长垣外围A区块调驱体系优选与评价

陈丽蓥 周志军

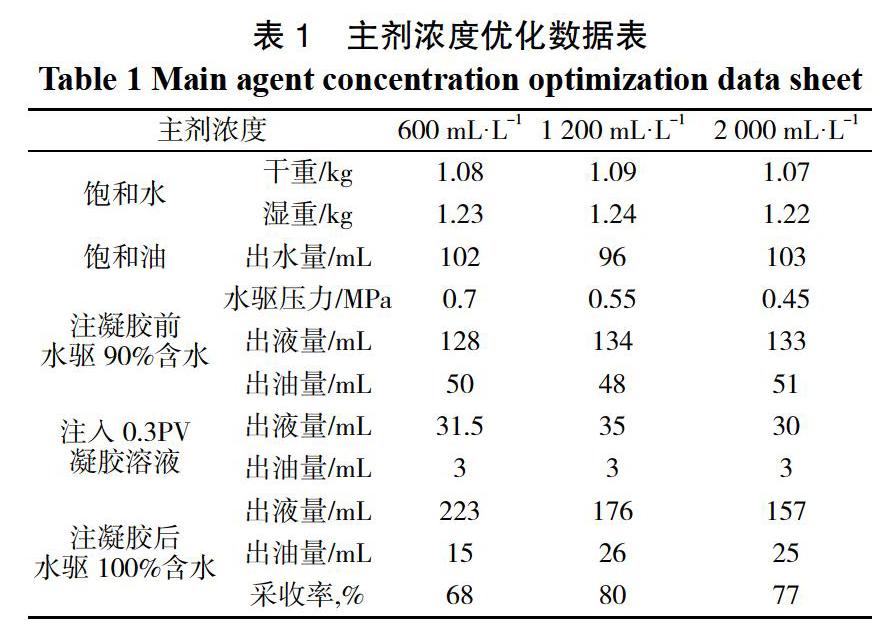

摘 要:为了解决目前长垣外围油田的特高含水开发期其开采增油量增幅小的问题,普遍使用交联剂与聚合物(HPAM)组成的弱凝胶调驱体系来提高采收率,通过室内岩心流动实验方法研究了复合离子调驱体系的主剂浓度、注入量、注入方式和段塞优化、注入时机和注入速度参数进行优化分析。结果表明:选择1 200 mL/L的主劑浓度,0.3PV的注入量,90%的含水时机,采收率均能达到80%以上;三倍级差时采收率增幅达到最高值,封堵率随级差倍数的增加而降低。可见,复合离子弱凝胶调驱体系对长垣外围油田提高采收率方面有很大帮助,优选出最适宜的注入工艺可以达到最优效果。

关 键 词:调驱体系;应用性能评价;复合离子凝胶;采收率增幅

中图分类号:TQ 357.4 文献标识码: A 文章编号: 1671-0460(2020)04-0577-04

Abstract: In order to solve the problem of small increase rate in oil production increment in the development stage of extra high water cut in Changyuan peripheral oilfields, the weak gel flooding system composed of crosslinking agent and polymer (HPAM) was widely used to enhance oil recovery. The main agent concentration, injection volume, injection mode and slug optimization, and timing of injection were studied through laboratory core flow experiment. The injection velocity parameters were optimized. The results showed that, when the main agent concentration was 1 200 mL/L, the injection volume was 0.3 PV and the injection timing was at the water cut reaching 90%, the recovery rate was more than 80%; when the permeability ratio was 3, the increase rate of the recovery factor reached the highest value, and the plugging rate decreased with the increase of the permeability ratio. So the composite ion weak gel profile control and flooding system was very helpful for enhancing oil recovery in Changyuan peripheral oilfields.

Key words: Profile control and flooding system; Application performance evaluation; Composite ionic gels; Recovery increase rate

目前大庆油田开发进入注水开发的后期,地层处于高含水阶段,地层中的剩余油分布有很大变化且很散,但是采出程度只占40.6%,还有大量的剩余储量未被开采出来。而由于长期开采而水优先进入高渗层反复冲刷造成地层内非均质性非常严重,形成的水流通道也是油井出水、采收率较低的原因,由于这种现象造成的产出液量非常大,处理产出液的工作也很繁重,对管线有一定损耗还浪费资源,成本提高使经济效益下降,为了减少无效的水循环现象[1-3],提高原油采收率是现在最重要的问题,为了解决这一问题,众位学者都对其进行了研究认为做直接有效的方式就是进行调驱[4-6]。其中使用最广泛的就是凝胶调驱剂,而复合离子凝胶调驱剂的效果更好[7]。本文针对试验A区块的调驱需要,通过对复合离子凝胶调驱剂的参数和性能方面进行评估,来分析最适宜的调驱方式[8]。

1 实验部分

1.1 材料和仪器

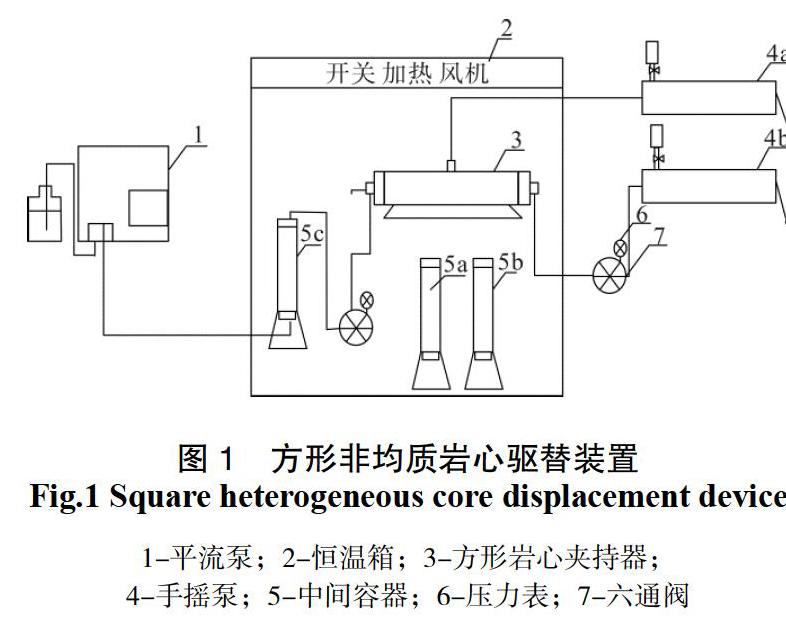

实验仪器:平流泵、电子秤、恒温水箱、方形岩心夹持器、中间容器、手摇泵、恒温箱、搅拌器、岩心、六通阀、10mL移液管若干、量筒若干、管线若干、布氏黏度计、广口瓶若干。

实验材料:弱凝胶A-800 ppm, B-1 800 ppm,C-200 ppm;级差岩心100/350、200/450;三层岩心:150/300/450。

1.2 实验步骤

凝胶配置工艺:取200 mL地层水装入500 mL烧杯中,开始搅拌;准确称量1.700 g聚合物;准确称量3.600 g交联剂,缓慢加入到搅拌旋涡中,搅拌均匀;准确称0.045 g稳定剂,缓慢加入到搅拌旋涡中,搅拌至完全溶解;将上述溶液装入密闭容器,以此模拟凝胶在地层中的实际成胶情况,放入48 ℃烘箱等待成胶。

岩心实验:模拟温度:40 ℃,所用模拟水为庆新油田提供的模拟水;用一定比例的原油和煤油混合配制模拟油。实验流程如图1。

(1)方形差异岩心饱和模拟水、饱和模拟油