Numerical Investigation of Centrifugal Compressor Surge Based on Plenum Chamber Model and Throttle Valve Model*

Xue-fei ChenGuo-liang QinCheng JiaYuan Li,2

(1.School of Energy and Power Engineering,Xi'an Jiaotong University,Xi'an 710049,P.R.China;2.Sinopec Si Chuan to Eastern China Transmission Gas Pipeline Co.,Ltd.,)

Abstract:In this paper,a correlation model between centrifugal compressor and its piping system is built based on plenum chamber model and throttle valve model.This model could be used to conduct numerical analysis of compressor systems from steady to surge operating points.Three dimensional unsteady numerical simulations were performed to predict the performance of a centrifugal compressor.The flow structures in blade passage and diffuser were plotted and analyzed. The fluctuations of pressure and mass flow rate over time at the outlet of diffuser are obtained at surge condition. The characteristic changes of compressor-pipe network under the surge condition were carried out,and the effects of model characteristics including valve coefficient and backpressure on surge were analyzed.

Keywords:Correlation Model, Numerical Investigation, Pipe Network,Valve Coefficient, Backpressure

0 Introduction

Centrifugal compressors have advantage in various departments for the characteristics of single stage high pressure ratio,simple structure,and small size,but it is sensitive to the change of operating conditions.When a centrifugal/axial compressor operating in the small flow rate,the phenomenon of rotating stall which may lead to the surge occur in the blade passage,which is a great threat to the safety operation of centrifugal compression units.The occurrence of surge is related to both self-characteristic of the compressor and the pipe network system which connected with the compressor[1].Therefore,with an aim to prevent and control surge,it is great significance to establish the association model between the compressor and pipe network,study the effect of the pipe network on surge characteristic and analyze the surge characteristic of compressor under different parameters of pipe network.

A tremendous amount of open literatures about compressor surge[2-5]and the mutual effect on compressor and pipe network system.[6-9]Cumpsty[10]introduced the three basic connection forms between compressor and pipe network system.Outa[11-12]simulated the stall cell behavior and characteristics of a single stage axial compressor by connecting a throttling valve at the outlet of compressor.Nizai[13]analyzed the cause of surge by adding the external disturbance into calculation process in a three-dimensional calculation of a transonic fan rotor.Stein[14]introduced the concept of plenum chamber model,and got the stall and surge characteristics in the low flow rate.Guo[15]carried out an unsteady numerical simulation of rotating stall phenomenon with a plenum chamber model added at the outlet of compressor volute.Ce Yang[16]simulated the influence of different inlet pipe types on the internal flow of the compressor,and analyzed the influence of the geometrical features of the inlet on the flow field of the impeller.But few numerical and experimental studies on the surge characteristic in different parameters of the pipe network have been done.

In this paper,unsteady simulations were carried out based on the correlation model.The compressor geometry will be given first,and the simulation method will be described.The influence of valve parameters on compressor surge characteristic will then be presented and analyzed.

1 The Correlation Model of Compressor and Pipe Network System

1.1 Plenum chamber model

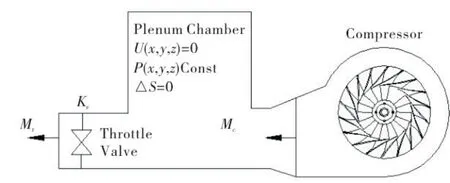

An assumption as shown in Figure 1,the flow from the outlet of compressor exhausted into a constant volume plenum chamber.The flow inside the plenum was assumed to have negligible velocity and be isentropic.

Fig.1 The plenum chamber model

The mass conservation equation for the plenum chamber is given by:

Where:Vprepresents the volume of plenum chamber,Mcrepresents the outlet mass flow rate of compressor,andMtrepresents the outlet mass flow rate of plenum chamber.

Ideal gas state equation is:

So,the Eq.(1)can be written as:

Sonic equation is:

So,Eq.(3)can be written as:

The Eq.(6)is obtained by the first-order time discretization of Eq.(5):

In the Eq.(6),Cis defined as:

Fig.2 The throttle valve model

Cis called plenum chamber parameter.In unsteady calculation,valueCkeeps in inverse proportion to the volume of plenum chamber.

1.2 Throttle valve model

The governing equation of throttle valve is:

Where:Mtrepresents the mass flow rate through the valve,p1represents the pressure before valve,p0represents the environmental pressure,KVand represents valve coefficient.

If the compressor outlet is directly connected to the throttle valve,just as shown in Figure 2,the pressure of compressor outlet can be written as:

Where:krepresents the flow coefficient of valve,which is related to valve coefficientKVand the structure of the valve itself.

1.3 Throttle valve model combined with plenum chamber model

If the fluid gets into plenum chamber firstly and exhausts to the throttle valve,as shown in Figure 3,theMtin the Eq.(6)can be replaced by the Eq.(8).So,the equation is:

In the process of CFD numerical simulation,Eq.(10)is set to the outlet boundary condition of compressor.The new outlet boundary condition of each time step is calculated by thepn,Tn,MtandMcvalues obtained from the last time step.

Fig.3 The new model(throttle valve model combine with plenum chamber model)

2 Numerical Method

As previously explained,a centrifugal compressor rotor with vaneless diffuser was adopted in the present work.The specifications of the impeller and diffuser are summarized in Table 1.The geometrical model of the impeller is shown in Figure 4.

Structured grid was divided by the turbo-grid module of ANSYS.Periodic boundary conditions were used on both sides of the blade.The O-type mesh was adopted near the rotor blade.The H-type mesh was used in the other parts of the passage.In the impeller,tip clearance was employed on the side of the wheel shroud with 5%blade height.The mesh of the whole model is 4 786 020.

Fig.4 The geometrical model of the impeller

Tab.1 Geometrical parameters of the compressor

The numerical simulation was carried out into two stages:a steady flow simulation was first carried out to calculate compressor performance curves by decreasing outlet mass flow rate gradually.The results were then used as initial conditions for unsteady simulations.During the unsteady simulation,unsteady boundary condition was coupled with the outlet of compressor.The physical time step was set to 1.39e-5s.

3 Results and Discussion

3.1 Steady simulation results

In the steady simulation,the calculated results were compared with the experimental data.Figure 5 shows the comparison of total pressure ratio between simulation and experimental results.

It can be seen from the Figure 5 that the calculated results are higher than the test results because the frictional resistance loss was not taken into account.For the total pressure ratio,the error is 1.4%in design condition and 0.8%in small flow rate.Therefore,the error of total pressure ratio between simulated value and the experimental value is acceptable.

3.2 Unsteady simulation results

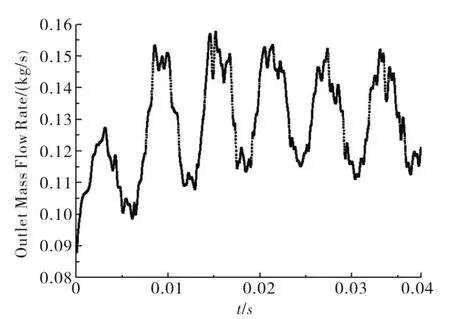

In the unsteady simulation,parameterCin Eq.(6)was set to 0.1 andMtwas 1.58kg/s(the flow rate of steady simulation when the result of the simulation does not convergence).

Figure 6 shows outlet mass flow rate fluctuation and Figure 7 shows outlet pressure fluctuation.The calculation results show that both the pressure and mass flow rate in the outlet of compressor diffuser fluctuate periodically,which is in accordance with the characteristics of the surge.It is shown that the plenum chamber model can well simulate the surge process of the compressor under certain pipe network conditions.

Fig.5 Characteristics plot of the compressor

Fig.6 Outlet mass flow rate fluctuation(C=0.1,Mt=1.58 kg/s)

Fig.7 Outlet pressure fluctuation(C=0.1,Mt=1.58 kg/s)

3.3 Effect of Outlet Throttle Valve Coefficient

ParameterCin Eq.(10)was set to 0.1 andP0was set to 1 atm.Throttle valve coefficientKVwas increased from 0.002 to 0.012(close to the design condition of the outlet mass flow rate)gradually for unsteady simulation of different open degree of the valve.Outlet mass flow rate and outlet pressure were monitored to analyze surge amplitude-frequency characteristic.The calculation results are shown in Table 2.The impact of valve coefficient on the surge characteristic are given in Figure 8 and Figure 9.Figure 8 and Figure 9 show that the fluctuation frequency of outlet pressure almost keep the constant and the fluctuation range of outlet pressure decrease with the increase of the valve coefficient.

Fig.8 Fluctuation frequency of outlet pressure

Fig.9 Fluctuation range of outlet pressure

From the above simulation results,fluctuations of outlet mass flow rate and outlet total pressure tend to be stable,and the compressor ultimately tends to no surge condition with the throttle valve coefficient increasing.

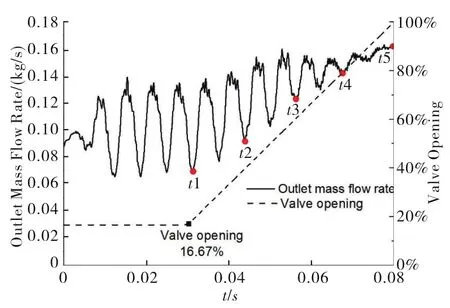

Figure 10 shows the time variation curve of the outlet mass flow rate with the valve opening increasing linearly from 16.67%to 100%,while the throttle valve coefficient is 0.012 kg/m.It can be seen from the curve that the average value of the compressor outlet mass flow rate increases gradually with the increasing of the valve opening,but the amplitude of outlet mass flow rate decreases gradually,and the oscillation is gradually relieved.

Fig.10 The curve of the outlet mass flow rate with time and valve opening

Velocity contours in meridian plane of impeller with gradual opening of the valve are shown in Figure 11.The deep blue areas in contours are the low velocity zones.And the deeper the color is,the more serious the stall is.According to the change of the contours,the stall condition in impeller has been improved significantly with the gradual opening of the valve.It proves that setting bypass exhausting valve can relieve surge.

3.4 The Influence of environmental pressure

When the plenum chamber parameterCand throttle valve coefficientKVare constant and the environmental pressureP0is different,the outlet parameters of the compressor show different characteristics.In surge condition,the amplitude-frequency characteristics of the outlet parameters are compared in Table 3 when the environmental pressureP0is 1atm and 1.5atm respectively.And the plenum chamber parameterCis 0.1,throttle valve coefficientKVis 0.06 kg/m.

By the comparison results in Table 3,it can be seen that the amplitudes of the compressor outlet parameters in environmental pressure 1atm are larger than that of 1.5atm.This shows that compressor surge characteristic is more obvious when in larger environmental pressure.

Influences of different environmental pressures on the surge characteristic with the larger valve opening are shown in Table 4.And the plenum chamber parameterCis 0.1,throttle valve coefficientKVis 0.012 kg/m.

The results can be obtained by the Table 4 that the amplitudes of the compressor outlet parameters are very small when environmental pressure is 1atm and valve opening is large.When the environmental pressure is 1.5atm,the fluctuation of pressure and mass flow rate can still be monitored at the outlet of the compressor.Therefore,the larger environmental pressure is more likely to lead to surge phenomenon.

3.5 Connecting throttle valve to compressor outlet directly

When the compressor outlet is directly connected with the throttle valve,Eq.(9)is set to the pressure boundary condition of compressor outlet.And the environmental pressure is 1atm,the flow coefficient of valvekis 20000.The curve in that the outlet total pressure varies with time is provided in Figure 12.

Figure 12 shows that when the compressor outlet is directly connected with the throttle valve,the fluctuation is more likely to be characterized by higher frequency and smaller amplitude compared with the variation of the outlet parameters in the plenum chamber model.It is more close to the rotating stall characteristic rather than surge characteristic.This can be interpreted as ignoring the impact of storage effect on the surge.Therefore,the compressor outlet parameters only exhibit the characteristic of rotating stall rather than surge even in small flow rate condition.It also shows that a sufficient pipe network capacity is a necessary condition for the occur of surge.

Tab.2 The impact of valve coefficient KVon the surge amplitude-frequency characteristic

Fig.11 Velocity contours in meridian plane of impeller

Tab.3 Amplitude-frequency characteristics of different environmental pressure in surge condition

Tab.4 Amplitude-frequency characteristics of different environmental pressure with larger valve coefficient

Fig.12 The curve of outlet total pressure with time(the compressor directly connected with the throttle valve)

4 Conclusions

This paper has established the correlation models between the compressor and network which could provide a reference for the further study of surge and the analysis of the compressor-pipe network system.And the unsteady numerical simulations have been carried out in a centrifugal compressor.The main conclusions have been identified as follows:

1)With the decrease of the valve coefficient KV,fluctuation frequency of outlet parameters does not change significantly,the amplitudes of outlet mass flow rate and outlet total pressure are showing an increasing trend.So,the surge condition can be relieved by opening the throttle valve when the compressor is in surge.

2)Larger environmental pressure will make amplitude greater and surge characteristic more obvious.When the environmental pressure in the large condition,the compressor system may be into the surge even though the mass flow rate is large.

3)When the compressor outlet is directly connected with the throttle valve,the characteristics of outlet parameters are different from surge conditions.This can be interpreted as ignoring the impact of storage effect on the surge.