Characterization of mixing in an optimized designed T-T mixer with cylindrical elements

Mechanical Engineering Department,National Institute of Technology Warangal,Telangana State,India

Keywords:CFD-simulation Cylindrical elements Micromixers Mixing quality Obstructions T-T-mixer

ABSTRACT Passive micromixers are preferred over active mixers for many microfluidic applications due to their relative ease in integration into complex systems and operational flexibility.They also incur very low cost of manufacturing.However,the degree of mixing is comparatively low in passive mixers than active mixers due to the absence of disturbance in the flow by external forces and the inherent laminar nature of microchannel flows.Various designs of complex channel structures and three-dimensional geometries have been investigated in the past to obtain an efficient mixing in passive mixers.But the studies on mixing enhancement with simple planar geometries of passive mixers have been few and limited.The present work aims to investigate the possibility of mixing enhancement by employing simple planar type designs,such as T-mixer and T-T mixer with cylindrical elements placed in the mixing channel.The mixing performance has been evaluated in the Reynolds number range of 6 to 700.Numerical results have shown that T-T mixer with cylindrical elements performed significantly well and obtained very good mixing quality over basic T-mixer for the entire range of Reynolds number(6 to 700).The device has also shown better mixing as compared to basic T-T mixer and T-mixer with cylindrical elements.A larger pair of vortices formed in the stagnation area due to the presence of a cylindrical element in the junction.Cylindrical elements downstream caused significant enhancement in mixing due to splitting and recombining action.The size of the cylindrical element in the T-T mixer has been optimized to obtain better mixing performance of the device.Remarkable improvement in mixing quality by T-T mixer with cylindrical elements has been obtained at the expense of small rise in pressure drop as compared to other passive designs considered in this study.Therefore,the current design of T-T mixer with cylindrical elements can act as an effective and simple passive mixing device for various micromixing applications.

1.Introduction

Micromixers are the most crucial components in micro Total Analysis Systems(μTAS)or lab-on-chips to carry out the biomedical,chemical and biochemical analyses.Recently,micromixers have also been widely employed in the field of chemical processing as microreactors.The miniaturized mixer reduces the amount of expensive reagents to be utilized,improves portability and provides rapid analysis.They require very low cost to manufacture and can be directly integrated with lab-on-chips which are not possible with their counterparts,macro batch reactors.Therefore,micro-scale mixing plays a major role in biochemical and chemical analyses using μTAS or lab-on-chips[1]as well as in the chemical processing field[2].Some of the important applications of micromixers are protein folding studies that provide information on the causes of a disease,DNA microarrays that are used to collect the genetic information,cell separation and detection,organic synthesis,reaction kinetic studies of chemical and biological substances,chemical assays for assessing and measuring the presence of an analyte[3].Micromixers can be classified into passive and active mixers.Passive micromixers do not need an external energy source to induce mixing in the channel.They only need a pressure head to drive the samples into the mixer.The channels in these devices are designed in such a way that the interfacial area between the fluid samples is increased and the diffusion distance is reduced to enhance mixing[4].The active mixers require an external energy source such as electrokinetic,magneto hydrodynamic or ultrasonic vibrations to induce mixing by perturbations[5].The vast numbers of currently used micromixers are passive type due to their low cost of manufacturing,ease of integration in a more complex system and robustness.

Gobby et al.[6]numerically studied the gaseous mixing in a passive T-micromixer by varying design parameters such as the angle between inlets,throttle size at the junction and viscosity of the fluid.They found that throttling has a positive effect of decreasing the mixing length.Hessel et al.[7]numerically and experimentally studied laminar mixing in different interdigital micromixers.Splitting liquid samples into a number of geometrically separated parallel channels and then focusing them into a narrow channel has significantly increased the mixing quality due to hydrodynamic focusing effect.Hoffmann et al.[8]experimentally investigated liquid-liquid mixing in T-micromixers using micro laser-imaging techniques to measure the concentration and velocity field to validate various numerical models.They have found a good agreement between experimental and CFD results qualitatively.In their study,Engler et al.[9]observed that diffusive mixing in a conventional T-shaped mixer when assisted by vortices and convective effects appearing after a critical Reynolds number resulted in highly efficient mixing.Wong et al.[10]experimentally and numerically studied the liquid mixing in a T-mixer and observed rapid mixing at high Reynolds numbers(400-500)due to the generation of secondary flows and vortices in the mixer.Bothe et al.[11]conducted experimental as well as numerical investigations to study the mixing behavior of flow in micro-scales.They showed that within laminar flow at higher Reynolds numbers(146<Re<186),the rolling up of interfacial planar contact area known as engulfment flow,resulted in more efficient mixing.Soleymani et al.[12]investigated the flow and mixing phenomenon in a T-micromixer to study the effects of various parameters such as mixing angle,aspect ratio,throttle size,and flow rates.They noted that for effective mixing,the development of vortices is crucial which depends on both the geometry and flow rate of the mixer.Dreher et al.[13]carried out numerical and experimental studies on the characterization of mixing in a T-micromixer for Reynolds numbers from 0.01 to 1000.They observed that the steady behavior of flow in the Reynolds number range of Re<240 turns into transient nature for flows of Re>240.They observed a chaotic pulsating behavior of flow for Re>500 with the mixing quality reduced significantly.Thomas and Ameel[14]conducted a similar experimental study and investigated the flow behavior in a T-mixer extensively in the Reynolds number range of 56 to 422.They observed a steady,symmetric and four-vortex flow for the range of Re<116,asymmetric(steady or unsteady)twovortex flow in the range 142<Re<298 and an unsteady,symmetric four-vortex flow for Re>355.They recommended a practical Reynolds number operating range of 142 to 298 for the T-mixer.This has shown an asymmetrical flow with a positive impact on mixing.In other ranges of Reynolds numbers,the flow is characterized by separation of samples about the central axis plane due to symmetrical flow.

To overcome the drawback of low mixing efficiency of planar type mixers(T-mixer),many researchers have introduced complex channel geometries like three dimensional(3-D)mixers and planar mixers with obstructions.Lin et al.[15]designed a 3-D vortex circular micromixer and studied mixing in the low Reynolds number flows(Re<6).They observed an enhanced mixing above a Reynolds number of 2.32 due to the onset of rotational flow in the circular chamber.Cortes et al.[16]designed a passive 3-D T-Mixer and carried out numerical simulations to study the mixing performance of the device.A good quality of mixing was obtained with 3-D T-Mixer as compared to conventional planar T-mixer due to better formation of vortices.Stroock et al.[17]designed a staggered herringbone mixer and carried out experiments to investigate the mixing phenomenon in the Reynolds number range of 0 to 100.The chaotic motion due to transverse flow in the mixing channel resulted in efficient mixing.Chen et al.[18]experimentally investigated mixing in a high-density pillar obstruction type passive micromixer.They observed very good mixing in the flow rate range of 0 to 5 μl·min-1.Tseng et al.[19]carried out numerical simulations on a Y-channel geometry with diamond-obstacles on the bottom wall and boundary protrusions on side walls.They observed that the length of the boundary protrusion showed a negligible effect on mixing whereas the placement of boundary protrusion showed considerable influence on mixing performance at low Reynolds number flows(Re≤10).Fang et al.[20]designed and carried out numerical simulations on a T-shaped geometry with mixing units of staggered bars in a periodic manner.They observed very good mixing after 28 number of such mixing units at a Reynolds number of 0.29.Afzal and Kim[21]numerically investigated mixing performance of three types of passive micromixer(containing circular cylinders)with convergent-divergent sinusoidal walls in the Reynolds number range of 10 to 70.They analyzed the effect of geometric parameters and observed that the ratio of throat width(W)to circular cylinder diameter(D)strongly influences the mixing performance of the device.They also noticed that as the number of split and recombination units increases,the mixing index,as well as the pressure drop,also increases and therefore a compromise has to be arrived at the design.Alam et al.[22]carried out a numerical study on three different planar mixers with circular obstructions in the Reynolds number range of 0.1 to 60.They observed that the curved micromixer with circular obstructions performed better mixing in the given range than T-micromixer with circular obstructions or the simple curved micromixer.Santana et al.[23]carried out numerical and experimental study on transesterification of sunflower oil in three different mixers(T-mixer,T-mixer with aligned circular obstructions and T-mixer with alternate arrangement of circular obstructions).They observed better performance for T-mixer with alternate arrangement of circular obstructions as compared to other two mixers.There are many promising techniques proposed in different studies[24-30]to accurately track the advancing front of the interphase formed in the mixing of immiscible liquids.The current study deals with the mixing of miscible liquids only.

It is found from the literature that various designs of passive micromixers have been tested experimentally and numerically to enhance the mixing performance of the device.It is observed that the secondary flows and convective effects that appear at high Reynolds number flows can improve mixing significantly in planar type passive T-micromixers[9-12].However,at very high Reynolds numbers,the flow starts to pulsate with weak chaotic nature and mixing deteriorates to a significantly low degree[13,14].Many new designs of passive mixers such as three-dimensional structures of mixer[15,16]or with complex channel structure[17]have been designed and investigated in the past to improve mixing.These types of mixers are sometimes difficult to fabricate or it is complicated to integrate such a device into μTAS or lab-on-chips when compared to planar type mixers.They also incur large pressure drops in high Reynolds number flows.Very few designs of planar mixers exist,which can enhance mixing with a simple modification in geometry[31].Many planar obstruction mixers have been investigated earlier[18-23]which provide an improved mixing quality over planar mixer without obstructions.In all the above studies,T-type or Y-type single contacting mixers were employed.But in the literature,it has been reported that a better mixing quality can be obtained with a double contacting type mixer(double entry of each sample into the mixer)[12].And also the obstruction type mixers[18,19,21-23]have incurred considerably large pressure drops compared to passive mixers without obstructions.

Therefore,the objective of the present work is to enhance the mixing quality of planar mixer significantly with minimum number of obstructions(for low-pressure drop)by combining the advantage of double contacting type mixer that resulted in choosing a T-T mixer with cylindrical elements.The cylindrical elements are considered as obstructions in the mixing channel such that they incur a lower pressure drop.The mixing performance of T-T mixer with cylindrical elements has been evaluated in the Reynolds number range 6<Re<700.The mixing performance of double contacting type planar mixers(T-T mixer)with and without obstructions(cylindrical elements)is also compared with conventional T-mixer with and without cylindrical elements of same mixing channel length.

2.Mathematical Modeling

The governing equations of the incompressible liquid flow in the mixing channel are given by continuity and Navier-Stokes equations as shown in Eqs.(1)and(2)respectively,

where,V,ρ,P,and ν are velocity vector,density,pressure and kinematic viscosity of the fluid respectively.The mass transfer of liquid species in the mixing channel is governed by the diffusion-convection equation(Eq.(3)).

where,c is the concentration and D is the diffusion coefficient of species.

The amount of mixing can be calculated using the relative variance of the concentration of species in a cross-section of the mixing channel.Therefore,the mixing quality‘α’at different cross sections along the length of the mixing channel is evaluated using Eq.(4).

Fig.1.Dimensions of 3-D solid model of T-T mixer with cylindrical elements.

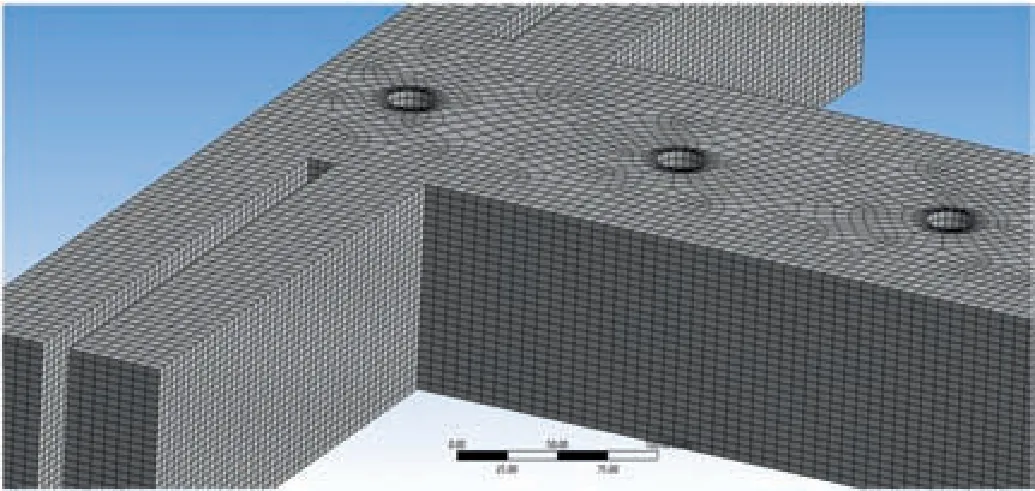

Fig.2.Grid of T-T mixer with cylindrical elements(inflation is provided on the boundary of cylindrical elements).

3.Methodology

The 3-D schematic of T-T-mixer with cylindrical elements considered in the current study is shown in Fig.1.Cylindrical elements are placed in line along the longitudinal mid-plane of the mixing channel up to a distance of less than one third of the mixing channel length.The height of the cylindrical element is equal to the depth of the mixing channel.The geometry is created in ANSYS Design Modeler and ANSYS ICEM CFD meshing module is used to generate a grid in the domain.ANSYS Fluent 15 is used to simulate the mixing phenomenon in the micromixer.The tool adopts a finite volume approach to solve the flow and mass transfer phenomenon in the micromixer.

The grid for the geometry is created using ICEM CFD meshing module,majorly with hexahedral elements and the remaining with prism elements as shown in Fig.2.The inflation is provided on the surface of cylindrical elements for an accurate inclusion of boundary effect on flow and mixing phenomenon of the mixer.

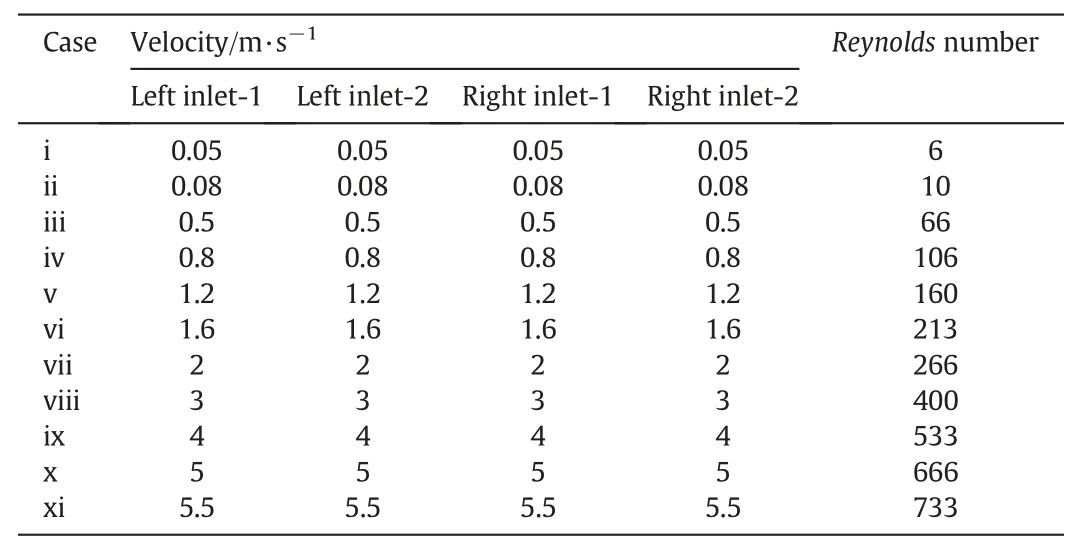

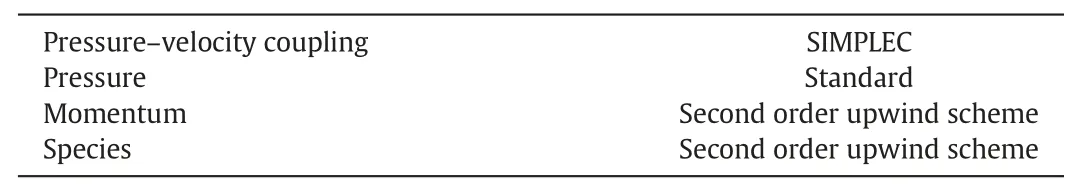

Two liquid samples labeled species‘a’and‘b’with the same properties of liquid water at 20°C(density ρ=998.2 kg·m-3,dynamic viscosity μ=0.001 Pa·s and diffusion coefficient D=2×10-9m2·s-1)were chosen to analyze the mixing phenomenon numerically in the T-T mixer with cylindrical elements.Species‘a’is given as input at left inlet 1 and right inlet 2 whereas species‘b’is given as input at left inlet 2 and right inlet 1 as shown in Fig.3.The liquid samples are assigned to the inlets in the above manner to make sure that both species(‘a’and‘b’)enter from the left as well as right sides of the mixer.The concentration in terms of the mass fraction of species b for the inlet boundary conditions is set to zero at left inlet 1 and right inlet 2 whereas it is set to one at left inlet 2 and right inlet 1.The velocity boundary conditions applied at the inlet of T-T mixer with cylindrical elements for various Reynolds number flows are shown in Table 1.The pressure at the outlet of the mixer is set to atmospheric pressure and the concentration in terms of species b mass fraction is set to 0.5.Laminar flow model along with the species transport model is used in ANSYS Fluent to solve the flow mixing problem.The scheme of pressure-velocity coupling and the spatial discretization methods used for pressure,momentum,and species transport equations are given in Table 2.To minimize the problem of numerical diffusion error in the solution,second order upwind schemes have been used for solving the governing equations.The convergence criterion for the residuals is set to 10-6for continuity and 10-5for momentum and species equations.

Fig.3.Schematic of T-T mixer with cylindrical elements with names of species assigned to each inlet.

Table 1 Boundary conditions for T-T mixer with cylindrical elements

Table 2 The solution methods used in the numerical simulation

4.Results and Discussion

4.1.1.Grid independence test

Grid independence test has been carried out to find the optimum element size for the accurate control volume analysis of flow and diffusion in the T-T mixer with cylindrical elements.Fig.4 shows centerline axial velocity at the outlet of T-T mixer with cylindrical elements(Re=266)with different mesh element sizes(15,10,7 and 5 μm)of the grid.The error in the axial velocity for mesh elements of size 7 and 5 μm is only 0.2%.Therefore,an element size of 7 μm is found to be optimal enough for the analysis and is used for all the simulations in meshing the geometry.

Fig.4.Axial velocity profiles on the outlet centerline of T-T mixer with cylindrical elements.

4.1.2.Validation

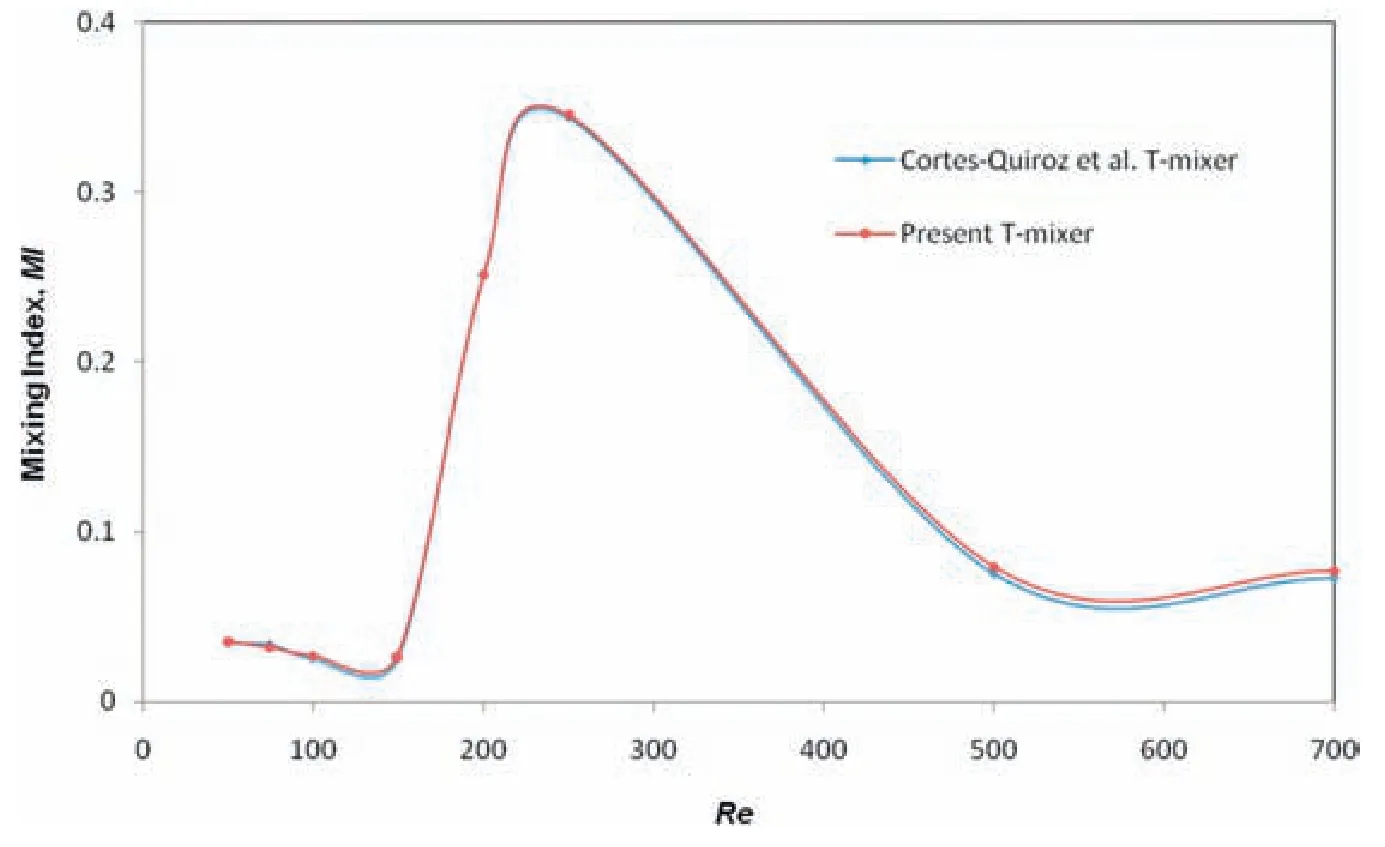

The governing equations of fluid flow and species transport for the T-mixer in the current study have been solved numerically with similar conditions as that of Cortes et al.[16].These results are compared with the results of Cortes-Quiroz et al.[16]to check the accuracy of the current solution.Mixing index has been evaluated at the outlet of T-mixer using Eq.(6)as shown below.Then a quantitative comparison is made between the mixing index values of present T-mixer and Cortes-Quiroz et al.[16]as shown in Fig.5.The plot shows that the results obtained in the current work are in good agreement with data in existing literature[16].

4.2.Basic T-mixer and T-T mixer

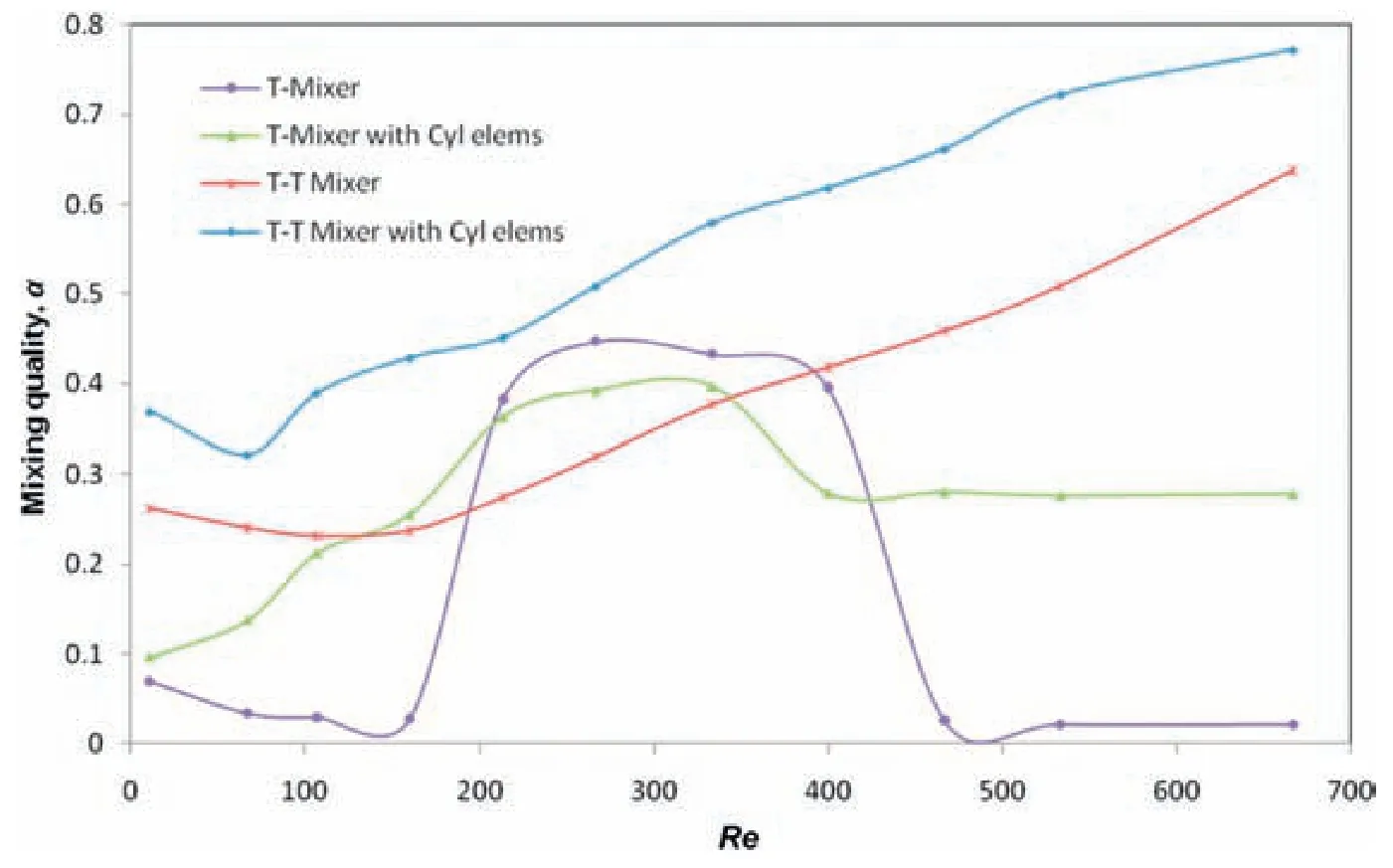

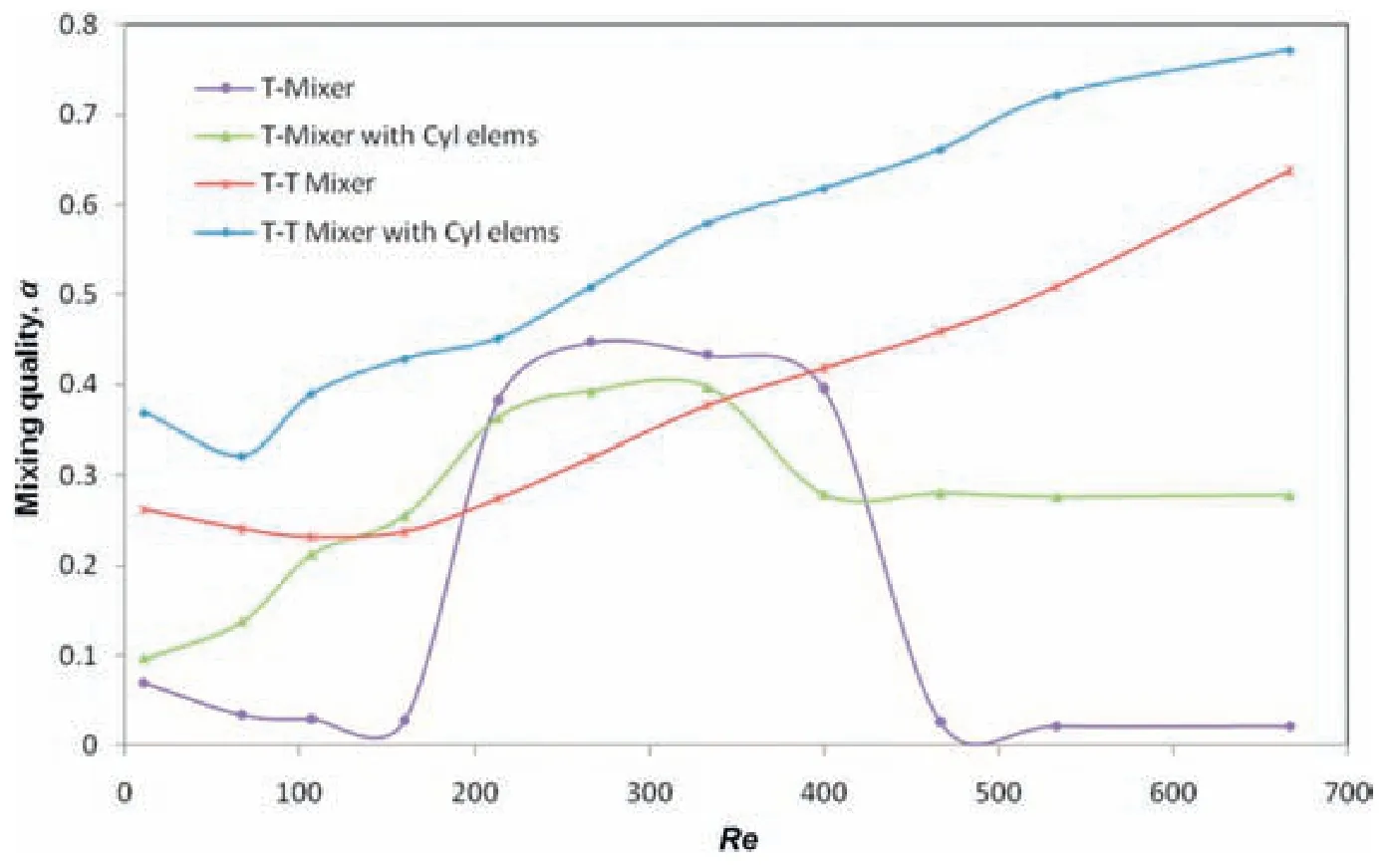

Initially,the mixing performance of basic T-mixer and T-T mixer has been evaluated at various Re number flows(6<Re<700).The numerical results have shown that T-T mixer has performed considerably well compared to T-mixer(Fig.6).For low Reynolds number range(6<Re<160),the laminar(6<Re<50)and vortex(50<Re<160)regimes take place in the T-mixer as shown in Fig.7(a)and(b).Both regimes exhibit poor mixing due to the availability of only a small interfacial area between the liquid samples.However,due to the hydrodynamic focusing effect in the T-T mixer,the interfacial area has considerably increased between the samples and therefore the mixing in T-T mixer(Fig.8(b))is improved as compared to T-mixer(Fig.8(a)).

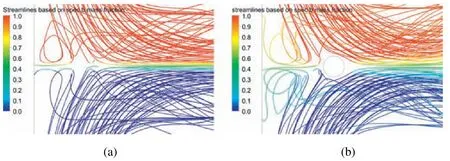

In the high Reynolds number range(400<Re<700),even though strong vortices are created at the junction of T-mixer,the vortices are confined to the same side at which they enter into the mixer as shown in Fig.9(a).Therefore,mixing remains very poor similar to the vortex regime.However,in T-T mixer,since the two samples enter from both sides(left and right)of the mixer,the strong vortices created at junction continue to overlap throughout the length of the mixing channel as shown in Fig.9(b).Therefore,the mixing quality of T-T mixer is significantly high(Fig.10(b))compared to T-mixer(Fig.10(a))in the Reynolds number range as shown in comparison with outlet mass fraction contours at a Reynolds number of 666.

However,in the Reynolds number range of 200 to 400,the mixing quality of T-T mixer is considerably low compared to T-mixer(Fig.6).The engulfment flow regime has been observed in this range of Reynolds number in T-mixer(Fig.11(a)),which significantly improves its mixing performance.On the other hand,such an effect is absent in T-T mixer as shown in Fig.11(b),due to varied geometrical conditions of the inlet in T-T mixer.

4.3.Mixing performance of T-mixer with cylindrical elements

Fig.5.Comparison of mixing index between T-mixer of present study and T-mixer of Cortes-Quiroz et al.[16]at different Reynolds numbers.

Fig.6.Comparison of mixing quality at various Reynolds numbers between T-mixer and T-T mixer.

Fig.7.Streamlines based on species b mass fraction of T-mixer at(a)Re=10 and(b)Re=106.

Now,the mixing performance of a single contacting type mixer(T-mixer)with the obstructions(cylindrical elements)placed in the mixing channel has been evaluated for different Reynolds number flows(6<Re<700).In the low Reynolds number range(Re<200),there is an improvement in the mixing quality for T-mixer with cylindrical elements(Fig.12).The splitting and recombining action due to the presence of cylindrical elements has enhanced the interfacial area in the mid-plane as well as in the top and bottom surfaces(Fig.13(b))which did not take place in the basic T-mixer,shown in Fig.13(a).However,the mixing performance of T-mixer with cylindrical elements is reduced in the Reynolds number range of 200 to 400 as compared to basic T-mixer(Fig.12).Due to the presence of the cylindrical element,the engulfment of samples did not take place well(Fig.14(b))as compared to that of basic T-mixer shown in Fig.14(a).Therefore,there is a reduction in the mixing quality of T-mixer with cylindrical elements in this Reynolds number range(200 to 400).

Fig.8.Outlet mass fraction contours at Re=66:(a)T-mixer and(b)T-T mixer.

Fig.9.Comparison of streamlines at the junction at Re=666:(a)T-mixer and(b)T-T mixer.

Fig.11.Streamlines at the junction at Re=266:(a)T-mixer and(b)T-T mixer.

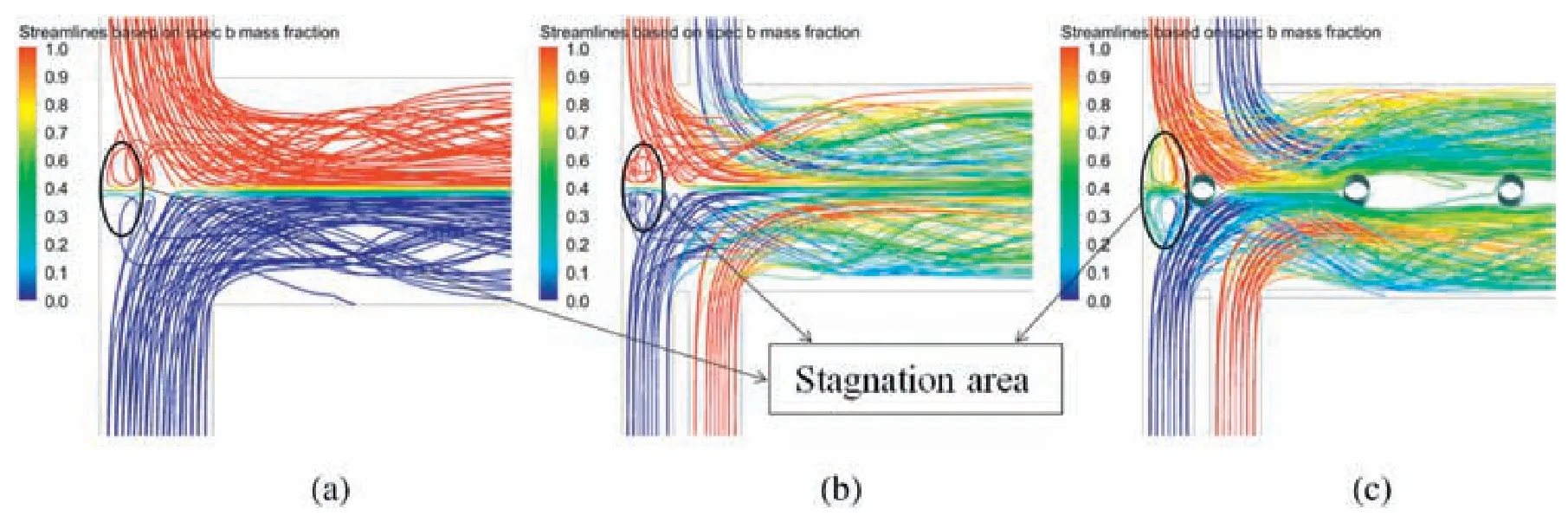

For higher Reynolds number flows(Re>400),a good improvement in mixing has been obtained with the placement of cylindrical elements in the T-mixer(Fig.12).The effective mixing zone in T-type mixers corresponds to the area near the junction.For sufficiently higher Reynolds number flows(Re>400),a pair of vortices are typically generated in the stagnation area of T-type mixers(Fig.15).The stagnation area is the upstream mid-portion of the junction(Fig.15).It can be observed that a better pair of vortex is formed in the stagnation area of T-mixer due to the presence of the cylindrical element as shown in Fig.16(b)as compared to that of basic T-mixer(Fig.16(a)).These vortices allow a better swirling of samples in the T-mixer with cylindrical elements.However,this was unable to improve the mixing quality of the device significantly since the single contacting type mixer(T-mixer)allows only a single sample from each side(left and right)of the mixer.The enhanced swirling due to large vortices has only generated more self-rotation of the sample on each side of the mixer.It did not contribute to significant enhancement in mixing since the samples still stay on the same side of the mixer(left or right)with an increased self-rotation.A moderate improvement in mixing quality has been achieved for T-mixer with cylindrical elements as shown in Fig.17(b)as compared to that of basic T-mixer as shown in Fig.17(a)in Reynolds number range(400<Re<700).This improvement is due to the splitting and recombining action of cylindrical elements.Therefore,it is concluded that the mixing performance of single contacting type T-mixer improved marginally in the Reynolds number range of 6 to 700 with the placement of cylindrical elements in the mixing channel.

Fig.12.Variation of mixing quality with Reynolds number for T-mixer and T-mixer with cylindrical elements.

Fig.13.Outlet mass fraction contours at Re=160:(a)T-mixer and(b)T-mixer with cylindrical elements.

Fig.14.Streamlines based on mass fraction of species b at Re=266:(a)T-mixer and(b)T-mixer with cylindrical elements.

Fig.15.Streamlines in top view highlighting the stagnation area at Re=466:(a)T-mixer and(b)T-mixer with cylindrical elements.

Fig.16.Streamlines pointing pair of vortices in the stagnation area at Re=466:(a)T-mixer and(b)T-mixer with cylindrical elements.

Fig.17.Outlet mass fraction contours at Re=466:(a)T-mixer and(b)T-mixer with cylindrical elements.

4.4.Mixing performance of T-T mixer with cylindrical elements

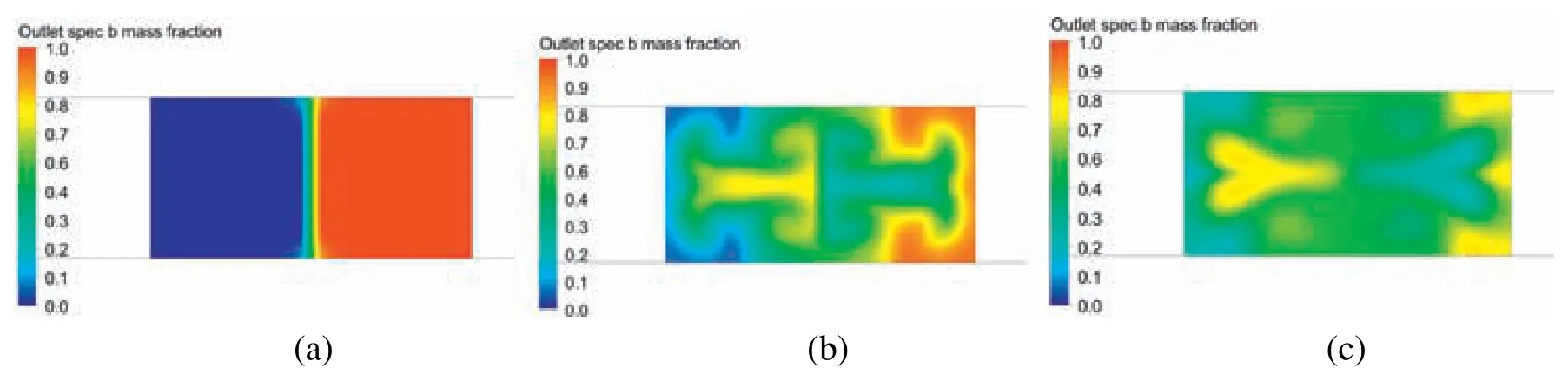

Later,the mixing performance of a double contacting type mixer(T-T mixer)with the obstructions(cylindrical elements)placed in the mixing channel has been evaluated for different Reynolds number flows(6 to 700).In the low Reynolds number range(Re<200),a significant improvement in the mixing quality has been obtained by T-T mixer with cylindrical elements(Fig.18(c))as compared to basic Tmixer(Fig.18(a))and T-T mixer(Fig.18(b)).The cylindrical elements cause some obstruction to flow.This increases the residence time for samples as well as induce transverse flow in the mixing channel,which enhances mixing.

In the moderate Reynolds number range of 200 to 400,the low mixing efficiency of basic T-T mixer has been overcome by placing cylindrical elements in the mixing channel(Fig.19).This is due to the splitting and recombining of samples in the mixing channel owing to the presence of cylindrical elements.Therefore,there is good increment in the mixing quality with the device(Fig.20(c))as compared to basic T-T mixer as shown in Fig.20(b).However,the percentage of increase in the mixing quality obtained by the device in this Reynolds number range is considerably low as compared to basic T-mixer(Fig.19).The engulfment flow regime that takes place in the basic T-mixer in this Reynolds number range suddenly increases its mixing quality(Fig.20(a)).

Fig.18.Outlet mass fraction contours of different mixers at Re=160:(a)T-mixer,(b)T-T mixer and(c)T-T mixer with cylindrical elements.

Fig.19.Variation of mixing quality with Reynolds number for T-mixer,T-T mixer and T-T mixer with cylindrical elements.

Fig.20.Outlet mass fraction contours of different mixers at Re=333:(a)T-mixer,(b)T-T mixer and(c)T-T mixer with cylindrical elements.

Fig.21.Streamlines in different T-type mixers highlighting stagnation area at Re=533:(a)basic T-mixer,(b)basic T-T mixer and(c)T-T mixer with cylindrical elements.

Fig.22.Pair of vortices formed in the stagnation area at Re=533:(a)basic T-mixer,(b)basic T-T mixer and(c)T-T mixer with cylindrical elements.

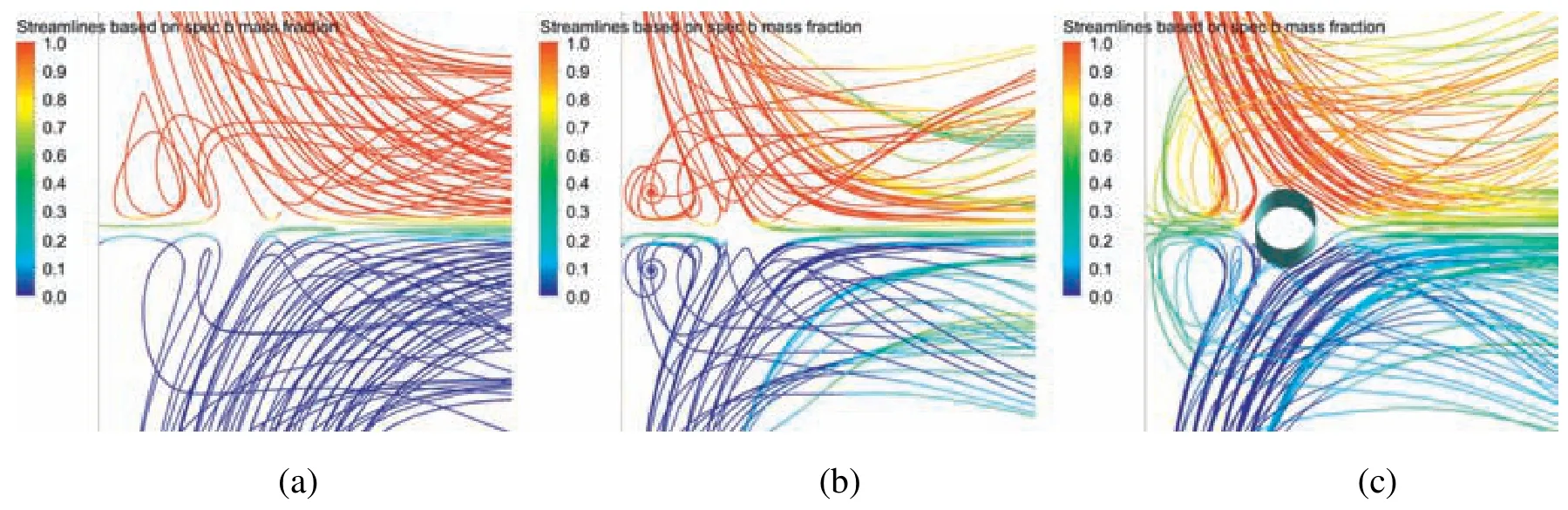

In the high Reynolds number range(400<Re<700),the mixing performance of T-T mixer with cylindrical elements is significantly high compared to that of basic T-mixer,T mixer with cylindrical elements and T-T mixer(Fig.19).The comparison of mixing phenomenon in the stagnation area of T-mixer,T-T mixer and T-T mixer with cylindrical elements(at Re=533)has been shown in Fig.21(a),(b)and(c)respectively.It can be observed that the pair of vortices formed in the stagnation area of T-T mixer with cylindrical elements is larger in diameter and well-defined as shown in Fig.22(c)as compared to the smaller and indistinct formation of the pair of vortices in case of basic T-mixer and T-T mixer as shown in Fig.22(a)and(b)respectively.The presence of a cylinder just upstream of the stagnation area has increased the suction head greatly in the stagnation area which helped in the formation of larger and distinct pair of vortices.The better vortex formation in the stagnation area implies an enhanced swirling of samples.Moreover,the double contacting type mixer(T-T mixer)has the advantage of utilizing the enhanced swirl very well as it overlaps the strong vortices generated in both the samples.This creates an intense entanglement of samples in T-T mixer with cylindrical elements.Therefore,a striking improvement in mixing quality is obtained in the high Reynolds number flows with the device as observed in a qualitative comparison of mass fraction contours,of basic T mixer,T-T mixer and T-T mixer with cylindrical elements shown in Fig.23(a),(b)and(c)respectively.

One of the disadvantages of basic T-T mixer is the lower amount of swirling in the samples at the junction due to smaller pair of vortices.This results in a considerable amount of sample being separated towards the wall and remaining unmixed in the mixing channel as shown in Fig.24(a)even at high Reynolds number flows(Re>400).The presence of cylindrical elements in the downstream of the junction increases the uniformity of the mixing of samples in the mixing channel.This is due to the splitting action of the fluid flow in the presence of cylindrical obstruction and the recombination due to the suction head created on the downstream semi-circular face of cylindrical elements that pull the samples into the mixing channel as shown in Fig.24(b).Therefore,the non-homogeneous and lower mixing observed near the walls of basic T-T mixer(Fig.25(a))become uniform and enhanced in the case of T-T mixer with cylindrical elements as shown in Fig.25(b).Therefore,it is concluded that placing obstructions(cylindrical elements)in a double contacting type mixer(T-T mixer)has greater impact in improving the mixing performance of the passive device over a wide range of Reynolds number flows(6 to 700)as compared to that of basic T-mixer and T-T mixer(Fig.19).

4.4.1.Effect of gap between cylindrical elements on mixing performance

Fig.23.Outlet mass fraction contours at Re=533:(a)basic T-mixer,(b)basic T-T mixer and(c)T-T mixer with cylindrical elements.

Fig.24.Streamlines based on species b mass fraction from left inlet 1 at Re=466:(a)basic T-T mixer and(b)T-T mixer with cylindrical elements.

Fig.25.Outlet mass fraction contours at Re=466:(a)T-T mixer with cylindrical elements and(b)basic T-T mixer.

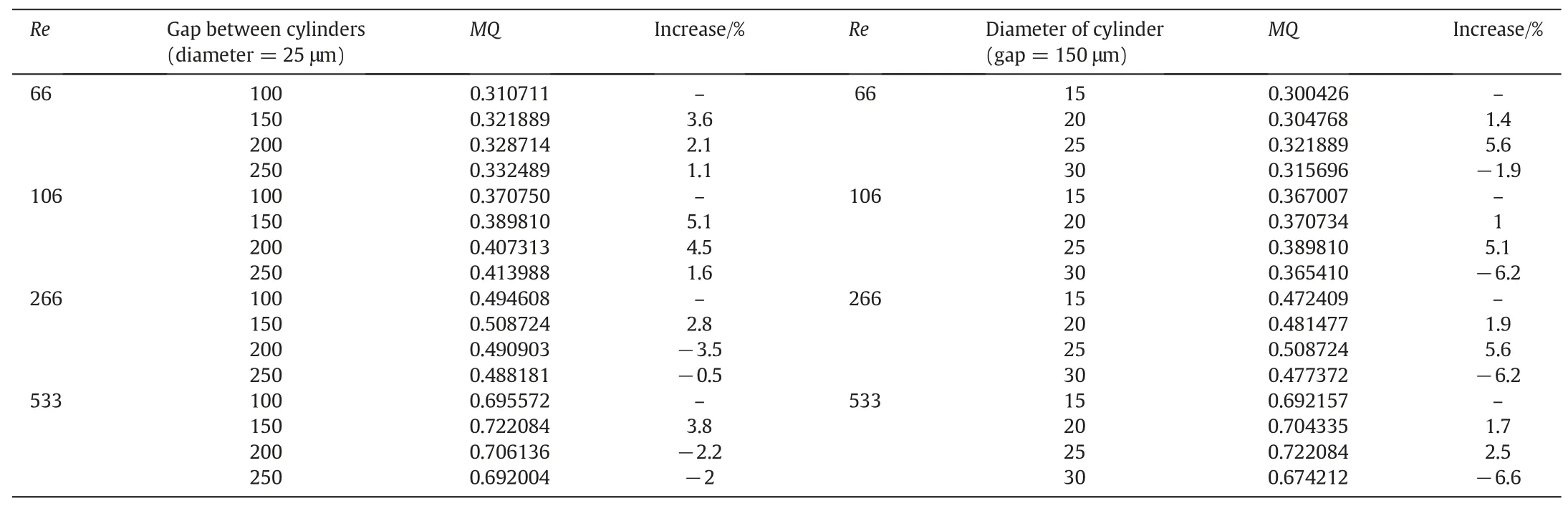

The gap between cylindrical elements in the mixing channel has been varied,keeping constant diameter of the cylindrical element(15 μm)when evaluating the mixing performance.It is observed that the effect of the gap on mixing performance has been varying for different Reynolds number flows.For low Reynolds number flows(Re<250),the mixing quality has continuously increased when the gap between cylindrical elements is increased from 100 to 200 μm and remains constant with further increase in the gap(Fig.26).Since the inertial effects are absent at lower Reynolds number flows,interfacial area between samples plays a major role in the mixing process.Therefore,the additional interfacial area available between samples in the case of a larger gap between obstructions(200 μm)(Fig.27(a))showcases better mixing as compared to smaller gap between obstructions(100 μm)where a separation of flow has been witnessed behind the downstream faces of cylindrical elements as shown in Fig.27(b).However,increasing the gap further(250 μm)has not shown any further improvement in mixing(Fig.26),as the interfacial area is not affected and remains the same.For higher Reynolds number flows(Re>250),the mixing quality increases with an increase in the gap from 100 to 150 μm and then continuously decreases with further increase of the gap(Fig.26).It implies that at higher Reynolds numbers,an optimum gap(150 μm)can produce better secondary flow effects that can enhance the mixing performance of the device as compared to other gaps maintained between the obstructions.The improvement in mixing quality can be observed when the gap is increased from 100 μm(Fig.28(a))to 150 μm(Fig.28(b)).The optimum gap obtained in the high Reynolds number range(150 μm)has been considered the best and used for all other simulations.

Fig.26.Variation of mixing quality with Reynolds number for different gaps between cylindrical elements.

Fig.27.Streamlines based on species b mass fraction of T-T mixer with cylindrical elements at Re=160(a)gap between elements=200 μm(b)gap between elements=100 μm.

Fig.28.Outlet mass fraction contours T-T mixer with cylindrical elements at Re=400:(a)gap between elements=100 μm and(b)gap between elements=150 μm.

4.4.2.Effect of diameter of cylindrical elements on mixing performance

The diameter of the cylindrical elements in the mixing channel has been varied,keeping the gap between cylinders constant(150 μm),to find its effect on mixing performance.The change in the diameter of the cylindrical element has shown considerable variation on the mixing quality of the device,particularly at higher Reynolds number flows(Re>300)as shown in Fig.29.The mixing quality of the device gradually increased as the diameter of the cylindrical element is increased from 15 μm to 25 μm.A larger size of cylindrical element can cause better suction head in the stagnation area and in turn generate a better vortex formation.However,the mixing quality suddenly decreases as the diameter is further increased to 30 μm.It is observed that a further increase in the size of the cylindrical element(30 μm)has negatively affected the mixing due to reduction in the availability of stagnation area(Fig.30(a))as compared to more available stagnation area(25 μm)for vortex formation(Fig.30(b)).Therefore,an optimum size of the cylindrical element is required(25 μm)which can favor better vortex formation in the stagnation area and thus obtain better quality of mixing.The optimum gap of 150 μm has been obtained for a cylindrical element of size 15 μm.However,the same gap of 150 μm was also found to be optimum for the cylindrical element of size 25 μm also.

4.5.Comparison of mixing performances of different mixers

The numerical analysis of mixing phenomenon in the four different mixers considered viz.,basic T-mixer,T-mixer with cylindrical elements,basic T-T mixer and T-T mixer with cylindrical elements has been carried out here.It is observed that better formation of vortices in the stagnation area and the splitting and recombining action in the mixing channel exercise a major influence to greatly improve the mixing performance of any T-type mixer.Moreover,the double contacting of samples in T-type mixers(T-T mixer)has the positive effect of better utilizing the vortices generated at the junction and thus enhances the mixing quality of the device.Therefore,T-T mixer with cylindrical elements has performed significantly well over a wide range of Reynolds number flows(6<Re<700)compared to basic T-T mixer,basic T-mixer and T-mixer with cylindrical elements as shown in Fig.31.

Fig.29.Variation of mixing quality with different Reynolds numbers for T-T mixer with different gaps between cylindrical elements.

Fig.30.Streamlines based on species b mass fraction from left inlet 1 of T-T mixer with cylindrical elements at Re=466:(a)cylinder diameter=30 μm and(b)cylinder diameter=25 μm.

Fig.31.Variation of mixing quality at various Reynolds numbers for different T-type mixers.

Fig.32.Outlet mass fraction contours of different mixers at Re=666:(a)T-mixer,(b)T-mixer with cylindrical elements,(c)T-T mixer,and(d)T-T mixer with cylindrical elements.

The mass fraction contours are shown for a qualitative comparison of mixing quality at the outlet of different mixers at a Reynolds number of 666 in Fig.32.The limitation of poor mixing in the basic T-mixer,particularly at high Reynolds number flows is shown to have been successfully overcome by employing a simple passive design of T-T mixer with cylindrical elements.The remarkable improvement in the mixing quality of T-T mixer with cylindrical elements has also been obtained at the expense of only a small rise in pressure drop compared to other T-type mixers as shown in Fig.33.The quantitative values of mixing quality and pressure drop,and the percentage increase of these quantities for different mixers as compared to basic T-mixer at three different Reynolds number flows(low,moderate and high)are presented in Table 3.It has been observed that for T-T mixer with cylindrical elements,there is a marginal rise in pressure drop as compared to T-mixer.However,the mixing quality for T-T mixer with cylindrical elements has increased manyfold(35 times)as compared to T-mixer.Therefore,use of T-T mixer with cylindrical elements is a better option over T-type mixers.

Fig.33.Variation of pressure drop with Reynolds number for different mixers.

Table 3 Quantitative comparison of mixing quality and pressure drop of different T-type mixers with and without cylindrical elements at three different Reynolds numbers

4.6.The effect of control parameters on mixing performance of T-T mixer with cylindrical elements

There is a considerable effect of two control parameters viz.,gap between cylindrical elements and diameter of cylindrical elements on the mixing performance of T-T mixer with cylindrical elements.To find the influence of these factors,the mixing quality of the device obtained at different ranges of Reynolds numbers viz.,66,106,266 and 533 for different gaps between cylindrical elements(with constant diameter of 25 μm)and different diameters of cylindrical element(with constant gap of 150 μm between cylindrical elements)has been summarized in Table 4.At each Reynolds number(66,106,266 and 533),the absolute values of mixing quality are presented for different gaps and diameters of cylindrical elements.The percentage increase in the mixing quality between successive gaps and diameters of cylindrical elements is also shown.A maximum percentage increase in mixing quality is found for a gap of 150 μm and diameter of 25 μm of cylindrical elements for all Reynolds numbers.However,the percentage change is high in the case of variation of diameter of cylindrical elements as compared to variation in the gap between cylindrical elements.Therefore,the diameter of cylindrical elements is considered to be most contributing factor for enhancement in the mixing performance of the current device.

5.Summary and Conclusions

The T-mixer has been considered as a simple passive design and a low-cost mixing device for many micromixing applications.However,T-mixer has the limitation of very poor mixing over a wide range of Reynolds number flows except in the short engulfment flow regime.Many passive designs with complex channel structures or threedimensional geometries of mixers have been introduced in the past to overcome the limitation of T-mixer.However,the executions of such designs either involve challenges in fabrication or integration difficulties.Majority of these devices also incur large pressure drops during operation.In the present study,a significant improvement in mixing performance over a wide range of Reynolds number flows(6<Re<700)is obtained by a simple passive design of T-T mixer with cylindrical elements at the expense of a very low rise in pressure drop as compared to basic T-mixer.The designs of T-T mixer and T-mixer with cylindrical elements have shown considerable improvement in mixing over conventional T-mixer design,but both designs failed to show any improvement in the engulfment regime of T-mixer(160<Re<300).However,the combination of both designs known as T-T mixer with cylindrical elements has shown a significant improvement in mixing over conventional T-mixer in the complete range of Reynolds numbers(6<Re<700)studied here.Due to the presence of a cylindrical element just upstream of the stagnation area,a better vortex formation took place that resulted in more swirling of samples.The cylinders placed in the downstream of mixing channel carry out the function of splitting and recombining of samples.The double contacting for the entry of samples into mixer helped in better utilization of vortices formed in the stagnation area of the mixer.The above three factors created very favorable conditions for an efficient mixing in the passive mixer(T-T mixer with cylindrical elements)without the need of a complex design.In the present study,optimization of the gap between cylindrical elements and the diameter of the cylindrical elements has also been carried out.The gap between cylindrical elements has shown considerably small effect whereas the size of cylindrical elements has shown considerable effect on the mixing performance of the device.Therefore,this mixer design can be utilized as a very effective passive device and has the potential to replace complex designs of passive mixers and high-cost active mixers that are currently being utilized in many micromixing applications.Particularly,the present device would be a very suitable choice for chemical processing applications,which require a low cost and efficient mixer allowing higher throughputs at the expense of lower pressure drops.

Table 4 Quantitative comparison of mixing quality with the variation of gap between cylindrical elements and diameter of cylindrical elements at different Reynolds numbers

Chinese Journal of Chemical Engineering2019年10期

Chinese Journal of Chemical Engineering2019年10期

- Chinese Journal of Chemical Engineering的其它文章

- A review of low-temperature heat recovery technologies for industry processes☆

- Current scenario and potential of biodiesel production from waste cooking oil in Pakistan:An overview☆

- Structure and synthesis of graphene oxide☆

- Co-firing of coal and biomass in oxy-fuel fluidized bed for CO2capture:A review of recent advances

- Effects of internals on phase holdup and backmixing in a slightlyexpanded-bed reactor with gas-liquid concurrent upflow☆

- Distribution performance of gas-liquid mixture in the shell side of spiral-wound heat exchangers☆