A novel graphite/phenolic resin bipolar plate modified by doping carbon fibers for the application of proton exchange membrane fuel cells

Bo Lv ,Zhigng Sho ,Ling He ,Yong Gou ,Shucheng Sun

a Fuel Cell System and Engineering Laboratory,Key Laboratory of Fuel Cells&Hybrid Power Sources,Dalian Institute of Chemical Physics,Chinese Academy of Sciences,457 Zhongshan Road,116023,Dalian,China

b University of Chinese Academy of Sciences,Beijing,100049,China

ABSTRACT In this study,the carbon fibers treated by three methods were selected as a reinforcement to investigate the influence on the properties of composite bipolar plates.The properties and microstructure of the composite bipolar plate were characterized by the four-point probe,universal test machine,contact angle tester and scanning electron microscopy.The optimum treatment methods and the fiber content were analysed.The results showed that the carbon fibers treated by Fenton reagent for 2 h exhibited the best performance,which could improve the electrical conductivity and the flexural strength for composite bipolar plate.Besides,the optimal content content of carbon fibers treated by Fenton reagent was 4%.The maximum power density of the PEMFC with the composite bipolar plates could reach 662.75 mW cm-2 in H2-air conditions.Therefore,the phenolic resin/graphite composite bipolar plate modified by doping carbon fibers was a promising candidate for bipolar plate materials for PEMFC.

Keywords:PEM fuel Cell Natural graphite Phenolic resin Composite bipolar plate

1.Introduction

Nowadays,because of its clean and efficient properties,proton exchange membrane fuel cells have been considered as one of the most promising energy transformation instruments for future [1-3].But the expensive costs limit the use of PEMFC in large-scale.Bipolar plate is one of the most significant parts of fuel cell,which distributes oxidants and reductants,realizes good current conduction between single cell,brings out waste heat from the reactive area,prevents the leakage of gas and coolant in the fuel cell stacks.At present,the cost of bipolar plates accounts for about 15%-30% of the total cost of fuel cell stacks [4,5].

According to material classification,bipolar plates can be divided into graphite bipolar plates,metal bipolar plates and composite bipolar plates [6].Graphite bipolar plates have good electrical conductivity,thermal conductivity,and corrosion resistance.However,graphitization and surface flow field processing are very expensive [7].In content,graphite bipolar plates have higher gas permeability.Metal bipolar plates have higher mechanical strength,lower gas permeability and good processability,but the main problem of metal bipolar plates is the poor corrosion resistance in acidic and muggy environment of PEMFCs[8-10].Moreover,the performance degradation of fuel cells may be caused by metal cations.Compared with graphite bipolar plates and metal bipolar plates,composite bipolar plates have the characteristics of light weight,easy forming and low cost,but they are considered as lower conductivity[11].

Recently,the graphite/polymer composites bipolar plates have aroused extensive research interest because of lower cost,higher corrosion resistance and easier fabricating [11,12].Currently,three main methods of fabricate graphite/polymer composite bipolar plate have been proposed,such as compression molding process [7,12,13],injection molding process [14,15],vacuum impregnation process [16,17].However,injection molding process is required to good fluidity of the mixture,therefore the mixture must contain more polymers,which reduces the conductivity of the composite bipolar plates.Vacuum impregnation is more suitable for the preparation of expanded graphite-based composite bipolar plates.DICP (Dalian Institute of Chemistry Physics) synthesized composite bipolar plates with satisfactory properties by vacuum impregnation of expanded graphite sheets successfully [18].

Compression molding process is widely used in the preparation of graphite/polymer composite bipolar plates.Moreover,compression molding process is not only suitable for thermoplastic resins,but also for thermosetting resins,which is very suitable for laboratory research and industrial production [6,13].Ali Adloo et al.[19] prepared the graphite/modified polypropylene/carbon black composite bipolar plates,the test results showed that when graphene content was 1 wt%,composite bipolar plates have the best cell performance.Kang et al.[7]investigated the graphite/epoxy/composite bipolar plates,and the test results showed that the composite bipolar plate could meet the requirements of the US Department of Energy (DOE).Furthermore,Guo et al.[20,21] prepared water transport plates with excellent performance by using hydrophilic acetylene black as filler with the molding process in the PEM fuel cell.Moreover,other kinds of polymers were employed in production of composite bipolar plate,such as,PVDF[14,22,23],PP [24,25],PPS [26,27]etc.However,the biggest issue of molding composite bipolar plates is the contradiction between electrical conductivity and gas permeability,especially the gas permeability of hydrogen.

Herein,a novel graphite/phenolic resin bipolar plate modified by doping carbon fibers was reported.The effects of carbon fibers treatments were compared,and the amount of carbon fibers was optimized.The results showed that the carbon fiber composite bipolar plate modified by Fenton reagent had good electrical conductivity,flexural strength,low gas permeability and outstanding cell performances.

2.Experimental

2.1.Materials

The natural flake graphite(NG,99.5% purity) was purchased from Qingdao Tengsheng Carbon Co.Ltd.(China).The phenolic resin (PF,MW=200,000) was purchased from Henan Xincheng Engineering Plastics Co.Ltd.(China).The carbon fibers (CF,length 0.4 mm) was purchased from Beijing Special Protection Antistatic Equipment Co.Ltd.(China).The 30 wt% H2O2(AR),FeSO4⋅7H2O (AR),were purchased from Tianjin Kemiou Chemical Reagent Co.Ltd.(China).

2.1.1.Treatment of carbon fibers with Fenton reagent

The carbon fibers(10g)were added to fresh Fenton reagents(3 wt%H2O2and 1.6 ppm FeSO4)at 80°C for a certain time.The treatment time was 1 h,2 h and 3 h,respectively.Finally,the modified carbon fibers were washed with deionized water and dried under vacuum oven for 24 h.

2.1.2.Treatment of carbon fibers with air oxidation

The carbon fibers(10g)were heated in tube furnace at 800°C for 20 h at a heating rate of 10°C min-1.After cooling to room temperature,the product was collected for preparation.

2.2.Preparation of composite bipolar plate

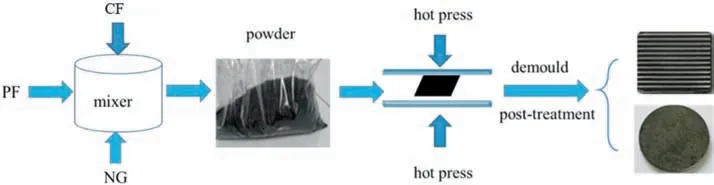

The mixture was prepared by the mass ratio of 10% phenolic resin and 90% graphite.Moreover,the mass ratio of 4%,6%,8% and 10%carbon fibers (compared with the sum mass of phenolic resin and graphite)were added respectively.The powder was mixed by small ball mill pulverizer for 2 h.The mixture was placed in the stainless steel mould with pre-press(40 MPa)to remove the air from the powder.The composite bipolar plate were fabricated by hot compression molding method under a pressure of 100 MPa at 180°C for 5 min.Finally,the composite bipolar plate was polished with sandpapers for preparation.The process diagram of the composite bipolar plate is shown in Fig.1.

2.3.Characterization of the composite bipolar plate

2.3.1.Electrical conductivity test

The electrical conductivity of the composite bipolar plate was measured by the four-probe tester(ST-2258A) and the samples are cylinders with a diameter of 30 mm and a thickness of 1 mm.

2.3.2.Interface contact resistance test

The interface contact resistance (ICR) was tested by a universal testing machine(WDW-1010).A circular plate with a diameter of 30 mm and a thickness of 1 mm was placed between two pieces of carbon paper(Toray,TGP-H-060).The plate and carbon paper were press between two pieces of gold-plated copper blocks with a certain pressure (0-2.0 MPa).A current of 5 A was supplied by a DC power to test the output voltages of composite bipolar plates with different contact pressures.The ICR could be calculated by the current and the change of voltage.

2.3.3.Mechanical performance test

The flexural strength of composite bipolar plate was tested by a universal testing machine (WDW-1010).The three-point flexural method was used,the span was 20 mm and the indenter speed was 5 mm min-1.

2.3.4.Microstructure characterization

A scanning electron microscope (SEM,JSM-IT300) was used to get cross-sectional morphology of the composite bipolar plates.

2.3.5.Surface contact angle measurement

The surface of the sample was cleaned up,the deionized water droplets were placed on the surface of the sample with photographed immediately.Then the contact angle of the sample surface was calculated by the droplet shape fitting algorithm of the software.

2.3.6.Gas permeability test

Gas permeability was measured by a self-made device according to previous work in our group [16,17].The composite bipolar plate was sealed in the annular sample chamber and hydrogen was flowed into the upper chamber.The pressure in the chamber was 0.2 MPa and the carrier gas was flowed into the lower chamber.The pressure in the chamber was 0.1 MPa.The effective diameter of the plate sample was 23 mm.

2.3.7.Characterization of single cell

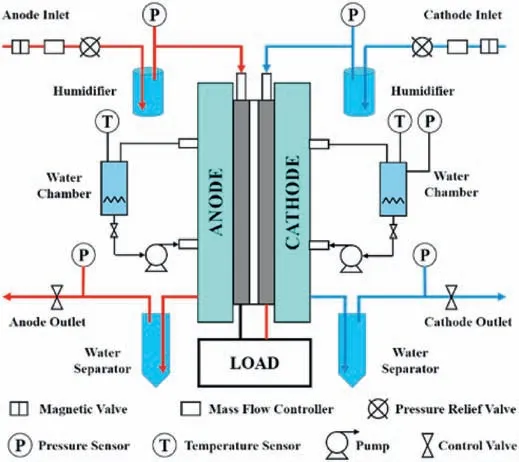

At the anode side of the fuel cell,hydrogen was supplied at flow rates of 100 ml min-1.At the cathode side,the air was supplied at flow rates of 800 ml min-1,the gas pressure of both anode and cathode was 0.05 MPa.The humidification temperature of hydrogen and air was set at 60°C,and the cell temperature was 65°C The composite bipolar plate was tested to evaluate the performance of fuel cells.The active area of membrane electrode assembly(MEA)was 5 cm2.The proton exchange membrane was Nafion 211 (DuPont),the platinum catalyst (Johnson Matthey,70 wt%) load of anode and cathode side electrodes were 0.2 mg cm-2and 0.4 mg cm-2,respectively.The Toray TGPH-060 carbon paper was hydrophobically treated as the diffusion layer of electrode.The schematic diagram of single cell test station is shown in Fig.2.

Fig.1.Process diagram of the composite bipolar plate.

3.Results and discussion

3.1.The influence of carbon fibers treatment on the ICR of composite bipolar plate

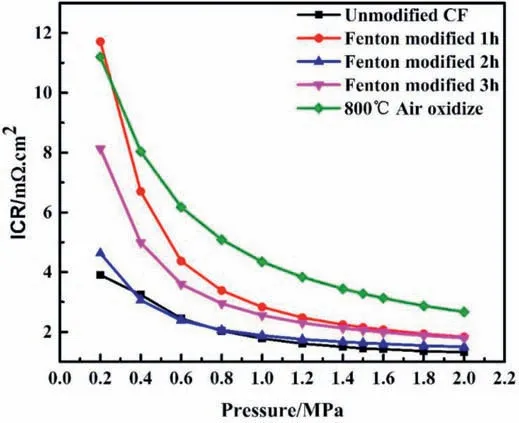

In order to investigate the influence of carbon fiber treatment on the properties of composite bipolar plate,the ICR of composite bipolar plates was investigated.The mass ratio of carbon fiber or modified carbon fiber in the composite bipolar plate was 6%.The results are shown in Fig.3.The carbon fibers treated for 2 h had the almost the same ICR as the original carbon fibers.Moreover,the carbon fibers oxidized at 800°C had the largest contact resistance.

Fig.2.Schematic diagram of single cell test station.

Fig.3.The influence of CF treatments on the ICR of composite bipolar plate.

The results showed that the ICR were mainly depended on the surface structure of the composite bipolar plate.The ICR of the composite bipolar plate is slightly affected by treatment time of Fenton reagen,which might be attributed to the little influence on the surface structure.However,A large number of structural defects and functional groups were produced due to carbon fibers oxidized at 800°C,resulting the decrease of conductivity of carbon fibers.More importantly,the transmission of electrons along the thickness direction of the bipolar plate was destroyed by structural defects of carbon fibers.Therefore,carbon fibers oxidized at 800°C in air has the largest ICR.

3.2.The influence of carbon fibers treatment on electrical conductivity and flexural strength of composite bipolar plate

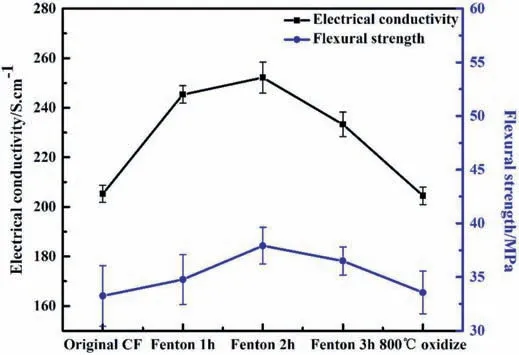

To investigate the influence of carbon fibers treatments on composite bipolar plate,the electrical conductivity and flexural strength were measured.As is shown in Fig.4,the composite bipolar plate modified by carbon fibers treated with Fenton reagent for 2 h had the best the electrical conductivity and flexural strength.The increase of flexural strength is associated closely with the bonding force between carbon fibers and the resin.Moreover,the bonding force was depends on the strength of the modified carbon fiber and the number of functional groups.When the composite bipolar plate was break by force,the crack would propagated along the cross-section of the plate to the fibers.It means the carbon fibers must be pulled off before the bipolar plate can be destroyed completely.

Fig.4.The influence of CF treatment on the electrical conductivity and flexural strength.

When Fenton reagent was used to treat carbon fibers for 1 h,the number of functional groups on the surface of carbon fibers was lower,resulting the limited bonding force between modified carbon fibers and phenolic resin.With the increase of

Treatment time to 2 h,the surface of modified carbon fibers could generate more functional groups,which could enhanced the interaction between carbon fibers and phenolic resin.However,the surface of carbon fibers would be etched severely by Fenton reagent treatment for 3 h or oxidation in air at 800°C,which cause the flexural strength decreased greatly.A large number of defects were generated on the surface of carbon fibers because of the strong oxidation.Therefore,Fenton reagent oxidation treatment for 2 h was chosen as the optimal treatment of carbon fibers.

3.3.Microstructure of the composite bipolar plate

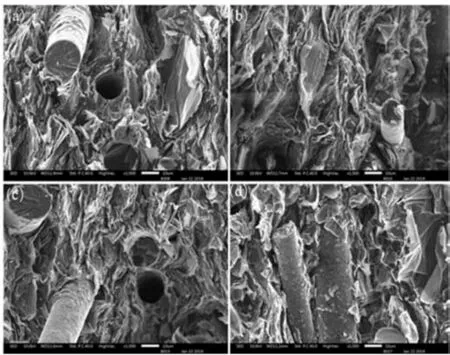

Fig.5.The SEM images of the composite bipolar plate by different treatments(a) Fenton 1 h,(b) Fenton 2 h,(c) Fenton 3 h,(d)800 °C oxidize.

To further confirm cross-sectional morphology of the composite bipolar plates,SEM diagrams were measured.The results are shown in Fig.5.It can be seen that exposed carbon fibers exist on the section of composite bipolar plate treated by Fenton reagent for 1 h,2 h,3 h and air oxidation at 800°C.In Fig.5(a),(c),(d),most of carbon fibers were pulled out rather than pulled broken,and the surface of carbon fibers hardly adheres to resin.It means the role of carbon fibers in high strength has not been fully utilized.In comparison,in Fig.5(b),the cross-sectional hardly contains pulled-out carbon fibers,most of carbon fibers could play a part in enhancing the flexural strength of composite bipolar plates.Therefore,the carbon fiber reinforced composite plate treated with Fenton reagent for 2 h had the best flexural strength.

The next day the wedding took place, and the two brothers came to the house, and they all lived happily together, but they never forgot the holy man who had been such a good friend

3.4.Contact angle test

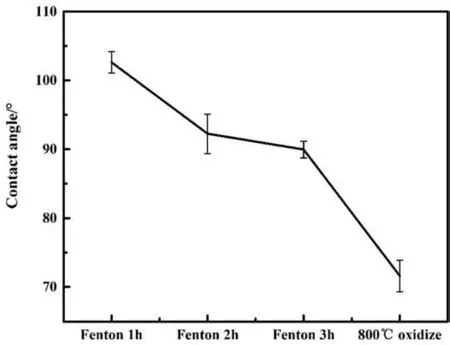

In order to investigate the hydrophobicity of the surface of the composite bipolar plate,the contact angles of four kinds of composite bipolar plates modified by doping carbon fibers were tested.In Fig.6,the results showed that the surface of the composite bipolar plates was hydrophobic which CF was treated by Fenton reagent for 1 h and 2 h,which was beneficial to the water management of PEMFC.

Fig.6.The contact angles of composite bipolar plate by different CF treatmentss

3.5.The influence of carbon fiber content on properties of composite bipolar plate

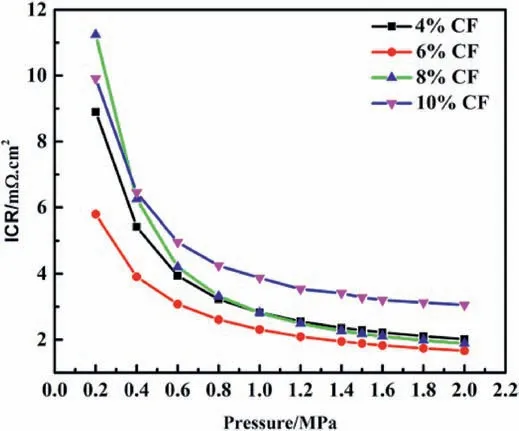

According to the optimization results,carbon fibers treated by Fenton reagent for 2 h were selected to prepare the composite bipolar plates.The mass content of carbon fibers was 4%,6%,8%,and 10%,respectively.The ICR of the modified carbon fiber reinforced composite plates were tested.

The result was shown in Fig.7.The bipolar plate with the mass content of 6% modified carbon fibers had the lowest ICR,which was only 1.88 mΩ cm2.The composite bipolar plate with the mass content of 10% modified carbon fibers has the highest ICR.

Fig.7.The influence of CF mass content on the ICR of composite bipolar plate.

3.6.The influence of modified carbon fiber content on the electrical conductivity and flexural strength of the composite bipolar plate

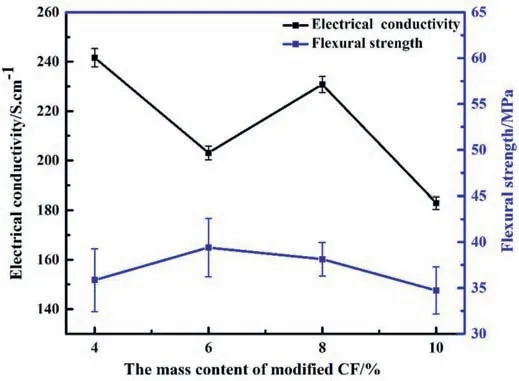

The electrical conductivity and flexural strength of different mass content of modified carbon fibers were tested.As shown in Fig.8,it could seen that with the increase of carbon fiber content,the electrical conductivity of the composite bipolar plate decreases firstly,then increases and decreases again finally.Besides,the flexural strength of composite bipolar plate was increased firstly and decreased finally.The electrical conductivity could be attribute to the following factors,when the carbon fiber mass content of the composite bipolar plate was 4%,the carbon fibers would agglomerated into bundles due to the interaction of functional groups,which was less conductive.When the mass content of carbon fibers increased to 6%,the dispersion of the fibers was improved effectively.When the mass content of modified carbon fibers exceeds 8%,excessive carbon fibers would increase the porosity of the composite bipolar plate,result in the decrease of electrical conductivity.

The influence of carbon fibers on the flexural strength of composite bipolar plates was reflected in two aspects.On the one hand,the combination of carbon fibers and resin could form the chemical interaction and increase the interfacial adhesion.On the other hand,the modified carbon fibers tend to agglomerate into bundles because of the van der waals force,which could reduce the flexural strength of the composite bipolar plate.When the mass content of carbon fibers was small amount,the favorable factors dominate the improve of flexural strength.When the content of modified carbon fibers was large number,the reduction of flexural strength plays a dominant role [28].

Fig.8.The influence of modified mass content of CF on the electrical conductivity and flexural strength.

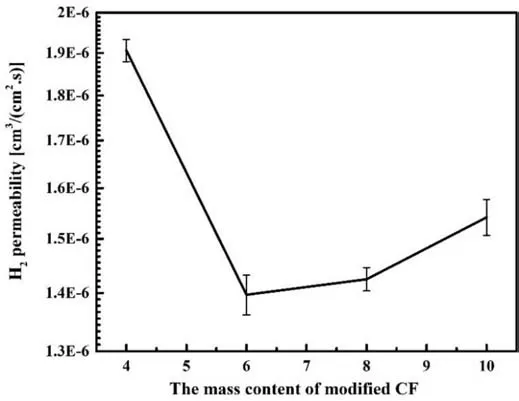

3.7.Gas permeability test

Gas permeability is one of the important parameters of bipolar plate.Low gas permeability can realize the good separation of oxidant and fuel.The gas permeability of the composite bipolar plate has been tested.As illustrated in Fig.9,it was found that the mass content of modified carbon was 6%showed the lowest gas permeability.With the increase of the modified carbon fiber,the functional groups on the surface of carbon fiber could form chemical interaction with the resin,which could reduces the porosity of the composite bipolar plate and the gas permeability.When the amount of modified carbon fiber was higher than the optimal value,a large number of carbon fibers would be agglomerate,and the porosity and gas permeability of composite bipolar plate would be increase.The results showed that the modified carbon fiber doping composite bipolar plate has good gas permeability and could meet the commercial requirements.

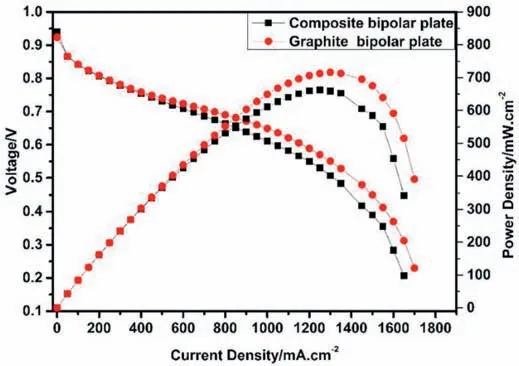

3.8.Single cell test

The composite bipolar plate with the mass content of 4% modified carbon fibers was selected as the anode plate to assemble the single cell.The performance I-V and I-P curves were tested in Fig.10.When the current density reached 1250 mA cm-2,the maximum power density could reach to 662.75 mW cm-2.When the current density was less than 1000 mA cm-2,the single cell performance of the composite bipolar plate was similar to the pure graphite bipolar plate.Therefore,the carbon fiber reinforced composite bipolar plate is a promising fuel cell bipolar plate.

4.Conclusions

In this study,the optimum treatment methods and the fibers content were achieved.The results showed that the carbon fibers treated by Fenton reagent for 2 h exhibited the best performance.Besides,the optimal mass content of carbon fibers treated by Fenton reagent for 2 h was 4%.The surface of the bipolar plate was hydrophobic,which was beneficial to water management of PEMFC,and gas permeability was suitable for the bipolar plate.The maximum power density of the proton exchange membrane fuel cell with composite bipolar plate could reach 662.75 mW cm-2in H2-air atmosphere.

The results in this work indicated that the graphite/phenolic resin bipolar plate modified by doping carbon fibers was considered to be one of the most promising candidates for PEMFC.

Fig.9.The influence of mass content of modified CF on the gas permeability.

Fig.10.Performance of the single cell assembled by optimum composite bipolar plate and commercial bipolar plate.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (2016YFB0101206),the National Natural Science Foundation of China (Grant No.21676268) and the LiaoNing Revitalization Talents Program (XLYC1902079).

Progress in Natural Science:Materials International2020年6期

Progress in Natural Science:Materials International2020年6期

- Progress in Natural Science:Materials International的其它文章

- Stability of PGM-free fuel cell catalysts:Degradation mechanisms and mitigation strategies

- Understanding of free radical scavengers used in highly durable proton exchange membranes

- Electrolyte membranes for intermediate temperature proton exchange membrane fuel cell

- Key technologies for polymer electrolyte membrane fuel cell systems fueled impure hydrogen

- Electrolyte materials for intermediate-temperature solid oxide fuel cells

- Carbon-free nanoporous gold based membrane electrocatalysts for fuel cells