Optimization of Extraction Process of Yingshan Cloud Tea Polysaccharides by Response Surface Methodology

Wei YANG Tingting CHEN Sui YU Jisong ZHOU Peng WU Ting Hu

Abstract [Objectives] This study was conducted to explore the optimal process conditions for hot water extraction of polysaccharides from Yingshan cloud tea.

[Methods] Based on single factor experiments, with the extraction rate of polysaccharides as the response value and liquidtosolid ratio, extraction temperature and extraction time as investigation factors, the optimum extraction process for tea polysaccharides from Yingshan cloud tea was determined by BoxBehnken central componse design and response surface analysis method.

[Results] Under the conditions of the liquidtosolid ratio of 50∶1 (ml/g), the extraction temperature at 94 ℃ and the extraction time of 210 min, the extraction rate of polysaccharides from Yingshan cloud tea reached 2.16%.

[Conclusions] This study will provide theoretical basis and reference for subsequent related research.

Key words Yingshan cloud tea; Polysaccharide; Water bath extraction; Response surface methodology

Received: May 12, 2019Accepted: August 4, 2019

Supported by Highgrade Cultivation Program of Huanggang Normal University (201816703).

Wei YANG (1998-), female, P. R. China, devoted to research about extraction of food macromolecules.

*Corresponding author. Email:843076915@qq.com.

Yingshan cloud tea is produced in the Tiantangzhai Mountains of the Dabie Mountains and is one of the most distinctive products of Huanggang. It was awarded the "gold award product" at Chinas International Tea Culture Exposition. Its producing area is foggy all year round, and the tea produced has the characteristics of pleasant aroma, bright color, mellow taste and resistance to brewing[1-4]. Tea contains a large number of health care factors beneficial to human body, among which tea polysaccharides are one of the main active ingredients and are a class of polysaccharide complexes[5-6]. A large number of studies have shown that tea polysaccharides have immunityimproving, blood sugarlowering, anitoxidation, antibacterial and anticoagulation effects, and have good research value and economic benefits[7-10]. Therefore, people pay more and more attention to tea polysaccharides, and the degree of exploration is getting deeper and deeper. At present, there are many reports on optimizing the extraction process of tea polysaccharides by response surface method, but few studies have been conducted on the extraction of polysaccharides from Yingshan cloud tea. Therefore, in this study, polysaccharides were extracted from Yingshan cloud tea by the hot water extraction method, and the extraction conditions were optimized by single factor experiments and response surface method. This study will provide a theoretical basis and reference for subsequent related research.

Materials and Methods

Materials and reagents

Yingshan cloud tea: Huangzhou Huangshang Group; concentrated sulfuric acid (analytically pure) and absolute ethanol (analytically pure): Shanghai Xilong Chemical Co., Ltd.; phenol (analytically pure): Sinopharm Chemical Reagent Co., Ltd.

Instrument and equipment

723 visible spectrophotometer: Shanghai Spectrum Instruments Co., Ltd.; HH6 digital thermostat water bath: Jintan Shunhua Instrument Co., Ltd.; AL204 electronic balance: METTLER TOLEDO (Shanghai) Co., Ltd.; TG16WS Desktop highspeed centrifuge: Hunan Xiangyi Laboratory Instrument Development Co., Ltd.; SHZD (III) circulating water vacuum pump: Gongyi Yuhua Instrument Co., Ltd.; RE52AA rotary evaporator: Shanghai Yarong Biochemical Instrument Factory.

Technological process

The technological process for extracting crude tea polysaccharides from Yinshan cloud tea included pulverization and sieving, extraction in water bath, vacuum filtration, concentration, ethanol precipitation, centrifugation, drying and dilution.

Determination method

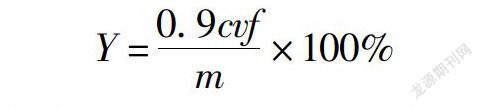

The total sugar content in the crude tea polysaccharide extract was determined by the phenolsulfuric acid method[11]. The regression equation of the standard curve was determined: y=0.008 9x+0.017 7, R2=0.99. The extraction rate (Y) of tea polysaccharide was calculated according to the following formula:

Y=0.9cvfm×100%

Wherein Y is the extraction rate of tea polysaccharide; 0.9 is the conversion ratio of glucose[12]; c is the mass concentration of a tobedetected liquid (μg/ml); f is the dilution ratio of the tobedetected liquid; v is the volume of the tobedetected liquid (ml); and m is the mass of corresponding sample (g).

Design of single factor experiments

Effect of liquidtosolid ratio on the extraction rate of tea polysaccharide from Yingshan cloud tea

A certain amount of Yingshan cloud tea powder (1.0 g) was weighed. The weighed powder was extracted in water according to the liquidtosolid ratios of 30∶1, 40∶1, 50∶1, 60∶1, 70∶1 and 80∶1 ml/g, respectively, at 80℃ for 60 min, to investigate the effect of liquidtosolid ratio on the extraction rate of polysaccharides from Yingshan cloud tea.

Effect of extraction temperature on the extraction rate of tea polysaccharide from Yingshan cloud tea

A certain amount of Yingshan cloud tea powder (1.0 g) was weighed. The weighed powder was extracted in water under the liquidtosolid ratio of 50∶1, at 70, 75, 80, 85, 90 and 95 ℃, respectively, for 60 min, to investigate the effect of extraction temperature on the extraction rate of polysaccharides from Yingshan cloud tea.

Effect of extraction time on the extraction rate of tea polysaccharide from Yingshan cloud tea

A certain amount of Yingshan cloud tea powder (1.0 g) was weighed. The weighed powder was extracted in water under the liquidtosolid ratio of 50∶1 at 90 ℃, for 60, 90, 120, 150, 180 and 210 min, respectively, to investigate the effect of extraction temperature on the extraction rate of polysaccharides from Yingshan cloud tea.

Response surface analysis

Based on the single factor experiments, with the extraction rate (Y) of Yingshan cloud tea polysaccharides as the response value, and liquidtosolid ratio (A), extraction temperature (B) and extraction time (C) as investigation factors, the BoxBehnken design in the DesignExpert software was adopted to design a 3factor 3level test, and the response surface method was applied to optimize the extraction conditions of Yingshan cloud tea polysaccharides.

Results and Analysis

Results of single factor experiments on polysaccharide extraction from Yingshan cloud tea and analysis

Effect of liquidtosolid ratio on the extraction rate of polysaccharides from Yingshan cloud tea

The effect of liquidtosolid ratio on the extraction rate of polysaccharides from Yingshan cloud tea is shown in Fig. 1. As can be seen from Fig. 1, as the liquidtosolid ratio increased, the change in the extraction rate of the tea polysaccharides first increased and then decreased. When the liquidtosolid ratio was 50∶1, the extraction rate of tea polysaccharides reached the maximum, which was 1.63%. When the liquidtosolid ratio is too small, the dissolved tea polysaccharides gradually approach the saturation point, which hinders the further dissolution of the tea polysaccharides[13]. When the liquidtosolid ratio is too large, it not only increases the cost and workload, but also is incapable of improving the yield of tea polysaccharides. Therefore, the optimum liquidtosolid ratio was 50∶1. Then, 40∶1 (-1), 50∶1 (0) and 60∶1 (1) were selected as the three levels of liquidtosolid ratio in the BoxBehnken central composite design.

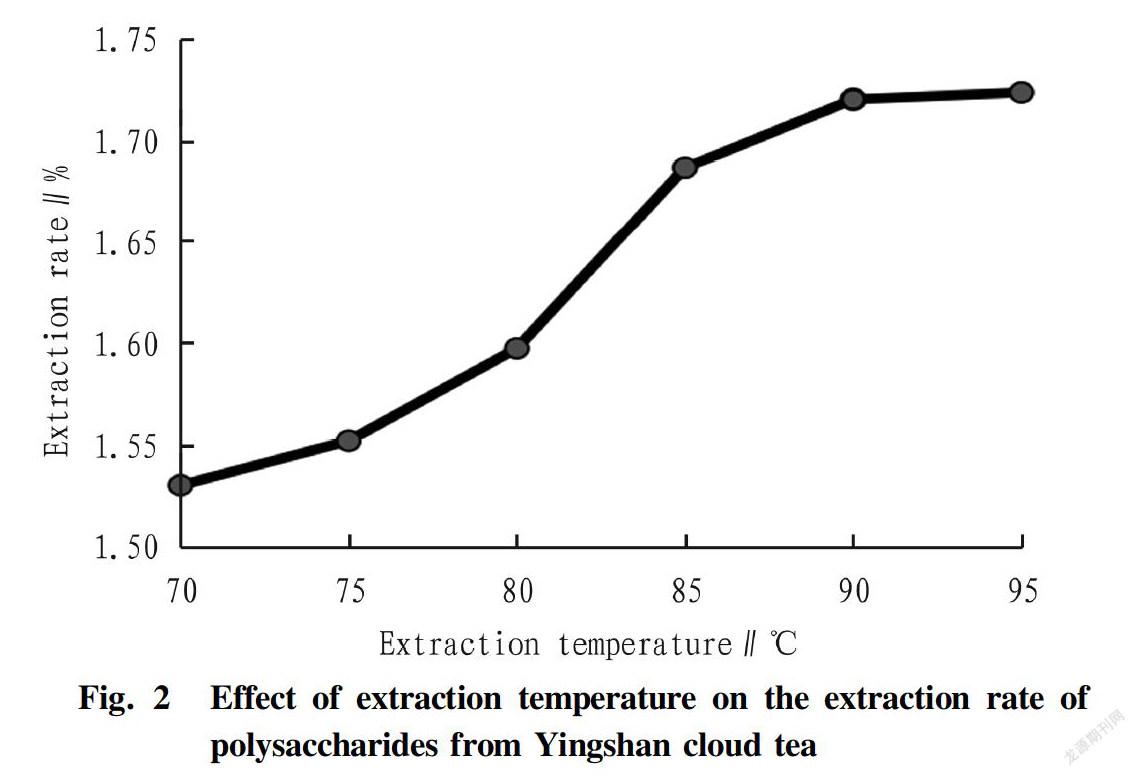

Effect of extraction temperature on the extraction rate of polysaccharides from Yingshan cloud tea

The effect of extraction temperature on the extraction rate of polysaccharides from Yingshan cloud tea is shown in Fig. 2. It can be seen from Fig. 2 that as the extraction temperature increased, the extraction rate of the tea polysaccharides gradually increased and then tended to be stable. When the temperature reached 90 ℃, the extraction rate of tea polysaccharides tended to reach the maximum, and with further increase of the extraction temperature, the extraction rate increased little. Therefore, the extraction temperature was selected at 90 ℃. As a result, 85 (-1), 90 (0) and 95 ℃ (1) were selected as the three levels of extraction temperature in the BoxBehnken central composite design.

Effect of extraction time on the extraction rate of polysaccharides from Yingshan cloud tea

The effect of extraction time on the extraction rate of Yingshan cloud tea polysaccharides is shown in Fig. 3. As can be seen from Fig. 3, as the extraction time increased, the extraction rate of the tea polysaccharides gradually increased and then tended to be stable. After 180 min, with further prolongation of the extraction time, the extraction rate increased very little, or remained almost unchanged. If the extraction time is too short, the tea polysaccharide cannot be fully dissolved, and the longer the extraction time, the higher the cost and time. Therefore, the extraction was selected as 180 min. In the BoxBehnken central composite design, 150 (-1), 180 (0) and 210 min (1) were selected as the three levels of extraction time.

Response surface design results and analysis

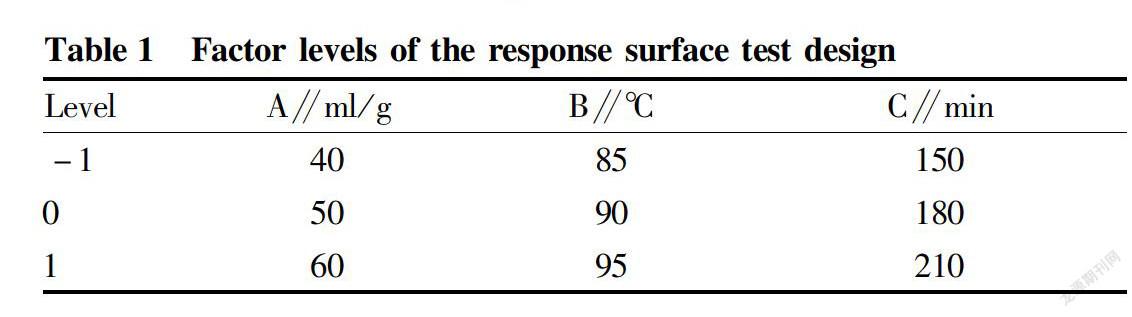

Selection of factor levels

The extraction rate (Y) of Yingshan cloud tea polysaccharides was taken as the response value, and liquidtosolid ratio (A), extraction temperature (B) and extraction time (C) were taken as the independent variables based on the single factor experiment results, to carry out a 3factor 3level test. The factor levels are shown in Table 1.

Agricultural Biotechnology2019

Optimization of the extraction process for polysaccharides from Yingshan cloud tea by Response Surface methodology

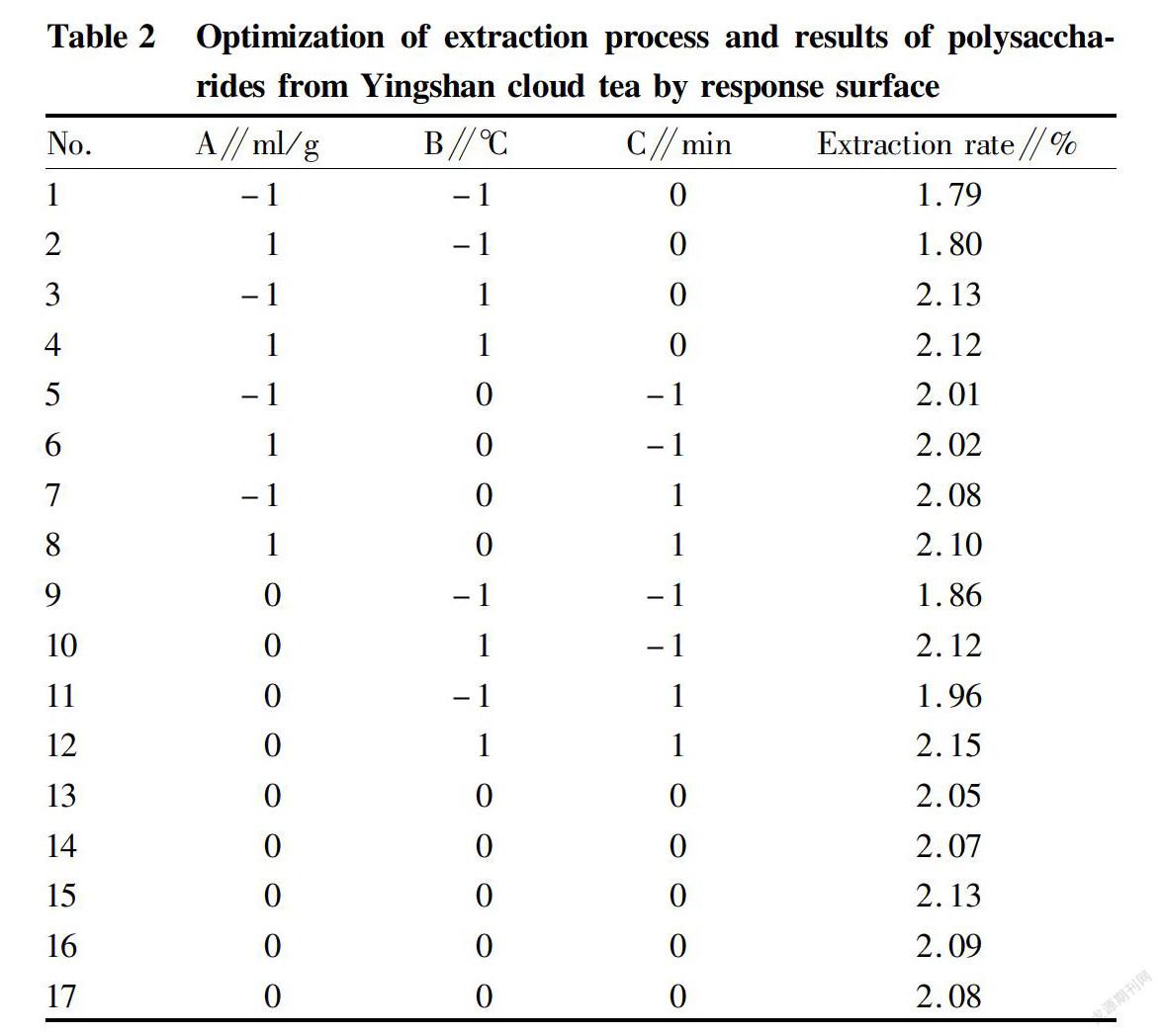

The results of the response surface analysis experiment are shown in Table 2. Polynomial regression analysis was performed using DesignExpert 8.0.6.1 software, obtaining a multivariate quadratic regression equation: Y= 2.08+0.003 75A+0.14B+0.035C-0.005AB+0.002 5AC-0.018BC-0.047A2-0.077B2+0.015C2.

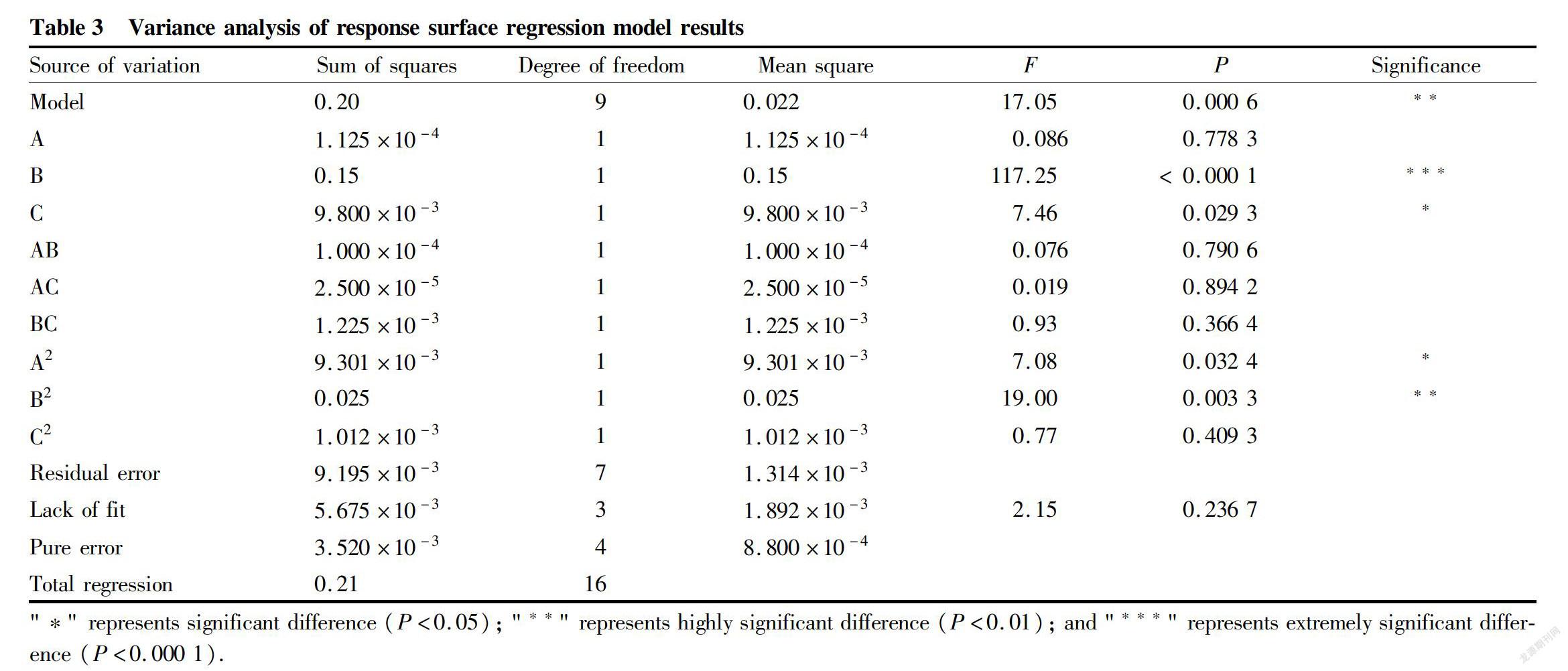

The results of the variance analysis of the response surface regression model are shown in Table 3. The results showed thatthe probability of the model was P<0.01, indicating that the model was significant, and the lack of fit (0.236 7>0.05) was not significant. The correlation coefficient (R2) was 0.956 4, and the adjusted coefficient (R2Adj) was 0.900 3, indicating that the model had a good degree of fitting, and there was a significant linear relationship between the independent variables and the response value[14-15]. The results of variance analysis showed that the effects of factors on the extraction rate of polysaccharides ranked as B>C>A. The one degree item B in the model had a significant effect on the polysaccharide extraction rate of Yingshan cloud tea; the effect of C was significant; and the effect of A was not significant. The effects of the interaction items AB, AC and BC were not significant. The effect of the quadratic term B2 was highly significant; the effect of A2 was significant; and the effect of C2 was not significant.

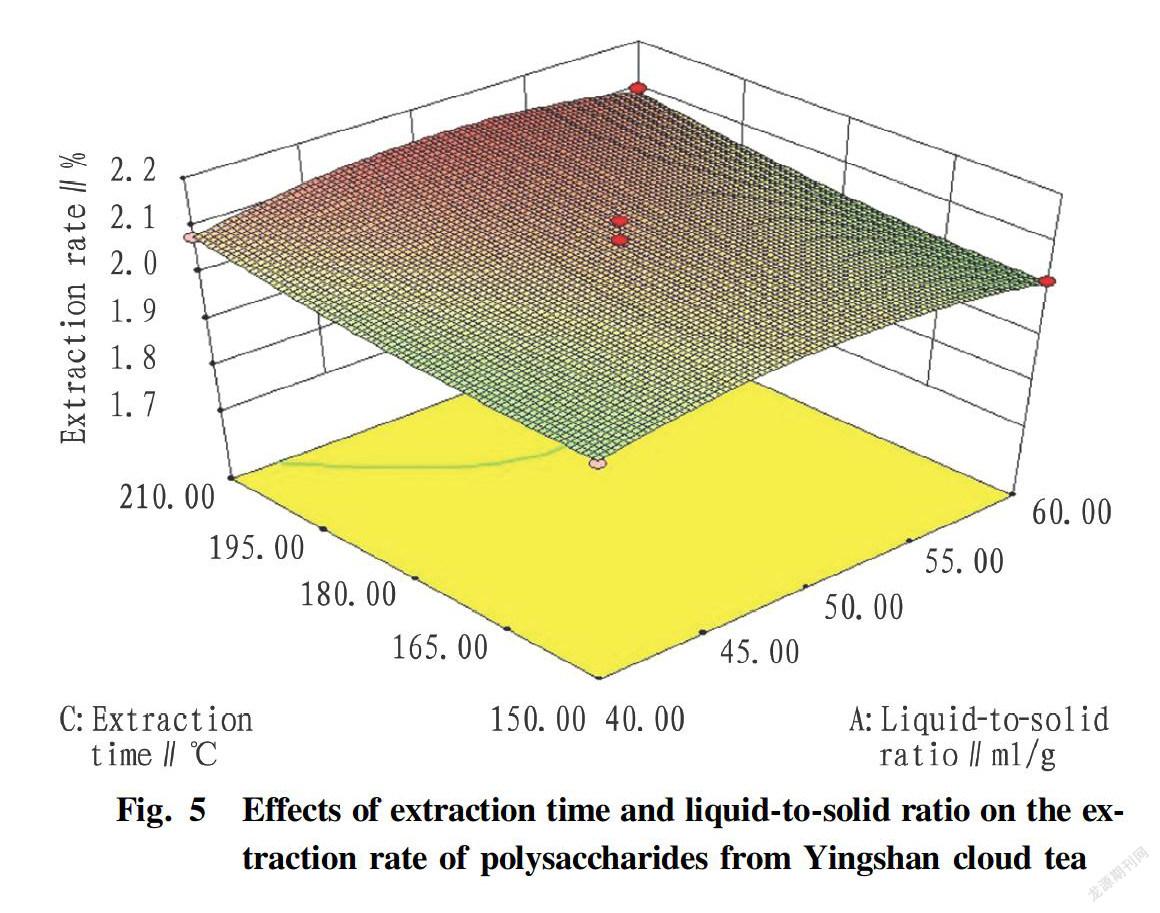

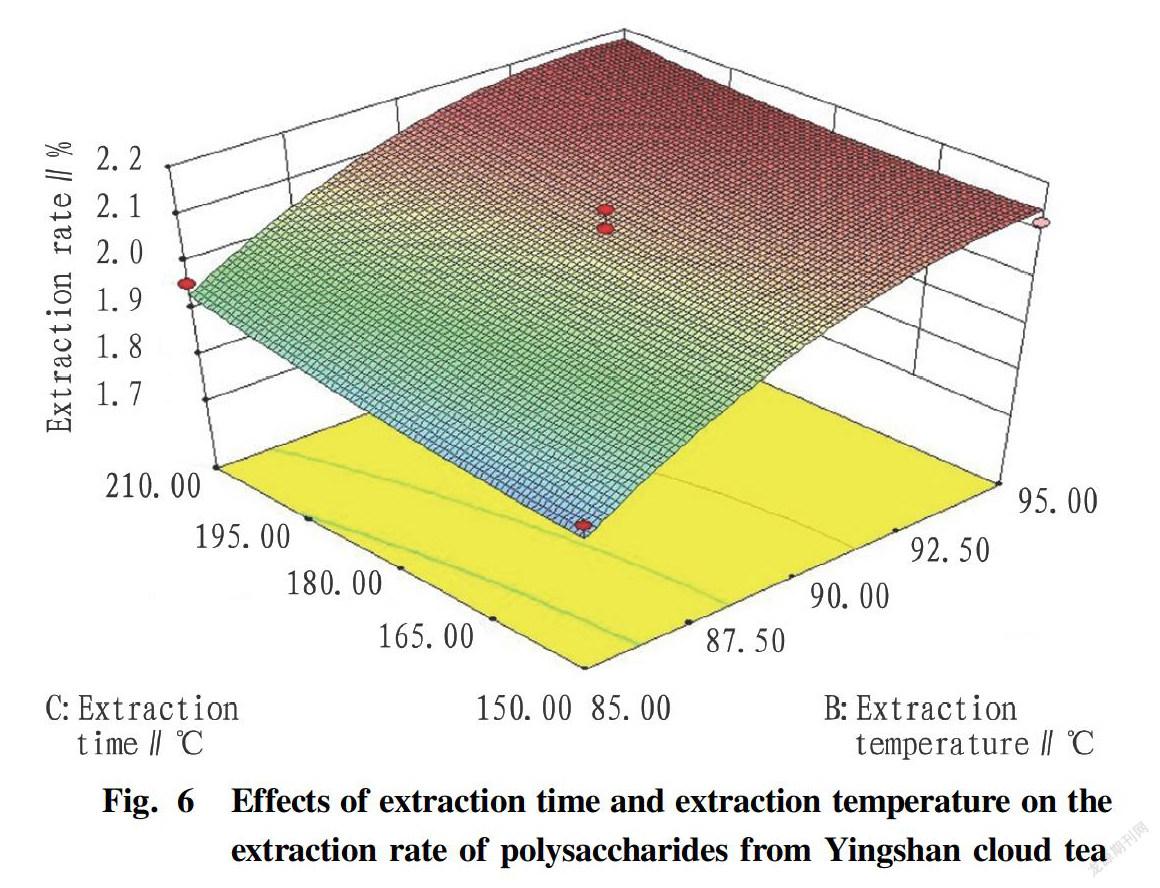

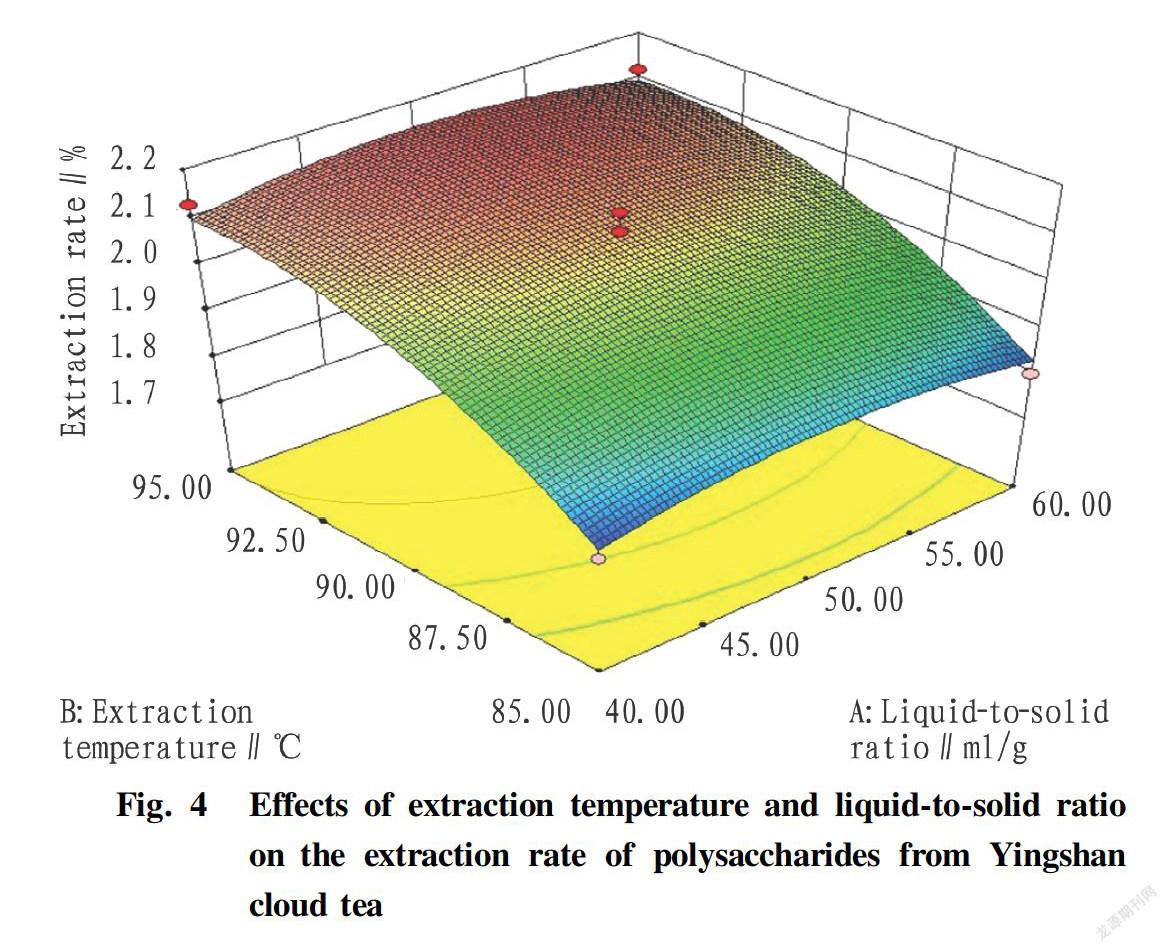

Fig. 4-6 visually show the response values and contour plots for the interaction between various factors. In general, the steeper the response surface, the greater the effect of factor interaction on the response value[16]. Fig. 4 shows the effect of the interaction between B and A on the extraction rate of polysaccharides from Yingshan cloud tea when C was 180 min. It can be seen that the whole response curve was convex, and the higher the B, the steeper the response surface, the larger the slope, and the larger the elliptical arc of the contour line, indicating that the interaction between A and B was significant. Fig. 5 shows the effect of the interaction between C and A on the extraction rate of polysaccharides from Yingshan cloud tea when B was 90 ℃. It can be seen that the response curve was relatively stable, indicating that the interaction between C and A was not significant. Fig. 6 shows the effect of the interaction between C and B on the extraction rate of polysaccharides from Yingshan cloud tea when A was 50∶1. The whole response curve was convex. The higher the B, the steeper the response surface, and the larger the slope, indicating that the interaction between B and C was significant.

The optimal process conditions for the extraction of polysaccharides from Yingshan cloud tea were calculated by the response surface analysis software DesignExpert 8.0.6.1 as the liquidtosolid ratio of 50.24∶1, the extraction temperature at 93.94 ℃ and the extraction time of 210 min, under which the predicted extraction rate of Yingshan cloud tea polysaccharide was 2.18%. In practice, the optimum conditions were corrected to the liquidtosolid ratio of 50∶1, the extraction temperature at 94 ℃ and the extraction time of 210 min. According to this condition, three times of verification tests were carried out, and the extraction rate of Yingshan cloud tea polysaccharides was 2.16%, which differed by 0.02% from the predicted value. The actual value was consistent with the predicted value, indicating that the optimal extraction conditions obtained by the response surface optimization method are reliable.

Conclusions

In this study, the effects of liquidtosolid ratio, extraction temperature and extraction time on the extraction rate of polysaccharides from Yingshan cloud tea were investigated by single factor experiments. The extraction process of polysaccharides from Yingshan cloud tea was optimized by the response surface methodology. The optimized extraction conditions were the liquidtosolid ratio of 50∶1, the extraction temperature at 94 ℃ and the extraction time of 210 min, under which the extraction rate of tea polysaccharide reached 2.16%, which differed from the predicted value (2.18%) by 0.02%. In this process, only the conventional water extraction method was used to extract polysaccharides from Yingshan cloud tea, and the extraction rate was not high. In the subsequent research, ultrasonic wave or microwave will be used to assist extraction on the basis of this study, in order to further improve the extraction rate of tea polysaccharides from Yinshan cloud tea.

References

[1] ZHANG YB, ZHOU SJ, YU LZ, et al. Study on regional characteristics of tea quality in Yingshan County, Hubei Province[J]. China Tea, 2016, (4): 17-19. (in Chinese)

[2] YU H. Study on the spreading method of Yingshan cloud tea brand[J]. Journal of Seeking Knowledge Guide, 2015, (11): 53-54. (in Chinese)

[3] HUANG DJ, MAO YX, TAN RR, et al. Studies on the leaching and morphology distribution of active aluminum in Yingshan cloud tea[J]. Acta Tea Sinica, 2017, 58(2): 55-57. (in Chinese)

[4] MA QN. The influence of tea development on Hubei agricultural economy——A case study of the countermeasures of Yingshan cloud tea industry development[J]. Studio Classroom: Social Science, 2011, (2): 242-243. (in Chinese)

[5] LIU Y. Research status of extraction, purification and biological activity of tea polysaccharides[J]. Scientific and Technological Innovation, 2016, (18): 115-116. (in Chinese)

[6] XIE MY, NIE SP. A review of the research progress on tea polysaccharide[J]. Journal of Food Science and Biotechnology, 2006, 25(2): 107-114. (in Chinese)

[7] ZOU DF, ZHANG KF, XIE AZ. Study on the antimouse immunological liver injury of Camellia nitidissima polysaccharide[J]. West China JOurnal of Pharmaceutical Sciences, 2014, 29(5): 525-527. (in Chinese)

[8] SHAO SH. Physicochemical properties, antioxidant and hypoglycemic activities of the polysaccharides from Oolong tea[D]. Hangzhou: Zhejiang University, 2015. (in Chinese)

[9] CAI J, HUANG MT, HUANG YF, et al. Dynamic change in bioactive polysaccharides and antimicrobial activity of Kudingcha (Ilex kudingcha C.J. Tseng.)[J]. Food Science, 2014, 35(9): 43-47. (in Chinese)

[10] XIE LL, CAI WR, ZHANG H, et al. Isolation, purification and anticoagulant activity of tea polysaccharide[J]. Food and Fermentation Industries, 2012, 38(9): 191-195. (in Chinese)

[11] ZHANG WJ. Biochemical research techniques of sugar complexes[M]. Hangzhou: Zhejiang University Press, 2003. (in Chinese)

[12] ZHANG WJ. Biochemical research techniques of sugar complexes[M]. Shanghai: Shanghai Science and Technology Press, 1987. (in Chinese)

[13] ZHENG LH, YAO LY, ZHANG XF, et al. Extraction optimization and radical scavenging activity of the polysaccharides from Tieguanyin tea dust[J]. Journal of Yunnan Nationalities University: Natural Science Edition, 2017, 26(5): 344-348. (in Chinese)

[14] ZHANG HH, HONG B, LI ZL. Optimization of extraction of polysaccharides from Ziziphus jujubes Mill "Jinsixiaozao” by response surface methodology[J]. Journal of Jilin Agricultural University, 2014, 36(3): 352-359. (in Chinese)

[15] LU XJ, FENG YB, CHEN XR, et al. Optimization for extraction technology of Lycium ruthenicum Murr. polysaccharides by response surface methodology[J]. China Brewing, 2013, 32(6): 79-83. (in Chinese)

[16] LUO L, ZHOU BX, GUO W, et al. Research on the extraction technology of Puerh tea polysaccharide by response surface analysis[J]. Chinese Agricultural Science Bulletin, 2012, 28(30): 263-266. (in Chinese)

- 农业生物技术(英文版)的其它文章

- Observation on Cardiac Opening of the Inferior Vena Cava in Goat Fetuses

- Evaluation on Application and Spraying Effect of AirAssisted Sprayer in Apple Orchard with Dwarfing Rootstocks

- Problems in the Development of Traditional Chinese Medicinal Materials Planting Industry in Shiyan City and Countermeasures

- Study on Practical Mature Age of Individual Pinus thunbergii×P. densiflora

- Effects of Different Densityreducing Methods on Canopy Microenvironment, Tree Growth and Fruit Quality in Closed Apple Orchard

- Development of Whole Potato Flour Fish Noodles