A novel non-separation opening scheme of front cover for rocket launch canister

Ce Zhang,Xin Zhao,Zonglai Mo,Zhuoyu Guo,Jun Li

School of Mechanical Engineering,Nanjing University of Science and Technology,Nanjing,210094,China

ABSTRACT In view of that existing opening technologies of front cover for rocket launch canister have disadvantages such as causing damage on the ground equipment,not being reused and easily broken.A novel reusable non-separation spring-driven opening scheme is proposed to achieve rapid and reliable opening of the front cover.The mathematical model of the opening process of the front cover is established by the rigid body dynamics theory.To establish a response surface model to optimize the opening scheme,three main influencing factors of the opening process are obtained through the designed experiments,including the pre-compression,the stiffness of the thrust spring,and the thrust spring force arm length.In addition,the prescribed kinematic law was taken as constraint,and the smaller thrust spring preliminary pressure and angular velocity was taken as optimization expectations.The results show that the opening scheme meets the design requirements on opening process well.It also shows that the optimized scheme can reduce the kinetic energy of the front cover,and the impact on the canister effectively,achieving a reliable and rapid opening of the front cover.

Keywords:Canister covers Spring-driven Non-separation Optimized opening scheme Rocket launch canisters Launch safety

1. Introduction

In rocket launch system,the launch canister technology has been widely used in many kinds of rockets launch system because of the advantages of convenient maintenance,fast reloading of ammunition, and universality for launching various kinds of rockets with different calibers[1,2].The launch canister has two functions:storing rockets at ordinary days and launching rockets in wartime.Therefore,it must meet not only the storage requirements of rocket weapon on dust-proof,temperature and humidity maintenance,and electromagnetic shielding function but also the requirements on rocket launching.It should have the ability to help the rocket safely and quickly flying out of the canister at a certain speed and direction.The front and rear covers on the launch canister are designed to achieve the above two functions,which is a key technology of launch canister.Whether the front and rear covers of the launch canister can be opened smoothly is directly related to the combat effectiveness and the precision of the rocket launcher.It is,therefore,necessary to study their opening mode and opening process.

During the rocket launch process,the rear cover can be broken directly by powerful rocket engine gas jet.Comparatively,the opening way of the front cover is complex.Fu[3]designed a low impact separation type of small mass front cover,realizing the front cover opening in short time and small impact loads.But for large caliber launch canisters,the front cover will be quite heavy and may induce some serious damage of the ground equipment and the deformation of the front cover.

According to opening modes,the front covers of rocket launch canisters can be divided into three kinds:the explosive cover[4],the switching cover[5],and the fragile cover[6].The explosive front cover is opened by explosive gas produced by detonating bolts and explosive cables,it cannot be reused and needs to initiate explosive devices every time before rocket launching,which may bring security risks and reliability problems during storage and launching[7,8].The switch cover made of metal material is relied on hydraulic,pneumatic or electric power to drive the mechanical structure. However, the mechanical structure can be easily damaged by gas jet,affecting the reliability of the mechanism[9,10].The fragile front cover made of brittle material has a simple structure and light weight,but the impact load of the launch process is too large for the canister,and its manufacturing process is very complex[11,12].In addition,it is also easily to be broken by gas jet during launching.

In view of all above facts, a non-separation spring-driven opening scheme of front cover is proposed in this paper.The theoretical parameterized model is established to simulate the opening process of the front cover,the opening process is characterized through the response surface model and the opening scheme of front cover is optimized.

2. Working principle of front cover

The design schematic of the front cover is shown in Fig.1.The front cover system mainly consists of a locking mechanism,a driving mechanism and a stopping mechanism. The locking mechanism contains a locking block,a locking interface and a flexible cable.The driving mechanism contains a thrust spring and a torsion spring.The stopping mechanism contains a hook and a preformed groove.

Before the rocket launching,the front cover and the canister are locked by the locking block.When the launching process begins,the locking block is unlocked and then the front cover is opened quickly by the spring force.When the front cover is locked,the thrust spring and torsion spring(seen in Fig.1)have some precompression and pre-torsion to provide the energy for the quick opening of the front cover.The stopping part has a preformed groove on the front cover and a fixed hook on the bottom surface of the launching canister.The working principle of the front cover is as follows:

1.In the locking condition,the front cover is fixed with a locking groove.The upper and lower locking interfaces are fixed on the launching canister through bolts.To keep the flexible cable straight and lock the canister with the preload of the spring,the lower locking block is inserted into the lower locking interface,and the upper locking block is inserted along the locking groove into the upper locking interface.

2.In the opening process of the front cover,the rocket engine produces thrust force after ignition.When the rocket moves near the front of the launching canister,the head of the rocket pulls the flexible cable and enables the locking block to separate from the locking interface.After separation,the canister cover starts to rotate quickly due to the preload release of the thrust spring and torsion spring.

3.The opening process is stopped when the front cover is opened about 270°.In this condition,the outer surface of the front cover keeps touching with the bottom of the launching canister,and the hook fixed on the canister bottom(as shown in Fig.1)inserts into the preformed groove of the front cover,then the front cover is locked.

3. Dynamic model

3.1. Definition of coordinate systems and variables

In this research,for the opening process of the front cover,assumption is made first that the unlocking process is completed instantaneously,and the unlocked moment of the cover is set as the initial state of the opening process.Considering that the opening process is a fixed-axis rotation under the changing load,to describe this process,the following two coordinate systems are established.The movement coordinate system of the front cover and its variables are shown in Fig.2.The systemOx1αz1is a relative coordinate system expressed in cylindrical coordinates to describe the opening process.The origin of the coordinate is set at the midpoint of the axis of the front cover along the width of the canister.As shown in Fig.2,x1is parallel to the front cover,z1is along the axis of rotation,facing outside towards the paper is positive,rotating angle α is zero when the cover is closed.

There are nine variables in the coordinate systemOx1αz1in Fig.2,they are respectively front cover heightla,front cover widthlb,front cover weightm,moment of inertiaIzof front cover aroundOz1axis,centroid position(lc,α1),front cover rotating angle around axis α,pre-torsion angle of torsion spring α0and torsional stiffnessk2.The angular velocity of the front cover around theOzaxis isω=,and angular acceleration isε=.

In order to describe the angle of fire and calculate the gravity component,an absolute coordinate canister systemOx2y2z2fixed with the ground is built in Fig.2.The firing angle projection θ0relative to the ground is an independent parameter in the coordinate system.The coordinate system is represented byOx2y2z2,which is co-origin and commonz-axis with the front cover movement coordinate system.The positive direction ofOy2is the rocket movement direction.Under this coordinate system,the main thrust springs(two springs)involve these parameters:spring precompressionlk,stiffnessk1,distance between spring force line and the origin isld,also the arm length.

Fig.1.Design schematic of the front cover.

Fig.2.Coordinate systems and variables of front cover.

3.2. Dynamic model of the front cover

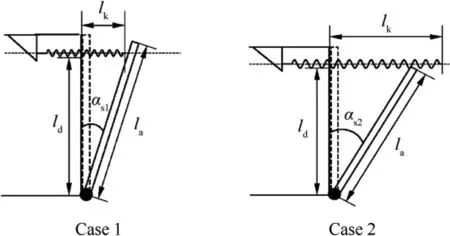

During the opening process of the front cover,it is assumed that the thrust force always applies along the thrust line when the thrust spring works.After being unlocked,the front cover starts to rotate around the shaft under continuously driving of the thrust and torsion spring.The contact point of the thrust moves towards the top of the front cover,until the contact between the thrust spring and front cover disappears completely.The separation angle αsis introduced to describe the contact relationship between of the thrust spring and the front cover.

For different arm lengthld,spring pre-compressionlk,and canister heightla,the separation angle is different.As shown in Fig.3,there are two kinds of separation cases.For case 1,when the spring is restored to the free length,the thrust contact point does not move to the top of the cover(shown in case 1 of Fig.3).But at this moment the spring has reached the limit position of separation and thrust spring will not contact with front cover.Thus,the separation angleFor case 2,when the thrust point has reached the top of the cover,and the spring is not yet restored to the free length(shown in case 2 of Fig.3).At this moment the spring has reached the limit position of separation,therefore the separation

Then the separation angle can be expressed by

wherelkis the thrust spring pre-compression,ldis the arm length andlais the height of the front cover.

The moment of the spring thrust forceMFis

whereFis the spring thrust force,lFis the distance between thrust point and the axis of the rotating shaft,α is the rotation angle,F=k1lk-k1Δlk,whereΔlkis the spring restoration.They can be obtained from the geometric relationlF=ldcot α and Δlk=ldtan α.

The moment of the gravity to front coverMGis

Fig.3.Two separation cases of front cover.

Wheremis the mass of the cover,lGis the distance between gravitational action line and the axis of the rotating shaft,it can be obtained from the geometric relation thatlG=l1sin(θ0-α1-α).

The torsion spring torque to the cover is

Table 1Displacement of rocket and angle of canister cover.

Fig.4.Relationship between motion of rocket and rotation angle of canister cover.

wherek2is torsional stiffness,α is the rotation angle,α0is pretorsion angle of torsion spring,M0is the pre-moment of the torsion spring at the axis of the rotating shaft,M0k2α0.

Therefore,the motion differential equation of the cover without air resistance is

whereIzis moment of inertia of front cover aroundOz1axis,α is the rotation angle,αsis the separation angle,MFis the moment of the spring thrust force,MNis the torsion spring torque to the cover,MGis the moment of the gravity to the cover.

If the effect of the air resistance[13]is considered,the calculation equation of air resistance is

WhereCis the coefficient of load,ρ is the density of air,Sis the area of the air contact surface,vis the velocity of air flow.

When the front cover revolves around the rotating shaft,the linear velocity of positions along the front cover changes accordingly,thus the velocity of the air flow on the front cover is different.Therefore,air resistance force moment to front coverMfcan be found by

wherelais front cover height,lbis front cover width,Cis the coefficient of load,ρ is the density of air,Sis the area of the air contact surface,˙α is angular velocity.

Therefore,the motion differential equation of the cover with air resistance is

wherelZis moment of inertia of front cover aroundOz1axis,α is the rotation angle,αsis the separation angle,MFis the moment of the spring thrust force,MNis the torsion spring torque to the cover,MGis the moment of the gravity to the cover,Mfis the air resistance force moment.

The above differential equation is solved by numerical calculation method,according to the assumption of section 2.1,the initial condition of the differential equation is:

3.3. Dynamic simulation of opening process of front cover

Under the condition of safe opening of the front cover,the geometric shape of rocket and the results of the launching dynamics are given[14]in Table 1,and the relationship between the motion of rocket and the rotating angle of canister cover is shown in Fig.4.

Taking a certain type of launch canister[14]as an example,according to the actual dimension of the front cover and the structure of the canister,the parameters of preliminarily designed front cover opening scheme are shown in Table 2.

To obtain the impact of air resistance on the opening process,the two dynamic models with and without air resistance are adopted and calculated respectively.Eq.(8)and Eq.(5)are used for simulating and the input parameters for the differential equations are shown in Table 2.The simulation result in Fig.5 shows that the rotation time histories of the front cover with and without air resistance,which are far higher than the limit angle.Due to the fast angular velocity of the front cover,the cover has a great impact onthe launching canister during the front cover rotation within 270°,and it consumes the spring stored energy.Therefore,it is necessary to optimize the design parameters to obtain a better opening process of the front cover scheme.At 0.4s after launching,the rotation angle of the model without air resistance is 254°,the angle of the model with air resistance is 242°,and the difference between them is 4.96%.It shows that the air resistance has an obvious influence on the opening characteristics.Therefore,the air resistance model must be considered in the optimization analysis.

Table 2Design parameters of the front cover scheme.

Fig.5.Rotation time histories of the front cover with and without air resistance.

4. Characteristics optimization of the front cover opening process

4.1. Selection of factors for experimental design

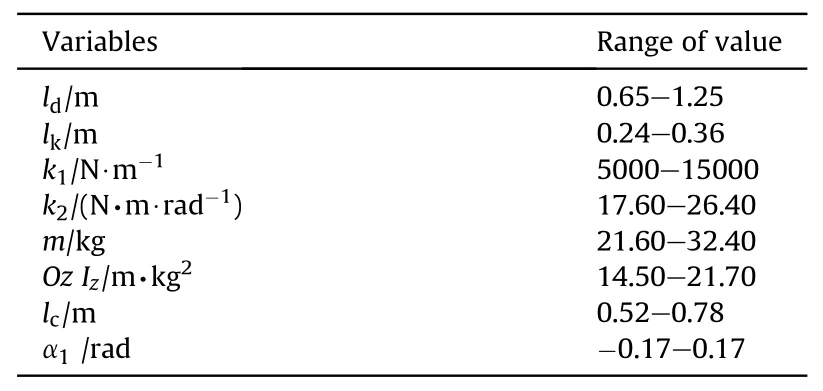

To measure the impact of different design parameters on opening process,a 2-level factorial experiment of the opening process of the launch canister was designed using the experimental design method[15].The 2-level factorial experiment is used to identify the parameters that have a great influence on the cover performance.Taking into account the limitations of the space arrangement of the front cover opening mechanism and the installation space of the spring,the selection of design factors and the range of values are shown in Table 3.

To measure the influence of the design factor on the rotating angle of the front cover,takeas the design response,and αiis the rotating angle of the cover attiduring a certain period of cover opening.According to the analysis in section 2.3,leti=6,taket1~t6respectively as 81 ms,115 ms,160 ms,205 ms,270 ms,382 ms,and the angular velocityωsat the angle of 270°of the cover as the response.Eq.(8)is used for the experiment and the Design-Expert software[16]is used to calculate the contribution based on the experiment results.

Table 3Value range of design factors.

Table 4Contribution of different factors.

After the experiment design,the contribution of nine parameters to the response is obtained(shown in Table 4).

From Table 4 it can be seen that,when each design parameter changes within the range in Table 4,the arm lengthld,the spring pre-compressionlk,the thrust spring stiffnessk1and the moment of inertiaIzhave a greater effect on the. The spring precompressionlk,the spring stiffnessk1and the moment of inertiaIzall have a greater effect on theωs.The moment of inertia has a negative effect on both α(-8.23%)and ωs(-13.35%),therefore,in the design process of the front cover,the moment of inertia about the rotating shaft should be small.For the typical canister in this paper,its cover mass and rotary inertia have generally been determined.Therefore the three factors:arm length,the pre-compression and the thrust spring stiffness are selected to be optimized.

4.2. The response surface model

The motion equation(8)of the front cover shows that each design factor affects the opening process of the front cover together.As it is hard to calculate an explicit function response of the design factors,response surface methodology(RSM)is often used to establish an approximate functional relationship between response and design factors in engineering[15].In this paper,the two order form response surface model with cross terms is adopted:

wherey(x)is the predictive value for the response surface model,xiis the component of then-dimensional independent variable(i=1,2,…,n),β0βj,βijare the undetermined coefficient of the constant term,the linear term and the quadratic term,and they can be calculated according to the least squares method.The arm lengthld,the spring pre-compressionlk,and the spring stiffnessk1are taken as the test factors of the response surface model of the opening process of the front cover.The value ranges of these three factors are the same as in Table 3.

To establish the response surface model of the opening process of the front cover,the output responses are defined asRi(i=1 ~8),the rotation angle of the front cover att=81 ms,115 ms,160 ms,205 ms,270 ms and 382 ms,the angular velocity when the front cover has rotated 270°and the preliminary pressure of the thrust spring.

The location of the test point is arranged by Box-Behnken design[17],which is a three-level design for fitting two order response surface.After the experimental design,the undetermined parameters of the response surface model are fitted by the least squares method.The approximate model of the response surface could be expressed by:

Where R is response matrix:

χ is test factors matrix:

Table 5Error analysis of response surface model.

β0is constant term matrix:

β is total coefficient matrix:

After the approximate RSM model is established,the fitting degree of the model to the test data is tested by using the multiple correlation coefficientR2and revise multiple correlation coefficienttends to be 1,indicating the high similarity between the response surface and the original model.R2tends to be close toindicating that the RSM model does not contain redundant parameters.The test results of the RSM model for the opening process of the front cover are shown in Table 5,which demonstrates that the model can accurately describe the relationship between design factors and response.

4.3. Optimization analysis of the front cover

According to analysis in section 2.3,the opening process of the ultimate angle is taken as the target process constraints,and the smaller thrust spring preliminary pressure and the smaller angular velocity when the front cover is opened at 270°are taken as expectations.

The Design-Expert software is used to solve the optimization of the experimental factors through the response surface model,a number of experimental factors satisfying the above expectations can be obtained.The partial optimal solutions are shown in Table 6.The optimization parameters of the serial number 1 are selected and Eq.(8)is used for obtaining the opening process.The comparison of the rotation angle of the front cover before and after optimization is shown in Fig.6.And the comparison of the angular velocity of the front cover before and after optimization is shown in Fig.7.

Table 6Partial optimal solutions.

Figs.6 and 7 show that the optimized rotation angle curve of the front cover is close to and higher than the planning curve,which ensures the safety of the opening process of the front cover.After optimization,the preliminary pressure of the thrust spring decreases from 6660N to 2400N,meaning that the thrust spring storage energy is reduced greatly;and the angular velocity of the front cover is also greatly reduced after optimization,which reduces the impact of the front cover on the launching front part of launch system effectively.

Fig.6.Rotation angle of front cover before and after optimization.

Fig.7.Angular velocity of front cover before and after optimization.

5. Conclusions

A non-separation spring-driven opening scheme for the front cover of the launch canister is proposed in this paper,and the main conclusions are as follows:

(1)The theoretical model of the front cover is established,the analysis result shows the feasibility of the opening scheme.The non-separation spring-driven type can avoid the damage on the ground equipment and achieve a reliable and rapid opening of the front cover.

(2)A response surface model is established to characterize and optimize the opening process of the front cover.After optimization,the better opening process of the front cover is obtained.

(3)For different launch canisters with various rockets, the opening process of their front covers could be different.This paper provides a method to obtain a desirable opening process by controlling the parameters of the front cover.And it will provide useful information for design and application of the opening scheme of the launch canister.

In this paper,the energy loss of the spring work is not taken into account may bring the error.And the theoretical model will be verified and corrected by further experiments in the future work.

- Defence Technology的其它文章

- Round robin using the depth of penetration test method on an armour grade alumina

- Sonochemically assisted synthesis of nano HMX

- Effect of particle gradation of aluminum on the explosion field pressure and temperature of RDX-based explosives in vacuum and air atmosphere

- FEM analysis and experimental investigation of force and chip formation on hot turning of Inconel 625

- Study on liquid-filled structure target with shaped charge vertical penetration

- Thermal decomposition of ammonium perchlorate catalyzed with CuO nanoparticles