Underwater explosion effects of 60 mm H.E.mortar bomb on a cylindrical concrete structure-PIT

Faruk Razi ,Burek Miralem

a Defense Technologies Department,University of Sarajevo,71000,Sarajevo,Bosnia and Herzegovina

b Faculty of Mechanical Engineering,University of Sarajevo,Vilsonovo setaliste 9,Bosnia and Herzegovina

c Pretis d.d.Igmanska bb,71320,Vogoˇsća,Bosnia and Herzegovina

Keywords:Underwater explosion Mortar bomb Blast Comp B Dummy fuze Fragments

A B S T R A C T PIT tests are usually performed when a mass distribution of High Explosive(H.E)projectile fragments is required.This paper shows the underwater detonation effects of 60 mm,M90 H.E.mortar bomb filled with Comp.B on cylindrical concrete structure(concrete pipe closed at one end-similar to a PIT test)which is 2 m high(inner height)with inner diameter of also 2 m.Thickness of both wall and bottom of a pipe is 0.35 m.Detailed characteristics of concrete which is used for manufacturing of a pipe are specified.Mortar bomb is submerged directly in to the water(no free airspace around the bomb)with the nose pointing to the bottom of a pipe.Number and mass of fragments after detonation are presented by table and photographs.Fragments of dummy fuze,through which blasting cap was protruded,are collected and reassembled to form a shape of a fuze after detonation where expanding of fuze material due to a detonation products is visualized.After underwater detonation,detonation of the same mortar bomb is performed in an empty pipe and the effects of this kind of detonation are observed.Distance at which fragments generated from submerged mortar bomb will not reach concrete pipes wall is also determined.

1.Introduction

Underwater explosion is no more different in concept of detonation than the explosion in the air,but the effects of this kind of explosion are.It is well known that underwater explosion cause more damage than the same amount of explosive detonated in the air[1].Most of the underwater explosion research available to authors refers to numerical simulations,and there are very limited data on this subject when actual explosion occurs.Actual explosion research is usually expensive or it presents a secret company information,hence the reason for scarce data.

This case study presents real explosion in both cases,underwater and in the air,and its effects on the reinforced concrete structure.There are two important damage mechanisms of projectile detonation,high energy fragments generated from the projectile body expansion and blast effect created by rapid expansion of gaseous products.Projectiles are usually designed to maximize one of these effects[2].This particular projectiles,M90 mortar bomb,primary damage mechanism is due to a kinetic energy of the fragments.The blast effect is a secondary damage mechanism.

It was of significant importance for authors to determine distance at which fragments generated from projectile explosion in the water will not reach concrete wall.Fragments and projectiles travelling through water experience more drag than the one in the air and direct consequence of this phenomenon is decreased range.It was important to slowdown these fragments before they hit the concrete wall so their shape gained after explosion can stay undeformed.In air,these fragments will hit the wall and deform significantly.Second goal was to define structural behaviour of a concrete pipe after both types of explosions.

2.Material and methods

2.1.PIT installation concept

PIT tests are usually designed for defining a mass distribution of fragments generated by some particular H.E.projectile.Installation is based on a pit of defined dimensions,depth and height in which a projectile is going to be detonated.The medium in which a projectile is going to be detonated is sand,sawdust or water.This medium is used to slow down fragments.It is known that the size of the air space surrounding the projectile has a strong in fluence on fragmentation[3].

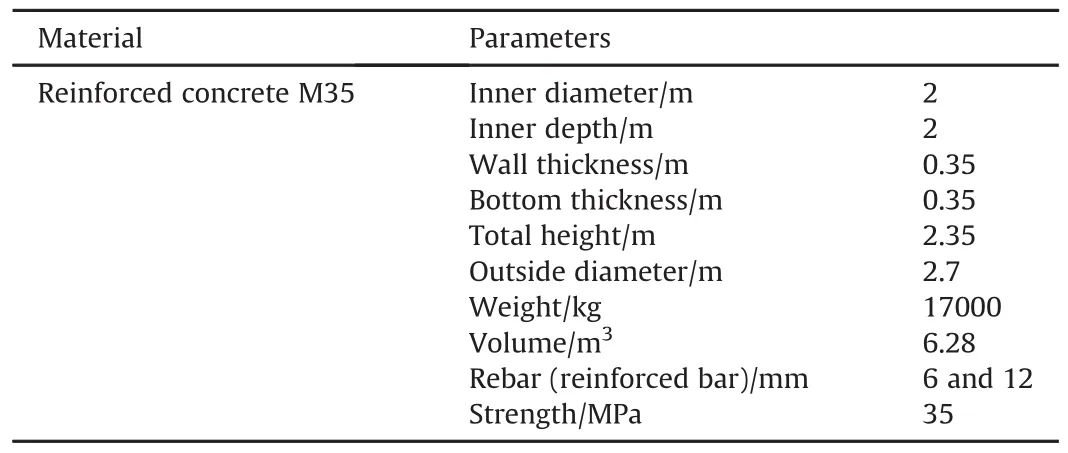

Design of PIT for the experiment presented in this paper is no more different than the standard PIT installation except for dimensions.Simply stated,it is a cylinder closed at one end.Detailed specifications are presented in Table 1.

Concrete used for construction of PIT installation was reinforced by two layers of 6 and 12 mm rebar.PIT was manufactured in a company which is specialized in concrete products and concrete manufacturing.Because of a size and weight of PIT,special kind of transportation had to be organized so it could be delivered to a test site.Finalized and delivered concrete PIT installation is presented in Fig.1.

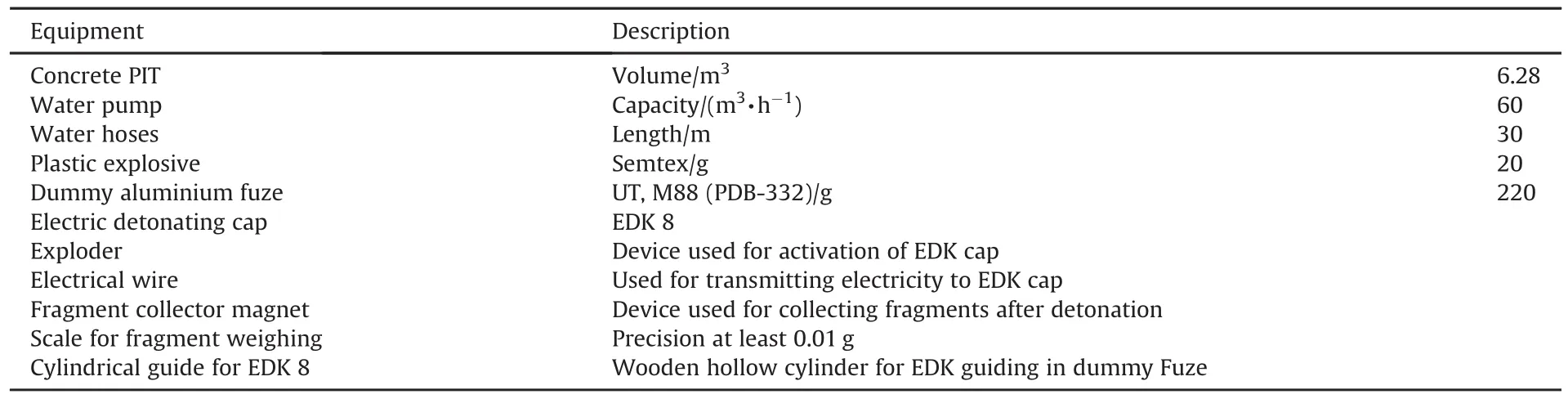

2.2.Test equipment and its preparation

Bearing in mind concrete PIT volume of 6.28 cubic meters,it was important to use high capacity water pump in order to reduce water loading time.Using this kind of pump took 6.5-7 min to fully load PIT installation.Detailed list of equipment needed for this experiment is in Table 2.

2.3.Fuze preparations

For successful detonation of explosive charge in projectile,proper explosive train must be established.This is achieved when a projectile, fired from a weapon,hits hard surface.Fuze,which is located on top of a projectile,is initiating explosive train.Detonation pulse from fuze activates buster charge which is found inside of explosive charge of projectile creating necessary conditions for beginning of detonation process of explosive charge of projectile.Shock wave is moving through explosive charge,and behind the shock wave are detonation products which are acting upon the inner structure of projectile body.It is important to point out that detonation process is not instantaneous and that it lasts for tens of microseconds[4].

In this experiment,real armed fuze cannot be used for safety reasons,and detonation of mortar bomb is done from a safety bunker with a device for detonating blasting caps-Exploder.Dummy fuze made of aluminium is used instead of a real fuze.Both,real fuze UT,M88(PDB-332)and dummy fuze have the same mass,220 g.In order to properly detonate mortar bomb,9 mm hole was made in dummy fuze through which detonating cap was protruded.UT,M88(PDB-332)fuze and dummy fuze are presented in Fig.2.

Table 1 Dimensions and material specifications for concrete PIT installation.

Projectile provided for this experiment is 60 mm H.E.Mortar bomb,M90.This mortar bomb is not equipped with buster charge.For that reason 10 g of plastic explosive was applied to the bottom of the fuze(In Fig.2(e)).

For a proper guidance of EDK 8 Blasting cap,wooden cylinders are made and inserted in the fuze.This has been done before plastic explosive was applied.

2.4.Preparations for detonation

Afterconcrete pipe was filled with water,60 mm mortar bomb is assembled with dummy fuze.EDK 8 blasting cap was inserted in a fuze and sealed using silicone caulk.The whole assembly is then submerged in water with a bomb nose pointing down.Nylon rope was used to position bomb by hanging it to a 1 m height above the bottom of a concrete pipe.Electrical wires,length of about 100 m,are used so detonation could be performed from a secured place.Bomb characteristics are in Table 3.

According to[6]53%of energy from an underwater explosion(UNDEX)is released in a form of a shock wave.The rest of the energy is used for a gas bubble pulsation(Upon detonation of high explosive,TNT,RDX,PETN etc.highly compressed gas bubble is formed along with a shock-wave in the surrounding water).20%of the shock wave energy is lost during the early propagation and only 33%of this energy will be available as damaging energy.Regarding bubble pulsation,13%of the explosion energy is radiated during the first bubble,17%at first bubble minimum as pressure pulse and the rest of the 17%is available for the second pulsation.Both,incident shock wave and bubble pulsation can cause severe structural damage.

It is possible to predict maximum bubble radius,R max,which depends on charge type,weight“w”and distance from the target,using next equation given for TNT.

Where Z0=D+9.8,and D is distance from the target.

For this case R max is 1.46 m.This radius is larger than 1 m(which is inner pipe radius)so it is convenient to assume that beside shock wave,formed bubble will cause damage to this structure too.

3.Results

3.1.Underwater detonation of 60 mm mortar bomb

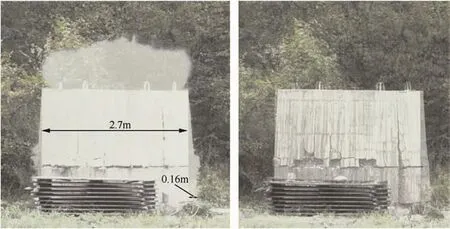

Bomb is detonated using exploder(device for activating detonation caps)from a safety bunker designed for these purposes.Detonation is presented in Fig.3.

After detonation,largest expansion of concrete pipe was 0.16 m at one side.Detailed examination of a structure is performed.Mostly tangential(0.70-2.00 m height)cracks are noticed on the inside of the structure.Radial cracks are noticed on outer side following whole circumference.Rebar used for concrete reinforcement is completely cut of,and all surface cracks are following line of rebar.Fig.4 presents overlay images of undeformed concrete pipe versus pipe after detonation (transparent grey image).Expansion of material is evident.Water which was inside the pipe leaked out through cracks in about 60 s.

Fig.1.Concrete PIT installation delivery and setting.

Table 2 Necessary equipment.

Fig.2.Real and dummy fuze UT,M88(PDB-332)[5].

Table 3 Characteristics of 60 mm,M90 mortar bomb.

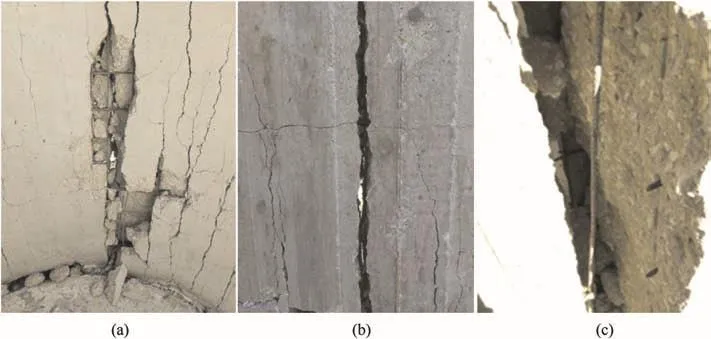

As shown in Fig.5,cracks were expanding through the whole thickness of the wall(0.35 m).

One of the important observations is that there are no significant marks of fragments on the inside wall of a concrete pipe.In fact,fragments spray which is characteristic for HE projectile is completely missing.This suggests that most of the fragments generated from the explosion of the projectile body did not hit the wall.Since fragments were moving through the water which has much larger density than the air,hence much more resistant,they slowed down enough to not hit the wall.This implies that fragments did not additionally deform after bomb fragmentation and that their shape after detonation is preserved.Distance from the center of explosion to the concrete pipes wall was 1 m.Fig.6 shows PIT installation after detonation.

Rebar mesh was rectangular.That was the reason for cubical concrete elements to be expelled from a structures outer surface.The rebar actually formed this kind of shape because of the stress which was produced by the blast effect on a wall,Fig.7.

Fig.3.Detonation of 60 mm mortar bomb in a concrete pipe.

Fig.4.Overlay images of concrete pipe expansion.

Fig.5.Cracks of the concrete pipe(a)light protruding from the other side,(b)taken from the outside,(c)rebar cut-off.

Fragments are collected using handmade fragment collector based on neodymium magnets.Six N52 magnets,each pulling more than 10 kg,are glued on the upper surface of a trowel(Fig.8).

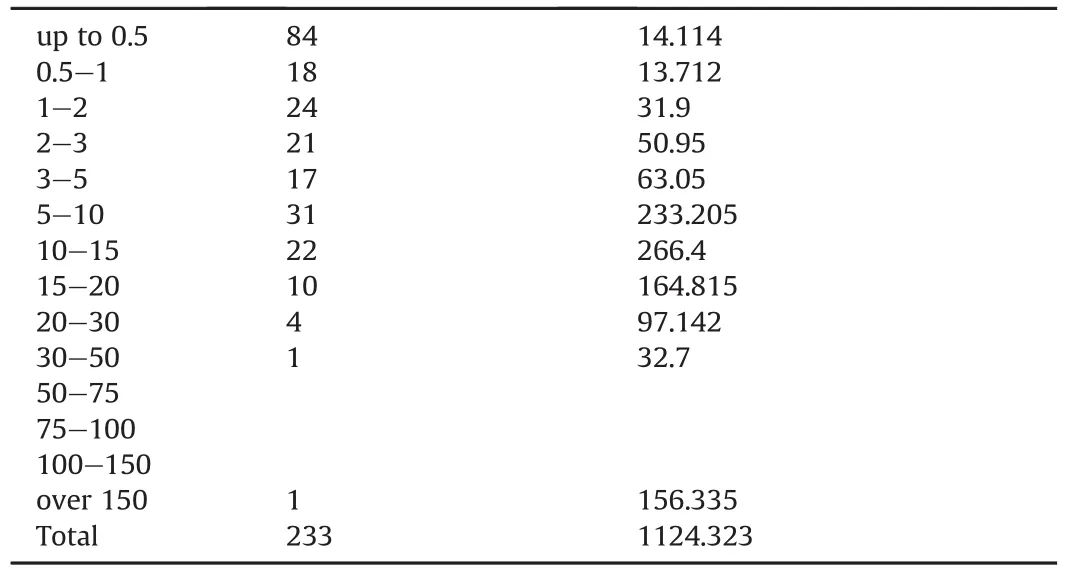

About 75%of fragments are collected,as shown in Table 4,restof the fragments leaked out through cracks after detonation.

3.2.Mortar bomb detonation in empty pipe

Fig.6.Outer surface of the concrete pipe((b)developed surface of the pipe).

Fig.7.Cubical shaped concrete elements expelled from the structure.

Underwater detonation caused significant damage on a PIT installation.Still,it kept its original cylindrical form which was enough for authors to test in air detonation and its effects on a heavily damaged structure.Preparations for detonation were identical to those which were performed in water.This detonation did not have any significant in fluence on a structure,even though structure was heavily damaged during underwater explosion it did not suffer any additional damage.In air detonation shows spray pattern of fragments on the inside wall.Fig.9 shows preparation of a projectile for detonation and at the same time it depicts construction after undex detonation and construction after in air explosion.

Luckily Grumedan did not perceive this, as he was too much occupied in whipping up the frogs, many of whom perished miserably35 from fatigue36, since he did not allow them to rest for a moment

Lack of fragment spray pattern in underwater explosion compared with explosion in air is evident.When it comes to a damage caused by the explosion in the air,it is primary due to a high velocity fragment impacts on the inside wall.Chips of concrete are severed from the inner surface.This level of damage is far less intensive and destructive than the one caused by the shockwave in underwater explosion and it does not jeopardize construction

Mass group/g Number of fragments Mass of fragments in a group/gintegrity.

Table 4 Mass and number distribution of fragments according to[7].

3.3.Reassembling of a dummy fuze after detonation

EDK 8 blasting cap was protruded through the body of the dummy fuze.Also,10 g of plastic explosive was applied at the bottom of the fuze where buster charge should be placed in a real fuze.Heaving this in mind,fuze acts as a small grenade which is consisted of a body(aluminium body),explosive(10 g of plastic explosive)and ignition device,EDK 8 cap.After initiation,EDK cap detonated plastic explosive which then detonated explosive charge in mortar bomb(comp B).Fig.10 shows reassembly of the fuze after detonation.

Initiation of EDK 8 cap and 10 g of plastic explosive reacted on a fuze body causing its fragmentation.Just like in a mortar bomb,hand grenade or any other HE projectile.According to[8]initial volume of a projectile is increased to about three times before complete fracturing.

Fragments of the dummy fuze are collected.Since dummy fuze is made of aluminium it was very simple to separate these fragments from projectile body fragments(aluminium is not magnetic material).

There was increase of an original volume more than two times.Fractures of fuze were both,plastic and elastic which made reassembly of its parts very complex.There were fragments which could not be glued to its original place because of plastic deformation.Almost 90%of fuze fragments are collected.

4.Discussion

There are very few data available for public use on actual underwater explosions.Having that in mind,it is very important to publish all significant information gained through original research and experiments.

Fig.8.Fragment collector and collected fragments.

Fig.9.(a)Preparation for detonation(b)fragment prints after detonation.

Fig.10.Dummy fuze UT,M88(PDB-332),reassembly of exploded fuze,overlay of two images.

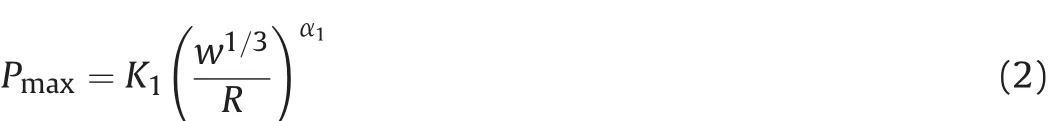

Some predictions of a behaviour of a structure could be made using undex pressure equations proposed by Cole[9].

Where K1andα1are constants depending on type of the explosive charge,see Table 5,Pmaxis peak of the underwater explosion pressure,R is the distance of the explosive from the target and w is the charge weight.

Mass of explosive used in this 60 mm mortar bomb was 350 g of comp B(50:50).Comp B is a mixture of TNT and RDX;in this case ratio is 50:50.Since RDX has a relative strength of 175%[2]than the whole mass of 350 g of comp B is equivalent to about 481 g of TNT.Using equation(2)and constants K1andα1for TNT,peak pressurein this explosion is almost 40 MPa which is more than a strength of concrete that has been used for construction(35 MPa).

Table 5 Constants for different explosives[10].

Strong magnets are usually used for fragment collecting in regular PIT tests.For this purpose magnetic fragment collector is designed and handmade by the author.These fragments now form a small group of fragments formed in underwater explosion without free air space around mortar bomb before detonation and they could be compared to those collected from in air explosion in future studies.

Damage level of underwater projectile explosion is very difficult to predict.According to[1]shockwave peak pressures in undex are higher than those in air for about 42 times.

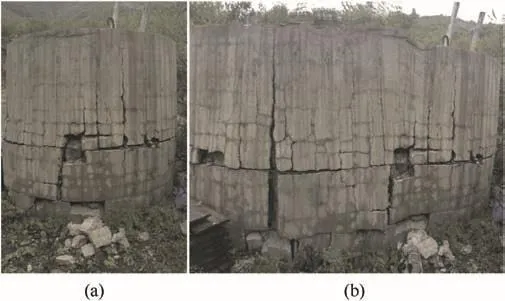

Minimum distance at which fragments generated from projectile body explosion will not reach the surface wall in this case is determined based on the effects on a concrete structure of both explosions.PIT Installation(Concrete pipe)before and after both detonations is shown in Fig.11.

5.Conclusion

Underwater detonation of a 60 mm mortar bomb showed the in fluence of blast effect in water on a concrete cylindrical structure.Level of damage was expected since strength of a concrete was less than peak pressure calculated using Cole equation.

Also,fragment deceleration due to a media through which fragments were moving is evident,and distance at which fragments will not reach PIT installations wall is defined to at least 1 m from the epicentre of explosion.Analytical prediction of fragments range in undex explosion was not made in this case.

Detonation in open air(empty concrete pipe)was also performed,and the results showed that even though pipes structure was weakened and heavily damaged by underwater detonation,there were no additional damage on the construction regarding blast effect through air,but damage from fragments created by mortar bomb detonation is evident through fragments spray on the inside wall.Level of damage achieved by fragment hits is far less effective than the shock wave produced in underwater explosion.

Reassembly of a dummy fuze was made and overlay images are shown.This reassembly shows expansion of a body during explosion.This expansion correlates with HE projectile body expansion during detonation and its increase of original volume.

This research graphically shows the effects of underwater explosion on a concrete structure.Behaviour of the fragments regarding distance and deceleration can be deduced upon the results of both detonations.

After this research PIT installation can be used for demilitarization by detonation of HE projectiles up to 60 mm caliber.

Fig.11.PIT installation(a)before testing(b)after underwater explosion(c)after in air explosion.

Acknowledgments

The authors would like to thank Mr.Ahmed Turbo and Company“Termobeton D.O.O.”Breza,for providing their facility,equipment and expertise in manufacturing and transportation of a PIT installation(Concrete pipe).

The authors are thankful to Company “Pretis d.d.”Vogosca(in Sarajevo),which provided their test site for our research.Projectiles,detonators,dummy fuzes and all necessary equipment needed for this case study was enabled by this company.

- Defence Technology的其它文章

- Fluorine-containing oxidizers for metal fuels in energetic formulations

- On the formation of Basu's Type III(peeled orange)gunshot residues

- Interaction of TATB with Cu and Cu+1.A DFT study

- Control of exterior ballistic properties of spin-stabilized bullet by optimizing internal mass distribution

- Crystal lattice free volume and thermal decomposition of nitramines

- Tribological and vibrational characteristics of AISI 316L tested at elevated temperature and 600 Torr vacuum