含水率对小麦粮堆弹塑性力学特性的影响

蒋敏敏,陈桂香,刘超赛,刘文磊,张志静

·农产品加工工程·

含水率对小麦粮堆弹塑性力学特性的影响

蒋敏敏,陈桂香,刘超赛,刘文磊,张志静

(1. 河南工业大学土木工程学院,郑州 450001;2. 粮食储运国家工程实验室,郑州 450001)

不同地区粮仓中粮堆的含水率会有较大的差异,为了明确含水率对粮仓设计参数的影响,通过三轴试验研究了含水率对小麦粮堆非线性强度、临界状态和模量等的影响规律。结果表明:不同含水率下小麦粮堆的峰值强度和残余强度符合非线性强度指标的Mohr-Coulomb强度准则;参考压力(100 kPa)下峰值内摩擦角和残余内摩擦角随着含水率的增大呈线性增大,含水率每增加1%,峰值内摩擦角和残余内摩擦角分别增大0.22°和0.30°。小麦粮堆的临界状态特性符合剑桥弹塑性理论,偏应力随着平均法向应力的增大呈线性增大;峰值应力比和临界状态应力比随着含水率的增大呈线性增大;含水率每增加1%时,峰值应力比和临界状态应力比分别增大0.012和0.014。不同含水率下初始模量、割线模量与围压间可采用幂函数模型表示;参考压力下初始模量和割线模量均随着含水率的增大呈线性降低;含水率每增加1%,初始模量和割线模量分别降低0.98和0.25 MPa。

粮食;含水率;强度;临界状态;弹性模量

0 引 言

2013年以来中国粮食年产量超6亿t,国内各地环境差异较大,储存于粮仓内的大体积粮堆含水率也存在着较大的差异,如中国西北地区为干燥区域,粮食含水率较低,而东南地区为湿热区域,相应的粮食含水率会较高[1]。目前随着粮食仓储技术的发展,出现了不少高度和直径大于30 m、仓容量达数万吨的大型粮仓[2-3]。粮食在装卸过程中的力学指标是现代大型粮食仓储设施设计[4-5]和研究的重要指标[6-10]。含水率变化会影响粮堆力学性质,进而改变粮仓结构受力状态,研究含水率对仓内粮堆力学指标的影响具有重要的科学和工程意义。

粮食储藏和加工中籽粒的基本物理和力学特性受到了国内外学者的关注。Afkari Sayyah[11]利用压缩试验,基于Hertz理论得出小麦籽粒的表观弹性模量范围,并得出最大接触应力和籽粒破损力等参数,提出颗粒硬度与力学性质指标之间为线性关系。周显青等[12]对糙米的锥刺、三点弯曲、剪切、挤压等破碎力学特性进行了研究,提出三点弯曲力更能反映籽粒的破碎特性。Singh等[13]提出随着含水率增大,粮食休止角、内摩擦角、外摩擦角越大,而体积密度、颗粒破损荷载则越小。Yang等[14]提出稻种状态和含水率对杂交水稻的容积密度影响显著,并给出了包衣稻谷物理参数的范围。张克平等[15]通过压缩试验研究了不同含水率下小麦籽粒的弹性模量、屈服强度、破碎负载等特性,表明破碎负载、弹性模量、屈服强度随着含水率的增加有明显降低,并对比分析了不同压缩型式下的压缩破坏指标。

粮仓中的粮食是以大体积粮堆的形式存在,粮堆力学性质对于粮仓的研究更为重要。刘志云等[16]研究了法向压应力和含水率对糙米粮堆力学特性的影响,表明内摩擦角随着法向压应力的增大而减小,法向压应力小于25 kPa时,内摩擦角随着含水率的增加而逐渐增大,法向压应力大于75 kPa时,内摩擦角随着含水率增大至一定值后逐渐降低。彭飞等[17]给出了不同含水率、粒度小麦粉堆的内摩擦角、滑动摩擦角、休止角等指标的范围。Subramanian[18]提出随着含水率增大,粮堆的堆积密度逐渐减小,而粮堆内摩擦角、粮堆与结构间的静摩擦系数均越大。

近年来由于大型、新型粮仓结构和偏心卸料等问题的研究,在粮堆复杂力学特性方面取得了一些进展。蒋敏敏等[19]通过三轴试验研究了密度和加载条件对小麦粮堆模量和强度特性的影响。陈家豪等[20-21]将小麦粮堆的三轴剪切曲线分为线弹性、应力强化、剪切面滑动和破坏4个阶段,建立了小麦粮堆弹性模量与围压间的拟合关系曲线。曾长女等[22]通过三轴试验研究了含水率、孔隙率对小麦粮堆强度参数的影响,提出随着孔隙率的减小和含水率的增大,内摩擦角和黏聚力呈增大趋势。Cheng等[23]通过压缩试验,研究了压力和含水率对玉米粮堆堆积密度和等效体积模量的影响,并建立了堆积密度和等效体积模量的计算公式。程绪铎等[24]通过三轴试验研究了含水率、围压对稻谷粮堆的堆积密度、体变模量的影响,以及堆积密度和体变模量的变化范围。陈雪等[25-26]研究了不同含水率下稻谷粮堆的修正剑桥模型参数,得出了弹性模量、泊松比、临界状态应力比、初始孔隙比、对数硬化模量、等向膨胀指数等的变化范围以及随含水率的变化规律。高梦瑶等[27]研究了不同含水率下小麦粮堆修正剑桥模型参数的数值范围,建立了弹性模量与广义剪切力、平均主应力的关系模型。

目前对于粮食力学性质的研究集中于粮食籽粒、粮堆基本力学性质和复杂力学特性等几个方面,在粮堆复杂力学特性方面,现有的研究主要集中于线性强度特性和弹塑性力学指标的数值范围。然而粮食籽粒具有一定的可压缩性[11-13],以往借鉴于土体材料的线性强度理论在反映粮堆强度特性上有一定不足,不能反映籽粒可压缩性对整体粮堆强度的影响,同时现有研究未深入分析含水率对粮堆复杂弹塑性力学特性的影响。本文通过三轴试验,研究不同含水率下粮堆的非线性强度、临界状态和模量等特性,并建立含水率与非线性内摩擦角、应力比和模量之间的关系模型。针对不同含水率粮堆的问题,为粮仓研究和设计提供粮堆的力学计算模型和参数,相关模型可编制程序用于数值计算,对实际粮仓在不同工况下的受力特性进行计算。

1 试验材料与方法

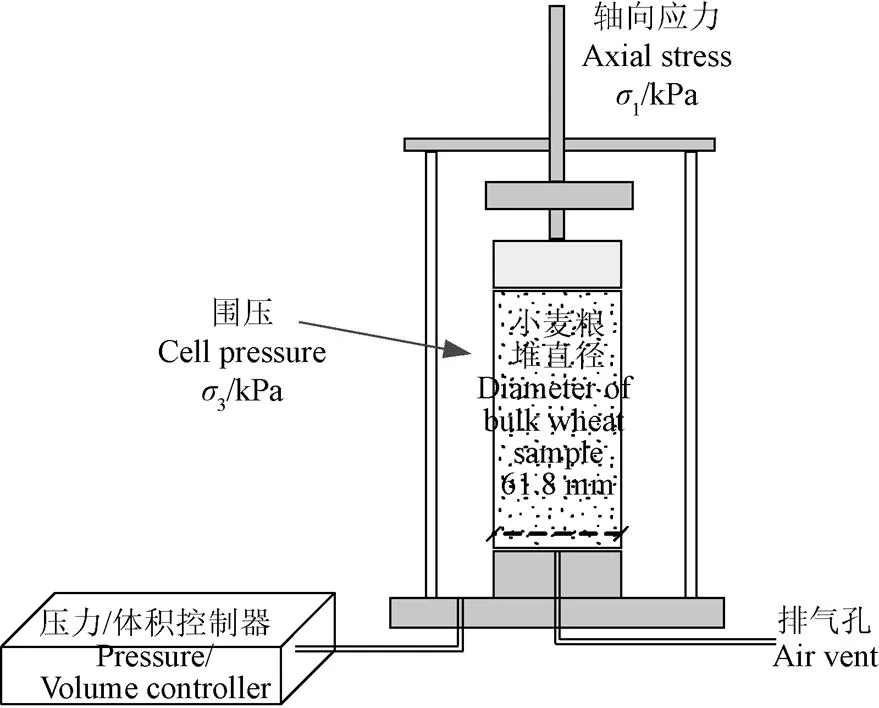

粮仓内粮堆由于受到装、卸料等不同工况的作用,在不同位置应力状态变化较大。为了得出粮堆弹塑性力学规律,本研究采用单元试验的方法,在粮仓大体积粮堆内取小单元(高度124 mm、直径61.8 mm),对单元施加不同的竖向和侧向应力组合,还原粮仓内不同位置、不同工况下的应力状态,进而研究粮堆的弹塑性力学特性。

河南小麦产量占全国的四分之一,本研究采用河南郑州产小麦作为试验材料,品种为关陵113。将小麦试样在105 ℃的恒温箱中烘至恒质量,再将小麦试样配至4.90%、8.56%、10.64%和13.45%四种不同的含水率,并将试样密封在塑料袋内,在10 ℃下静置7 d,保证试样内含水率均衡。

试验在多功能应力路径三轴仪中进行,三轴试验装置和试样示意图如图1所示。在承膜筒中将配制好的小麦装入橡皮膜中,制成高度124 mm、直径61.8 mm、堆积密度为0.8 g/cm3的圆柱形粮堆试样。小麦籽粒的等效平均粒径为4.5 mm,粮堆试样直径与籽粒直径的比为13.7,符合三轴试验尺寸比的要求[28]。通过对试样分别施加50、100、150、200、250、300 kPa不同等级的围压,模拟粮仓内不同深度的粮堆单元受到的压力,再对试样施加轴向应力,使试样中产生剪切偏应力直至试样的轴向应变大于25%,达到临界状态[28](即随着轴向应变的增大,偏应力趋于稳定值),剪切时粮堆孔隙中的气体通过底座排气孔自由排出。

图1 小麦粮堆三轴试验示意图

2 强度特性

典型的小麦粮堆(含水率为8.56%)三轴剪切试验结果如图2所示。从试验结果可见,在短暂的弹性阶段后,小麦粮堆的偏应力=(1-3)与轴向应变1呈现明显非线性特性(曲线斜率逐渐变小),在轴向应变大于一定值后,偏应力增量逐渐变小,表明小麦粮堆单元接近剪切破坏。

图2 含水率8.56%的小麦粮堆不同围压下的应力应变曲线

粮仓内大体积粮堆在装卸或受力条件发生变化时,当单元最大剪应力达到强度条件时会发生破坏,因此强度是仓内粮堆最重要的弹塑性指标。峰值强度是对应于三轴剪切中产测的最大的偏应力的一半,残余强度是对应于三轴剪切中轴向应变大于15%后,稳定偏应力值的一半[28]。

以往研究在分析粮堆强度时采用线性强度理论[22]

式中为无围压时材料的抗剪强度,kPa;是材料内摩擦角,(°)。用线性强度理论拟合得出小麦粮堆的介于8.8~12.6 kPa之间,这与小麦粮堆是松散堆积体不符。

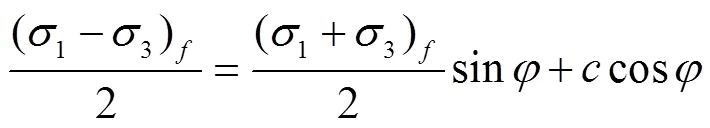

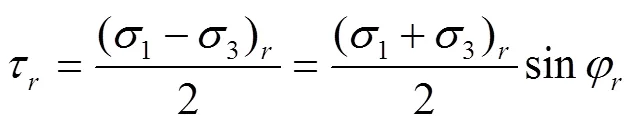

本研究对小麦粮堆的强度特性采用Mohr-Coulomb理论表示,峰值强度τ表示为[28]

式中1、3分别为轴向应力和围压,kPa;(1+3)/2为峰值平均应力,kPa。

残余强度τ表示为

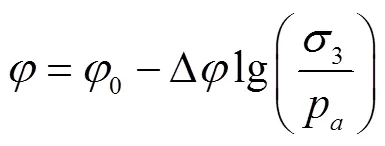

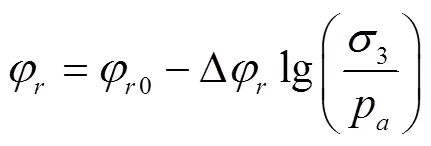

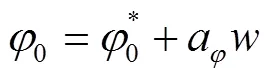

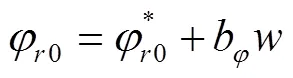

式中(1+3)/2为残余平均应力,kPa。φ是材料的残余内摩擦角,(°)。粮食籽粒在荷载下具有一定的可压缩性[11,15],具有可压缩性或破碎性的无黏性颗粒材料内摩擦角可表示为随着压力变化的非线性强度指标形式[29-30],内摩擦角和残余内摩擦角可分别表示为

式中0和φ0是参考压力(围压100 kPa)下的内摩擦角和残余内摩擦角,(°);Δ和Δφ是反映内摩擦角随着围压增长而降低的参数,(°);p为大气压力,本文取100 kPa。将式(4)和(5)代入式(2)和(3),峰值强度可进一步表示为

残余强度可进一步表示为

不同含水率和围压下,小麦粮堆的峰值强度和残余强度如图3所示。由图可知,不同含水率下峰值强度、残余强度的试验值与拟合值的相关系数介于0.998~1.0之间,具有较好的相关性。从试验结果可见,小麦粮堆的强度符合非线性强度理论,平均应力(1+3)/2为0时,最大剪应力(1−3)/2为0,内摩擦角(曲线倾角)随着平均应力的增大略有降低。含水率对参考压力下内摩擦角0和残余内摩擦角φ0的影响如表1所示。

注:τ为峰值强度,τ为残余强度。

Note: τis peak strength,τis residual strength.

图3 不同含水率下小麦粮堆强度

Fig.3 Strength of wheat bulk under different moisture content

表1 含水率对参数φ0、φr0、Δφ和Δφr的影响

注:0和φ0是参考压力下的内摩擦角和残余内摩擦角,(°);Δ和Δφ是反映内摩擦角和残余内摩擦角随着围压变化的参数,(°)。

Note:0andφ0are internal friction angle and residual internal friction angle under reference cell pressure respectively, (°); Δ和Δφare the parameters of internal fiction angle and residual internal fiction angle that changed with increase of cell pressure (°).

从结果可见,含水率从4.90%增大为13.45%,参考压力下内摩擦角0从25.4°增大为27.4°,残余内摩擦角φ0从24.1°增大为26.7°。0、φ0与含水率之间的线性公式拟合为

3 临界状态特性

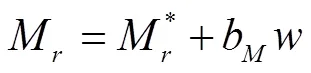

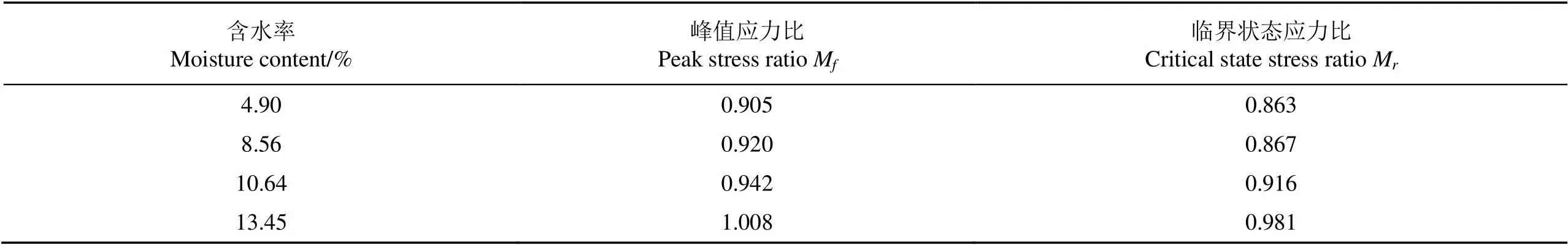

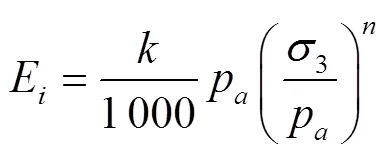

剑桥弹塑性理论[28]中,无黏性颗粒材料在-(为偏应力,1-3;为平均法向应力,=(1+23)/3)平面上,峰值结果和临界状态结果呈线性规律[28,30-31],分别表示为

q=Mp(10)

q=Mp(11)

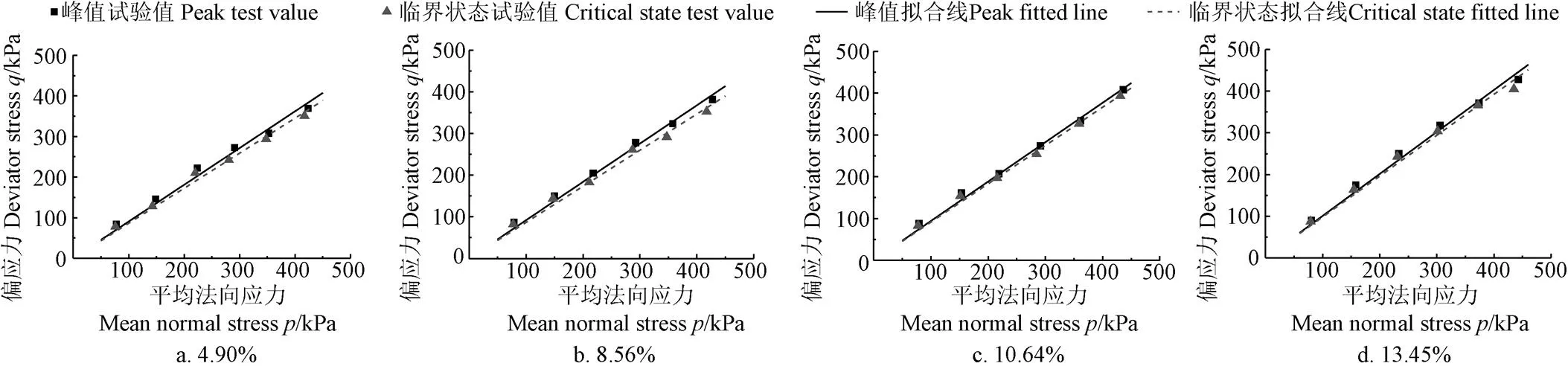

式中q、p分别为峰值时偏应力和平均法向应力,kPa;q、p分别为临界状态时偏应力和平均法向应力,kPa;M、M为峰值应力比和临界状态应力比。不同含水率下小麦粮堆的临界状态特性如图4所示,图中包含了峰值结果(偏应力为峰值)和临界状态结果(轴向应变较大且偏应力趋于稳定时)。从试验结果可见,不同含水率下小麦粮堆的临界状态特性均符合剑桥弹塑性理论,即偏应力随着平均法向应力的增大呈线性增大。不同含水率下临界状态应力比M较峰值应力比M略低。

含水率对峰值应力比M和临界状态应力比M的影响如表2所示。从结果可见,含水率从4.90%增大至13.45%,小麦粮堆峰值应力比M从0.905增大至1.008,而临界状态应力比M从0.863增大至0.981。M和M随着含水率的增大呈线性增大,峰值应力比、临界状态应力比与含水率之间的线性拟合公式为

图4 不同含水率下小麦粮堆临界状态特性

表2 含水率对应力比的影响

4 模量特性

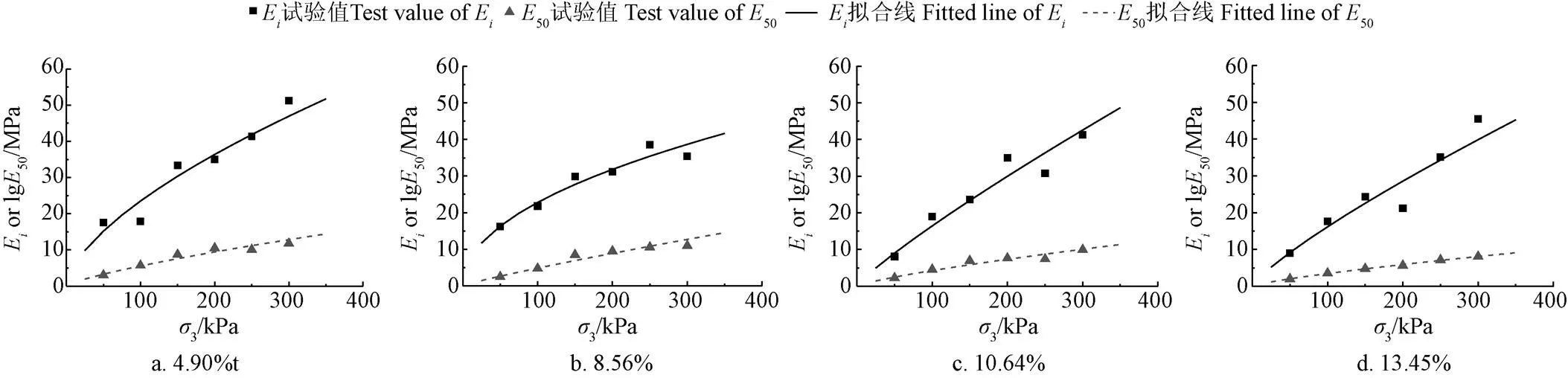

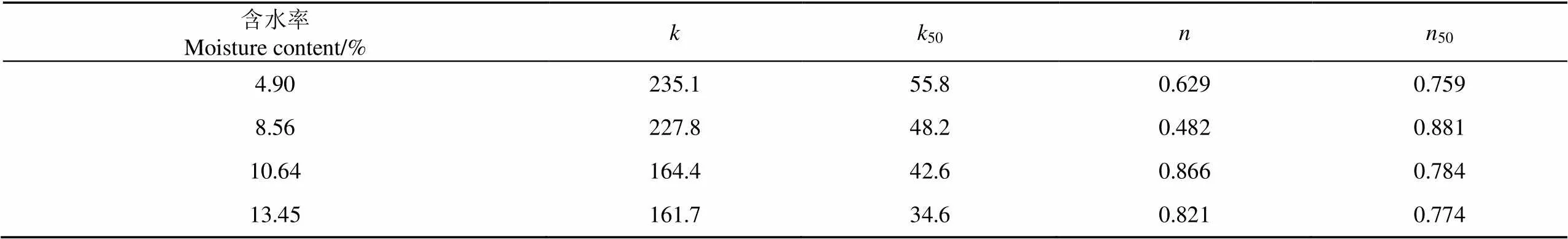

模量是粮堆弹塑性分析计算的重要参数,初始模量E是轴向应变极小(ε=0.05%)时的模量,割线模量50是偏应力为(1−3)/2时的模量[30]。根据三轴试验结果得出不同含水率下小麦粮堆的初始模量E和割线模量50随围压的变化如图5所示。从结果可见,小麦粮堆的割线模量远小于初始模量,在双对数坐标中初始模量、割线模量与围压之间为线性关系,即模量与围压之间可采用幂函数模型表示[28]。初始模量可拟合为

割线模量可拟合为

参数和50分别是参考压力(围压100 kPa)下初始模量比值E/p和割线模量比值50/p;、50为模型指数。

初始模量比值和割线模量比值50随含水率的变化如表3所示。从结果可见,随着含水率的增大,参数和50降低,表明含水率越大,参考压力下初始模量和割线模量均越小,参数和50的线性公式拟合为

注:Ei和E50分别为初始模量和割线模量。

表3 含水率对参数k、k50、n和n50的影响

注:和50分别是参考压力下初始模量比值E/p和割线模量比值50/p。

Note:and50is initial modulus ratioE/pand secant modulus ratio50/punder reference pressure.

5 结 论

本研究针对不同含水率的小麦粮堆弹塑性力学特性的问题,通过三轴试验研究了含水率对非线性强度指标、临界状态特性和模量等的影响规律,并建立了各指标的数学模型,得到以下主要结论:

1)不同含水率下小麦粮堆的峰值强度和残余强度可用非线性强度指标的Mohr-Coulomb强度准则表示。参考压力下(100 kPa)峰值内摩擦角和残余内摩擦角随着含水率增大呈线性增大;含水率为0时,参考压力下峰值内摩擦角和残余内摩擦角分别为24.03°和22.31°;含水率每增加1%,参考压力下峰值内摩擦角和残余内摩擦角分别增大0.22°和0.30°。

2)小麦粮堆的临界状态特性符合剑桥弹塑性理论,偏应力随着平均法向应力的增大呈线性增大。峰值应力比和临界状态应力比均随着含水率的增大呈线性增大;含水率为零,峰值应力比和临界状态应力比,分别为0.835和0.776;含水率每增加1%,峰值应力比和临界状态应力比分别增大0.012和0.014。

3)不同含水率下小麦粮堆的初始模量、割线模量与围压间均可用幂函数模型表示。参考压力下初始模量和割线模量均随着含水率的增大呈线性降低;含水率为0时,参考压力下初始模量和割线模量分别为28.9和6.86 MPa;含水率每增加1%,参考压力下初始模量和割线模量分别降低0.98和0.25 MPa。

[1]汤子俊,王明洁,吴曙球. 从气候条件看中国的储粮区域[J]. 粮食储藏,1999(4):22-31. Tang Zijun, Wang Mingjie, Wu Shuqiu. Preliminary study on Chinese stored grain areas according to Chinese climate[J]. Grain Storage, 1999(4): 22-31. (in Chinese with English abstract)

[2]鲍国良,姚蔚. 我国粮食生产现状及面临的主要风险[J]. 华南农业大学学报,2019,18(6):111-120. Bao Guoliang, Yao Wei. Current situation and main risks of grain production in China[J]. Journal of South China Agricultural University, 2019, 18(6): 111-120. (in Chinese with English abstract)

[3]Cao Q, Zhao Y. Buckling design of large steel silos with various slendernesses[J]. Journal of Zhejiang University- SCIENCE A, 2017, 18(4): 282-305.

[4]国家粮食局. GB50322-2011粮食钢板筒仓设计规范[S]. 北京:中国计划出版社,2011.

[5]Song C Y, Teng J G. Buckling of circular steel silos subject to code-specified eccentric discharge pressures[J]. Engineering Structures, 2003, 25(11): 1397-1417.

[6]Sanad A M, Ooi J Y, Holst J M F G, et al. Computations of granular flow and pressures in a flat-bottomed silo[J]. Journal of Engineering Mechanics, ASCE, 2001, 127(10): 1033-1043.

[7]Vidal P, Couto A, Ayuga A, et al. Influence of hopper eccentricity on discharge of cylindrical mass flow silos with rigid walls[J]. Journal of Engineering Mechanics, ASCE, 2006, 132(9): 1026-1033.

[8]Abdel-Fattah M T, Moore I D, Abdel-Fattah T T. A numerical investigation into the behavior of ground- supported concrete silos filled with saturated solids[J]. International Journal of Solids and Structures, 2006, 43: 3723-3738.

[9]Vidal P, Gallego E, Guaita M, et al. Finite element analysis under different boundary conditions of the filling of cylindrical steel silos having an eccentric hopper[J]. Journal of Constructional Steel Research, 2008, 64: 3723-3738.

[10]Goodey R J, Brown C J, Rotter J M. Rectangular steel silos: Finite element predictions of filling wall pressures[J]. Engineering Structures, 2017, 132: 61-69.

[11]Afkari Sayyah A H, Minaei S. Behavior of wheat kernels under quasi-static loading and its relation to grain hardness[J]. Journal of Agricultural Science and Technology, 2004, 6(1/2): 11-19.

[12]周显青,张玉荣,褚洪强,等. 糙米机械破碎力学特性试验与分析[J]. 农业工程学报,2012,28(18):255-262. Zhou Xianqing, Zhang Yurong, Chu Hongqiang, et al. Experiment and analysis of mechanical properties of mechanical crushing brown rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(18): 255-262. (in Chinese with English abstract)

[13]Singh K P, Mishra H N, Saha S. Moisture-dependent properties of barnyard millet grain and kernel[J]. Journal of Food Engineering, 2010, 96(4): 598-606.

[14]Yang L, Yang M , Li Q, et al. Experimental study on physical properties of coated rice seed[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(9): 7-11.杨玲,杨明金,李庆东,等. 包衣稻种物理特性的试验研究[J]. 农业工程学报,2005, 21(9): 7-11. (in English with Chinese abstract)

[15]张克平,黄建龙,杨敏,等. 冬小麦籽粒受挤压特性的有限元分析及试验验证[J]. 农业工程学报,2010,26(6):352-356. Zhang Keping, Huang Jianlong, Yang Min, et al. Finite element analysis and experimental verification of wheat grain under compression loads[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(6): 352-356. (in Chinese with English abstract)

[16]刘志云,黄之斌,程绪铎. 含水率对糙米内摩擦角影响的实验研究[J]. 粮食储藏,2012,41(3):33-36. Liu Zhiyun, Huang Zhibin, Cheng Xuduo. Influence of moisture content on internal friction angle of coarse rice [J]. Grain Storage, 2012, 41(3): 33-36. (in Chinese with English abstract)

[17]彭飞,杨洁,王红英,等. 小麦粉摩擦特性的试验研究[J]. 中国粮油学报,2015,30(8):7-12. Peng Fei, Yang Jie, Wang Hongying, et al. Experimental research on friction characteristics of wheat meal[J]. Journal of the Chinese Cereals and Oils Association, 2015, 30(8): 7-12. (in Chinese with English abstract)

[18]Subramanian S, Viswanathan R. Bulk density and friction coefficients of selected minor millet grains and flours[J]. Journal of Food Engineering, 2007, 81(1): 118-126.

[19]蒋敏敏,郭祝辉,陈桂香. 三轴压缩下小麦粮堆模量和强度特性研究[J]. 河南工业大学学报,2017,38(6):80-85. Jiang Minmin, Guo Zhuhui, Chen Guixiang. Study of modulus and strength properties of wheat heap in triaxial compression tests[J]. Journal of Henan University of Technology, 2017, 38(6): 80-85. (in Chinese with English abstract)

[20]陈家豪,韩阳,任杰,等. 小麦堆压缩模量的三轴试验研究[J]. 河南工业大学学报,2016,37(1):23-28. Chen Jiahao, Han Yang, Ren Jie, et al. Research on triaxial tests of compression modulus of wheat piles[J]. Journal of Henan University of Technology, 2016, 37(1): 23-28. (in Chinese with English abstract)

[21]许启铿,陈家豪,王录民. 小麦力学参数的三轴压缩试验研究[J]. 河南工业大学学报,2015,36(5):101-105. Xu Qikeng, Chen Jiahao, Wang Lumin. Mechanical properties of wheat in triaxial compression tests[J]. Journal of Henan University of Technology, 2015, 36(5): 101-105. (in Chinese with English abstract)

[22]曾长女,冯伟娜. 小麦强度特性的三轴试验研究[J]. 中国粮油学报,2015,30(5):96-101. Zeng Changnü, Feng Weina. Strength properties of wheat in triaxial tests[J]. Journal of the Chinese Cereals and Oils Association, 2015, 30(5): 96-101. (in Chinese with English abstract)

[23]Cheng X, Zhang Q, Yan X, et al. Compressibility and equivalent bulk modulus of shelled corn[J]. Biosystem Engineering, 2015, 140: 91-97.

[24]程绪铎,严晓婕,徐鑫,等. 稻谷堆的压缩密度与体变模量的测定与分析[J]. 中国粮油学报,2014,29(8):101-105. Cheng Xuduo, Yan Xiaojie, Xu Xin, et al. The measurement and analysis on compressive density and bulk stain modulus of paddy pile[J]. Journal of the Chinese Cereals and Oils Association, 2014, 29(8): 101-105. (in Chinese with English abstract)

[25]陈雪,程绪铎,龙桃,等. 稻谷堆修正剑桥模型参数的测定及含水率对其影响[J]. 中国粮油学报,2019,34(10):68-73. Chen Xue, Cheng Xuduo, Long Tao, et al. Determination in the parameters of modified cam-clay model of paddy pile and the effect of moisture content[J]. Journal of the Chinese Cereals and Oils Association, 2019, 34(10): 68-73. (in Chinese with English abstract)

[26]Du X, Cheng X, Gao M. Determination of the parameters of Modified Cam-Clay model for paddy grain[J]. Journal of Cereal Science, 2017, 76: 1-7.

[27]高梦瑶,程绪铎,杜小翠,等. 小麦堆修正剑桥模型的参数研究[J]. 中国粮油学报,2017,32(7):103-107. Gao Mengyao, Cheng Xuduo, Du Xiaocui, et al. Research on parameters of modified Cam Clay for wheat pile[J]. Journal of the Chinese Cereals and Oils Association, 2017, 32(7): 103-107. (in Chinese with English abstract)

[28]殷宗泽. 土工原理[M]. 北京:中国水利水电出版社,2007.

[29]陈志波,朱俊高. 宽级配砾质土三轴试验研究[J]. 河海大学学报,2010,38(6):704-710. Chen Zhibo, Zhu Jungao. Triaxial tests on widely graded gravelly soil[J]. Journal of Hohai University, 2010, 38(6): 704-710. (in Chinese with English abstract)

[30]朱俊高,史江伟,罗学浩,等. 密度对砂土应力应变强度特性影响试验研究[J]. 岩土工程学报,2016,38(2):336-341. Zhu Jungao, Shi Jiangwei, Luo Xuehao, et al. Experimental study on stress-strain-strength behavior of sand with different densities[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(2): 336-341. (in Chinese with English abstract)

[31]蔡正银,李小梅,韩林,等. 考虑级配和颗粒破碎影响的堆石料临界状态研究[J]. 岩土工程学报,2016,38(8):1357-1364. Cai Zhengyin, Li Xiaomei, Han Lin, et al. Critical state of rockfill materials considering particle gradation and breakage[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(8): 1357-1364. (in Chinese with English abstract)

Effects of moisture content on elastic-plastic properties of bulk wheat

Jiang Minmin, Chen Guixiang, Liu Chaosai, Liu Wenlei, Zhang Zhijing

(1.,,450001,; 2.,450001,)

The total annual output of grain is about 600 million tons in China. With the development of grain storage technology, grain bins with diameter larger than 30 m and capacity exceed tens of thousand tons emerged in recent years. As the climate in different regions vary greatly in China, grain moisture content varied significant in bins accordingly, for instance, grain moisture content is high in bins in southeast of China, while it is substantially low in northwest of China. The effect of moisture content on elastic-plastic properties of bulk wheat was investigated in this study. Wheat grain produced in Zhengzhou, China was utilized in this study, the equivalent diameter of kernel was 4.5 mm. The wheat was dried in oven under 105 ℃, wetted to moisture content of 4.90%, 8.56%, 10.64% and 13.45%, and sealed in plastic bag and placed in refrigerator under 10 ℃ to equilibrate for 7 days to a stable state. Then bulk wheat sample was tested in stress path triaxial apparatus. The bulk density was 0.8 g/cm3, the height of sample was 124 mm, and diameter was 61.8 mm which was about 13.7 times of equivalent kernel diameter, and diameter ratio conformed to the requirement of triaxial test. Cell pressure in the test was set to be 50, 100, 150, 200, 250 and 300 kPa, the maximum cell pressure of 300 kPa covered most situation in grain bins. The wheat samples were sheared by increase axial stress, while keep cell pressure constant, until axial strain was large than 25%, which was correspond to the critical state. Test results showed that peak shear strength and residual shear strength followed nonlinear Mohr-Coulomb criterion for granular material, in that the cohesion was zero, friction angle was a nonlinear parameter depending on cell pressure. The friction angle decreased with the increase of logarithmic value of cell pressure. Peak friction angle and residual friction angle under reference pressure (100 kPa) increased with the increase of moisture content, as moisture content increased from 4.90% to 13.45%, peak friction angle increased from 25.4° to 27.4° and residual friction angle increased from 24.1° to 26.7°. Peak friction angle and residual friction angle under reference pressure were 24.03° and 22.31° when moisture content was zero. As moisture content increased for 1%, peak friction angle and residual friction angle under reference pressure increased by 0.22° and 0.30° respectively. In deviator stress - mean normal stress plane, the peak result and critical state result followed Cambridge elastic-plastic theory, i.e. deviator stress increased linear with mean normal stress. Peak stress ratio and critical state stress ratio increased linear with moisture content. As moisture content increased from 4.90% to 13.45%, peak stress ratio increased from 0.905 to 1.008 and critical state stress ratio increased from 0.863 to 0.981. When moisture content was zero, peak stress ratio and critical state stress ratio was 0.835 and 0.776 respectively, and moisture content increased for 1%, peak stress ratio and critical state stress ratio increased by 0.012 and 0.014 respectively. Initial modulus was the modulus under axial strain of 0.05%, secant modulus was the modulus under half of peak deviator stress. The relationship between initial modulus, secant modulus and cell pressure could be expressed through power function model. Initial modulus and secant modulus under reference pressure decreased linear with moisture content. Initial modulus and secant modulus under reference pressure was 28.9 and 6.86 MPa when moisture content was zero, and moisture content increased for 1%, initial modulus and secant modulus under reference pressure decreased for 0.98 MPa and 0.25 MPa respectively. As moisture content ranged from 4.90% to 13.45%, the exponent in initial modulus model was between 0.482 and 0.866, the exponent in secant modulus model was between 0.759 and 0.881.

grain; moisture content; strength; critical state; elastic modulus

蒋敏敏,陈桂香,刘超赛,等. 含水率对小麦粮堆弹塑性力学特性的影响[J]. 农业工程学报,2020,36(10):245-251.doi:10.11975/j.issn.1002-6819.2020.10.030 http://www.tcsae.org

Jiang Minmin, Chen Guixiang, Liu Chaosai, et al. Effects of moisture content on elastic-plastic properties of bulk wheat[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(10): 245-251. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.10.030 http://www.tcsae.org

2019-11-28

2019-05-15

国家自然科学基金项目(51408197);粮食公益性行业科研专项(201513001);河南省科技攻关项目(162102210188)。

蒋敏敏,博士,副教授,主要从事粮食仓储结构等方面的研究。Email:jiangmmhaut@126.com

10.11975/j.issn.1002-6819.2020.10.030

TS210

A

1002-6819(2020)-10-0245-07