Current state and suggestions for mechanical harvesting of corn in China

XIE Rui-zhi,MING Bo,GAO Shang,WANG Ke-ru,HOU Peng,LI Shao-kun

Institute of Crop Sciences,Chinese Academy of Agricultural Sciences/Key Laboratory of Crop Physiology and Ecology,Ministry of Agriculture and Rural Affairs,Beijing 100081,P.R.China

Corn (Zea maysL.) accounts for the largest shares of planting area and total yield of grain crops in China. Corn production has played a significant role in the country’s development of agriculture and national economy.Harvesting requires the largest amount of manual labor in the entire corn production process,accounting for about 50–60% of the total labor input. Thus,the development of mechanized corn harvesting can greatly improve the labor efficiency of corn production (Yanget al.2016;Cuiet al.2019). Mechanical harvesting of corn grains is a common component of modern corn production. Most developed countries have already achieved a high level of mechanization in corn harvesting. For example,almost all corn were harvested mechanically by the 1970s in the United States. However,the development of corn mechanical harvesting was relatively late in China.The percentage of the crop harvested mechanically was only 1.9% in 2003,increasing to 10.5% in 2008,49% in 2013,and 75.85% in 2018. At present,mechanical corn harvesting in China mainly involves the harvesting of ears,not grains. As of 2015,the proportion of mechanical grain harvesting was <5% and in 2019,the proportion was still <10%. Furthermore,the higher the cost of drying,threshing and labor input,the greater the mildew risk that needs to be solved. The low proportion of mechanical grain harvesting in China has led to a bottleneck in the continuing development of the industry (Department of Agricultural Mechanization Management 2003–2018)Ministry of Agriculture and Rural Affairs 2003–2018;Nanjing Institute of Agricultural Mechanization 2003–2018).

Agricultural mechanization is an important part of agricultural modernization and development. Mechanical harvesting,especially grain harvesting,is the most difficult mechanized component of corn production and has received widespread attention from the agricultural industry (Liet al.2012). In 2014,selection and breeding of corn varieties suitable for mechanical grain harvesting was initiated by a Chinese National Joint Research Project on improved corn varieties. In 2016,the National Key Research and Development Program of China funded a study on addressing the problems related to mechanical corn harvesting (No.2016YFD0300300). Additionally,the National Corn Industry Technology System regards the research and development of corn mechanical grain harvesting technology as its key research goal. It employs experts in relevant fields,such as germplasm resources and corn breeding,corn cultivation,corn harvesting machinery,plant protection,and agricultural economics,to conduct the research. Research has shown that poor harvest quality is the main factor limiting the popularization and application of mechanical corn harvesting technology in China. The main factors affecting harvest quality are the high grain moisture content at harvest and the harvest loss from fallen ears caused by lodging (Xueet al.2018;Liet al.2021).

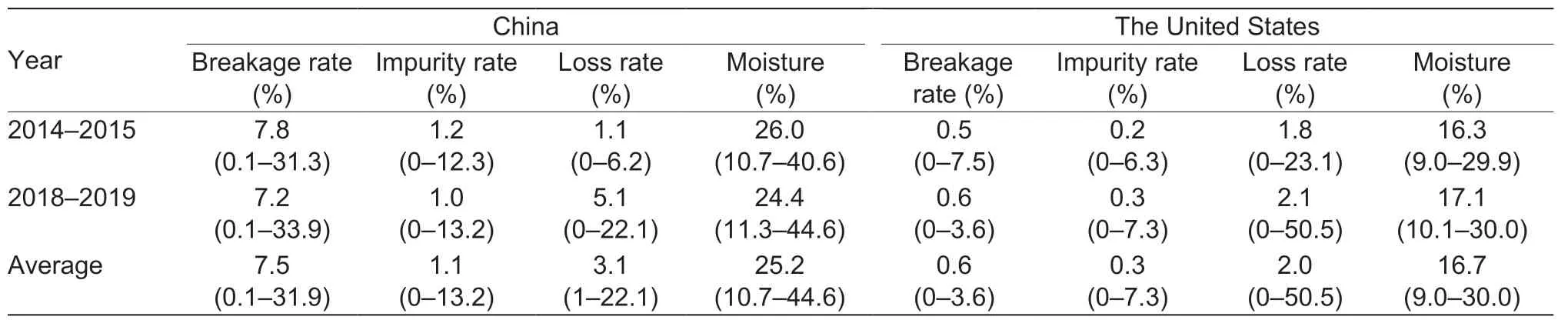

Mechanical corn harvesting technology has attracted continuous attention and investment. Varieties suitable for mechanical grain harvesting have gradually appeared and matured,and have been increasingly promoted and used,leading to an improvement in harvesting machinery.Other technological improvements,such as the matching of variety characteristics with regional meteorological resources,innovation in cultivation management technology,investment in storage and drying facilities,the development of other key technologies,and the adoption of mechanical grain harvesting technology in different regions,have also significantly improved the quality of the harvested grain. From 2012 to 2015,1 698 groups of corn harvest quality data were obtained from 168 plots located in 15 major corn-producing provinces and autonomous in China(Wanget al.2021). The results showed that the average values for grain moisture content,breakage rate,impurity rate,and loss rate were 26.83%,8.63%,1.27% and 4.12%,respectively. The main factor that contributes to the high breakage rate is the high grain moisture content (Chaiet al.2017). Additionally,in the study of 465 and 436 field test samples in 2018 and 2019 (Wanget al.2021),the average grain moisture contents,breakage rates and impurity rates were 24.4%,7.2% and 1.0%,respectively (Table 1;reanalysis of the data of Wanget al.(2021)),all of which have decreased in China in recent years,compared to their respective values of 26.0%,7.8% and 1.2% in 2014–2015(Table 1),resulting in improved harvest quality overall.

The United States has developed the world’s most advanced mechanical corn grain harvesting technology and has achieved a high degree of corn harvesting mechanization and automation. Generally,after corn reaches physiological maturity,the grain is allowed to dry in the field for 2–4 weeks before harvesting to acquire the low grain moisture content (15–18%). According to theAnnual Corn Harvest Quality Reportreleased by the U.S.Grains Council (2014–2019),the average of grain moisture content,breakage rate and foreign material rate (impurity rate) of harvested corn samples in the United States were 16.7,0.6 and 0.3%,respectively(Table 1). Although the measurement methods and standards for breakage rate and impurity rate differ between China and the United States,the average values of the measurements are much higher in China than in the United States. Therefore,it is necessary to improve the quality of mechanical harvesting in China.The State Council has estimated that by the end of 2020,nearly 100% mechanization of corn and other major food crops should be realised in China. Mechanical grain harvesting technology had been fully adopted in Europe,the United States and other advanced countries by the 1970s,and continuously improved over the next 40 years (Aljalilet al.1980;Plett 1994),which was mainly contributed by research on machinery and equipment,innovations in production technology and the selection of corn varieties suitable for mechanical grain harvesting. In Europe and the United States,the relatively uniform climatic conditions and single-season planting system of corn provide sufficient time for grain dry-down before harvesting. However,there are many corn planting models in China,in order to adapt the extensive corn planted areas and diverse geographical and ecological environments. Due to constraining factors such as natural,social and economic considerations,the popularization and application of mechanical corn grain harvesting technology is more complicated in China than in other parts of the world.

Table 1 Comparison of the mechanical harvesting quality of corn grown in China and the United States in 2014–2015 and 2018–20191)

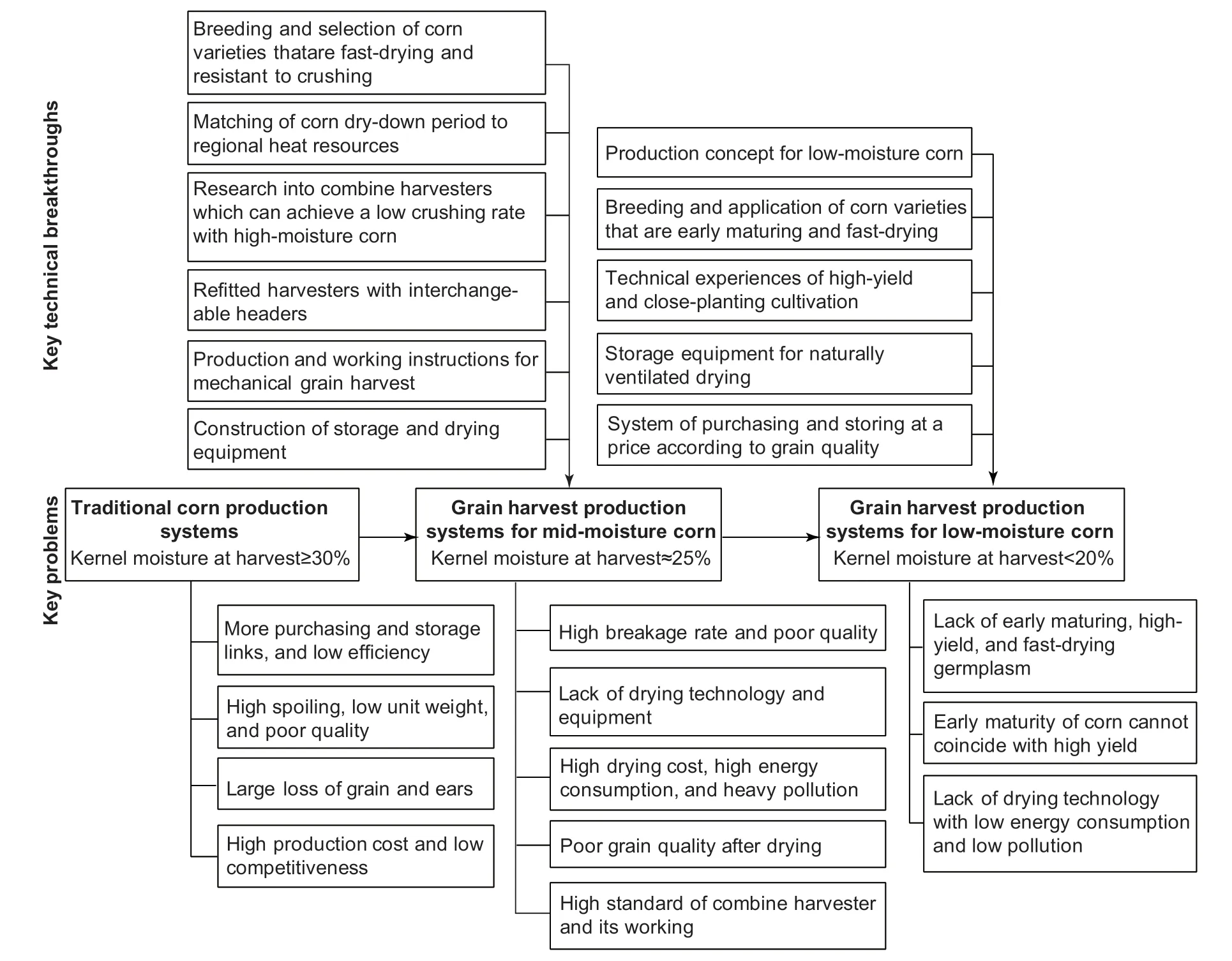

The transformation to mechanical corn grain harvesting production system involves various factors such as plant varieties,equipment,management,drying,storage,and sales (Liet al.2012). A comprehensive analysis of the current corn production conditions and the development of foreign corn harvesting technology showed that the promotion of mechanical grain harvesting technology in China should be based on currently-used domestic corn varieties and management technologies (Chaiet al.2017). The direction of future development for mechanicalharvesting of corn in China is to analyze and identify the limiting factors,conduct research on the main restrictive techniques,popularize technological concepts,and transform corn production methods. In the years 2010–2020,corn production system in China gradually shifted from the“traditional production system”to a“mid-moisture grain harvesting production system”. In the future,a“lowmoisture grain harvesting production system”should be developed as soon as possible in order to improve the quality of mechanical corn grain harvesting in China (Fig.1).

Fig.1 Obstacles and technical requirements for implementing mechanical corn grain harvesting technology in China.

In order to better promote the application of mechanical corn grain harvesting technology in China,the following aspects should be strengthened:

(1) Breeding of new varietiesThere is a large gap between the former yield-oriented breeding goal and the current demand for mechanical grain harvesting in China.There is also a lack of high-quality corn germplasm such as early maturing,density-tolerant,high-yielding,fastdrying,and highly disease resistant breeding materials.Based on the regional ecological conditions,optimizing the distribution of varieties can basically meet the current production needs. However,in the long-run,the most fundamental way to promote the application of mechanical corn grain harvesting in China is to breed varieties that are early-maturing,high-yielding,fast-drying,densitytolerant,stress-resistant,lodging-resistant,and crushingresistant (Fenget al.2018;Wanget al.2020).

(2) Improving the quality of machineryThe moisture content of corn grains is high during harvesting,which necessitates more stringent requirements on key components of harvesting,such as corn picking and harvesting headers,threshing and cleaning systems,and requires the wide adaptability of machinery to reduce the rate of grain breakage and loss. In addition,the operating conditions in fields vary greatly across China. In the Huang-Huai-Hai Region and Southwest China,there is a general demand for harvesting machines that can be used to harvest different types of crops,which places stringent requirements on the manufacturing and quality of the machinery (Genget al.2016;Pan 2016). Statistics show that during the 10 year period from 2008 to 2017,the number of corn harvesting machines in China increased 10-fold and the number of self-propelled harvest machines increased 20-fold. However,research and development on new harvesting equipment adapted to different regions and different production methods in China is insufficient,and there is an urgent need to improve the reliability and adaptability of corn harvesting machinery.

(3) Integrated production technologyThe application of mechanical grain harvesting technology will lead to major changes in the way that corn is produced. Research and development into mechanical harvesting technologies should be adapted to match local production methods and ecological conditions (Liet al.2017;Gaoet al.2021).At present,the development of corn grain harvesting technology in China is not uniform between regions. In the single cropping regions of Northeast and Northwest China,key factors affecting mechanical grain harvesting are tillage pattern,planting pattern,variety maturity,and lodging. In the Huang-Huai-Hai Region,where multiple crops are planted each year,the problems that influence the harvesting operations are the distribution of heat resources among multiple crops,the matching of varieties to heat resources,the development of machinery suitable for high-moisture-content corn,and drying and storage conditions. Additionally,in Southwest China,there is also a need for high-quality harvesting machines suitable for small fields. With recent advances in social and economic development,research and development on mechanical grain harvesting technology should focus on factors such as plant variety configuration and sowing time at different production scales,operating time of the machinery and harvest efficiency improvement.

(4) Formulation of technical standardsThe application of mechanical corn grain harvesting technology involves many aspects of the corn production industry. Standardization of operating procedures and grain quality can promote technical coordination and cooperation,ensuring an appropriate application of the technology. For example,the Chinese national standard,“Corn Combine Harvester”(GB/T 21962–2020 2020),requires that the field planting lodging rate should be <5% for corn grain harvester. At present,locations such as Heilongjiang,Liaoning,Jilin,Ningxia,Gansu,Henan,Hebei,and Inner Mongolia have formulated and promulgated local standards and technical regulations related to mechanized corn grain harvesting. Henan Province has also put into effect technical regulations for mechanical corn grain harvest production. The formulation of standards should be adapted to the socioeconomic conditions and industrial development needs. Liet al.(2018) showed that grain breakage rate,impurity rate and loss rate are all significantly influenced by the moisture content of corn grain (Fig.2). However,the standard for grain moisture content at harvest is generally set at 25% or even 28% due to the limitations imposed by corn varieties,machinery and production conditions. Furthermore,there are differences in the standards and testing methods for the quality of mechanically harvested corn between the United States and China,and the Chinese standards for harvest quality and variety selection need to be further improved (Genget al.2016). Additionally,it is necessary to establish operable evaluation and supervision systems (e.g.,those evaluating the efficiency of harvesting equipment,the quality of equipment operation and harvest quality) to promote the standardization of harvesting technology.Monitoring harvest quality and disseminating harvest quality reports provide support for the development and promotion of corn grain harvesting technology.

Fig.2 Relationships between grain moisture content and breakage rate,impurity rate,grain loss rate,and ear loss rate in harvested corn in China (Li et al. 2018).

(5) Improving the industrial chainAccording to previous research reports (Department of Agricultural Mechanization Management 2003–2018;Nanjing Institute of Agricultural Mechanization 2003–2018),in China,the proportion of moldy grains after harvest is generally>2% due to improper moisture control,which leads to significant yield loss. Currently,the proportion of grain that is mechanically dried in China is <10%,which is dramatically less than the 95% rate found in developed countries. Moreover,the average moisture content of grains harvested in China is about 26%,which is nearly 10 percentage points higher than that in the United States.Additionally,the existing drying technology in China is costly to operate,has high energy consumption,and emits significant amounts of pollutants,which is not conducive to long-term sustainable development. Attention should be paid to the technical requirements for reducing grain moisture content at harvest and for developing environmentally friendly drying technology. Exploring the business model of the whole industrial chain,including drying,processing,storage,and sales after harvest,as well as establishing a quality-based collection and storage system,will help guiding the direction of variety breeding and will be conducive to the transformation of corn production technology and management habits.

(6) Policy support and personnel trainingUnder the corn production conditions that presently exist in China,the main component of mechanical corn harvesting technology is a new type of agribusiness.Studies have shown that factors such as education level,information acquisition,non-agricultural income share,planting scale,operational performance,and government subsidies have significant effects on the adoption of corn mechanical harvesting technology (Hou 2008). Even with the same equipment,harvest quality can vary greatly due to the operator’s ability,and the harvest quality directly affects the farmers’ willingness to adopt mechanical harvesting technology (Department of Agricultural Mechanization Management 2003–2018;Nanjing Institute of Agricultural Mechanization 2003–2018). Making full use of policy tools such as subsidies,promoting land transfer,building demonstration bases,subsidizing harvesting,subsidizing drying machinery and operations,and strengthening technical training,will effectively promote the popularization of mechanical corn harvesting technology.

At present,China is in a critical period of transition from traditional agriculture to modern agriculture.Development of the corn industry urgently requires the adoption of key technologies such as grain harvesting technology. Identifying the bottlenecks in technology promotion and formulating targeted solutions can promote the application of corn mechanical harvesting technology and improve the market competitiveness of corn production (Xuet al.2018). A number of local and trade standards for mechanical harvesting have been formulated and publicized. For example,“mechanical corn grain harvesting technology with a low grain breakage rate”was selected by the Ministry of Agriculture and Rural Affairs (MARA) as one of the top 10 leading agricultural technologies in China in 2018 and 2019;“high efficiency production technology for mechanical grain harvesting of corn”was selected by the MARA as one of“China Agricultural New Rural Technologies”in 2020. Mechanical corn harvesting technology has passed its initial development stage and is soon expected to enter a period of rapid development.Mechanical harvesting,as presently done for wheat and rice,will soon become a standard practice for corn in China.

Acknowledgements

We thank the National Key Research and Development Program of China (2016YFD0300110),the National Natural Science Foundation of China (31971849),the China Agriculture Research System of MOF and MARA (CARS-02-25) and the Science and Technology Innovation Project of Chinese Academy of Agricultural Sciences for their financial support.

Declaration of competing interest

The authors declare that they have no conflict of interest.

Journal of Integrative Agriculture2022年3期

Journal of Integrative Agriculture2022年3期

- Journal of Integrative Agriculture的其它文章

- Cotton cultivation technology with Chinese characteristics has driven the 70-year development of cotton production in China

- Recent advances in plant immunity with cell death:A review

- Locus TUTOU2 determines the panicle apical abortion phenotype of rice (Oryza sativa L.) in tutou2 mutant

- The removal of nitrate reductase phosphorylation enhances tolerance to ammonium nitrogen deficiency in rice

- Fine mapping and genetic analysis of resistance genes,Rsc18,against soybean mosaic virus

- Improvement in winter wheat productivity through regulating PSII photochemistry,photosynthesis and chlorophyll fluorescence under deficit irrigation conditions