Recent Progress for Gallium-Based Liquid Metal in Smart Wearable Textiles

TIAN Mingwei(田明伟) ,QI Xiangjun(齐祥君) ,QU Lijun(曲丽君)

1 College of Textiles and Clothing,Qingdao University,Qingdao 266071,China2 State Key Laboratory of Bio-Fibers and Eco-Textiles,Qingdao University,Qingdao 266071,China3 Research Center for Intelligent and Wearable Technology,Qingdao University,Qingdao 266071,China

Abstract: The development of smart textiles has presentend new requirements for integrated devices that can be compatible with both conductivity and deformation. At room temperature,liquid metal presents both metallic properties and flexible properties,as well as low toxicity and biocompatible,which makes it more and more popular on the research of liquid metal based electronic devices. This review summarizes the basic physical properties,and the key points to be fabricated into fibers and fabrics including oxides and wettability. Meantime,the application in the field of textiles is presented. Liquid metal based electrical conductive fibers and flexible sensors can be fabricated mainly by injection and printing,as well as direct-writing for smart fabrics. Liquid metal can be integrated as functional components for smart wearable devices in the future by assembling the as-prepared fibers and fabrics with textile technology,such as twisting,sewing,knitting,and embroidering.

Key words: smart wearable device; liquid metal; conductive fiber; flexible sensor; smart fabric

Introduction

Smart textiles[1]require functional capabilities including sensing,actuation,power storage,and electrical interconnections[2]onto textiles (e.g.,fibers,fabrics,and clothes) and other wearable substrates,which can be applied in sports monitoring,health care,data collection as well as mobile entertainment. Therefore,integrated functional modules which can meet the requirements of both conductivity and deformation[3]should be developed to better serve the smart wearable electronics[4]nowadays. Traditional electronic components are always rigid and planar while the textile production is soft,stretchable and flexible. Normally,there are many strategies to improve the compatibility between rigid conductors and soft textile materials. On the one hand,the rigid material can be remolded and then embedded into flexible basement. On the other hand,functional materials are made by means of doping conductive particles into wearable deformable matrixes. Stretchable and flexible conductive fibers[5-8]may be useful for incorporating electronic function into non-rigid substrates (e.g.,textiles,filters,clothes,papers,and sensors)[9]. In terms of conductors,most metals are the best choice but rigid. Moreover,electrolyte solutions are the most common conductor which are deformable,but the conductivity of such solutions is limited at merely several S·m-1[10]that is inefficient for the transmission of electrical signals.

It is worth noting that liquid metal[11]can achieve these two purposes with their outstanding intrinsic properties at the same time. As an attractive material,liquid metal not only has good liquid fluidity,but also has excellent metallic conductivity and thermal conductivity. It is a kind of material suitable for the micro-electro-mechanical system. Liquid metal is the softest and most deformable conductor. It is essentially stretchable and can be embedded in an elastic or gel matrix without changing the mechanical properties of composites. These composites keep the electrical conductivity of the metal under extreme strain and are in close contact with flexible surfaces. In recent years,room temperature non-toxic Gallium-based liquid metal has been developed and applied. At room temperature,Gallium and its alloys can be perceived as a low-toxicity substitute for Mercury. The surface of these metals reacts quickly with air to form oxide films on the surface allowing the liquid metal to better bond to the substrate despite high surface tension exiting. Recently liquid metal has been widely used as stretchable antennas[12-16],deformable interconnects[17],self-healing wires[18],reconfigurable circuit elements[19],and flexible circuit boards[20]. It can also be integrated as a functional component into circuits composed entirely of materials such as sensors,capacitors,storage devices and diodes[21]. Smart wearable devices based on liquid metal have recently attracted more attention,of which sensor systems are of vital important. Renetal.[22]summarized many kinds of potential stimuli and responses as illustrated in Fig. 1. Briefly,the basic changes of liquid metal including chemical,physical,mechanical,thermal,magnetic,optical and electrical properties can act as stimuli and be detected later,which evoke corresponding responses of the whole system to realize the various customized requirements of “smart”.

Fig. 1 Summary of the stimuli and the possible responses reported for Gallium-based liquid metal and related hybrid systems

1 Liquid Metal and Gallium-System Alloys

1.1 Liquid metal

Metals in liquid at or near room temperature mainly include Mercury,Cesium,Francium,Gallium and its alloys,which are the only materials having metallic and fluidic properties[23]. That made it possible for the integrated wearable electronic devices with the requirement of conductivity,flexibility,stretchability and softness. Mercury is the most common liquid metal but highly toxic and will accumulate in the elastic microstructure channel[24],which cannot guarantee the continuous transmission of electrical signals. Compared with the volatile and toxic of Mercury[25],oxidizability of Cesium and the radioactivity of Francium,Gallium and its alloys are more suitable for daily life.

1.2 Gallium-system alloys

Gallium was discovered by a French chemist in 1876 after the prediction of Mendeleev based on the periodic table of the elements,which was widely used in information storage materials,optical materials,semiconductor materials and solar cell materials[26]. The holistic study of the Gallium-Indium system began in the 1930s[27],and its phase diagram was a binary eutectic phase diagram[28-30],as shown in Fig. 2. Gallium has a wide range of liquid phase temperature,with a melting point of 29.8 ℃ and a boiling point of about 2 000 ℃[31]. Gallium-system alloys combined with other elements usually have a melting point below room temperature. The most common examples are eutectic Gallium Indium (EGaIn,75.5% Gallium and 24.5% Indium by weight) and alloys consisted of Gallium,Indium and Tin (Galinstan,62.5% Gallium,25.0% Indium and 12.5% Stammum by weight).

Fig. 2 Gallium-Indium phase diagram

1.3 Physic properties of Gallium-based liquid metal

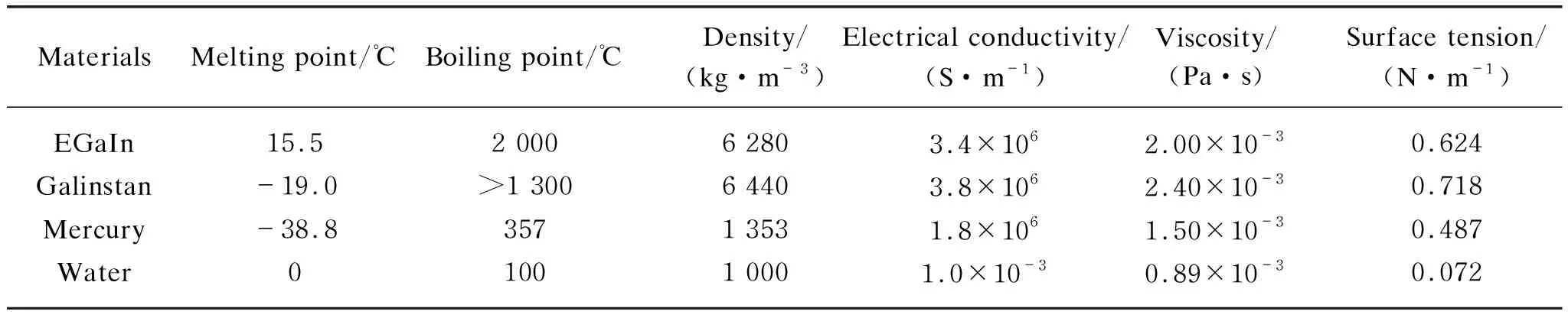

Main properties of Gallium and its alloys are listed in Table 1[10,23]. Gallium-based liquid metal shows high electronic conductivity. They also have low viscosity and huge surface tension,which means the pure metal can be hard to coat on the substrate. However,Gallium and its alloys are easy to form oxide layers[32]on surface while being exposed to the air,which not only prevents further oxidation within it,but also enlarges the viscosity and surface tension.

Table 1 Comparison of physical properties between common EGaIn,Galinstan,Mercury and water

1.4 Fabrication of Gallium-based wearable device

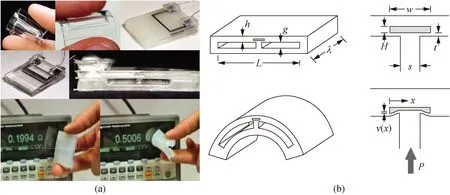

Liquid metal alloys made of Gallium usually have very low viscosity,which facilitates the filling of microfluidic channels. The greatest hindrance of application in the liquid metal is the large surface tension. However,it is surface oxidation that is a key property for forming a stable and continuous liquid metal based conductive fiber, which makes the liquid metal undergo the large deformations while retaining electrical continuity. For surface oxidation,Dickeyetal.[24]investigated the surface properties of EGaIn by using auger electron spectroscopy (AES),and proved its plasticity on the micro scale through the theory of fluid dynamics. As illustrated in Fig. 3[24],the EGaIn is placed and pressurized on one side of the microchannel,and then it takes on the slowly compressing without entering the channel,until the critical surface stress (0.5 N/m) is exceeded. When the critical dimension of a given channel exceeds the critical pressure,EGaIn can be forced to rapidly fill the channel. Even though the pressure is removed,the EGaIn still keeps filling the runner while the Mercury instantaneously (<1 s) withdraws from the channel after returning to ambient pressure. Compared with Mercury,the rapid outflow of Mercury from the channel after the removal of pressure shows poor ability to stay stable. The pressurePrequired to generate flow in the microchannel can be explained by the Young’s-Laplace equation:

P=2γcosθ(1/W+1/H),

(1)

wherePis the pressure drop across the metal-air interface(Pa),WandHare the width and height of the channel at the metal-air interface respectively (m),θis the contact angle,andγis the phenomenological parameter (N/m).

Fig. 3 Comparation on adhesion behaviors of EGaIn and Mercury in polydimethylsiloxane (PDMS) microchannel: (a) both filled the channels at the beginning; (b) rapidly (<1 s) filled the channels; (c) returning the system to ambient pressure

The adhesion of a “skin” oxide film composed of Gallium oxides on the EGaIn surface enables it to bind tightly to the microfluidic wall surface,allowing it to maintain its post-filling state after the pressure is removed. With external forces,the liquid metal can be easily injected into a complex network of high yield channels and attached to a variety of substrates under the adhesion of surface oxide layer. The wettability of liquid metal on different substrates is also significant. The factors that affect the wettability of liquid metal on the substrate are the internal doping and modification of liquid metal,the content of surface oxides,the interaction between substances and liquid metal,the external force including heat and electric stimulation,etc.

2 Applications in Textiles

Two strategies are typically employed in smart wearable application[33]. The first one is to construct hollow fibers filled with liquid metal[34]. The second one is to print metallic inks directly on the fabric[35]to form wearable electronics. The fabrication mainly includes injection[12-13,34,36-39],molding[40],microfluidic engraving[10],stencil printing[40],3D printing[17,41-46],mechanical sintering[47],vacuum filling method[48],etc.

2.1 Fibrous conductors

Since the research on stretchable electronic devices based on microfluidics technology from Whitesides[49],more and more elastic microstructural channels filled with low temperature fusion materials have been increasingly reported. By injecting liquid metal alloy into the microchannel etched in the silica gel substrate,the antenna with various functions such as flexibility,stretchability[12,37]and mechanical reconfigurability[36]can be prepared. Gradually,the concept of stretchable microfluidic electronic devices has been extended to the field of integrated electronic devices.

Researchers[23,34,50]firstly fabricated the Gallium-system based fibers by injecting the EGaIn directly into the hollow polymeric fiber shells extruded through a hollow configured mold using melt drawing process,which maintained metallic conductivity while stretching the fibers significantly (up to 700% strain),as shown in Figs. 4 (a) - (f). Doetal.[51]followed a customized dip-coating technique to fabricate the outside shell layer. The hollow structure was obtained by dipping a thin metal wire into uncured elastomeric solution,extruded immediately and removed the wire after solidification,which was illustrated in Fig. 4(g).

Fig. 4 Method for fabrication in Gallium-based conductive fibers: (a) - (d) a stretchable conductive fiber with a hollow core filled with liquid metal by the injection method,whose data were illustrated in (e) and (f); (g) fabrication for a conductive fiber with liquid metal by the dip-coating method

On the basis of ensuring electrical conductivity,more and more researchers began to study the flexible and stretchable liquid metal based conductive fibers. Chenetal.[52]reported a highly stretchable and electrical conductive fiber which contained a core stretchable fiber polyurethane (PU),an intermediate modified layer where polymethacrylate (PMA) was deposited to the surface of PU,and an EGaIn liquid metal outer layer. This three-layer structure PU@PMA@EGaIn(PPE) composite fiber can be stretched more than 500% with an electrical conductivity over 105S·m-1. Heetal.[53]developed a kind of liquid metal/cotton composite fiber. Compared with the conventional complex method to prepare liquid metal based composites,their work took advances from the friction on the surface of the twisted cotton yarns. During rubbing treatment,the liquid metal droplets were seperated into droplets,and were tightly stick to the surface of yarns due to the oxidation of droplets’ surface. This kind of conductor has the advantages of both the softness of cotton and the high conductivity (2.46×106S·m-1) of liquid metal. These works are exhibited in Fig. 5.

Fig. 5 Gallium-based liquid metal in smart fibers: (a) fabrication process; (b) basic electromechanical properties of the PPE fiber; (c) representation of liquid metal droplets adsorbed on the cotton fiber surface; (d) related properties

Rahimietal.[54]used the traditional sewing machine to stitch tygon microtube to a highly stretchable polyester fabric,and then injected the liquid metal. It is a facile method for direct integration of highly flexible and stretchable microfluidics into textile-based substrates,as illustrated in Fig. 6.

Fig. 6 Directly embroidering a liquid metal based fiber: (a) illustration of embroidering microtube onto a fabric substrate; (b) and (c) stretchable embroidered microfluidics with liquid dye and liquid alloy; (d) and (e) application of tension/stretch and indentation to the substrates

2.2 Flexible sensors

Liquid metal based sensors can be dated back from the work of Majidietal.[39]As shown in Fig. 7,their work embedded liquid metal into a soft elastomer such as PDMS and obtained a thin-film resistance-type strain sensor that could perceive curvature changes through structural design,which was soft (modulus 0.1-1.0 MPa),stretchable (strain 100%-1 000%) and elastic. The sensor consisted of two coplanar elastic membranes connected along its edge and center by a base support. One of them is configured with a microchannel along the center pillar that can be injected with liquid metal. When the strain occurs,the curvature deformation of the thin film sensor will exert pressure on the central pillar. This pressure will cause the deformation of the cross section of the microchannel injected with liquid metal,which is manifested as the change of resistance.

Fig. 7 Electrical resistance-type sensor with an embedded conductive liquid microchannel: (a) digital photographs; (b) schematic diagram

The most typical strain sensing behavior occurs when the liquid metal exists in the cavity of the hollow fiber,and thus the capacitive strain sensor can be formed by sensing the change of capacitance due to the deformation caused by external stimulation. Fibrous strain sensors have drawn many attention in the wearable electronic field because they can be woven[53,55].

Heetal.[53]further coated their as-prepared liquid metal/cotton composite fiber with PDMS and then stacked vertically to form a capacitive-type pressure sensor [shown in Fig. 8(a)] at the cross point,which can also be assembled as an integrated array. Stretchable elastic fibers with liquid metal can also be intertwined into a helix-like module to fabricate capacitive sensors of torsion,strain,and touch [shown in Fig. 8(b)]. Cooperetal.[56]twisted two hollow wires filled with liquid metal to form a double helix structure [shown in Fig. 8(c)]. When the helix fibers were twisted or streched,the contact area between them increased,and therefore the capacitance was changed [shown in Fig. 8(d)]. Similarly,Do and Visell[51]produced the hollow silicone microtubule by simple roller coating process and then injected liquid metal into the channel. After being twisted into a helix structure,it is demonstrated that it is possible to control their mechanical performance and electronic sensitivity.

Fig. 8 Fibrous sensors based on liquid metal: (a) digital photographs; (b) sensing proeperties for sensors prepared by the PDMS-coated metal/cotton composite fiber; (c) digital photographs; (d) sensing proeperties for sensors prepared by helix twisted hollow fibers filled with liquid metal

2.3 Smart fabrics

In the smart wearable field,the researchers’ target turned from one-dimensional fibrous elements to two-dimensional direct assembled fabrics gradually. Initially,the thin-film type liquid metal composite with liquid phase electronic circuits was formed mainly based on PDMS[57-59]by encapsulating the liquid metal within a carved elastomer. Furthermore,the researchers hope to use liquid metal directly forming circuits on the surface of various substrates in simpler and more efficient ways,such as directly writing and printing[45,60-61]. Through the doping modification of liquid metal,the wettability of liquid metal on different substrates can be changed,so as to be better combined with them. Hanetal.[60]presented a series of work in Fig. 9(a) on directly writing on a group of either soft or rigid substrates exhibited in Fig. 9(b) such as epoxy resin board,glass,plastic,silica gel,paper,cotton,textiles,clothes and fiber,by controlling the content of the oxide on its surface so as to change the wettability. Meantime,Lietal.[62]deposited EGaIn droplets on various substrates by the evaporation-induced sintering method. When the stable combination between the liquid metal and a variety of materials achieves,especially textile fabrics,it becomes a reality to applicate liquid metal in the field of smart textiles. For example,Guoetal.[63]reported new smart wearable fabrics fabricated by screen and roller printing liquid metal mixed with Cu particles (Cu-EGaIn) onto cotton fabrics and polyvinyl acetate (PVAC),making it possible to fabricate large-area and low-cost smart fabrics,as shown in Fig. 9(c).

Fig. 9 Gallium-based liquid metal in smart fabrics: (a) soft matter comb capacitors consist of PDMS and liquid metal; (b) directly writing on different substrates; (c) Cu-EGaIn based wearable electronics for smart fabrics

3 Conclusions

At present,the research of smart wearable technology is the forefront of the textile industry. As a flexible conductor,liquid metal has excellent properties,which can satisfy both the metallicity and flexibility,as well as formability. Conductive fibers,fibrous sensors and smart fabrics made from liquid metal are refreshing and significant for the development of flexible electronics and smart textile industries.

Although the oxide film on the surface of liquid metal stabilizes its connectivity in the hollow structure,it is difficult to be controlled precisely. At present,researchers fabricated liquid metal based electronics mainly by injection,printing and coating. Despite the difficulty of preparation is constantly reduced,how to fabricate it easily and produce in large-scale still needs to be further explored. Meanwhile,the giant surface tension and dispersion difficulties of liquid metal have great influences on the wettability interacting with substrate materials. Currently,it is still hard to stick to textile fabrics directly,which requires doping modification and external factors such as force,heat and electricity.

In summary,although the liquid metal based textile research is newly-developing,its advantages still spark the smart wearable field. Above shortages should be solved while researchers put forward to seeking more integrated application systems,such as healthy care and E-skin.

Journal of Donghua University(English Edition)2020年3期

Journal of Donghua University(English Edition)2020年3期

- Journal of Donghua University(English Edition)的其它文章

- Accident Analysis and Emergency Response Effect Research of the Deep Foundation Pit in Taiyuan Metro

- Effect of Elastane on Physical Properties of 1×1 Knit Rib Fabrics

- Knowledge Graph Extension Based on Crowdsourcing in Textile and Clothing Field

- Analysis on the Application of Image Processing Technology in Clothing Pattern Recognition

- Clothes Keypoints Detection with Cascaded Pyramid Network

- Encryption and Decryption of Color Images through Random Disruption of Rows and Columns