A ‘‘One Engine with Six Gears” System Engineering Methodology for the Economic Development of Unconventional Oil and Gas in China

Guoxin Li, Chenggang Xian*, He Liu

a State Key Laboratory of Petroleum Resources and Prospecting, China University of Petroleum (Beijing), Beijing 102249, China

b PetroChina Qinghai Oil Co., Ltd., Mangya 817500, China

c PetroChina Research Institute of Petroleum Exploration & Development, Beijing 100083, China

Keywords:Unconventional oil and gas resources System engineering Methodology transformation Life-cycle management Geoscience-to-engineering integration

A B S T R A C T Unconventional oil and gas resources have become the most important and realistic field for increasing China’s domestic oil and gas reserves and production.At present,the production scale does not match the massive amount of resources and the rapid growth of proven geological reserves.The challenges of technology, cost, management, and methodology restrict large-scale and economic development. Based on successful practices,a‘‘one engine with six gears”system engineering methodology is put forward,which includes life-cycle management, overall synergy, interdisciplinary cross-service integration, marketoriented operation,socialized support,digitalized management,and low-carbon and green development.The methodology has been proved to be effective in multiple unconventional oil and gas national demonstration areas,including the Jimusar continental shale oil demonstration area.Disruptive views are introduced—namely, that unconventional oil and gas do not necessarily yield a low return, nor do they necessarily have a low recovery factor.A determination to achieve economic benefit must be a pervasive underlying goal for managers and experts. Return and recovery factors, as primary focuses, must be adhered to during China’s development of unconventional oil and gas. The required methodology transformation includes a revolution in management systems to significantly decrease cost and increase production, resulting in technological innovation.

1. Introduction

After more than a decade of effort, major breakthroughs and progress have been made in China’s development of unconventional oil and gas, the gap in primary technology between the United States and China has rapidly narrowed, and the specifications of many individual technological devices have reached mainstream levels in the United States[1-20].However,the disparities in the development scale of unconventional oil and gas between China and the United States remain substantial, despite the massive resources of unconventional oil and gas underlying China[21]. In addition, the cost per barrel of some Chinese unconventional oil and gas projects remains high, and the capacity to prevent risks and the potential for sustainable development in China remain to be improved[21-23].This paper proposes a‘‘one engine with six gears” system engineering methodology to support the large-scale and economic development of unconventional oil and gas resources in China.

2. Current status of and challenges in China’s exploration and development of unconventional oil and gas

China has abundant unconventional oil and gas resources.Based on the national oil and gas resource assessment in the 13th Five-Year Plan,China’s onshore shale oil resources are as high as 2.83×1010t and its tight oil resources are 1.39×1010t.By the end of 2020,the known geological reserves of shale oil and tight oil were 7.580×108and 2.758×109t,respectively;the onshore shale gas resources were 1.22×1014m3,and the technically recoverable resources of shale gas were 2.2×1013m3[1-13].In addition,China has ample tight gas and coalbed methane reserves [1-13].

Unconventional oil and gas resources have become the most important and realistic field for increasing China’s domestic oil and gas reserves and production. In 2019, China’s domestic unconventional oil and gas production reached 7.668 × 107t of oil equivalent,accounting for 23%of total oil and gas production,of which unconventional gas accounted for 35% of total gas production (including 4.10 × 1010m3of tight sandstone gas,1.54×1010m3of shale gas,and 5.90×109m3of coalbed methane)and unconventional oil accounted for 11% of total oil production(including 2.3 × 106t of tight oil, 1.5 × 106t of oil shale oil,1.5×107t of heavy oil,and 2.0×106t of oil sand)[3-11].According to the China National Energy Administration’s 2022 National Energy Working Conference, as announced on 24 December 2021, China’s domestic shale oil and shale gas production and coalbed methane utilization respectively reached 2.4 × 106t,2.3 × 1010m3, and 7.7 × 109m3by 2021.

The proportion of unconventional oil and gas production out of the total domestic oil and gas production increases year after year.The annual production increase and the increasing annual rate of tight oil and gas and of shale oil and gas outweigh those of conventional oil and gas. Unconventional oil and gas are becoming increasingly important in ensuring the domestic oil and gas production base and safeguarding the national oil and gas supply.However, critical challenges in technology, cost, management,and methodology constrain the further development of China’s unconventional oil and gas resources.

2.1. Technological challenges

The unconventional oil and gas resources that are mainly continental facies in China present tremendous technical challenges in economic unconventional oil and gas development. Typical challenges are classified as follows:

● A lack of solid understanding of the fundamental geology and difficulty setting up a standard for categorizing the‘‘sweet area” laterally and ‘‘sweet interval” vertically[6,7,21-23];

● Significant obstacles in horizontal drilling, particularly in terms of the low drilling-encounter ratio,long drilling cycle,and increase of rotary steering duration and economic cost,which restrict the extension and application of threedimensional(3D)horizontal well clusters[15,19,24-26];

● Complex lithologic characteristics,rock fabrics,multi-scale heterogeneities, and microscopic seepage mechanisms, as well as significant differences in the applicability of reservoir stimulation materials and associated technologies,which largely limit the effectiveness of volume fracturing and hinder the increase of well productivity and estimated ultimate recovery (EUR) [16-20,24-26];

● Complexity in constructing high-resolution, high-precision geological models of the highly heterogeneous and thinly interbedded formations, resulting in large uncertainties of precise well layout, production forecast, and multielement synergy in cube development with hybrid well configurations or multi-layer staggered horizontal wells,and large disparities in the adaptability of development plans and strategies;

● Due to weak data foundation, inadequate engineering experience, insufficient use of smart instruments and equipment, and the common existence of ‘‘data silos,”intelligent digital oilfields are insufficiently developed for sharing through the subsurface system, surface facility,gathering and transportation system,remote-work system,and decision-making system [11,23,27-29].

2.2. Cost challenges

Unconventional oil and gas development relies on continuous drilling to maintain and expand production, which requires the constant input of substantial resources, workforce, technology,and funding. Since unconventional oil and gas are considered to be low-grade and low-quality resources, continuously reducing the cost of barrel oil equivalent and consistently breaking through the cost limit are essential in order to reduce risks and improve the profit-earning capability.At present,the cost per barrel oil equivalent of developing unconventional oil and gas in China is high.The financial risk resistance of Chinese unconventional oil and gas projects is fairly weak, lagging far behind the requirements for large-scale and economic development [11,21-23]. According to a survey by the China National Petroleum Corporation (CNPC),under similar conditions of drilling depth and horizontal lateral length, the drilling cycle and well construction fee for shale oil development in China essentially exceeds its counterpart in North America. Taking shale oil projects as examples, by 2020, the lifecycle costs per barrel oil equivalent were 52, 72, and 97 USD,respectively, in the Chang-7 Formation of the Qingcheng Oilfield located at Ordos Basin, the Lucaogou Formation of the Jimusar Depression located at Junggar Basin, and the Kongdian Formation of Dagang Oilfield located at Cangdong Sag of Bohai Bay Basin. In comparison, the cost per 365-day produced barrels for all major unconventional liquid-rich basins in the United States has dropped below 50 USD and has generally been lower than West Texas Intermediate prices since 2017. The full cost per barrel oil equivalent reached new lows in 2020 [30].

2.3. Management challenge

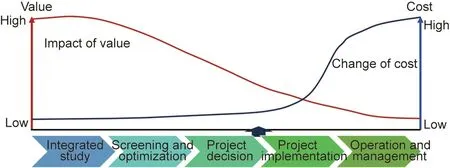

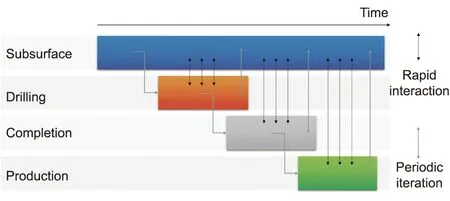

Life-cycle management with the asset project as the basic unit is an effective management model that has been demonstrated by long-term practice in international oil companies and is the most efficient organization methodology for unconventional oil and gas development. This model emphasizes the value impact of systematic research and development with sufficient investment at an early stage, in order to build a solid foundation to ensure an optimized life-cycle value curve of the asset project(Fig. 1) [31]. Thus far, the management methodology of sequentially relaying tasks among various disciplines and majors is still adopted in China’s unconventional oil and gas development projects,such that poor connections—or even disconnections—are present through different periods, processes, and links. Instant input,dynamic feedback,and timely adjustment mechanisms are incomplete; interdisciplinary interaction and integration are complicated; and the global optimization of the whole system cannot be ensured,although the local optimization of subsystems in specific disciplines can be done individually. The failure to realize lifecycle management results in a lack of timely adjustments and a need for integral optimization in rapid response to changes in the unconventional oil and gas industry (Fig. S1 in Appendix A).

2.4. Mentality and cognition challenges

Fig.1. Schematic value curve of asset projects.It should be stressed that consistent process is better than process. Reproduced from Ref. [31] with permission.

Unconventional oil and gas are relatively low-grade and lowquality resources, compared with conventional oil and gas. Still,they should by no means be characterized by a low recovery factor and low return. Domestic and international practices in the field show that unconventional oil and gas are quite capable of obtaining high recovery factors [32-37]. Large-scale economic development has been realized in North America by continuously lowering the cost per barrel oil equivalent in the intense oil price fluctuation market [30].

In China,many unconventional oil and gas development projects are assumed to result in a low recovery factor and low return when designing at the oilfield level—and even at the headquarters level.Such projects are often set with a low recovery factor of less than 10% and a low or even negative internal rate of return under high oil prices by default, as their leadership holds to thinking patterns of reductionism without integration and maintains an unchanging metaphysical mentality,which severely limit the space for innovation and further development[38].Generally speaking,among the four levels of challenges presented by unconventional oil and gas economic development in China, the technological challenges are the status quo, the cost challenges stem from preconceptions of the situation,the management challenges are the crux of the problem,and the mentality and cognition challenges are the root of the issue(Fig.2).Only by solving the mentality and cognition challenges can we realize the crux of management, adhere to bottom-line thinking about cost, implement life-cycle management, carry out whole-process optimization, and overturn the preconception of a high full cost. Therefore, we should apply innovative thinking as a guide and promote a revolution in management,with management transformation as a breakthrough point and key approach for the development of unconventional oil and gas. In this way, the scale and economic development of unconventional oil and gas in China can be accelerated,and we can ensure the domestic oil and gas supply, serve the national energy security strategy, and adapt to the national strategy’s new requirements of achieving peak carbon emissions and carbon neutrality.

3. The ‘‘one engine with six gears’’ methodology for unconventional oil and gas economic development

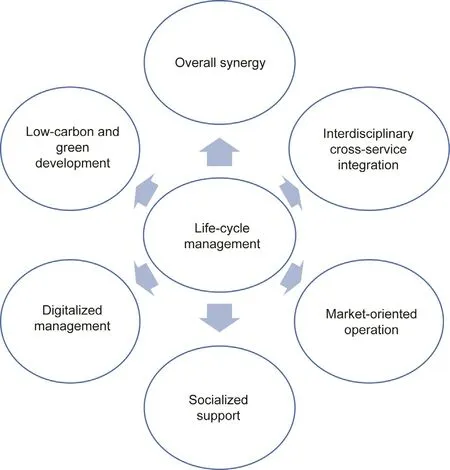

Based on the philosophy of system engineering,we put forward the ‘‘one engine with six gears” management methodology for unconventional oil and gas economic development in China’s oil companies. This methodology orchestrates life-cycle management with six elements: overall synergy, interdisciplinary cross-service integration,market-oriented operation,socialized support,digitalized management,and low-carbon and green development(Fig.3).

Different departments implement life-cycle management in stages during concrete operations, with the asset project as the fundamental unit. Spending should be examined and evaluated in detail from an overall process point of view in order to maximize the project’s key performance indicators (KPIs). Due to the unique subsurface characteristics and engineering constraints of unconventional oil and gas resources, project progress requires coordinated cooperation between various departments, disciplines, and systems, along with frequent interactions with the government,society,environment,and third parties.Knowledge and experience must be constantly accumulated and evolved. Steady progress in technology and management is required, based on an iterative learning curve. Rapid and proactive adjustments should be made in response to dynamic changes in critical requirements [39-44].Beginning with the exploration stage and top-level design, this methodology concentrates on the aspects of technology, management, people, and markets using holistic and dialectic thinking,in order to promote optimization and innovation in the planning,processes, and management mechanism. The proposed methodology aims to create an attractive environment for targeted and adaptive technological innovation and for the achievement of breakthroughs to resolve main technical bottlenecks, in order to promote efficiency,effectiveness,and economic benefits in unconventional oil and gas development in China.

3.1. Life-cycle management

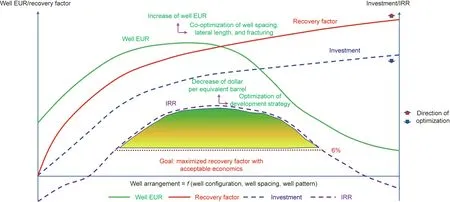

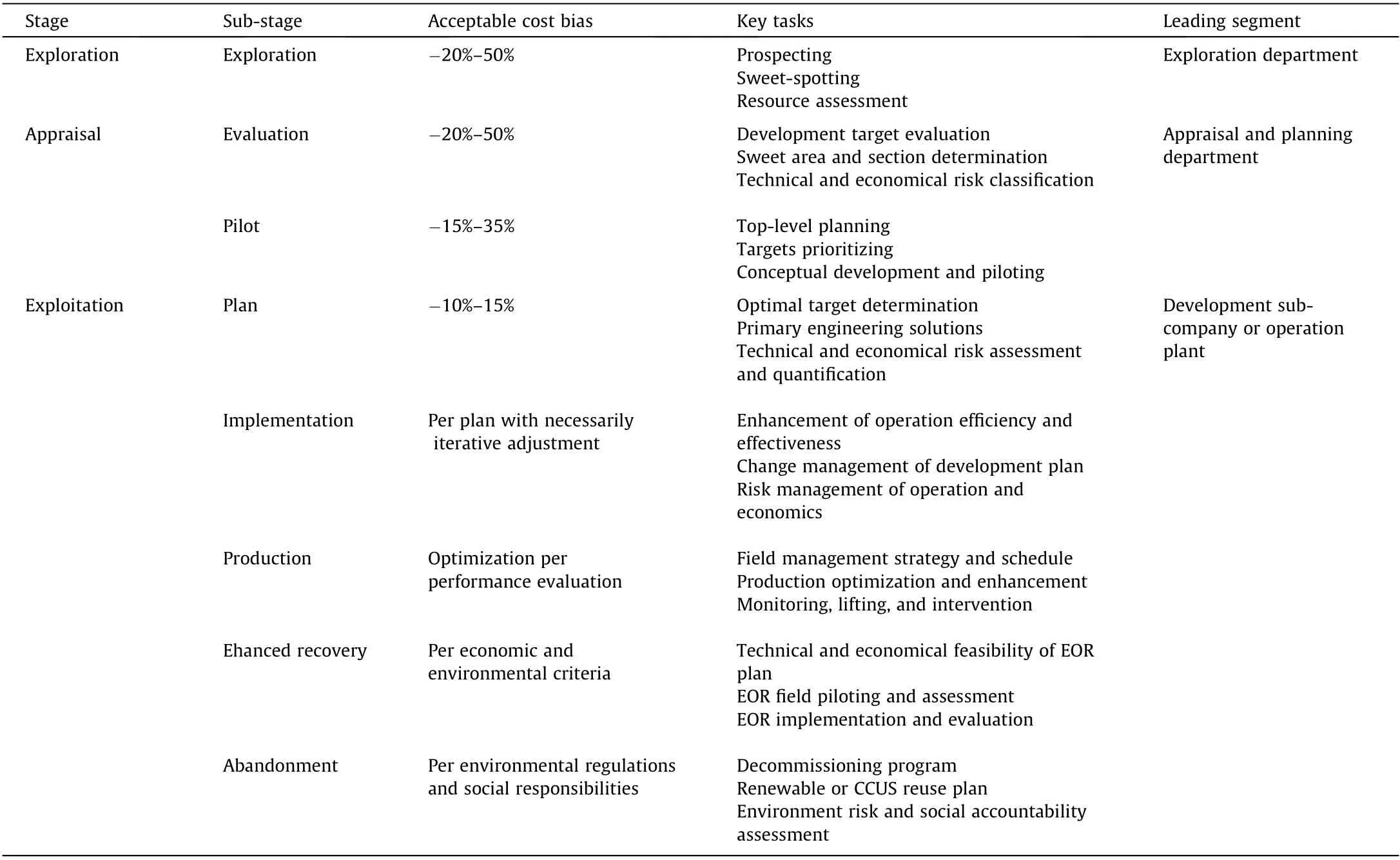

Life-cycle management involves achieving the ultimate goal of maximizing recovery throughout the entire process of the asset project, with acceptable economics (Fig. 4). Independent projects should be set up according to asset blocks, with clear boundaries during the implementation process.A forced backward mechanism starting from the bottom-line cost and return and recovery factors,which comprises a separated and independent project setting,investment budgeting, program evaluating, cost accounting, production metering,and return analysis,should be employed to forecast the benefit of the project in the life-cycle,with which integral management across leading segments can be realized throughout the optimization of the key tasks of all sub-stages,with acceptable cost biases from exploration to abandonment(Table 1).In this way,it will be possible to achieve an ideal situation with an optimal plan at the beginning, efficient implementation during operation,and excellent performance.

Fig. 2. The ‘‘challenge pyramid” for the four levels of unconventional oil and gas development in China.

Fig. 3. Diagram of the ‘‘one engine with six gears” system engineering methodology.

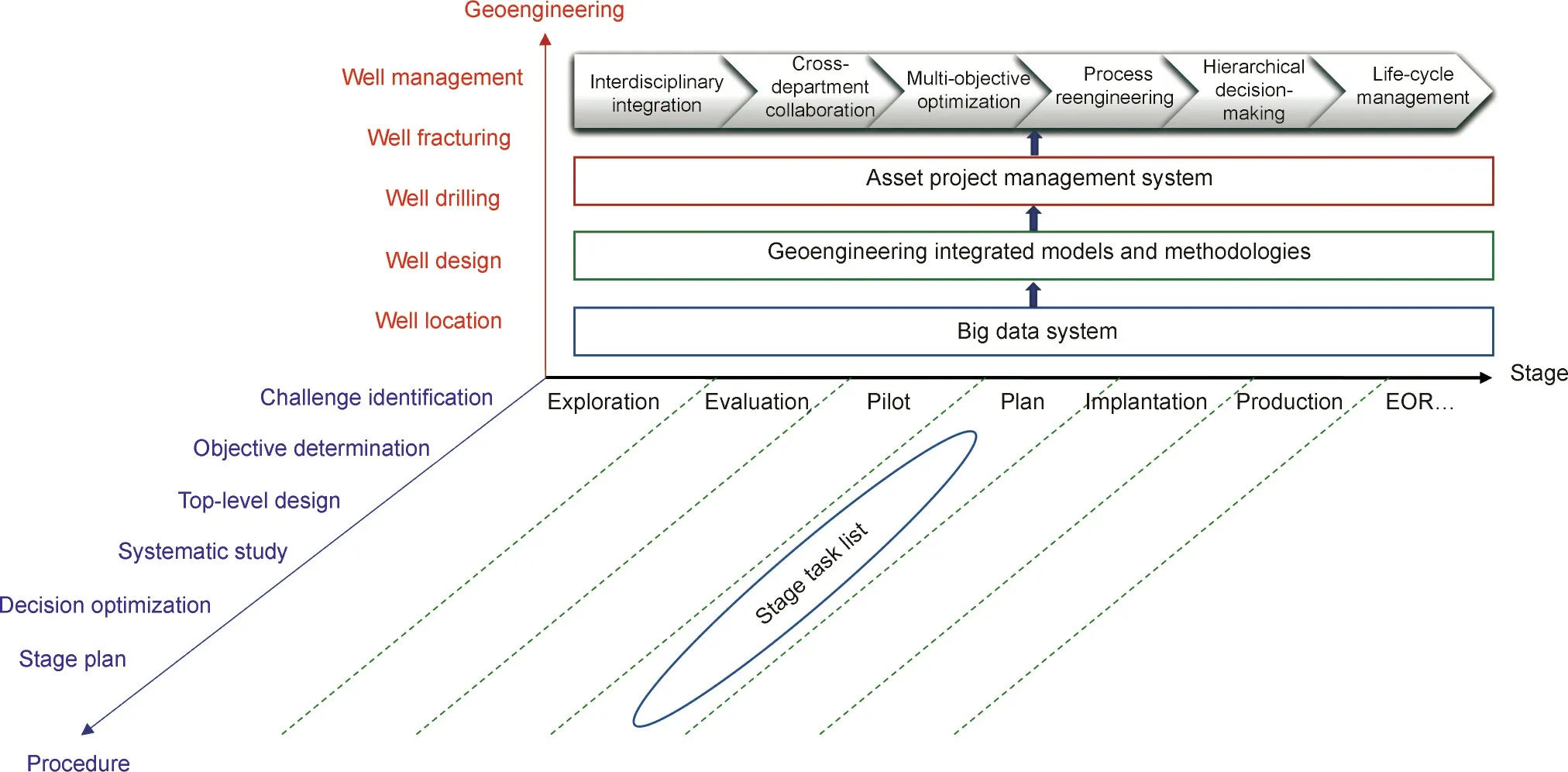

A development project of unconventional oil and gas, as a system,should investigates its integrity,hierarchy,complexity,openness, and dynamics from a system engineering point of view.Multiple disciplines and departments should be comprehensively coordinated in accordance with the‘‘point-line-area”methodology of unconventional oil and gas exploration and development, in which the ‘‘point” holds the key to technological problems, the‘‘line” ensures that the program can connect all stages and processes, and the ‘‘area” formulates schemes for implementation and application [45].All elements and stages, as well as the entire process,should be seamlessly connected based on data fusion and knowledge sharing. A systematic Wuli-Shili-Renli [46] learning curve should be constructed to form a reliable and efficient large-scale system with currently available theory and technology at the early stage, which can be shaped into a more efficient and outstanding system equipped with more advanced theory and technology in future. Hence, a universal conceptual model of lifecycle management is proposed, in which each stage is organized with clearly defined tasks (X-axis) and structured procedures(Y-axis) for the key processes of geoscience-engineering integration (geoengineering) (Z-axis), enabled by big-data- and artificialintelligence-supported optimization, in which geoengineering integrated models and methodologies support the global optimization of the asset project management system throughout interdisciplinary integration, cross-department collaboration,multi-objective optimization, process reengineering, hierarchical decision making, and life-cycle management (Fig. 5).

3.2. Overall synergy

Overall synergy is centered on the three core tasks of an asset project: controlling the resources, building the production capacity, and obtaining production. The interrelation and interaction between each subsystem in both the inner and external systems of the asset project should be considered when planning and designing the whole process. A novel functional management structure and execution model must be established to promote synergism across different systems, departments, disciplines,majors, and levels under the current management and functional design in state-owned oil companies (Fig. S2 in Appendix A).

Overall synergy includes six key components: exploration-toexploitation integration, geoscience-to-engineering integration,subsurface-to-surface integration, study-to-operation integration,production-to-management integration, and design-tosupervision integration.

Fig. 4. Recommended life-cycle optimization model for unconventional oil and gas development. IRR: internal rate of return; f: function.

Table 1 Life-cycle management framework for unconventional oil and gas development.

Fig. 5. A universal conceptual model of life-cycle management.

●Exploration-to-exploitation integration highlights headquarterlevel planning and the dynamic adjustment of development plans and implementation strategies according to current progress in exploration and appraisal, for improvement in decision-making efficiency and reduction of the project’s technical and economic risks. Fig. S3 in Appendix A [39]provides a general summary of the exploration-to-exploitation integration approach based on the practice and experience obtained from the Zhaotong National Shale Gas Demonstration Zone. The scientific and technical details of this general approach can be specifically defined according to different types of unconventional oil and gas.

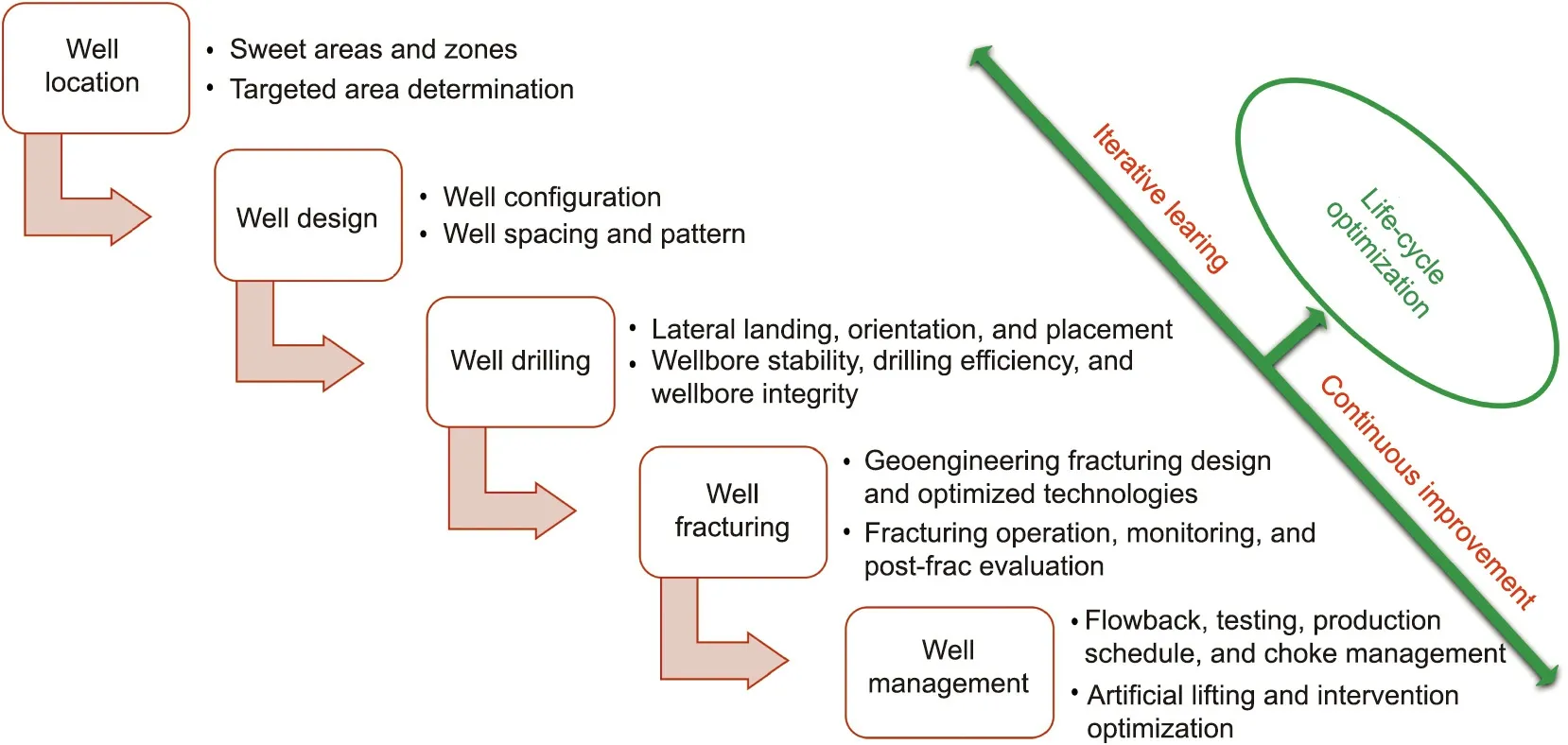

●Geoscience-to-engineering integration clearly defines the procedures and key factors during different operation stages in subsystems. It requires a breaking down both of the narrow focus on specific disciplines and of the obstacles between majors and management boundaries. Iterative learning is necessary in order to continuously improve the total system and subsystems and increase the rate of implementation, the technological effectiveness, and the operational efficiency. It also helps control geoscience uncertainty and reduce engineering risk to support the optimization of life-cycle management (Fig. 6) [39].

●Subsurface-to-surface integration refers to the impacts of human and geographical conditions on oilfield development. Environmental and ecological constraints on engineering complexity should also be examined, with maximizing the effective use of resources as the primary task. The overall situation should be taken into account—not only the fundamental infrastructure,such as the base, warehousing, water supply, electricity, and transportation, but also the coordination and dynamic flexibility of the surface subsystem, environment subsystem,and supply chain subsystem. The overall development plan should be strengthened as well,in order to improve the support capability of the project and reduce related costs [40].

●Study-to-operation integration refers to the establishment of a multidisciplinary integrated study team in the asset project to support the whole process of optimization from exploration to development. The study team should be deployed at the front lines and integrated closely into the subsystems, with team members frequently interacting with each other in order to make outstanding advancements and technical breakthroughs in phases, according to the significant demands and requirements from the field.In this way,the project’s deployment quality and engineering operation efficiency can be further improved(Fig.7).

●Production-to-management integration is responsible for the quality and key performance of the life-cycle management.Thorough design, process, and cost management measures should be taken at all stages, from headquarter-level design and project deployment to detailed engineering operation.With all these practices,improved economic benefits,cost reduction,an increased anti-risk capacity, and profitability can be expected [31,47-49].

●Design-to-supervision integration ensures the deployment and implementation of the overall project plan and rigorous execution and quality operation of all the technical programs, after systematic reasoning and decision-making have been gone through.The oil company must take charge of the process management and supervision,clearly assigning duties and responsibilities and providing rapid feedback and timely decisionmaking.

3.3. Interdisciplinary cross-service integration

An unconventional oil and gas development project usually involves multiple subsidiaries and departments comprising personnel from different majors and backgrounds, covering numbers of service teams, multiple professional processes, dozens of business activities, and hundreds of work procedures and workflows.Associated centralized camps, drilling and fracturing materials,communication networks, emergency materials, powergeneration equipment,logistics support,and external coordination are also included in the project. Therefore, technical plans and implementation procedures should be logically combined and streamlined, and service teams must be selected based on welldirected demands.With interdisciplinary cross-service integration,which features the sharing of relevant resources,technologies,and procedures [31,39-43], project efficiency and profitability can be expected to significantly improve, and the related serviceproviders’ interests can be protected. Fig. S4 in Appendix A provides a sketch of professional coordination for a hydraulic fracturing subsystem, which includes multiple processes divided into various activities and workflows.

3.4. Market-oriented operation

The decisive role of the market in resource allocation should be emphasized, and market-oriented operation should be vigorously organized and promoted in order to realize the large-scale and economic development of unconventional oil and gas in China[45,49].Treating unconventional oil and gas development in China as an extensive system,it is essential to promote the concept and mechanism of interest-/risk-sharing and ‘‘win-win” cooperation between operations and service-providers, as well as to cultivate a marketized environment with healthy competition. As the very first step, state-owned oil companies should thoroughly open up their internal technical service market among their subsidiaries.Then, the technological service markets of these state-owned oil companies should be gradually opened to each other. Finally, all state-owned oil companies should open the technical service market in the unconventional oil and gas domain to the public step by step.We should innovatively perfect the management mechanism and examine evaluation and commercialization models based on asset projects to ensure high-quality and highly cost-effective services. In this way, all related parties and players can grow and move forward together in order to decrease cost, increase benefit,and form a market-oriented cooperation paradigm.

Fig. 6. Geoscience-engineering integration: A recommended general process.

Fig. 7. A framework of multidisciplinary study and operation coalescence.

3.5. Socialized support

Lightweight operation supported by local government and society is an important measure to realize the economic development of unconventional oil and gas. In such development, the project model requires full use of professional services from social networks and the public to enhance the infrastructure support capacity, optimize supply-chain allocation, and win public support. A self-owned system, whether large or small, that is characterized by extreme comprehensiveness but lacks professionalism and a cost-effectiveness ratio should be avoided.Making full use of social support and seeking efficient and high-quality services from external sources should become a way of thinking and a pattern of project operation. Purchasing services or leasing should replace purchasing equipment and products, reliance on all available service providers should replace internal autonomy, and a part of the project’s investment should be transformed into cost to reduce the fixed assets investment as much as possible.

3.6. Digitalized management

Digitalization and digitalization-based intelligence are accelerating the transformation of society and industry. The corresponding revolution in organizational management structure, process optimization, and reconstruction has improved the rapidresponse ability, operation efficiency, and decision-making reliability of the oil and gas industry by several orders of magnitude.Shale gas and tight oil production in the United States nearly doubled in 2020 in comparison with 2014, and digitization and intelligence played a crucial role in improving labor productivity and efficiency and significantly reducing costs [50,51].

The digitalization of China’s oil and gas industry is in the stage of rapid development [29]. In an unconventional oil and gas project, comprehensive digital construction should be based on digitalized oil and gas fields and big data systems to achieve knowledge perception and insights; automatic production; realtime surveillance, diagnosis, prognosis, and alerts; collaborative research; multi-level and multi-objective life-cycle optimization;integrated operation; energy conservation and carbon emission reduction; and intelligent decision-making. Hence, production,management-structure, operation-model, and reconstructedprocedure modes are more efficient and effective when driven by big data and artificial intelligence. Fig. S5 in Appendix A provides a suggestion for designing a digitalized management structure in unconventional oil and gas projects.

3.7. Low-carbon and green development

Low-carbon and green development is essential in the new era of the oil and gas industry.Compared with conventional oil and gas projects, unconventional projects face even more tremendous environmental and carbon reduction pressure, because those projects need continuous and high-intensity drilling and fracturing activities.Under the rigorous constraints of achieving peak carbon emissions and carbon neutralization, the concept of low-carbon and green development should be established and embraced in the unconventional oil and gas project at the very beginning. Harmony between oil and gas projects and environmental protection can be achieved through technological progress and management transformation.

Detailed requirements are listed as follows. ①The production process should be clean; environmental materials and clean production technology should be employed to reduce the waste from the source. ②Waste should be recycled; reuse of wastewater,solids, and gases should be ensured in order to establish a ‘‘zerowaste” project. ③Road and land use should be intensified; development platforms with large-scale well clusters should be vigorously promoted to realize the standardized, integrated, and preengineered construction of stations. ④Stations should be constructed ecologically;greening and restoring oil and gas field areas should be sped up. Carbon-sink forest and carbon neutralization programs should be carried out. ⑤Low-carbon industrial chains should be formed through a series of measures to promote the combination of unconventional oil and gas projects and carbon capture, utilization, and storage (CCUS), with the expected results of energy/water conservation, consumption reduction, and greenhouse gas/volatile organic compounds emissions control. The necessary measures include improving and upgrading the current technology and equipment, digital intelligent empowerment, the transformation of closed-loop operation processes, and green/new-energy substitutions in project construction and operation.

4. ‘‘One engine with six gears’’: A system engineering methodology for unconventional oil and gas development

Unconventional oil and gas development is a complex system formed by many interrelated,interdependent, mutually restricted,and interactive cross-disciplinary, cross-domain, and cross-level components. A system engineering methodology should be followed to realize the large-scale and economic development of unconventional oil and gas. The ‘‘one engine with six gears” concept is the concrete embodiment of a system engineering methodology for the practice of unconventional oil and gas development;this perspective can be broken down into four main aspects,which are detailed below.

4.1. ‘‘One engine with six gears”: Representing the integrity of the unconventional oil and gas development system

An unconventional oil and gas development project involves two main internal systems in a state-owned oil company: the exploration and production system and its subsidiary engineering service; and the external system. Each system can be further subdivided into many related subsystems.In terms of engineering and operation, the project involves activities related to planning, geology, appraisal, drilling, production, surface equipment and facilities, operation, maintenance, and other professional fields. In regard to management, the involved parties include design and research institutes, technical service providers, drilling and engineering sub-companies, development service and field construction sub-companies, production management, and functional departments. The external system involves the local government and citizens, external service enterprises, the environmental ecology, public infrastructure, logistics and transportation, material supply, and other stakeholders.

In the project,all parties work jointly and rely on each other to accomplish various tasks through overall synergy,interdisciplinary cross-service integration, and socialized support toward maximizing the project performance. An unconventional oil and gas development project is also a symbiotic system. Key elements of the project pass through stages of reformed and optimized integration to establish a mutualistic and symbiotic environment and to create a ‘‘one plus one is greater than two” synergistic effect. All the stakeholders must work together with tolerance, coordination,and win-win strategies to achieve a ‘‘butterfly effect” of common interests and self-development, embodying overall optimization and system engineering principles with integrity.

4.2. ‘‘One engine with six gears”: Achieving hierarchical coupling optimization of an unconventional oil and gas development system

An unconventional oil and gas development project includes several subsystems,such as drilling,completion,and sub-level elements and components. At the same time, the project itself is a subsystem of the entire system of oil and gas exploration and production in a giant state-owned company that serves the even larger and more complex system of national oil and gas supply security.Therefore, a distinct hierarchical system structure is formed.

The ‘‘one engine with six gears” methodology optimizes the hierarchical structure of the unconventional and gas development system with its universal features of cross-discipline integration,cross-domain collaboration, and cross-level interaction. The purpose of the methodology is to ensure that all the subsystems operate smoothly and in alignment, with high efficiency and high effectiveness for large-scale and economic development. Oil and gas exploration and development in China have entered an era that focuses on both conventional and unconventional resources.Unconventional oil and gas resources are the most realistic and crucial increment in stabilizing domestic crude oil production and expanding domestic natural gas production. Thus, they are the strategic choice for the long-term development of China’s oil and gas industry [6,7,9,10]. The proportion of unconventional oil and gas annual output from PetroChina and Sinopec will steadily increase year by year [11-13,19]. Improved project efficiency and effectiveness, barrel oil cost reduction, significantly improved recovery, and low-carbon and green oilfield development can be realized for the large-scale exploitation of resources and the steep increase of annual output through the guidance of the‘‘one engine with six gears” methodology.The growth space of unconventional oil and gas in China is expected to dramatically expand to firmly safeguard the interest of state-owned oil companies,in compliance with the requirements of national oil and gas supply security and the national carbon emission peak and carbon neutralization strategies.In addition,in regard to state-owned companies’development space, interest, and strategy, the ‘‘one engine with six gears” methodology achieves the hierarchical coupling optimization of the unconventional oil and gas development system.

4.3. ‘‘One engine with six gears”: Effectively dealing with the complexity of unconventional oil and gas development systems

Unconventional oil and gas have some inherent complexities,such as the qualitative and quantitative evolution of the integral and partial system and subsystems of unconventional oil and gas development, along with key elements involved in each step of production; and the uncertainty, nonlinearity, and fuzziness of interactions among subsystems and their key elements. Furthermore,unconventional oil and gas development in China has unique complexities. First, the multi-source, multi-facies, and multi-cycle subsurface characteristics of China’s unconventional oil and gas have presented great theoretical and technical challenges[6,7,22,23]. In particular, there is no precedent or direct analog for the development of Gulong shale oil, for which both theory and technology have been unexplored till now [26].

Second, the current management mode for unconventional oil and gas development adopts the conventional oil and gas development model, in which the departments responsible for a specific stage or period of the project are relatively isolated from each other. Staff and professionals within the same department that have different majors and are in different disciplines work separately from each other, with insufficient interaction. The management structure is vertical, with layers of refined sub-departments and sub-levels. Independent goals are set for each subsystem,sub-department, and sub-level at different stages or periods in the program plan(as shown in Fig.1).At the same time,for historical reasons, the internal business model between the exploration and production subsidiaries and the engineering and technology service subsidiaries of each state-owned oil company is relatively fixed, lacking flexibility.

Third, unconventional oil and gas development projects are constrained by the complex external environment;that is,it is necessary to consider the long-term stability of the oil and gas supply,the support for social and economic development, the capacity of the environmental ecology, and local infrastructure constraints.To address these complexities, the ‘‘one engine with six gears”methodology applies life-cycle management and overall synergy to accomplish overall temporal and spatial optimization and coordination between the whole project and its individual parts.Crossintegration is expected after the barriers between different disciplines,majors,and domains have been broken down through interdisciplinary cross-service integration. Market-oriented operation and socialized support can support the construction of symbiotic development between internal and external systems. The fundamental theory and technology system, organization management system, and knowledge and experience system can be seamlessly managed using digital technology, and can be united and synergized using the WSR approach [46]. The harmonious symbiosis of humans and nature can be realized, guided by the concept of low-carbon, green, and sustainable development.

4.4. ‘‘One engine with six gears”: Adapting to the openness of a complex system

The openness of the unconventional oil and gas development system to external environments and systems can be classified according to the following aspects. First, an unconventional oil and gas development project has a specialized development pattern; it is necessary to continuously reduce the barrel oil cost in order to improve the project’s capability to resist economic risks.Consequently, the theory and technology system and organization management system for unconventional oil and gas need to be iteratively updated and evolved. Second, continuous drilling is required to achieve the desired stable production at the field,basin,and industry level. Intensively uninterrupted workforce, technology, capital, and resources must be input, and a large amount of data and information, knowledge and experience, and theories and technologies must be output.Third,all subsystems,disciplines,majors,and domains must share data,knowledge,and experience,with feedback and further optimization.For example,the emerging cube development approach involving a large-scale multi-layer stacking well-cluster platform requires a transformation of the development concept and optimization mode; research into and development of innovative drilling, completion, and other engineering technologies; and the construction of an adaptive organization management system and associated processes[32,52,53].

Unconventional oil and gas development should fully adapt to the development trends and demand changes of society and industries, make full use of information technologies such as big data and artificial intelligence,and apply the advanced technology and organizational management experience of other industries to strengthen and enhance the learning ability of the unconventional oil and gas development system in order to more effectively and efficiently ensure large-scale and economic development. The‘‘one engine with six gears” methodology advocates a symbiotic win-win model for both the operator and the service provider of unconventional oil and gas development, with emphasis on constructing a new mode of organization and management and establishing various learning curves through iterative optimization,thereby meeting the requirement of openness in unconventional oil and gas development systems.

In a word, the ‘‘one engine with six gears” methodology is targeted at the integrity, hierarchy, complexity, and openness of unconventional oil and gas development systems, with the aim of addressing problems by grasping the nature of the problem and optimizing the system as a whole.‘‘One engine with six gears”is a comprehensively integrated system engineering principle and methodology with both qualitative and quantitative features. It synergizes multiple disciplines, the macrocosm and the microcosm,the parts and the whole,theory/technology and knowledge/experience, and engineering implementation and organizational management, to ensure effectively adaptive, accurately predictive,and scientific decision-making during the planning, deployment,and operation stages in unconventional oil and gas large-scale and economic development.All the participating members of such a project should be integrated, organized, and coordinated; they must start from the various parts while keeping in mind the big picture,and must strive to use the least possible workforce, material, and financial resources in order to optimize the overall target and the operation plan in the shortest possible time. Through systematic learning, theory and technology, organization management, and knowledge/experience, the systems must be constantly and iteratively evolved to achieve timely dynamic optimization of the life-cycle.

5.Case study:Jimusar continental shale oil demonstration zone

5.1. Project overview

The Jimusar Sag covers 1170 km2. The main breakthrough of this continental shale oil exploration occurred in 2010, and approval was subsequently granted to build the first national shale oil demonstration zone[54,55].After a tortuous ten years’journey with three major upheavals,by 2020, the demonstration zone had failed to achieve an overall breakthrough in scale and economic development because the technical and economic feasibility standard had not been achieved.

Since 2020,the PetroChina Xinjiang Oilfield Company has transformed its mentality and mechanism and has consciously applied the system engineering methodology of ‘‘one engine with six gears.” In 2021, decisive breakthroughs in management, technology, and economic indicators were made in the No. 58 tightspacing cube-development platform. The essence of technology and management for the full-scale economic development of this national demonstration zone were confidently considered to be captured during the process.

5.2.The main practices of the‘‘one engine with six gears”methodology

Based on the principle of backward design starting from the bottom-line oil price, and according to the requirements of the life-cycle management system, the demonstration zone carried out changes in all aspects of the organization’s structure, objectives, mechanisms, and evaluation measures management. Under the organizational structure of life-cycle management, a department responsible for the management of the shale oil asset project department was established to promote an overall synergy from technical solutions to program implementation and operation,following system engineering project management principles. This department is regarded as the core of the project. An integrated tradeoff is carried out from the management line and technical line between the stakeholders in terms of interest, technology, economy, safety and environmental protection, social responsibility,and other tasks.Full play is given to the advantages of the different professional teams in their professional fields in order to achieve smooth cross-department, cross-level, and cross-domain professional coordination.

The demonstration zone breaks down the limitations of traditionally connected transactions within state-owned oil companies,promotes the comprehensive marketization of various service needs within and outside the system, and advocates the competition mechanism of ‘‘no quota, no ceiling, no floor, and equal responsibilities and rights,” thus speeding up the cultivation of a healthy competitive market. Relying on local government, enterprises, and contractors, the project management department obtains public and social services in infrastructure, water and power supply, road transportation, warehousing, and logistics, in order to reduce costs and consumption, reuse resources, and conserve energy, thereby alleviating the pressure on environmental protection.

A digital oil field was created that covers the whole process from construction to production. This dramatically reduced the operating cost, while improving rapid decision-making, response,and management efficiency, thus effectively ensuring low consumption,risk,and labor along with high efficiency and reliability.Efforts were made to create a new low-carbon and green development mode. Measures taken included strengthening energy conservation, reducing the consumption and emission of engineering subsystems through technological upgrades and innovation, and gradually expanding technical tests such as CO2pre-fracturing and CO2‘‘huff and puff” in order to eventually realize the integration of CO2enhanced oil recovery(EOR)and CO2underground storage. Environmental protection engineering and process optimization are highlighted to ensure zero drops of drilling cuttings and other solid wastes and to recycle drilling and fracturing fluids. Innovative and effective microbial technologies for enhanced stimulation,production,oil recovery,and environmental engineering have been developed, to form a low-cost green circulatory system. In this way, the low-carbon and green economic development capacity of the demonstration zone has been enhanced.

5.3. Implementation results

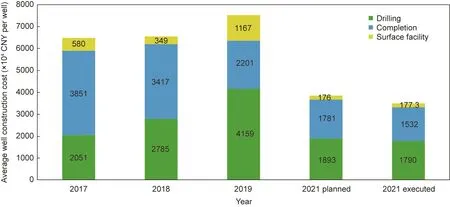

Fruitful progress has been achieved since the ‘‘one engine with six gears” methodology was implemented in 2020 at the Jimusar continental shale oil demonstration zone. First, the investment control has achieved remarkable results:According to the cost conversion of the eight wells put into production in 2021 to 2019 KPIs,the single well investment decreased by 54%according to the market price(Fig.8);of this,the drilling cost per footage decreased by 57%, and the hydraulic fracturing fluid cost per cubic meter decreased by 42%.

Second,the production effect of the No.58 platform,which was designed and constructed according to a geoscience-toengineering integration application, has become increasingly noticeable. The platform was opened for flowback and production in late May 2021; under the same nozzle system, the daily liquid production, daily oil production, and water cut decline rate have all reached the best levels compared with the previous production wells during the same period.

Fig. 8. Comparison of well construction cost from 2017 to 2021, with the ‘‘one engine with six gears” methodology having been applied in 2021.

Third, through market-oriented operation independently charged by the shale oil asset project department, working out the account profitability beforehand, and considering both quantity and effect,the economic indicator of the original development plan of the demonstration area has been significantly improved.Under a bottom-line oil price of 45 USD·bbl-1(1 bbl = 159 L), the project can turn losses into gains by 2026, and the project’s profit is predicted to be 6.666 billion CNY (Fig. S6 in Appendix A). By adjusting the development plan of the new area according to marketization, the new area will achieve positive cash flow in 2027,and the cumulative cash flow is expected to be 13.46 billion CNY.The overall new and old regions will achieve positive cash flow in 2028 with an estimated cumulative cash flow of 9.68 billion CNY. Compared with the original plan, the profitability of the market-adjusted program has been dramatically improved.

6. Conclusions and suggestions

Under the current situation, promoting a management revolution and leading technological innovation through methodology transformation comprise a decisive shift toward enabling China’s unconventional oil and gas development to achieve a technically and economically feasible unconventional oil and gas industry and to ensure sustainable development.Based on previous practice and experience, we have put forward the ‘‘one engine with six gears” system engineering methodology, which is mainly targeted at the unconventional oil and gas development system. This system engineering management methodology and technology takes the asset project as its base unit.The proposed life-cycle optimization is suitable for the characteristics and peculiarity of unconventional oil and gas development in China, with the goal of maximizing oil and gas recovery with acceptable economic indicators.

To achieve the large-scale and economic development of unconventional oil and gas in China, managers and experts in the field and at headquarters must have a deep-rooted determination to achieve economic benefit.Implementation of the‘‘one engine with six gears” system engineering methodology has already achieved fruitful results in the practice of unconventional oil and gas development, proving that the overall optimization of the unconventional oil and gas development system and its sub-systems promoted by innovative thinking and management transformation can act as a revolutionary driving force and promote leading technologies to increase the large-scale and economic development of China’s unconventional oil and gas industry. A series of accomplishments with pilot projects in China have demonstrated the disruptive point of view that unconventional oil and gas are not characterized by low return and low recovery factors.We strongly believe that it is possible to achieve the large-scale and economic development of unconventional oil and gas while adhering to the bottom-line cost.

Under the strict constraints of achieving peak carbon emissions and carbon neutralization, and given the national strategy of safeguarding the energy supply, China’s oil and gas practitioners should be much more determined to increase the domestic substitution for imported oil and gas, as well as more confident in their ability to do so. The system engineering methodology of ‘‘one engine with six gears” can also be heavily relied on to develop other types of oil and gas resources—even other geoenergy resources, such as geothermal energy. By continually practicing,learning, and improving this methodology, while simultaneously improving the structure of policies and regulations, constructing a corresponding big data system, and training talents in the systems engineering concept and methodology, ‘‘one engine with six gears” will become an essential methodology at the level of state-owned oil companies and even the whole oil and gas industry.

Acknowledgments

The authors would like to thank Professor Xu Tang at the China University of Petroleum (Beijing) for his fruitful discussions and suggestions on the system engineering principles and related descriptions. The authors thank Professor Bao Jia at China University of Petroleum (Beijing) for his intensive help with the writing.

This study is supported by the Project of Basic Science Center for the National Natural Science Foundation of China (72088101).

Compliance with ethics guidelines

Guoxin Li,Chenggang Xian,and He Liu declare that they have no conflict of interest or financial conflicts to disclose.

Appendix A. Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.eng.2022.05.018.

- Engineering的其它文章

- Editorial for the Special Issue on Unconventional and Intelligent Oil and Gas Engineering

- On-Chip LiDAR Technology Advances for Cars, Cell Phones

- Genetic Engineering Aims to Take a Bite Out of Insect Pests

- Two New Mega Dams Begin Operating as Hydropower Industry Booms

- Management Mode and Application of Geoscience-Engineering Integration

- Intelligent Petroleum Engineering