 2, 3.The Equation(3)shown that the relationship between effective RIniand the curvature,Cis the curvature,dis the distance between two adjacent cores andθis the rotation angle of the TCF relative to the neutral plane as shown in Fig.2(a)and the curvature direction as shown in Fig.2(b).According to Equation(3), the two adjacent cores of the effective RI difference at the rotation angle of 0° can be describe as

Fig.2 Schematic diagram of(a)the cross-section of triple-core fiber and(b)lateral curvature

(4)

Because of the middle core in the neutral plane, the RI is not changed.The Equation(2)~(4)shown that the effective RI can determine the wavelength shift of the dips and affect the sensitivity of curvature.The transmission spectrum of the MZI based on TCF with the different length as shown in Fig.3(a),(b).It can be seen clearly from the figure that the dips number increase in the same wavelength range with the length of the TCF increasing, which means that the free spectral range(FSR)of the interference fringe is decreased with the length of TCF increasing.The FSR can be expressed as

(5)

The figure also exhibited that the three cores mode were participated the interference with the different length of the triple-core fiber.We Fourier transformed the spectra to the spatial frequency domain as shown in Fig.3(c), and thus made it straightforward to observe whether the three core modes were involved in the interference.From the Fig.3(c), the three peaks in the frequency spectrum manifests that the three core modes participate in the interference process.

Fig.3 Transmission spectrum of the MZI based on TCF(a)L=40 cm,(b)L=50 cm and(c)is spatial spectrum

From the Equation(1)~(4)andn1=n3>n2, the sensitivity can be defined as

where

According to the same calculation method, the sensitivity of the two core fiber based interferometer can defined as

By contrast, the sensitivity of the three-core fiber interferometer isFtimes that of the two-core fiber interferometer

In view of the above-mentioned initial conditions are obtain

According to the above calculation,F>1.That is to say the sensitivity of the three-core fiber interferometer is at least twice as high as the twin-core fiber in the same conditions.

2 Experiments and results

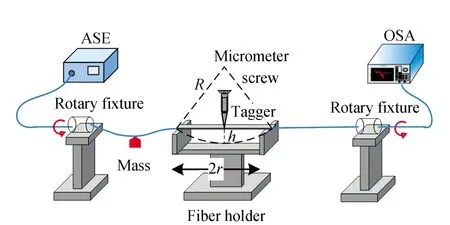

The vector curvature characteristics of the MZI based on TCF was measured by the experimental setup as shown in Fig.4.

Fig.4 Schematic of the experimental setup for vector curvature sensing

The two ends of the TCF were placed in the groove of the fiber holders and the one of the taper was ensured in the middle of the holders.A tagger was put in the groove of the fiber holders to cover the sensing region of the TCF.There have two rotary fixtures on both sides of the fiber holders with rotation angle of 0°~360°, which is 5° with the minimum scale value.In order to keep the fiber next to the tagger, we need hung a small weight between the fiber holders and rotary fixture during the curvature process.By rotating precise micrometer screw, the MZI based on TCF was bended with the tagger.The curvature of the sensing can be calculated byc=2h/(h2+r2), wherehis the displacement of the curvature at the center of the tagger, andris the half-distance between the two grooves.In this experiment,Lis about 40 cm and the displacement ofhis 1 mm at every time.We used that the source is a broadband light source with 1 550 nm and the spectral range is 1 520~1 610 nm.The interference spectrum of the MZI sensor was monitored by an optical spectrum analyzer(OSA)with 0.2 nm resolution.

The vector curvature characteristics of the sensor based on TCF were tested at the room temperature with different curvature directions at 0°,90°,180° and 270°.We supervised the two different dips at wavelength of 1 551.76 nm and 1 580 nm with the different curvature and the curvature range was 0~2.54 m-1.According to the location of the three cores in TCF, we defined the vertical direction of the three cores in the same plane as 0°.With the change of the curvature, the interference spectrum variations are shown in Fig.5 at 0°, 90°, 180°and 270°.From the figure, the interference spectrum proceed blue shift at the curvature direction of 0° and red shift at the curvature direction of 180°.The reasons of this result are the change of the optical path difference between the cores of TCF.At the curvature direction of 90° and 270°, the optical path difference between the cores always keeps constant due to the three cores are just in the neutral plane of the curvature.Therefore, the wavelength shift of the dips are minute during the curvature process.

The vector curvature characteristics of the sensor based on TCF were tested at the room temperature with different curvature directions at 0°,90°,180° and 270°.We supervised the two different dips at wavelength of 1 551.76 nm and 1 580 nm with the different curvature and the curvature range was 0~2.54 m-1.According to the location of the three cores in TCF, we defined the vertical direction of the three cores in the same plane as 0°.With the change of the curvature, the interference spectrum variations are shown in Fig.5 at 0°, 90°, 180°and 270°.From the figure, the interference spectrum proceed blue shift at the curvature direction of 0° and red shift at the curvature direction of 180°.The reasons of this result is the change of the optical path difference between the cores of TCF.At the curvature direction of 90° and 270°, the optical path difference between the cores always keeps constant due to the three cores are just in the neutral plane of the curvature.Therefore, the wavelength shift of the dips are minute during the curvature process.

Fig.5 Interference spectrum shift of the MZI based on the TCF with different curvature at(a)0°,(b)90°,(c)180° and(d)270°

The two different dips at wavelength of 1 551.76 nm and 1 580 nm to corresponding curvature at 0°, 90°, 180°and 270° are plotted in Fig.6.It can be seen clearly that the curvature sensitivity is directly related to the curvature direction and the wavelength shift of two dips are linearly dependent with the curvature.At the curvature direction of 0°, the wavelength shift of the two dips are moving toward the shorter wavelength as the curvature increasing and the curvature sensitivities relative to the two dips are-24 and-29 nm·(m-1)-1, respectively.At the curvature direction of 180°, the wavelength shift of the two dips are moving toward the longer wavelength as the curvature increasing and the curvature sensitivities relative to the two dips are 41.09 and 39.28 nm·(m-1)-1, respectively.

From the above data in the figure, it can be seen that the two wavelengths are different at the same curvature direction, because of the energy coupling between the cladding modes.The bandwidth of the broadband source used in the experiment is about 90 nm.In Fig.6, the wavelength of the dips was recorded at the curvature distance increases by 1 mm.According to the sensitivity of the measurement, the wavelength shift of the dips were stable at the curvature direction of 90° and 270°, so the wavelengths are within the detectable spectral range and only a few wavelengths can be monitored at the curvature direction of 0°and 180°.

The strain characteristics of the TCF-based MZI was monitored in the temperature range of 0~877 με.The wavelength of the dip at different strain are plotted in Fig.7.The wavelengths of the dip move toward the longer wavelength as the strain increasing and the strain sensitivities of dip is 0.68 pm/με.It can be seen from the experiment that the curvature of the proposed MZI has little influence on its strain response, and the simultaneous measurement of curvature and stress can be realized.

Fig.7 (a)Interference spectrum shift of the MZI based on the TCF with different strain at 0~877 με(b)Wavelengths shift of dip with different strain from 0~877 με

3 Conclusions

In this paper, we discussed and verified a vector curvature sensor based on MZI by TCF.The structure of the MZI is formed by SMF-TCF-SMF joint.The single mode fiber is used to introduce the beam into the middle core of the three-core fiber, and the beam enters the two side cores through the coupling of the taper, then the MZI is formed from the second taper.Due to the optical path of the two cores changed as the curvature increases or decreases, the variation of optical path difference caused the spectrum wavelength shift.The direction of curvature can be determined by detecting the wavelength shift direction.The experimental results show that the maximum curvature sensitivities of the MZI based on TCF can reach-29.07 nm·(m-1)-1at curvature direction of 0° and 41.09 nm·(m-1)-1at the direction of 180°, and the vector curvature sensing can be realized.This sensor has many advantages of high sensitivity, simple structure, easy fabrication and low cost.