不同类型油田采出水对阳极电压的影响

胡静怡,骆雪晴,李永峰,程国玲

(东北林业大学,哈尔滨 150040)

Introduction

Microbial fuel cell is a technology which use microbial degradation or oxidation of organic matter to produce the biological energy. With the growing need for oil resources and supply shortages, the eastern part of oil field in our country has entered the stage of tertiary oil recovery. Oil producted sewage contains a large amount of surfactant, increasing oil content, polymer concentration and oil emulsification degree aggravate. It increases much difficulty for treating sewage. For the increasingly complexly oilfield wastewater composition, it’s difficult to degrade higher content organic matter and to removal pure biological etc. The main processing technology we use are such as physical method, chemical method physical and chemical methods. The traditional method is not only unable to use energy but also large energy consumption of oil field waste water in processing waste water. Faced with more complex produced water of polymer flooding and ASP flooding produced water , the treatment efficiency is low. MFC gets use of energy in the waste water in the process of microorganism electrogenesis, at the same time the potential can accelerate the degradation of refractory organic matter or oxidation,to reduce the difficulty of the subsequent processing and provide new possibilities to oilfield produced water treatment technology.[1]This passage mainly talks about the oil produced water, produced water of polymer flooding and asp flooding produced water, checking the influence and influencial factors to MFC output voltage with the anode substrate respectively and the effect of treating different mainly refractory organic compounds produced water.

Test apparatus and methods

The test apparatus and materials

Running three sets of experiment device at the same time, the conditions are the same besides the different anode substrate. The traditional two rooms type MFC, composed of the cathode chamber and the anode chamber,the size is 9.7 cm*9.7 cm*7 cm, 658.63 mL3 volume, remove the electrode volume, effective volume is 620ml;Two rooms are divided into two parts, a proton exchange membrane in the middle. Effective area is 9.7 cm*9.7 cm, 94.09 cm2. proton membrane with rubber ring on both sides to prevent leakage and to ensure that the anode anaerobic environment.[2]Cathode and anode materials are made of conductive carbon fiber carbon brush carbon fiber average diameter 6 m, length 10 cm), using the titanium wire connected to the external circuit, an external fixed value is 100 Ω resistance. inserted into the Ag/AgCl reference electrode as the reference electrode In the anode . The output voltage and anode potential record and store. by signal acquisition system automatically .Reactor by organic glass, and its structure shows in Fig.1.

Fig.1 Microbial Fuel Cell Structure

Test process

Add the glucose and PBS buffer solvent (K2HPO4·3H2O,4.56 g/L;KH2PO4,4.35 g/L) to the mixture nutrient solution, three kinds of produced water. Domesticate living sewage treatment plant of anaerobic sludge anaerobicly for two months.Add domesticated good sludge respectively to three reactor anodes , three reactor anode substrate respectively corresponding to start-up: Add 0.3 g/L glucose and PBS (K2HPO4·3H2O,4.56 g/L;KH2PO4,4.35 g/L) allocation buffer solvent of water flooding produced water; add 0.3 g/L glucose and PBS buffer solvent configuration of polymer flooding produced water. Add 0.3 g/L glucose and PBS buffer solvent configuration of asp flooding produced water.[3,4]Cathode chamber using potassium ferricyanide (0.05 mol/L) is the same as the PBS buffer solution of solvent mixture in anode as a metal cathode electrolyte. MFC output voltage, anode voltage and cathode using data acquisition system sample per minute, average every 1 hours. We monitor three reactors respectively in the running time ,including produced water, flooding water and produced water’s COD, oil content, polymer concentration,table mixture concentration, experiment with the method of intermittent operation, operating temperature at about 25℃.

Analysis method

Results and Discussion.

Three kinds of oilfield produced water as anode substrate on the MFC: voltage, anode voltage and the influence of the cathode

Three groups of different extraction fluid add glucose and PBS buffer was added solven(K2HPO4·3H2O,4.56 g/L;KH2PO4,4.35 g/L.Domesticate the anodic microorganism in anaerobic situation; reduce the amount of glucose in every replacement time, until the concentration of glucose reduced to 0.3 mg/L; PBS buffer system always maintains concentration in the process of the experiment. As shown in table1, the oilfield produced water containing hard biodegradable material, adding glucose after this kind of small molecule organics, can make the don′t need refractory organics removal rate and the producing increased[5].

Table 1 The mainly of three oilfield produced water characteristics

Table 1 can show the ASP flooding produced water is the most complex and refractory organic content is the highest.

The oilfield produced water’s influencing factors

In the study we researched the influence factors on MFC electricity production of three kinds of produced water as anode substrate, at the same time, investigates the three kinds of produced water COD removal. The result showed that the output voltage of three groups changing trend is consistent with COD change.COD removal efficiency.[6]

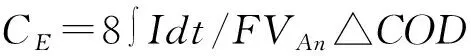

Characterize microorganism’s influence on the energy consumption and anode substrate consumption rate, coulomb efficiency can effectively reflect the microbial biomass electrical energy conversion rate in anode chamber, therefore, both affect the MFC anode potential. Water flooding produced water and the ASP flooding produced water coulomb efficiency were similar, then both the anode voltage and output voltage in accordance with the different COD value. It can summarize that three groups anode substrate COD removal efficiency and coulomb efficiency are the influencial factors for the anode potential. Different COD composition will affect the anode potential, and the research needs to be continue.

The effect of MFC for oilfield produced water treatment

The major organic removal efficiency of three refractory pro duced water in former 86h during the operation cycle is that the removal rate of polymer in polymer flooding produced water and oil content were 35.04%, 29.07%, that in ASP flooding produced water were 30.94%, 28.06%, of which only surfactants existing in ASP flooding produced water the best,up to 96.90%.Different extraction liquid of Polymer flooding produced water contains oil and the polymer removal rate is proportional to three groups of reactor’s corresponding output voltage, also in accordance with the changing rule of COD.Don’t replacing the anode, cathode solution after running 86 h and make the reactor continues to run,to 156 h, the water flooding produced water output voltage relatively stable at around 95 mv; Polymer flooding produced water and ASP flooding produced water, two groups reactor, in 86 h to 150 h ,COD and polymer removal is significantly lower. It can be concluded from this: polymer flooding produced water and ASP flooding produced water should replace the substrate at the point of 86 h in order to maintain a high output voltage and the removal rate of pollutants in next operating period.[7]And the operation cycle of flooding produced water is relatively too long, the output voltage and the pollutant removal efficiency too low. Compared with flooding produced water, the use of polymer flooding produced water and ASP flooding produced water as MFC anode substrate is better.

Conclusion

(1) polymer flooding produced water has minimum anode potential, maximum output voltage, maximum output voltage. Cathode potential differences is smaller than the anode potential’s in one operation cycle and the anode potential changing tendency is greater than that of cathode, total voltage opposite to anode potential changing, anode changing mainly affects battery voltage changing.The influence of different anode substrate to MFC mainly comes from its influence on the anode potential.

(2)Under the similar condition of coulomb efficiency level, flooding produced water and polymer flooding produced water anode potential difference is in line with the coulomb efficiency differences. In the case of quite COD removal efficiency, high coulomb efficiency polymer flooding produced water:anodic potential is the lowest, output voltage is the largest. Thus we can learn anode substrate COD removal efficiency and coulomb efficiency have an effect on the anodic potential.

(3)Surfactant has a better removal effect than polymer and oil composition in the MFC,removal rate as high as 96.90%.Different components and polymer oil produced water removal efficiency comply with the MFC anode voltage and output voltage difference. Compared with water flooding produced water, the use of polymer flooding produced water and ASP flooding produced water as anode substrate can obtain higher COD removal rate.

Acknowledgements

This work was financially supported by the Natural Science Foundation of Heilongjiang Province(E201354), the Fundamental Research Funda for the Central Universities(2572014AB09)and the Projects in the National “Twelfth Five-Year” Plan for Science & Technology Support (2011BAD08B01-03).