Impact of the Sulfur-Limiting Regulation on Engine Manufacturers

Chen Lu

“Ship emissions have become the main source of atmospheric pollution in ports and sea areas around the world.”Peng Chuansheng, chief engineer of the Environmental Protection and Energy Conservation Technology Research Center of the Water Transport Research Institute under the Ministry of Transport,said at the Southern Port Atmospheric Environment Advocacy and Survey Seminar held recently, “The use of low-sulfur oil to adapt to the sulfur limit regulation is the most convenient and reliable method, or perhaps the most economical method.” In the face of the increasingly approaching effective date of the IMO sulfur limit regulation in 2020,the industry keeps calling for ships to use low-sulfur oil to reduce pollution.Shipping companies and ship engine accessory factories are busy planning layout and making preparations.

Low Sulfur Oil Is Inevitable

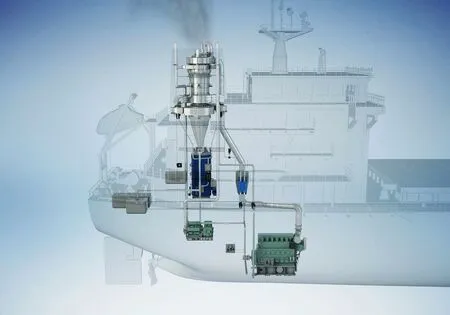

In addition to energy-saving schemes, there are three main measures to control sulfur oxide emissions from ships in the industry: Firstly, use compliant low-sulfur oil with sulfur content less than 0.5% or switch to marine light diesel oil (MGO/MDO);secondly, install ship exhaust gas cleaning system (EGCS), that is the much talked about desulphurization tower;thirdly, use clean energy such as LNG to replace fuel, as burning LNG will not emit sulfur oxides.

“I have always questioned the role of desulphurization equipment in reducing pollution.” At a news briefing in February, Maersk Group CEO John Schsornen again questioned the positive significance of desulphurization equipment for environmental protection. A number of shipping company executives, including Mr. Schsornen, have repeatedly said that although burning low-sulfur oil increases high operating costs and installing desulphurization equipment does have a short investment return period, the discharge of cleaning solution and other substances from desulphurization units,which appears to control emissions up to standard, is also a threat to the environment and is not a long-term solution to the problem. Schsornen once said that in the future, about 90% of Maersk shipping ships will still use low sulfur oil.

Aside from judging from the impact,the industry insiders analyzed and compared the feasibility of operation. Peng Chuansheng believes that the use of lowsulfur oil and ordinary fuel oil is consistent in the operation and management habits,hence easy for transition; using EGCS and LNG involves large one-off investment and takes the inventory space on board, and the crew needs to be retrained. “Therefore,most ships will use low-sulfur oil to meet the requirements for controlling sulfur oxide emissions, accounting for more than 85%.”

Although the use of low sulfur oil can fundamentally solve the problem of pollution source of ship emissions, there is still controversy over whether this measure can be popularized and applied on a large scale, mainly in the aspects of fuel cost and supply capacity of auxiliary items. In particular, the large fuel price difference induces many shipowners into taking risks, clinging to tapping regulatory loopholes. At the Southern Port Atmospheric Environment Advocacy and Survey Seminar, industry experts gave examples to illustrate this situation.

The difference of fuel price of a ship depends on two factors, one is the fuel consumption of the ship, which is affected by the ship type and the ship engine power, and the other is the sailing distance of the ship using low sulfur oil. For example, under the same route and time, the total fuel consumption of a 300,000 ton VLCC sailing 24 hours a day is about 90 tons; in the case of a large container ship, the average daily fuel consumption can reach about 276 tons at a faster navigation speed. The fuel cost accounts for about 30% of the total transport cost. In the comparison of the fuel price alone, the cost of a large container ship using compliant low sulfur oil will be 80,000-300,000 yuan more than that of high sulfur fuel.

"Judging from the current price charts of low-sulfur oil and high-sulfur oil in major ports around the world, for shipping companies or shipowners, the cost of using high-sulfur fuel would be$200 a ton cheaper than compliant lowsulfur oil." Cheng Huihui, a researcher at the Asian Clean Air Center, said the cost difference between using high-sulfur fuel and compliant low-sulfur oil is 280,000 to 350,000 yuan for a large container ship. "The high cost of compliance means that companies are more motivated to break the rules, and in the absence of effective regulation, it is difficult to deter violators," She added.

In February, the Group announced its full-year performance in 2018. The data show that the company's shipping fuel costs for the year were as high as $5 billion, with a year-on-year increase of more than 50%. If the price difference between the compliant low-sulfur oil and the high-sulfur fuel is $200/ton,MSK will need additional fuel costs that may be as high as $2 billion. This also means that the use of low-sulfur oil will add a substantial burden to the shipping company or the shipowner in the short term.

However, industry insiders also believe that, on the one hand, the additional costs brought by environmental protection to shipping companies will be passed on to the society in a variety of ways; on the other hand, with the extensive use of low-sulfur oil and the improvement of the relevant supply chain,the difference between heavy oil and lowsulfur oil will gradually narrow down."Every ship has to meet the requirements of sulfur emission control. As long as the regulation is in place, every shipping company will face the problem of increasing fuel costs, which can be translated into freight rates and borne by the whole society." Peng Chuansheng said: "The use of low-sulfur oil is the most convenient and reliable way to meet the requirements of sulfur control, and may also be the most economical method."

Noticeable Impact

If the use of low sulfur oil is an inevitable trend, what impact will it have on the main engines of ships that are now widely using heavy oil? Will the replacement of fuel lead to a mixture of high and low sulfur oil, resulting in greater pollution?

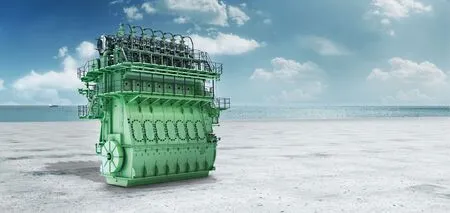

“At present, most ship engines can directly use low-sulfur oil, only operating in line with the cylinder oil grade recommended by the engine manufacturer. Therefore, the fuel change has little impact on the ship engine equipment factory.” Cao Erming with CSSC Marine Power Co., Ltd. said that the use of low-sulfur oil in place of heavy oil mainly needs to consider the influence of different sulfur content in engine fuel oil on cylinder liner lubrication, as the sulfur content is different, it is required to use cylinder lubricating oil corresponding to different BN values. “There are a few other changes as both low sulfur oil and heavy oil designs are taken into account in the fuel pump, fuel injector, common rail unit and pipeline in the current engine. As long as fuel oil of specifications stipulated by the engine manufacturer and ISO is adopted, use requirements can be met,”he added.

According to an insider close to Dalian Marine Diesel Engine Co.,Ltd., all the marine low-speed diesel engines developed by the company are manufactured according to the patent license of MAN Energy Solutions and WinGD, which can meet the use requirements of high and low sulfur oil."In fact, the problem of ship emissions is not a topic coming up in recent years, but with the approaching of the sulfur limit regulation, the control of sulfur emissions is becoming more and more urgent." The insider said that a ship usually operates for about 30 years after the completion,so the R&D patent company and marine equipment manufacturers will have a time for anticipation and prediction and develop the model in line with environmental and relevant requirements during the long period. For example, in the Baltic Sea of Northern Europe, IMO approved the establishment of sulfur oxide emission control area in as early as 2010, and the emission requirements are gradually increasing in the phased implementation. Therefore, for R&D patent companies and marine equipment manufacturers, disruptive transformation of products is not necessary to meet the needs of the shipowner’s low sulfur oil schemes, but optimizing the products according to specific requirements will do.

Since 2015, WinGD has launched a multi-type low-pressure natural gas dual-fuel engine to the market,including 52DF, 40DF and other new models developed jointly with CSSC Marine Power Co., Ltd. A set of cylinder lubricating oil automatic switching device is designed for this type of engine, taking into account the use requirements for low sulfur oil and heavy oil. "This is developed for DF dual fuel engines."According to Cao Erming, DF dual fuel engine will have the demand of cylinder lubricating oil switching when switching different fuels, so this type of DF dual fuel engine is equipped with this type of cylinder lubricating oil automatic switching device. And for the sulfur limit regulation that is bound to enter into force in 2020, as it does not involve the switching of different fuels,it is only necessary to use the low sulfur cylinder lubricating oil recommended by the engine manufacturer. If the ship is sailing in the low sulfur oil open sea area where the sulfur content is required to be 0.5% and 0.1% emission control area,such a device may be needed when it is necessary to switch fuel.

The impact is small but not zero, and the details still need to be paid attention to. In order to meet the environmental requirements such as sulfur limit regulation, if low sulfur oil is used, it may be either low sulfur residue fuel oil or fraction fuel oil. Because of the few supply of low sulfur residue fuel oil, ships usually use low sulfur fraction fuel oil to meet the control requirements. Peng Chuansheng said:"If the ship uses residual low sulfur fuel oil, the engine and its supporting fuel pipeline system are adaptable without the need of modification; if the ship uses fraction low sulfur fuel oil to meet the requirements, the original diesel engine and corresponding pipeline system can not meet the requirements, corresponding transformation is required, subject to approval of a classification society." Cao said, "Mixing the two kinds of fuel should be avoided as far as possible, especially if the mixing system is installed on board, unless the engine manufacturer's guidelines for fuel mixing are strictly abode by, it will be counterproductive."

"The long-term application practice in the international emission control areas has proved that there is no problem with the oil change of ships, and the occasional problems in the process does not demonstrate it is caused by oil change.It is because some ships of Chinese shipping companies or shipowners have not undergone the oil change operation training, fuel leaking into the engine room during the fuel swift operation, that they were retained by the European maritime regulatory authorities," Peng Chuansheng added.

In the short term, most ship engines only need adjustment and improvement for use of low sulfur oil, but in the long run, whether it is the whole engine technology or fuel requirements, the development of a direct use of low sulfur oil main engine, seizing the market, will become a new task of marine equipment manufacturers.