Wear of the working parts of agricultural tools in the context of the mass of chemical elements introduced into soil during its cultivation

Piotr Kostencki ,Tomsz Stwicki ,Aleksndr Królick

a Department of Renewable Energy Engineering,Faculty of Environmental Management and Agriculture,West Pomeranian University of Technology in Szczecin,Papieża Pawła VI Street 1,71-459,Szczecin,Poland

b Faculty of Mechanical Engineering,Wrocław University of Science and Technology,Smoluchowskiego Street 25,50-370,Wroclaw,Poland

Keywords:Soil cultivation Working parts Potentially toxic elements Soil contamination Cemented-carbide Low-alloy steel

A B S T R A C T For the manufacture of working parts of agricultural tools operating in soil,various structural materials are used:alloy and low-alloy steels,weld materials for hardfacing,and plates made from cementedcarbide.Manufacturers design new construction solutions to obtain components that are resistant to abrasive wear and impact.These components are subject to wear during soil cultivation,due to which wear products remain in the soil.In this work,the mass of chemical elements remaining in soil from materials used in selected working parts of agricultural tools intended for soil cultivation was estimated.During the operation of the tested parts,it was found that the following elements were introduced into the soil:Al,B,C,Co,Cr,Cu,Fe,Mo,Nb,Ni,P,Pb,S,Si,Ti,V,W and Zr.Iron was introduced into the soil in the highest amount(15.907-222.004 g∙ha-1).Among the chemical elements reaching the soil,there were also elements that may pose a toxicological threat.It was found that the mass of chemical elements introduced into the soil depends on their content in the used structural materials and also on the conditions of cultivation,which determine the wear intensity of the parts.

1.Introduction

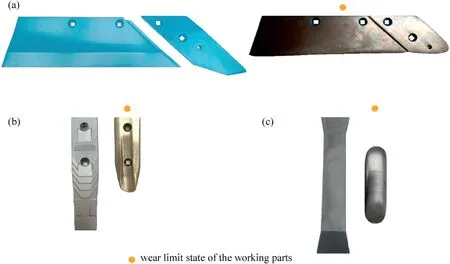

During soil cultivation,the working parts of agricultural tools are worn.This applies to such treatments as:subsoiling,plowing,cultivating,harrowing with tooth or disc harrows and weeding.During such operations,the working parts affect the soil,which in this case is an abrasive mass formed mainly by hard quartz grains.In addition,during the sowing of plants,as well as the harvest of potatoes or beets,working parts are subject to wear.Fig.1 presents examples of working parts of agricultural tools before and after their use in soil.It is clearly noticeable that the macroscopic wear processes are manifested by a change in the geometry of the parts,and thus the loss of their mass.

The mass of the material,which reaches the soil as a wear product of working parts,depends on the intensity of the wear.Scientific reports have found a relationship between the wear intensity of parts operating in soil with material-construction factors(geometry of elements,properties of materials used in their construction)(Fielke,1996);(Bhakat et al.,2004);(Białobrzeska &Kostencki,2015);(Buchely et al.,2005);(Er & Par,2006);(Kostencki,Stawicki,& Białobrzeska,2016a,2016b);(Novák et al.,2014);(Stawicki et al.,2018),agrotechnical cultivation conditions(depth,speed of cultivation)and the physicochemical soil condition(humidity,density,firmness,reaction,etc.)(Barzegari et al.,2015);(Hamblin&Stachowiak,1996);(Mosleh et al.,2013);(Napiórkowki,2005);(Napiórkowki,1997);(Natsis et al.,1999);(Natsis et al.,2008).

Fig.1.Examples of new and worn(wear limit)working parts of agricultural tools intended for soil cultivation:unreinforced plouhshares(a),working parts of cultivator(b),working parts of subsoiler(c).

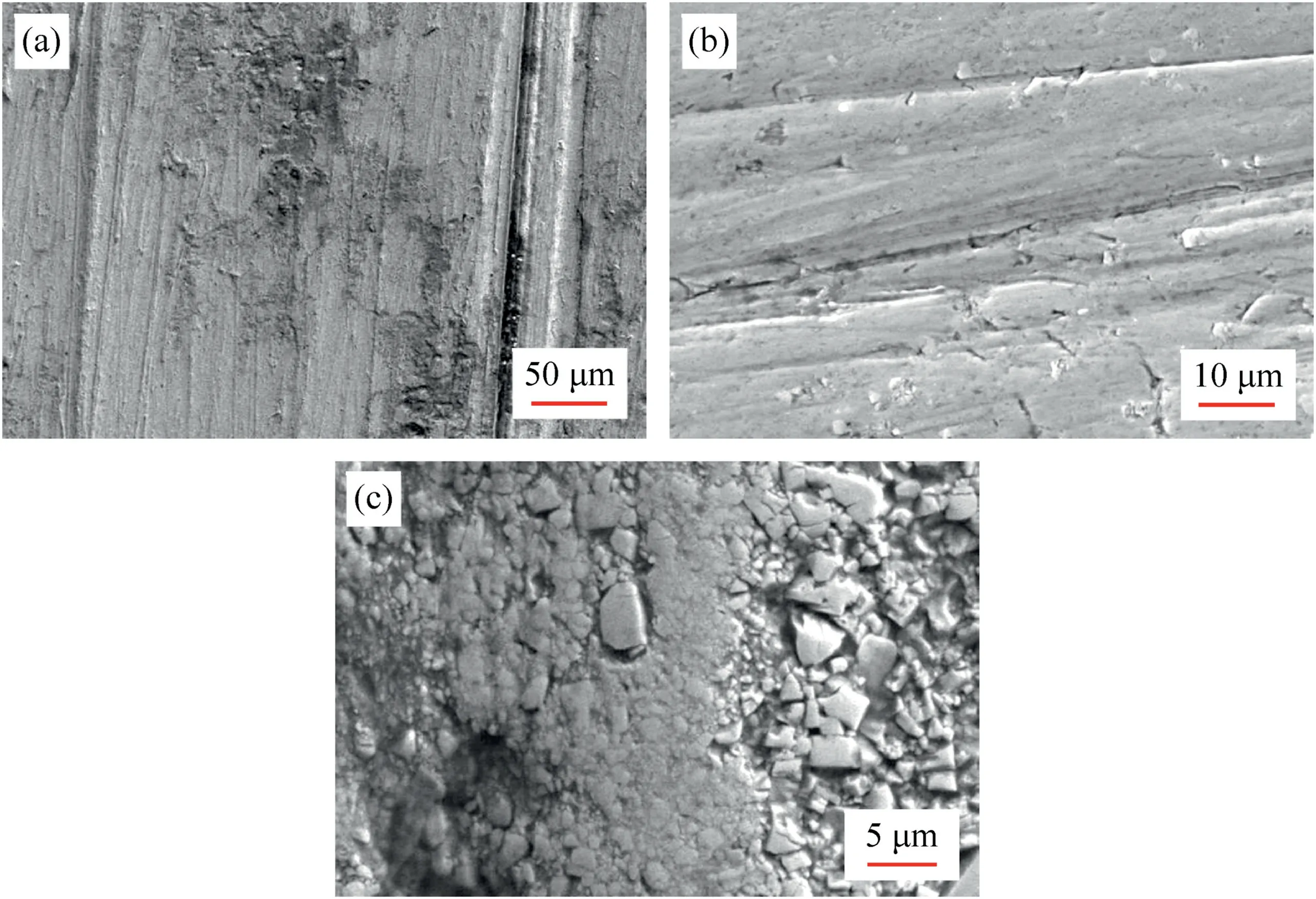

When compared to several decades ago,steels with a more complex chemical composition are currently used in the construction of the working parts of agricultural tools.In addition,components,in which the base material is reinforced by hardfacing and/or brazing of cemented-carbides plates,are more common.Reinforcement is performed in places where components are particularly exposed to wear.During the operation of elements in soil,the materials used in their construction are subject to destruction as a result of elementary tribological processes,such as:microcutting,grooving,ploughing and crushing/chipping of carbides.Mechanism of microcutting occurs when the material of the element is separated in the form of micro-shavings without plastic deformation of the material in the frictional contact zone.In contrast,ploughing mechanism occurs when soil grains cause plastic deformation of the material,which is thereby weakened and is more easily separated by subsequent soil particles.Grooving is an intermediate process in which both material deformation and micro-cutting occur.On the other hand,crushing and chipping are the characteristic processes of destruction of materials containing hard carbides,which,as a result of the dynamic impact of the soil,are crushed or chipped from the matrix of the material.The intensity and mechanisms of tribological wear processes are determined by the properties of the materials used in the construction of the working parts.When working in soil,steel is subject to wear mainly due to microcutting and grooving mechanisms(Fig.2a),which was confirmed,among others,in the works(Konstencki et al.,2019);(Stawicki et al.,2018);(Stawicki et al.,2017).The wear processes of padding welds are complex and depends on their chemical composition and microstructure.Generally,the dominant wear mechanisms of these materials are microcutting,partially grooving and chipping/crushing of carbides causing the wear intensification(Fig.2b),which was found in the works(Kostencki et al.,2019);(Królicka et al.,2020).However,in the case of cemented carbides,the wear mechanism consists of the following stages:removal of the matrix under action of the finest fractions of the abrasive mass,next cracking,and crushing or chipping of carbides from the matrix(Gee et al.,2007);(Kostencki et al.,2019);(Konstencki et al.,2016).An example of the wear topography of working elements made of cemented carbides is presented in Fig.2c.It should be highlighted that currently the most common methods of improving the abrasive resistance of working parts operating in soil include hardfacing,applied,among others,for ploughshares,working parts of cultivators,subsoilers and other agricultural tools.The effectiveness of such reinforcement has been repeatedly confirmed in laboratory tests(Buchely et al.,2005);(Choo et al.,2000);(Choteborsky et al.,2008);(Kenchi Reddy &Jayadeva,2012);(Buytoz et al.,2010).

Fig.2.Topography of the worn surfaces of working parts of agricultural tools used in soil:(a)martensitic steel(b)padding weld,(c)plate made of cemented-carbide(c).

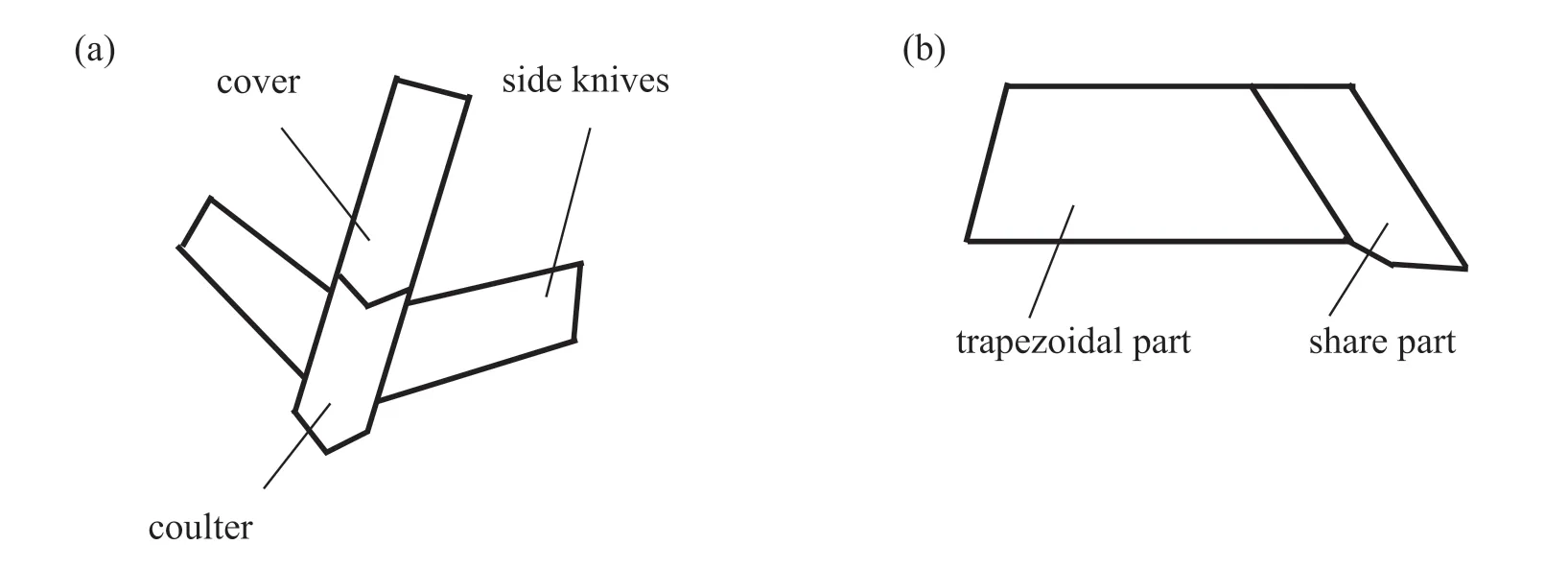

Fig.3.Schemes of working parts of agricultural tools analyzed in this research.Constructional solutions of components used in(a)stubble cultivators and(b)ploughshares.

Wear products of working parts used in soil contain various chemical elements including potentially toxic elements(PTE).These products in the form of very fine particles are introduced into the soil.Therefore,the question of what extent the wear of workelement materials contributes to anthropogenic soil contamination with potentially toxic elements can be posed.In previously published scientific research,this issue was not analyzed.On the other hand,the condition of soil contamination has been examined many times.The soil contamination is connected with the activity of industrial plants,means of transport,or the use of plant protection products,as well as mineral and organic fertilizers(Ahmadpour et al.,2012);(Bigalke et al.,2017);(Caussy et al.,2011);(Li et al.,2014);(Qian et al.,2018);(Shi et al.,2018).Of course,the content of the potentially toxic elements soil is not only due to human activity,but is also conditioned by natural soil-forming processes(Kabata-Pendias et al.,1995);(Sharma & Agrawal,2005).The aim of this study was to determine the mass of chemical elements introduced into the soil as a result of the abrasive wear of working parts of agricultural tools intended for soil cultivation.In this work,an attempt was made to answer the following scientific questions:

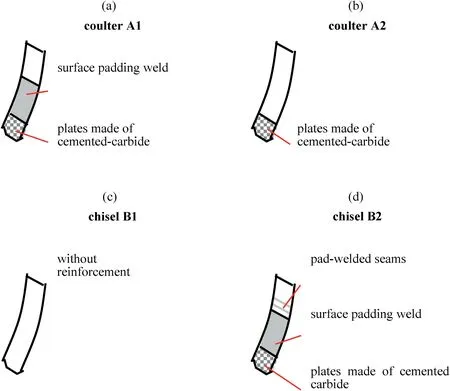

Fig.4.Reinforcement of working parts of agricultural tools analyzed in this study.Distinguished:coulters A1(a)and A2(b),and chisels B1(c)and B2(d).

·Which of the chemical elements are introduced into the soil as a result of the wear of elements working in the soil?

·What determines the variety and the mass of chemical elements introduced into the soil?

·How does the use of reinforced working parts affect this process?

2.Materials and methods

In this work,the results of mass wear measurements of the working parts of a stubble cultivator-a cultivator intended for basic cultivation(referred to as„cultivator”in the following part of this work)-a plow,and a subsoiler operated in specific soil conditions were used.

The working parts used in the stubble cultivator(intended forpost-harvest soil cultivation)were characterized by a divided structure-consisting of a cover,side knives and coulter(Fig.3).Two variants of cultivator coulters were used in the tests-subjected and not subjected to pad welding.The padding weld was applied along the cutting edge,on the side opposite to the rake face(from the bottom).In the cultivator,the working parts were arranged in two rows.

Ploughshares were also used in the tests and had a divided structure consisting of a separate trapezoidal and shared part(Fig.3).Two variants of ploughshares were used-subjected and not subjected to pad welding.The padding weld was placed on the surface opposite to the rake face of the elements(from the bottom),in the area adjacent to the edge cutting t The cultivator coulters and subsoiler chisel were one-piece elements,with two types of coulters and chisels being used in the research.The coulter variants are marked with A1 and A2,and the chisel variants are marked with B1 and B2.

The A1 coulters were reinforced by plates made of cementedcarbide(in the initial area of the rake face),as well as by surface padding weld placed on the rake face and sides(on a certain length,above the plates made of cemented-carbide)(Fig.4).On the other hand,the A2 coulters were reinforced only by brazing plates made of cemented-carbide in the initial area of the rake face.The investigations were performed using a 4-beam cultivator.

The B1 chisels did not have any form of reinforcement,whereas the B2 chisels were reinforced by brazing of their plates made of cemented-carbide(at the beginning of the rake surface),by surface padding weld placed on the rake face and the sides of the elements(above the plates made of cemented-carbide)and by pad-welded seams(above the surface padding weld).The investigations were performed using a 2-beam subsoiler.

Table S1 presents information on the initial mass,which in the case of the reinforced elements,was estimated for the pad-weld material and plates made of cemented-carbide.Table S1 also contains the designations of the working conditions in terms of the depth and speed of cultivation.Table S2 characterizes the cultivated soil granulometric group,humidity and the volumetric density of the soils.Granulometric group of cultivated soils were determined on the basis of soil and agricultural maps of the study area,while soil humidity and volume density were determined by the dryingweight method using Kopecky cylinders with a capacity of 100 cm3.

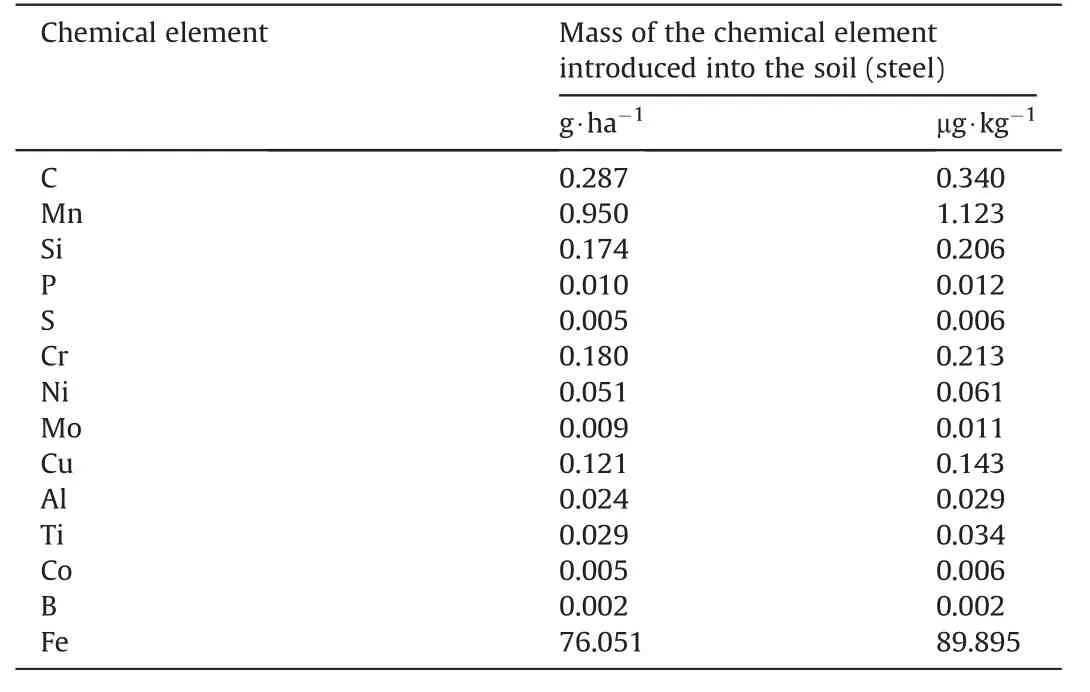

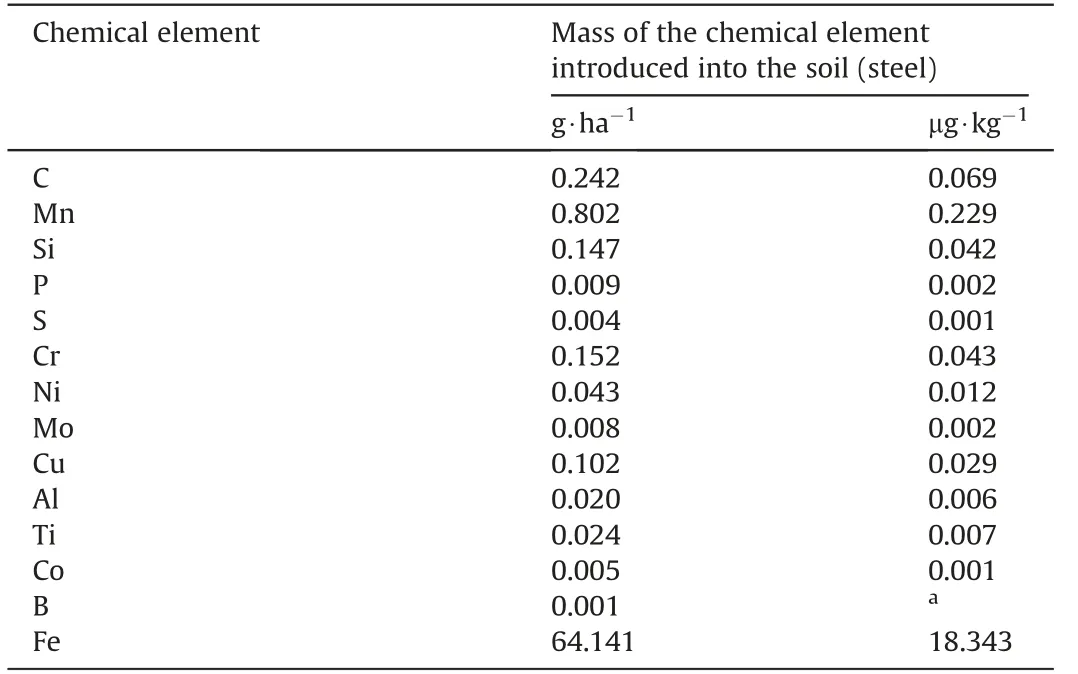

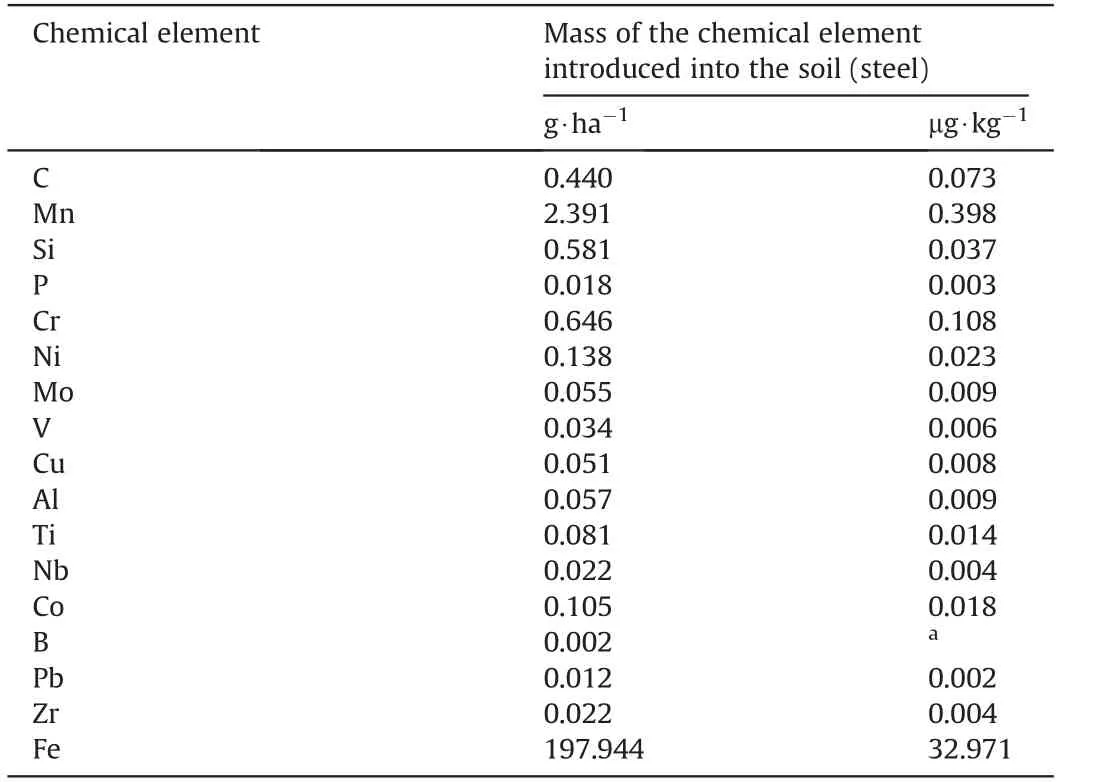

Table 1 Chemical elements introduced into the soil during use of the unreinforced working parts of the stubble cultivator(working conditions 1-according to Table S2).

Table 2 Chemical elements introduced into the soil during use of the unreinforced working parts of the stubble cultivator(working conditions 2-according to Table S2).

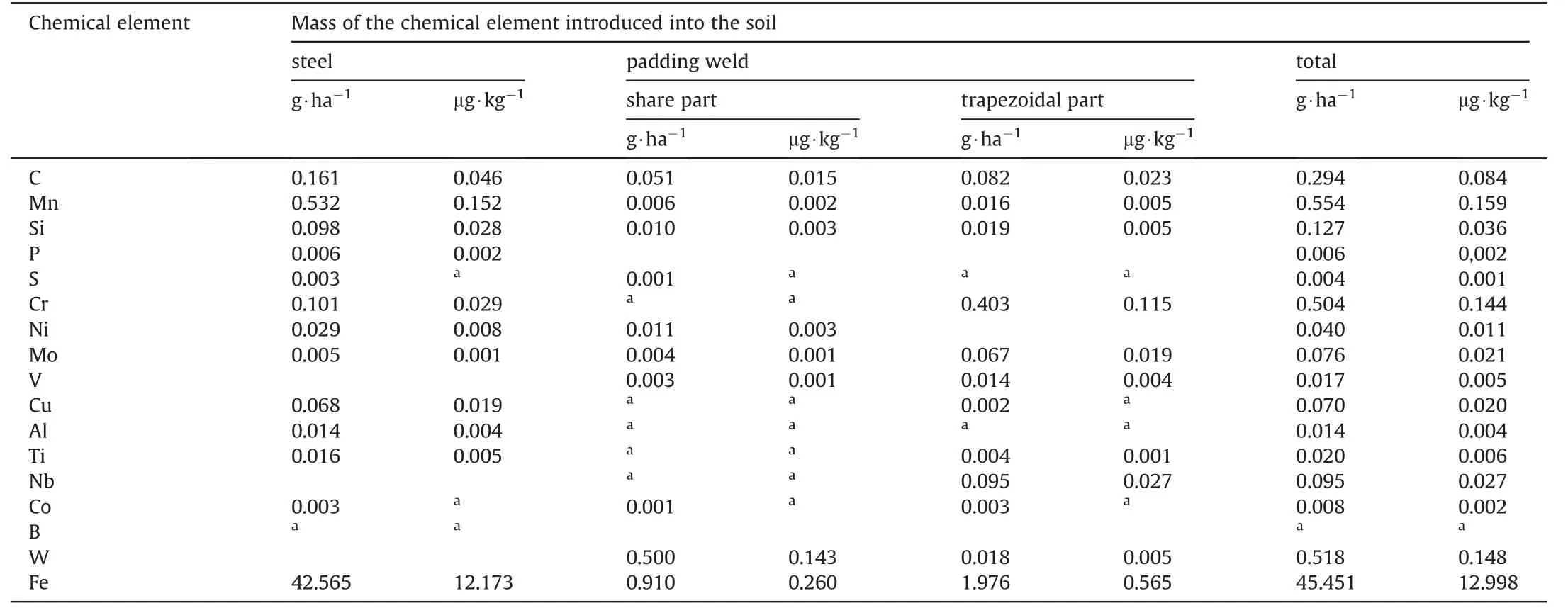

Table 3 Chemical elements introduced into the soil during use of the unreinforced working parts of the plow(working conditions 3-according toTable S2).

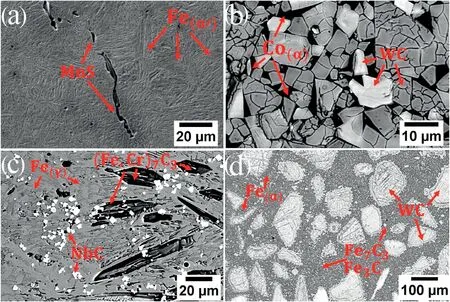

Tables S3,S4 and S5 present the chemical composition of the materials used in the construction of the tested parts.Steels and welding materials were analyzed by spectral method(using aGDS500A Leco glow discharge analyser),while plates made of cemented carbide by EDS chemical microanalysis method(using a JEOL JED-2300 energy-dispersed X-ray spectrometer coupled with a JEOL JSM-6610A scanning electron microscope).Exemplary images of microstructures of tested materials were made using a JEOL JSM-6610A scanning electron microscope.Topographic and material contrast(SE and BSE detector)were used.Tables S3 and S4 also include the chemical composition of selected other materials used to produce the soil-operating parts of agricultural tools.This data supplements information on the chemical composition of materials used for working parts operated in soil.

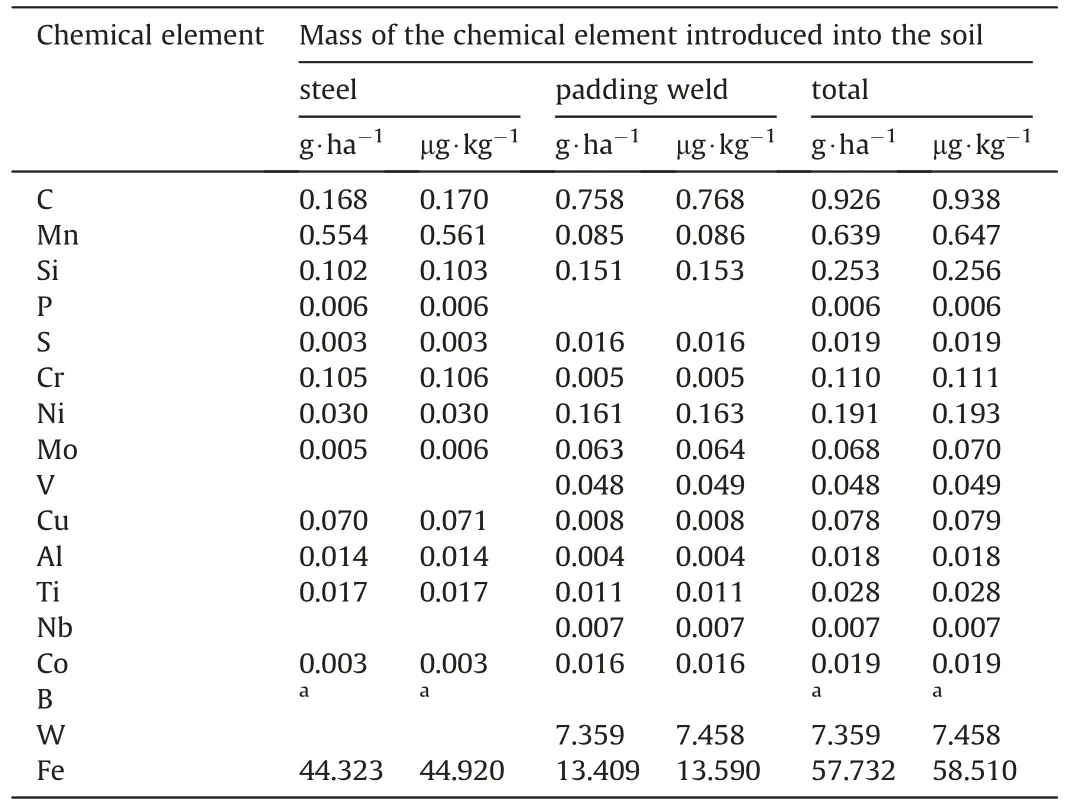

Table 4 Chemical elements introduced into the soil during use of the reinforced working parts of the plow(working conditions 3-according toTable S2).

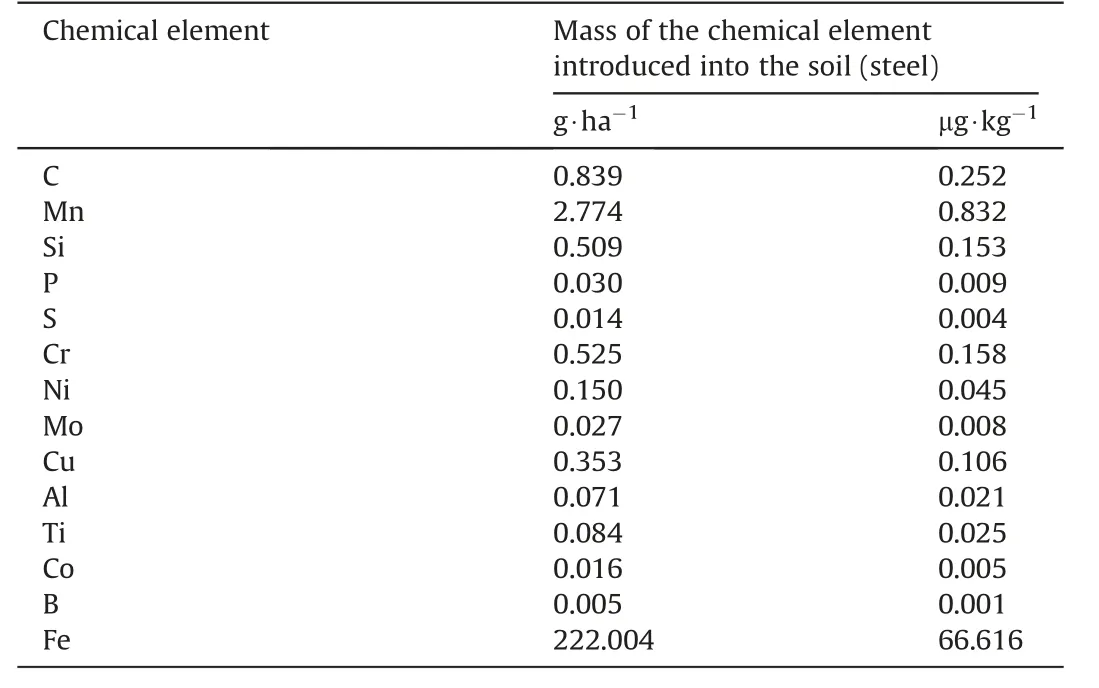

Table 5 Chemical elements introduced into the soil during use of the unreinforced working parts of the plow(working conditions 4-according to Table S2).

The wear investigations of the described working parts were carried out in the years 1998-2018,during typical field operations in several agricultural enterprises.The test was carried out to obtain the working parts of the wear limit state in which parts due to the geometry change cannot be further used.In terms of the total wear mass intensity of working parts(expressed in g·ha-1 and corresponding to mass loss of working parts when cultivating a hectare of field),the results of these tests have been partially published(Kostencki et al.,2016a,2016b);(Kostencki,2005);(Kostencki et al.,1999);(Kostencki et al.,2002);(Kostencki et al.,2019).In these publications,the procedure for determining the wear intensity of working parts was presented in detail,and the soil conditions of their work were more fully characterized(the share of gravel in soil,humus content,soil reaction,compactness and soil shear stress).However,in the currently presented work,using the collected results,the wear mass intensity of steel,padding weld and plates made of cemented-carbide used in tested working parts were determined separately for particular parts of the tested working parts.Therefore,using the data on the chemical composition of the used materials(Tables S3,S4 and S5),the mass of individual elements was estimated,which during the wear of the working elements were introduced into the soil.It should be noted that for the agricultural tools,in which the parts were installed on several beams,the estimation took into account the different wear intensity of these parts depending on the place of their attachment.

The amount of introduced chemical elements is determined in grams with reference to the hectares of the cultivation field(g·kg-1),and in micrograms per kilogram of dry matter of cultivated soil(μg·kg-1).The determined values in μg·kg-1were calculated on the basis of the average depth of the performed operations and the average volumetric density of soil in the cultivated layer.The calculations were carried out with accuracy to one thousandth g∙ha-1or μg∙kg-1,which was dictated(in some cases)by the low value of the chemical elements mass introduced into soil(lower accuracy of calculations would exclude the possibility of revealing them).Tables 1-10 present the values of the estimated mass of the chemical elements introduced into the soil during specific cultivation operations.In order to increase the readability of Tables 1-10,rows of the chemical elements,which were introduced into the soil in the highest amounts,are highlighted.The comments on the tables do not include the mass of Al,C and Si,because these elements are commonly found in soil.Phosphorus and sulfur,classified as macronutrients,which are introduced into the soil during fertilization,are also not included.The Fe is also present in significant quantities in the agricultural soil(Mico et al.,2006);(Martyn et al.,2011);(Rajmund & Bożym,2017).However,the amounts of Fe introduced into the soil as a result of the wear of working parts of the tested agricultural tools were discussed due to the significant content of this element in the wear products.

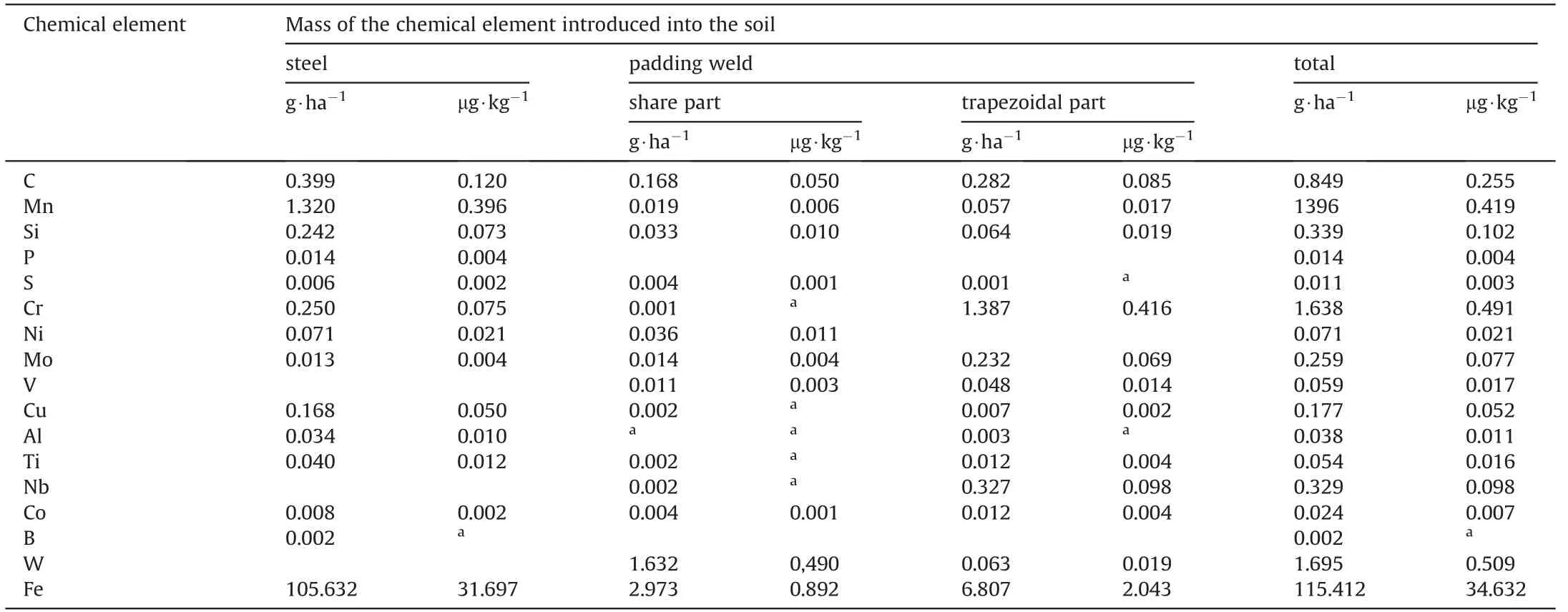

Table 6 Chemical elements introduced into the soil during use of the reinforced working parts of the plow(working conditions 4-according to Table S2).

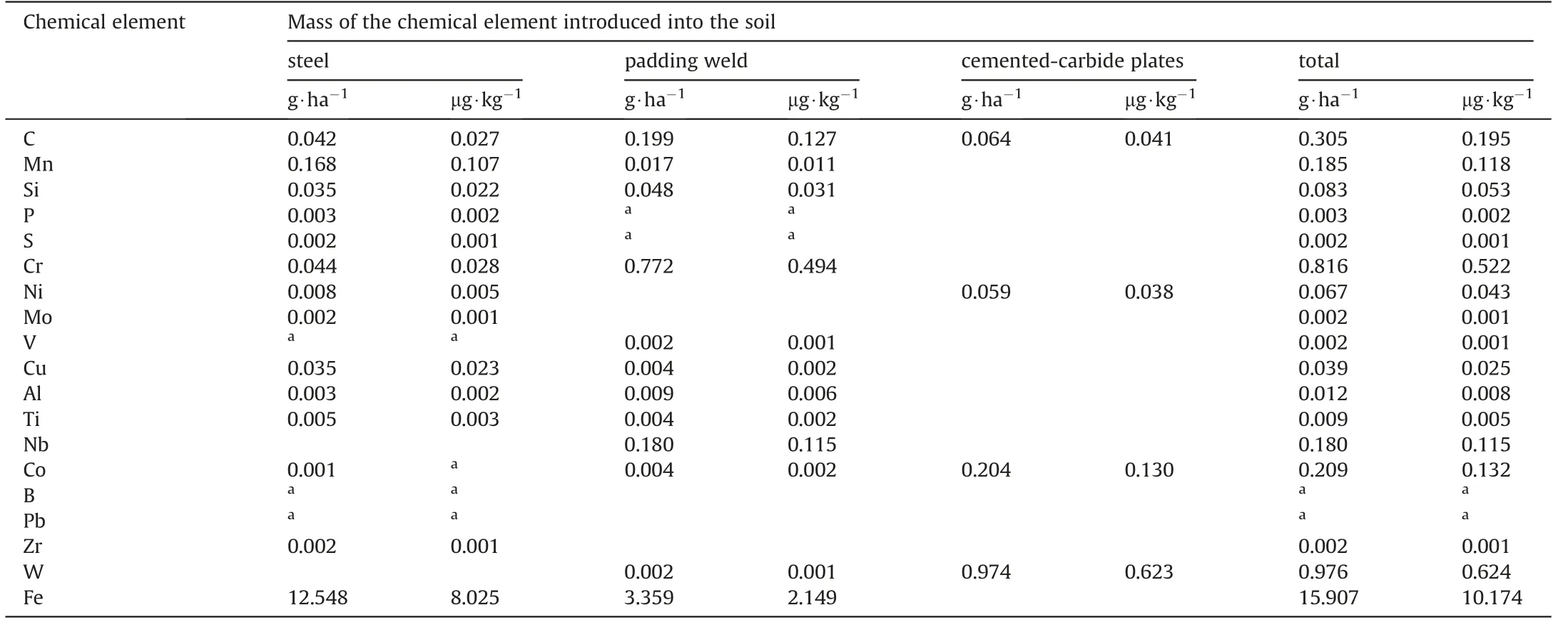

Table 7 Chemical elements introduced into the soil during use of A1 coulters of cultivator(working conditions 5-according to Table S2).

a-value below 0.001 g·ha-1or μg·kg-1.Moreover,this element is classified as PTE.

3.Results

3.1.Mass wear intensity of tested elements

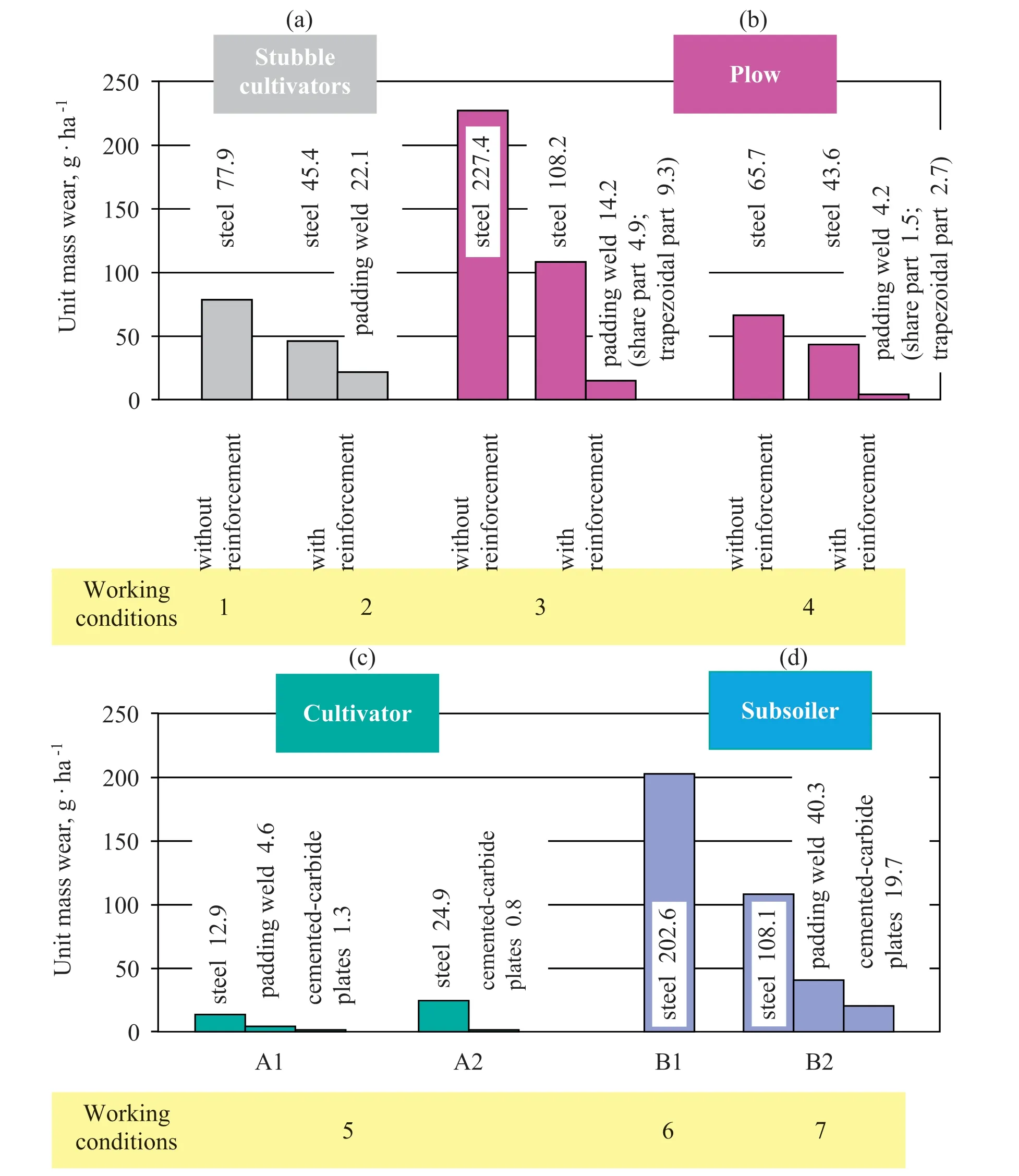

Fig.5 presents the estimated values of the wear unit mass of steel,padding weld material and plates made of cemented carbides used in the construction of the tested working parts.

It was found that the total unit mass of worn material is smaller for the reinforced parts when compared to the parts without reinforcement-about 1.15 times for the working parts of stubble cultivators(cultivation conditions 1 and 2 were similar-Table S2),1.86 and 1.37 times for the ploughshare operating respectively in conditions 3 and 4,and 1.21 times for chisels B1 and B2 operating under conditions 6 and 7 respectively(Fig.3).Thus,it can be concluded that the used reinforcement of the working parts fulfilled the intended function and that these parts were characterized by less abrasiveness.The value of the wear intensity of the working parts is strongly influenced by the cultivation conditions.This effect was confirmed for the ploughshare-the wear mass intensity of the ploughshare without reinforcement in conditions 3 was about 3.5 times higher,and for the reinforced ploughshares it was 2.6 times higher than in conditions 4.In conditions 3,dry sandy soils were cultivated,whereas in conditions 4-humid silty soils.

Table 8 Chemical elements introduced into the soil during use of A2 coulters of cultivator(working conditions 5-according to Table S2).

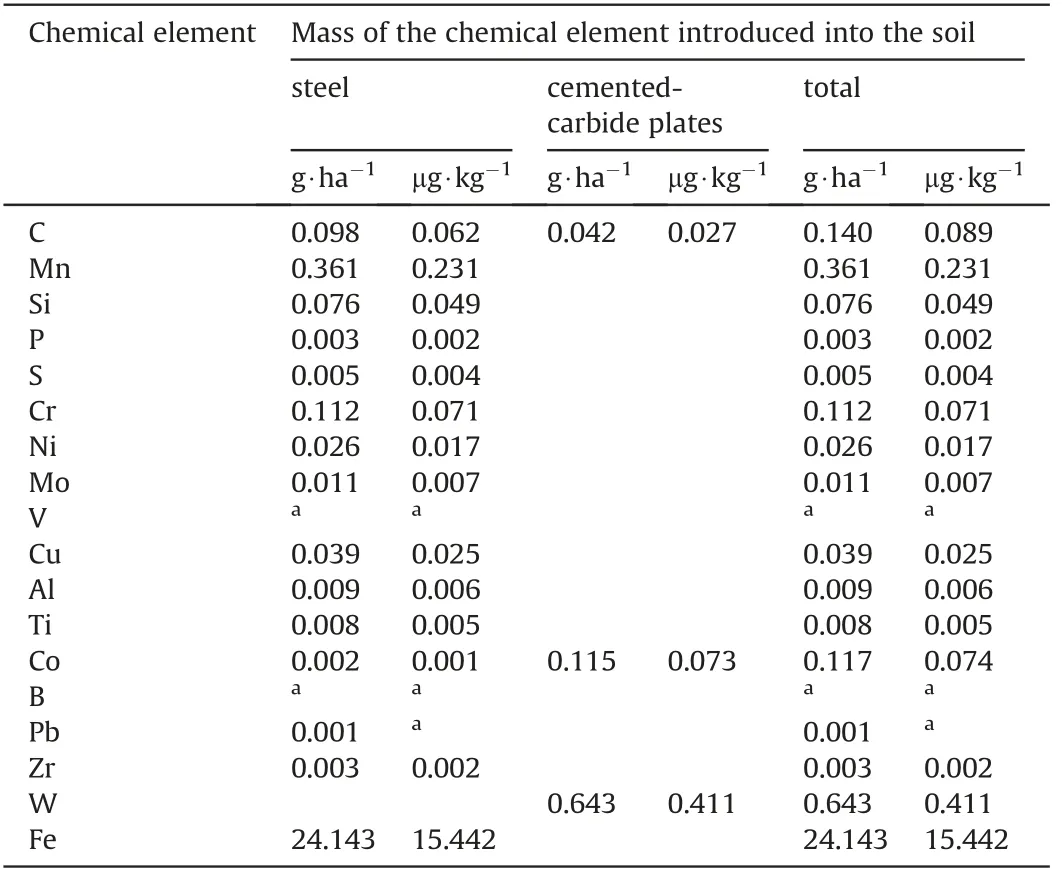

Table 9 Chemical elements introduced into the soil during use of B1 chisels of subsoiler(working conditions 6-according toTable S2).

The lowest intensity of wear was characterized by the plates made of cemented-carbide,except for the plates used in the B2 chisels.Cemented-carbide plates are characterized by high resistance to abrasive wear.On the other hand,the disadvantage of using cemented-carbide plates in working parts operated in soil is their brittleness.As a consequence they can be chipped when making contact with stones located in the soil,especially when thebase material of working parts is not rigid enough.It was found that the high value of the wear intensity of the cemented-carbide plates in the B2 chisels is caused by the dominance of such a wear mechanism.The padding weld material was characterized by higher wear intensity than the plates made of cemented-carbide,while the largest wear intensity was found for the used steel as a base material(Fig.5).

3.2.Chemical elements introduced into the soil as a result of wear of steel used in the working elements

For the unreinforced working parts,the mass of chemical elements introduced into the soil as a result of wear was higher than for the reinforced working parts.This is particularly noticeable for the working parts of the stubble cultivator(Tables 1 and 2),and also the ploughshares(Tables 3 and 4,5 and 6)that were subjected or not subjected to pad welding.It was found that in the case of steel used in the working parts of the stubble cultivator and ploughshare,Fe and Mn had the largest share in the wear products,which was determined by the chemical composition of the steel(Table S3).The amount of chemical elements introduced into the soil depended on the construction solution of the working parts,and to a large extent on the working conditions,which in turn determine the intensity of their wear(for example,for reinforced and unreinforced ploughares the mass of Mn introduced into the soil in conditions 3,which was respectively about 3.5 and 2.5 times higher than in conditions 4).Additionally,in the steel wear process of the working parts of the stubble cultivator and plow,the following chemical elements,among others,were introduced into the soil:Cr,Ni,Mo,Cu,Al,Ti,Co and B(Tables 1-6).

During the operation of the A2 coulters,the wear intensity of the steel used in their construction was higher than for the A1 coulters(Fig.5).Fe,Mn and Cr were introduced into the soil in the highest amount(Table 8).

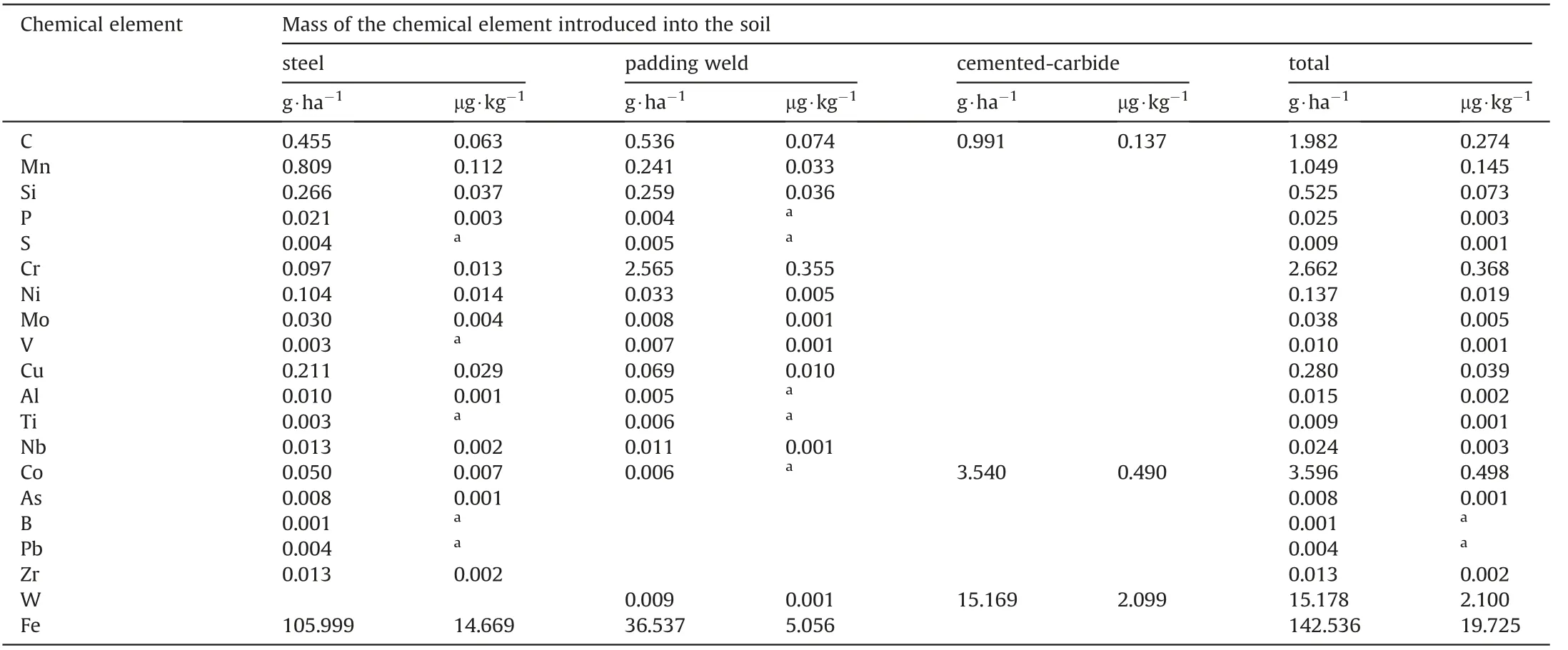

The wear intensity of the tested subsoiler(tools that deeply affect the soil)chisels was high and comparable with the abrasive wear intensity of the ploughshares working in conditions 3(Fig.5).The chemical elements introduced into the soil during operation of the B1 chisels came from only the wear products of steel,because no reinforcing form was used in the construction of these chisels.Fe,Mn,Cr,Ni and Co were introduced into the soil in the highest amount(Table 9).The B2 chisels reinforced by plates made of cemented-carbide and hardfacing were characterized by a slightly lower wear intensity than the B1 chisels.As a result of the operating steel used in their construction,Fe,Mn Cu and Ni were introduced into the soil in the highest amount(Table 10).

3.3.Chemical elements introduced into the soil as a result of the wear of materials used for reinforcement working elements

The used reinforcement of working parts,in the form of surface padding weld,contributed to the expansion of the variety of chemical elements with W,Nb and V introduced into the soil.As a result of the wear of the padding weld used in the working parts of the stubble cultivator,W,Fe and Ni were introduced into the soil(Table 2).On the other hand,for the reinforced ploughshares reinforced,Fe,W,Cr,Nb and Mo were also introduced.It should be noted that the mass of these chemical elements introduced into the soil in conditions 3 was about 3 times higher than in conditions 4(Tables 4 and 6).

The wear intensity of the A1 and A2 coulters was low in relation to the other tested working parts(Fig.5).

As a result of the wear of the padding weld used in the A1 coulters,the variety of chemical elements introduced into the soil increased in comparison to the chemical elements derived from the steel(Table 7).For example,the mass of introduced Cr was about 17.5 times higher than for the wear products of steel.On the other hand,during the wear of the cemented-carbide plates,W,Co and Ni were introduced in a relatively higher amount than during the wear of steel and padding weld(Table 7).

For the A2 coulters,as a result of the wear of the cementedcarbide plates,only tungsten and cobalt were introduced into the soil.

As a result of the wear of the padding weld Fe,Cr and Mn were mainly introduced in the highest amount,whiletungsten and cobalt were introduced into the soil from the wear products of the plates made of cemented-carbides(Table 10).The significant amount of tungsten and cobalt introduced into the soil was associated with the spalling of the plates made of cemented-carbide.For this reason,the wear products of the cemented-carbide plates were much larger than for other materials used in the B2 chisels.Itshould be added that the plates made of cemented-carbide that were used in the working parts are joined by brazing.The brazing alloys are also worn during operation.Typically,brazing alloys used to join steel with cemented-carbide plates contains Ag,Cu,Zn and Sn(additionally may contain Ni,Mn and Co).For example,the chemical composition of the brazing alloys used in the A1 cultivator coulters was:Cu-49.22%,Zn-40.68%,Ni-10.10%,and for the A2 cultivator coulters the composition was:Mn-22.29%,Ni-4.36%,and Cu-73.35%.However,due to the small thickness of the brazing layer(~0.1 mm)and the slow wear processes of the cementedcarbide plates,the mass of chemical elements introduced into the soil as a result of the wear of brazing alloys is negligible.Therefore,the authors did not include brazing alloys in this analysis.

Table 10 Chemical elements introduced into the soil during use of B2 chisels of subsoiler(working conditions 7-according to Table S2).

4.Discussion

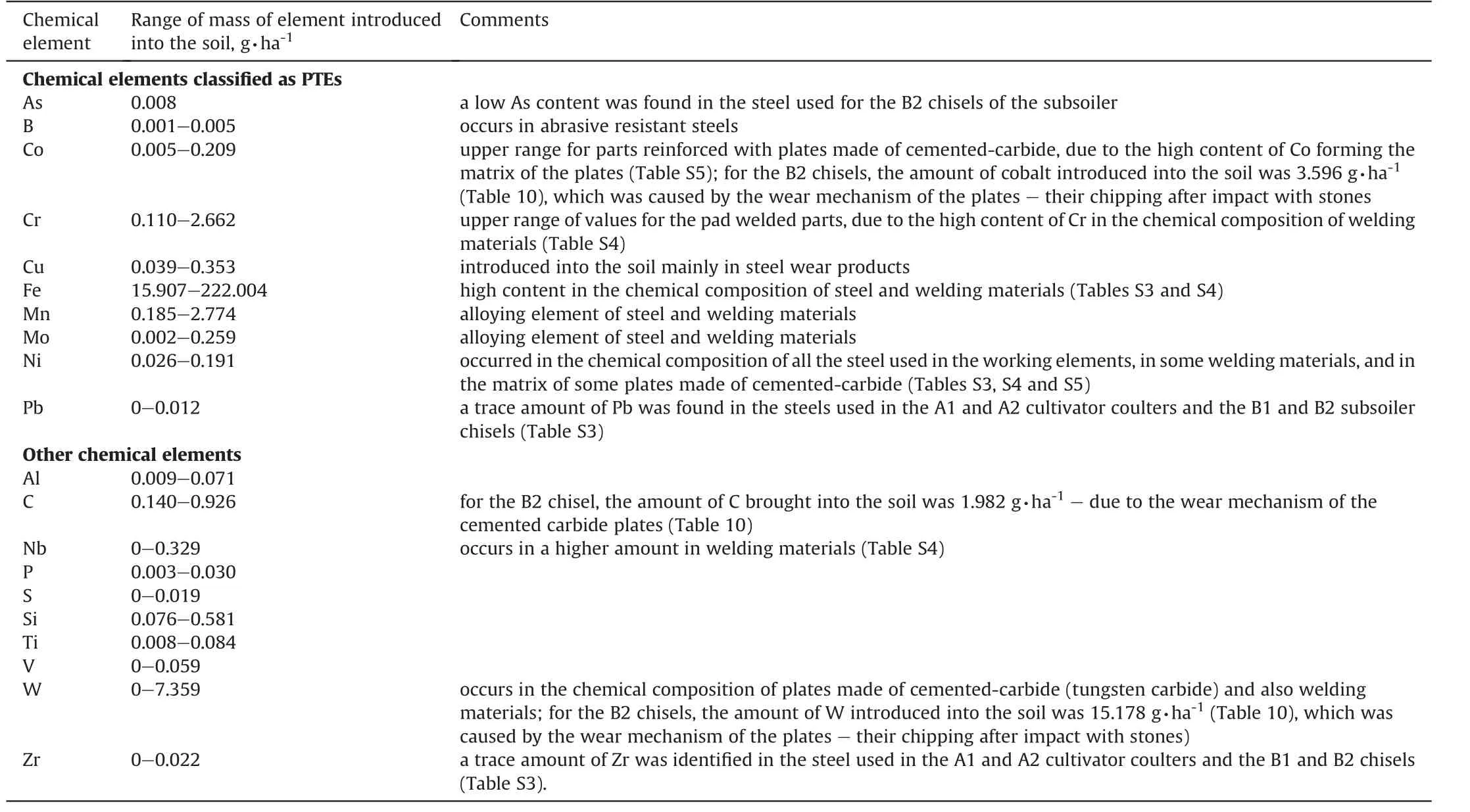

In literature,the most common causes of anthropological contamination of agricultural soils with PTEs are:the application of fertilizers,pesticides,and animal manure;sewage sludge and irrigation;emissions from industrial areas;and atmospheric deposition(Sharma & Agrawal,2005);(Wuana et al.,2011).The results presented in this work indicate that an additional source of PTEs in soils used for agricultural purposes is the use of working parts of agricultural tools intended for soil cultivation.Chemical elements that are introduced into the soil in the form of wear products of these working parts should be considered in the category of anthropogenic factors.Based on the current research results,the range of mass of chemical elements that can be introduced into the soil as a result of wear of working parts of agricultural tools was presented in Table 11.

The variety of elements brought into the soil in this way is wide(Table 11)and closely related to the chemical composition of the materials used in their construction.Potentially toxic elements were also classified among these chemical elements.It is not a strictly defined group of elements,but the following chemical elements are usually mentioned in scientific papers and normative reports:As,B,Ba,Cd,Co,Cr,Cu,Fe,Hg,Mn,Mo,Ni,Pb,Sn and Zn.It should be noted that normative reports defining the maximum content of a specific chemical element in agriculture soil,depending on the country,represent different values(He et al.,2015);(Regulation of the Minister of the Environment of,2016),which indicates the necessity of international agreement on the permissible amount of PTEs in soil.

Among the chemical elements introduced into the soil as a result of wear of the working parts,Fe was generally introduced in the highest amount (15.907-222.004 g∙ha-1;10.174-89.895 μg∙kg-1of dry matter of the cultivated soil).This is understandable due to the high content of this element in the chemical composition of steel and welding materials(Tables S3 and S4).Other chemical elements were introduced into the soil in a much smaller amount.During the cultivation operations,the highest concentration of Fe in the soil occurred as a result of the wear of the unreinforced working parts of the stubble cultivator(89.895 μg∙kg-1),and then of the unreinforced ploughshares(66.616 μg∙kg-1).The remaining chemical elements listed in Table 11 were introduced into the soil in a much lower amount.

Table 11 Summary of the mass of chemical elements introduced into the soil.

The literature describes a very high variability of the concentration of chemical elements in the soil.For example,the Fe content in rusty soils was determined by Martyn and Niemczuk at the level of 1600-2300 mg∙kg-1(Martyn & Niemczuk,2011),while by Rajmud and Bożym in non-fertilized soil at the level of 1830 mg·kg-1(Rajmund&Bożym,2017).On the other hand,Bai et al.found that in terms of the content of Cr,Ni,Cu,As,Cd,Pb and Zn,agricultural soils are located between greenhouse soils(the highest concentration of elements)and forest soils(the lowest concentration of elements).The authors described that in the case of agricultural soil,the highest mass share occurs for Zn and Cr(49.11 and 46.49 mg∙kg-1,respectively)with lower share of Ni and Cu(21.75 and 16.76 mg∙kg-1,respectively)(Bai et al.,2017).In this context,the concentrations of chemical elements specified in this research,expressed in μg·kg-1of soil dry matter,should be considered as low in relation to the total mass of chemical elements accumulated in the soil.However,it should be clearly highlighted that the research results presented in this work concern the mass of chemical elements introduced into the soil during a single cultivation treatment.Such agricultural treatments are performed annually,and the soil may be cultivated several times during the year.In addition,as a result of the wear of working elements of agricultural tools,elements are introduced into the soil also when sowing and planting plants,and also during the harvesting of some crops.Therefore,in view of the cyclical nature of agricultural treatments and the prospects of long-term agricultural use of soil,it can be concluded that the importance of the described issue is significant.

Fig.5.Unit mass wear of steel,padding weld and plates made of cemented-carbide for the tested working parts of the tested stubble cultivator(a),plow(b),cultivator(c)and subsoiler(d)operated in specified working conditions(determined in Table 2).

The intensity of wear of the working parts of agricultural tools operating in the soil is varied.It mainly depends on the constructional solution of the working parts,grain size,humidity and compaction of the cultivated soil,as well as the depth and speed of impact on the soil.Additionally,the current agriculture uses very different technologies of soil cultivation(from no-tillage to standard plow tillage),where the mechanical impact on the soil is highly diversified.This issue is also related to the species of the crop being cultivated,e.g.whether they are cereals or root crops.Hence,attempt was not made to estimate the total annual amount of elements introduced into the soil as a result of the wear of working parts of agricultural tools working in the soil.It seems that such anestimate,made with many variables,would be burdened with a large error and,consequently,misleading.

Fig.6.Examples of microstructures of materials used in the tested working parts of agricultural tools:(a)-martensitic steel,carbon-saturated iron solution Feα’and intermetallic inclusions(arrows indicate examples of MnS manganese sulfides),(b)cemented-carbide(arrows indicate WC carbides and matrix Coα),(c)high-chromium padding weld(arrows indicate primary(Fe,Cr)7C3 carbides,NbC carbides and matrix Fe(γ),(d)high-tungsten padding weld(arrows indicate carbide types of M7C3 i M3C,WC carbide and matrix Feα).Scanning electron microscopy,20 kV.

The values of the parameter expressed in μg∙kg-1,presented in Tables 1-10,illustrate the mass of the chemical element introduced into the soil during a given soil treatment in relation to a kilogram of dry matter of the cultivated soil.This parameter expresses the concentration of a given chemical element in the soil layer immediately after cultivation.Based on the analysis of the obtained results,it can be concluded that the concentration of individual chemical elements with tools deeper affecting the soil is less than when cultivating at a lower depth.For example,for deep cultivation performed with the subsoiler,Cr was introduced into the soil in the amount of 0.646 g∙ha-1,and its concentration was 0.108 μg∙kg-1(Table 9),while in the case of much shallower cultivation carried out with the use of stubble cultivator in quantities 0.180 g·ha-1and 0.213 μg∙kg-1(Table 1).Of course,in the long-term perspective,the wear products of working elements can be spread over the entire soil layer of the soil,which is facilitated by mixing the soil during cultivation operations carried out at various depths.Therefore,it seems that when assessing and comparing the mass of chemical elements introduced into the soil as a result of wear of working parts of agricultural tools,the parameter expressed in g·ha-1is more useful.The results presented in this work also indicate a large relationship between the mass of chemical element introduced into the soil as a result of cultivation conditions and the wear of the working parts of the agricultural tools(Tables 3 and 5,4 and 6).Of course,the higher the wear intensity of working parts corresponds with an increase in the mass of chemical elements introduced into the soil.Higher wear intensity of working elements occurs during cultivation of soil containing an increased share of large particles(sand,gravel),as well as soil that is strongly compacted or has reduced humidity.On the other hand,the application of reinforced elements(by hardfacing or cemented-carbide plates)reduces the rate of their wear,which contributes to the smaller mass of chemical elements introduced into the soil.However,the variety of introduced chemical elements is increased(Tables 1 and 2,3 and 4,5 and 6).For some cultivation conditions,this mass may be even higher than when using parts without reinforcement,as confirmed by the amount of chromium for ploughshares(Tables 3 and 4,5 and 6).It is also noticeable that with a higher depth of cultivation(plowing,subsoiling),a larger mass of elements is introduced into the soil(Tables 3,4,9 and 10)than with a shallower cultivation(post-harvest cultivation,shallow cultivating-Tables 1,2,7 and 8.This is caused by higher soil pressure on the surface of working parts,which contributes to intensification of their wear.

It should be noted that the chemical elements contained in the working elements working in the soil occur in various forms(examples of chemical elements forms are shown in Fig.6).These are chemical compounds(e.g.chromium carbide(Fe,Cr)7C3,(Fe,Cr)23C6,iron carbide Fe3C,niobium carbides NbC or tungsten carbide WC,as well as small amounts of non-metallic/intermetallic inclusions such as sulphides,oxides,nitrides,silicates,aluminates,etc.)or solid solutions(based on iron:Feα’,Feα,Feγ,or based on cobalt:Coα,Coε).The form of chemical elements may significantly determine the processes to which to which they were subject in the soil,which may consequently affect their bioavailability and impact on the environment.Carbides have different,but generally high chemical stability.However,it cannot be excluded that in such a complex environment as soil,they do not degrade to the ionic form as a result of soil factors(especially pH)and microorganisms(due to local acidification of the environment or the production of compounds which can complex metals(Giller et al.,1998).In contrast,the solid solution of Fe and Co in the soil environment can be subject to corrosion or biocorrosion processes and products resulting from these processes may transit to ionic form.It should also be highlighted that such elements as Cd,Cr,Pb,Cu,Mn,Zn,and Co exhibit individual behaviou(Bradl,2004).However,the described problem requires careful analysis and further experiments,due to the lack of scientific research in this area.

In these research,it was shown that with a single cultivation operation,the mass of chemical elements introduced into the soil as a result of the wear of working parts of agricultural tools is not high(with PTEs lower than the permissible values specified in the soil contamination standards).However,cultivation operations are usually carried out several times as part of the agrotechnical cycle and repeated in subsequent years.Wear of working parts used soil also occurs during sowing,planting and harvesting of certain agricultural products.Thus,in the perspective of continuous agricultural activity,the mass of chemical elements introduced in this way into the soil increases.Other phenomena may also play a role in this process,e.g.rinsing elements into deeper layers of soil or being absorbed by plants and then removing along with the crop being harvested.Hence,it was found that the wear of working parts of agricultural tools working in soil is an additional anthropological factor contributing to the introduction of undesirable chemical elements into the soil.

5.Conclusions

(1)The wear of the working parts of agricultural tools operating in soil is an additional,anthropological source of selected potentially toxic element(mainly Co,Cr,Cu,Mn,Mo,Ni).Due to the repeatability of cultivation treatments,the amount of heavy metals introduced into soil in this way may be increased.During the use of the working parts of agricultural tools,chemical elements are also introduced into the soil:Fe(contained in steel and welding materials),W(contained in plates made of cemented-carbide and welding materials),Nb(alloy addition of welding materials),and also small amounts of Al,B,C,P,S,Si,Ti,V and Zr.Due to the repeatability of specific field treatments,the introduction of given elements into the soil is periodic,and their content in the soil may increase.

(2)The variety of chemical elements introduced into the soil as a result of the wear of the working parts of agricultural tools depends on the chemical composition of the materials used in their construction.However,the mass of introduced elements depends on the chemical composition of the materials(and thus their mechanical properties)and the soil conditions.

(3)The application of reinforced working parts,which are characterized by a lower rate of wear,usually results in a reduction of the mass of chemical elements reaching the soil.Moreover,the variety of introduced chemical elements actually increases.Nevertheless,the mass of chemical elements,which occur both in used steels and in reinforcing material(padding welds and/or cemented-carbide plates),can be increased.

(4)Chemical elements introduced into the soil during wear of working part generally occur in two forms:solid solutions(formed on the basis of Fe and Co)or in the form of metal carbides(especially iron,tungsten and chromium).The bioavailability of such forms is difficult to clearly assess and requires appropriate research.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.iswcr.2020.11.001.

International Soil and Water Conservation Research2021年2期

International Soil and Water Conservation Research2021年2期

- International Soil and Water Conservation Research的其它文章

- Predictions of soil and nutrient losses using a modified SWAT model in a large hilly-gully watershed of the Chinese Loess Plateau

- Potential of conservation tillage and altered land configuration to improve soil properties,carbon sequestration and productivity of maize based cropping system in eastern Himalayas,India

- Carbon sequestration benefits of the grain for Green Program in the hilly red soil region of southern China

- Crop productivity,soil health,and energy dynamics of Indian Himalayan intensified organic maize-based systems

- Near-saturated soil hydraulic conductivity and pore characteristics as influenced by conventional and conservation tillage practices in North-West Himalayan region,India

- Determinants of adoption of multiple sustainable agricultural practices among smallholder farmers in Nigeria