China’s Process and Action Framework for Transforming to a Manufacturer of Quality

Li Jinhua

Abstract: China’s construction of a manufacturer of quality mainly relies on infrastructure improvement, cutting-edge technological breakthroughs,manufacturing development at the enterprise, sector and region levels, and the enactment and implementation of supporting policies, which can be combined to form an action framework for the construction of building China into a manufacturer of quality. At present, there are still some weak areas in China’s construction of a manufacturer of quality, such as backward technologies comparing with world’s leading players in some areas, limited contributes to the formulation of international standards, insufficient invests in building a system of supporting policies concerning finance, banking and taxation, and scant attention to cultural development as a manufacturer of quality. China should attach more importance to the technological research and development in these weak areas, align its manufacturing standards system with international standards, improve its system of supporting policies concerning finance, banking and taxation, and make more efforts in the development of advanced manufacturing system.

Keywords: manufacturer of quality; process of construction; action framework

1. Introduction

The Chinese government officially launched “Made in China 2025”strategy in May 2015, vowing to seize the historical opportunity of the redivision of international industries to develop an advanced manufacturing sector,optimize its manufacturing structure, and transform China into a world-class manufacturer of quality. “Made in China 2025” is the Chinese government’s 10-year strategic plan designed to comply with industrial development trends in today’s world, sharpen China’s manufacturing edge on the global stage, and eventually grow into a top player in the international manufacturing industry. According to this plan,China would first spend 10 years transforming into a manufacturer of quality, and then spend 10 more years emerging among the moderate group of manufacturers of quality. By 2050 China’s comprehensive manufacturing strength is expected to reach the top level worldwide.

The introduction of “Made in China 2025”marked the beginning of China’s journey towards a manufacturer of quality, enabling the transformation of its manufacturing sector. In 2016, the Chinese manufacturing industry saw a rise①2015 statistics bulletin of the national economic and social development. Retrieved from http://www.stats.gov.cn/tjsj/zxfb/201702/t20170228_1467424.html.2017-02-28.in its PMI,②Purchasing Managers’ Index (PMI) is calculated based on the weighted average of five indexes respectively concerning new orders, production, supplier delivery, inventory and employment. It is therefore a comprehensive index that reflects the overall situation in the manufacturing industry, employment performance and commodity price, usually with 50% being the cut-off point between strong and weak economic performance. An index higher than 50% is usually deemed a sign of economic expansion, while an index lower than 50% is usually deemed a sign of economic depression. An index between 40% and 50% indicates that manufacturing sector is declining against the backdrop of overall economic expansion.which reached the highest in November during these two years. That indicated the overall recovery of the Chinese manufacturing industry. The sub-PMI indicated that large manufacturing enterprises obviously outperformed small and medium-sized enterprises in operation. In 2016, China’s industrial added value saw a year-on-year increase of 6.0%to RMB 24.79 trillion; its manufacturing industry saw a year-on-year increase of 6.8%. All major industries, except ferrous metal smelting and rolling processing which suffered negative increase, saw a positive increase in their added value. In particular,the following industries saw more substantial year-on-year increases: automobiles(15.5%),computer-mediated communications and other electronic device manufacturing (10%),equipment manufacturing (9.5%), followed by electrical machinery and equipment manufacturing (8.5%),chemical materials and chemicals manufacturing(7.7%), special equipment manufacturing (6.7%)and non-metallic mineral products manufacturing(6.5%);traditional agro-food processing (6.5%),general equipment manufacturing (6.1%), textiles(5.5%),along with electric and thermal power generation and supply (4.8%). In 2016 China’s emerging industries of strategic significance saw a year-on-year increase of 10.5% in added value; and the figure for its high-tech manufacturing industry was 10.8%.

Likewise, in 2017 the total profit of Chinese industrial enterprises over a designated size was RMB 7, 518.71 billion, achieving a year-on-year increase of 21%, which was 12.5 percentage points higher than that of 2016. In 2017, 37 industries out of 41 major categories saw a profit increase year on year; the profit of the manufacturing industry increased by 18.2%, which was 5.9 percentage points higher than that of 2016; the profit of the high-tech manufacturing segment increased by 20.3%, which was higher than any other manufacturing segment.In 2017 China Technology Center made a total investment of RMB 509.68 billion in technology research and development, a year-on-year increase of 9% and the Technology Center in the manufacturing industry invested a total investment of RMB 397.88 billion, accounting for 78.1% of its total technology R&D expenditure and contributing 71% to the increase in that R&D expenditure (10 percentage points higher than that of 2016). In 2017, enterprises under China Technology Center had RMB 431.69 billion expenditure in new product development (a year-on-year increase of 9.6%)and their annual sales of new products reached RMB 7.904.2 billion (a year-on-year increase of 11%) accounting for 34% of their main business income. Also in the same year,the number of Chinese enterprises with over RMB 10 billion new product sales reached 156 (increased by 16) and for nearly half of these enterprises their new product sales accounted for over 60% of their main business revenue. Enterprises under China Technology Center submitted 214,000 patent applications, achieving a year-on-year increase of 7.5%. 118.000 applications were in the patent-forinvention category, which achieved a year-on-year increase of 8% and accounted for 55.1% of all patent applications. On average, every RMB 100 million R&D expenditure facilitated 35.8 patent applications,including 19.5 patent-for-invention applications. Both application figures saw a year-on-year increase.

According to the 2016 Global Manufacturing Competitiveness Index①Retrieved from https://www2.deloitte.com/cn/zh/pages/manufac-turing/articles/2016-global-manufacturing-competitiveness-index.html.(GMCI) jointly released by Deloitte Touche Tohmatsu Limited (Deloitte Global)and the Council on Competitiveness (the Council)in the USA, six countries played an important role in the development trend of global manufacturing;their combined manufacturing value added accounted for 60% of the global manufacturing industry and China was once again rated as the most competitive manufacturing nation. In recent years,China has made tremendous direct investments in scientific technology, technology transfer and infrastructure construction, significantly sharpening the competitive edges of Chinese enterprises.The Chinese government has seen various challenges facing China’s transformation to a major manufacturer of quality, and has been working hard to remove negative factors curbing the enhancement of enterprise competitiveness (a high individual income tax rate, unfavorable clauses of labor law,excessive government intervention, etc.). Meanwhile,the Chinese government also strives to implement“Made in China 2025” and the “Internet + Advanced Manufacturing” Plan and develop high-performance computer, major equipment manufacturing, and intelligent plant system. These moves will raise China’s status on the global value chain and provide key support for Chinese manufacturers in its advancement of and action framework for transforming to a manufacturer of quality.

There is some research focusing on China’s efforts to transform to a manufacturer of quality.According to Huang Qunhui,②Huang, 2017.supporting policies and plans have been introduced to be geared to“Made in China 2025” and specific measures have been enacted by relevant ministries and commissions. China has entered a new stage of fully implementing this strategy. According to Li Yan,③Li, 2017in this new era, manufacturer of quality is enriched with new connotations. More specifically, manufacturer of quality must be driven by an innovative economy, be centered on highly intelligent modern industrial systems, be supported by the integrated development of the manufacturing industry with modern producer services and be guided by the intrinsic requirements of an environment-friendly development model.A manufacturer of quality is necessarily a nation with outstanding innovation capacity, cuttingedge technology and superb information flow.China’s transformation to a manufacturer of quality cannot be achieved without forging a new landscape of high-level opening-up development,benign competitions and extensive cooperation.He Jun summarized China’s achievements in its transforming to a manufacturer of quality, holding that China began its substantial transformation in 2015.①He, 2017.More specifically, since 2015, the Chinese manufacturing industry has made notable progress in cultivating new dynamics, building a system of innovation and integrating manufacturing with information technology. Internet technology has now been extensively applied to research, development,design, production, etc., and a batch of industrial Internet-based platforms targeting specific sectors and segments are increasingly taking shape. Thanks to this, the Chinese manufacturing industry has seen its developmental environment significantly improved.

There are few papers and documents published over the past years thoroughly and comprehensively analyzing or interpreting the progress made in China’s transformation to a manufacturer of quality,or corresponding policy systems, practices and actions since the introduction of “Made in China 2025”.It is precisely to fill this research void that this study was carried out and this paper written.A systematic review of China’s manufacturer of quality policies and actions indicates that China’s transformation to a manufacturer of quality relies mainly on infrastructure improvement, cuttingedge technological breakthroughs, manufacturing development at the enterprise, sector and regional levels, and the enactment and implementation of supporting policies. Revolving around this fact, this paper analyzes and studies the process and policy system of China’s transformation to a manufacturer of quality and outlines an action framework for this transformation. The following parts of this paper mainly concern infrastructure construction,cutting-edge technological breakthroughs, advanced manufacturing development at the enterprise, sector and region levels, supporting policy systems, action frameworks, follow-up actions, and reflection.

2. Infrastructure construction for a manufacturer of quality

Following the issuing of “Made in China 2025”,the Chinese government introduced the “1+X”planning system②In the“1+X”planning system,“1”refers to“Made in China 2025,”“X”refers to 11 supporting guidelines concerning specific implementation, action and development planning. More specifically, they include five guidelines for implementing five major projects (national manufacturing innovation center construction, grass-roots level industrial development strengthening, intelligent manufacturing, green manufacturing, high-end equipment innovation), two guidelines for implementing two special actions (service-oriented manufacturing, and quality brand building in the equipment manufacturing sector), as well as four development guidelines for cultivating talents in new materials, information, medical and pharmaceutical and manufacturing industries.in a bid to gather all possible social resources, accurately target priorities and real challenges, improve and strengthen the weak parts for the development of advanced manufacturing, and promote the implementation of “Made in China 2025.”In accordance with the “1+X” planning system and relevant actions, China has prioritized the construction of industrial infrastructure during its transformation to a manufacturer of quality. This involves a series of moves to strengthen its industrial development.Strengthening industrial development means tackling the engineering and industrial bottlenecks in the production of core components, key materials and advanced processes. Consolidating industrial basis,improving the “four basic” industrial capacities,and building a basic service system for industrial technology. To this end, China has taken a series of actions, which in turn have delivered impressive results. China’s main policy plans, practices and actions concerning its industrial infrastructure construction are listed in table 1.

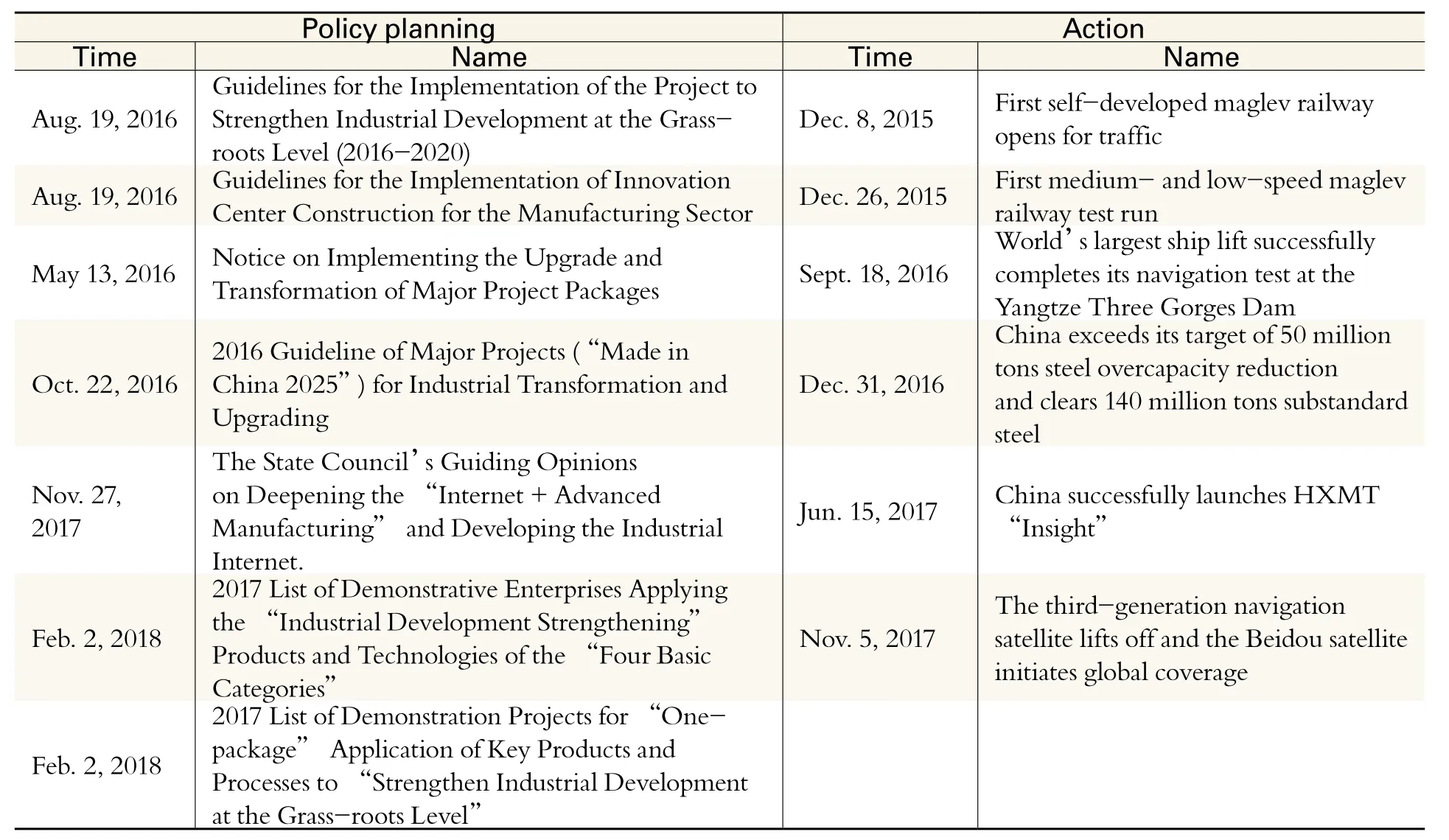

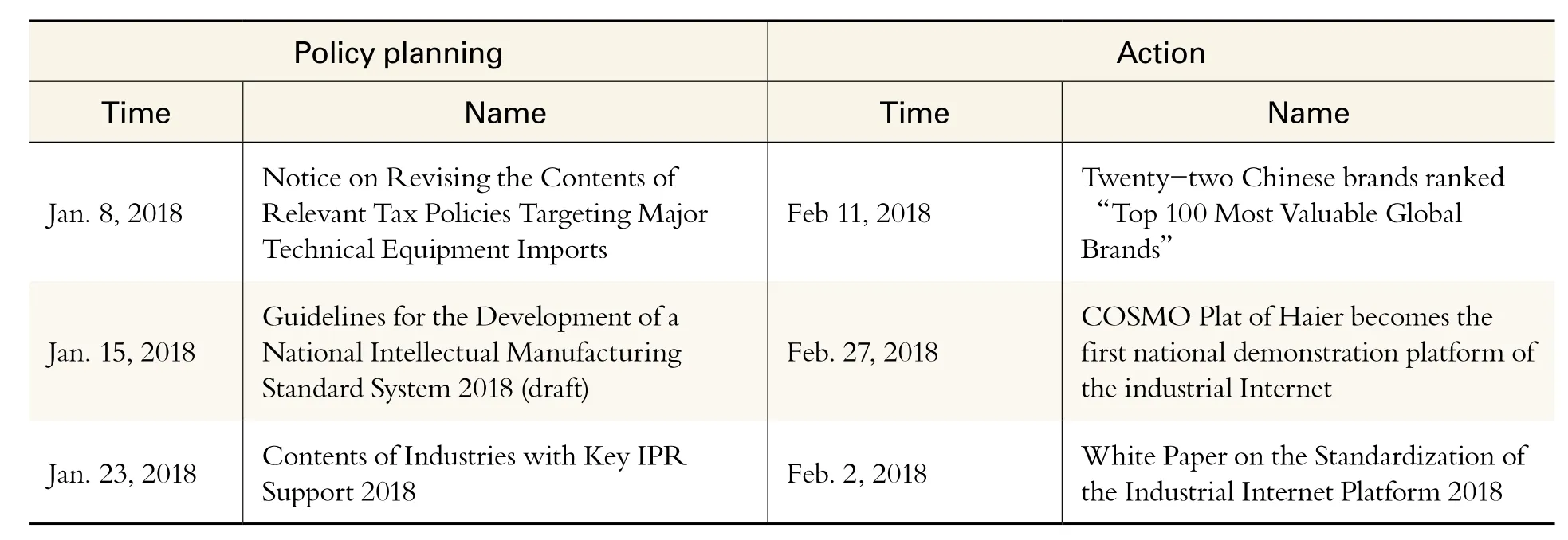

Table 1 Policy Planning and Action of Infrastructure Construction① All policies and plans listed in Table 1 are either separately or jointly issued by the State Council, the Ministry of Sector and Information Technology, the Ministry of Finance, the National Development and Reform Commission, as well as other ministries and commissions. Similarly hereinafter.

As shown in Table 1, in order to strengthen industrial development, relevant authorities of the Chinese government issued a number of policies and plans in a bid to solve four weak areas (also known as the “four basics”), i.e. core industrial components (components), key materials, advanced processes and industrial technologies; significantly improve the reliability, consistency and stability of basic components and basic materials; establish a basic system of industrial technology; and satisfy the need of high-end equipment manufacturing and major national project construction. According to the planning, China will use some 80 types of iconic core components , some 70 types of iconic key materials and some 20 types of iconic advanced processes to achieve engineered and industrialized breakthroughs, build about 40 service platforms for high-standard tests and checking and 20 information service platforms, foster 100 “little giant” enterprises with international competitiveness whose annual sales revenue will exceed RMB 1 billion, and shape 10 basic industrial clusters with international competitiveness whose annual sales revenue will exceed RMB 30 billion. As China further strengthened its industrial development in 2017, the Chinese government supported 331 key projects,②An introduction to the 2017 development of sector and telecommunications. Retrieved from Http://www.gov.cn/xinwen/2018-01/30/content_5262153.htm#2.2018-01-30.carried out 206 pilot projects to strengthen industrial development at the grass-roots level resolved a multitude of key technical problems in the gear transmission system of high-speed trains, nuclear power generation system-use seal components for pumps, and built a batch of digitalized workshops and smart factories.

China has initiated a series of moves to strengthen its industrial development, including a package of “four basics”-targeted “pioneering moves” in ten major areas(new information technology, aerospace equipment,rail transit equipment, advanced numerical control machines and robots, ocean engineering and hightech ships, power equipment, energy-efficient and new energy vehicles, agricultural equipment, new materials, bio-medicine and high-performance medical apparatus and instruments), and the “one-package”application of key products and processes. The key products and advanced processes include sensors,controllers, control systems, high-precision reducers,servo motors, precision forming technology of lightweight materials, engine electronic control fuel injection systems (EFI), high-speed EMU bearings and metro-vehicle bearings, insulated gate bipolar transistors (IGBT), advanced forming of ultra-large components, welding and processing, ultra-low loss communication optical fiber performance and optical fibers, high-pressure oil pumps for construction machinery, multi-way valves, motors, aero-engines and high temperature-resistant gas turbine blades,storage, graphene, high-performance refractory and intractable alloys, additive manufacturing of large complex components, etc. China will also build multiple public service platforms as industrial technology bases, such as industrial big data platforms, information service-related platforms,basic service platforms for industrial quality and technology, etc. and forge “specialized fine emerging enterprises”(“little giants”) and competitive industrial clusters. Moreover, it will launch special “four-basic”activities to promote military-civilian integrated development, combine military and civilian efforts to develop mutually beneficial and cutting-edge technologies, allow resources of the “four-basic”categories to be shared by the military and civilian,and let them co-formulate dual-use standards in key areas.

World’s largest ship lift successfully completes its navigation test at the Yangtze Three Gorges Dam

To lay a solid basis for the development of advanced manufacturing, China prioritizes its construction of the industrial Internet infrastructure which features low latency, high reliability and extensive coverage. This infrastructure tide has spread to regions and sectors across China, aiming to build an industrial Internet platform system and an industrial Internet security assurance system.Now, China begins the transformation and upgrade of its industrial Internet infrastructure and nextgeneration Internet, tries to build 3-5 industrial Internet platforms aligned with international standards and a batch of enterprise-level platforms capable of supporting digitalization, networking and intelligentization, and subsequently form an industrial Internet platform system supporting multiple functions (tool development, data integration, model design, etc.). Against such a backdrop, China is now formulating standards for industrial platform construction and developing an Internet resources naming system. It will introduce a minimum of 20 standards tailored to key industries and a minimum of 20 common standards concerning key elements and apply them to key industries and enterprises. It will also cultivate a batch of leading enterprises with international competitiveness and popularize emerging manufacturing technologies and manufacturing models among leading enterprises to bring the “industrialization-informatization”integration to a new level.

3. Cutting-edge technological breakthroughs

For a major manufacturer of quality, one distinctive feature is its acquisition of cutting-edge technologies in its manufacturing industry. Cuttingedge and pioneering technology demonstrates a country’s capacity for innovation and is also the core of future iterations of high technology and development of emerging industries. During the process of a new industrial revolution, with the rapid development of modern technology, nextgeneration technology keeps penetrating advanced manufacturing industry. In such a context,the global manufacturing industry is more and more digitalized, Internet-based and intelligent.China has timely grasped the development trend of global manufacturing, striving to give full play to the respective advantages of enterprises,research institutes, colleges and universities, etc.By integrating resources, China aims to develop cutting-edge technologies, and collaborate with partners to facilitate integrated innovation in key technologies, intelligent manufacturing of complete equipment, and software manufacturing and development in major areas. Now, China has identified a batch of research technological focuses, which represent the development direction of world-class high technology, take the lead in future advanced manufacturing and help upgrade manufacturing technology. They are expected to improve China’s R&D capacity in high technology and relevant industries’ international competitiveness. China’s main policy plans, practices and actions concerning its industrial infrastructure construction are listed in table 2.

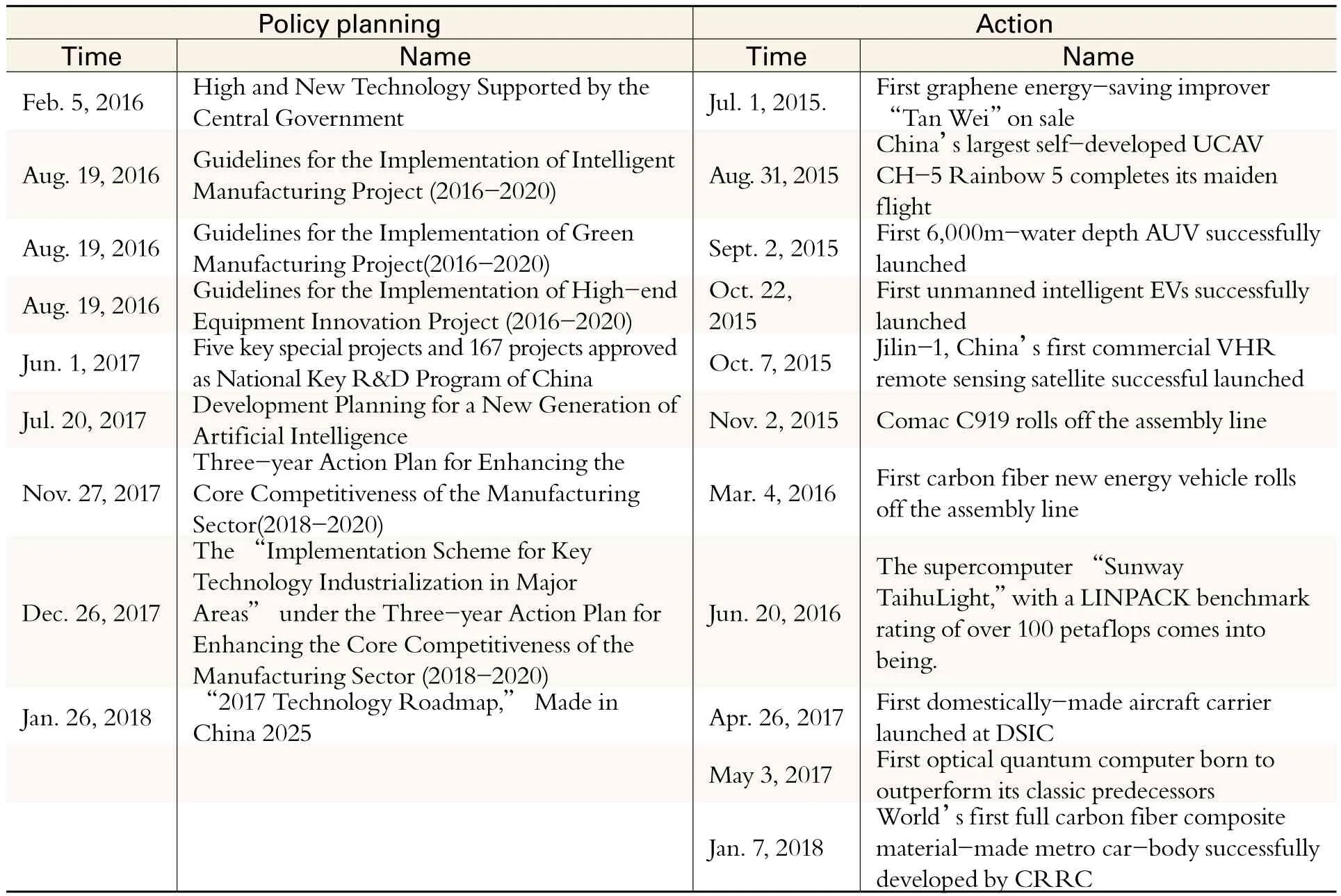

As shown in Table 2, China currently focuses on the technological breakthrough in intelligent manufacturing, green manufacturing (eco-friendly manufacturing), high-end equipment manufacturing,etc. In particular, cutting-edge technologies in intelligent manufacturing mainly refer to those concerning high-end CNC machine tools, industrial robots, process simulation systems, industrial control software, intelligent logistics and warehousing equipment, intelligent control equipment, intelligent detection and assembly facilities, additive manufacturing equipment, etc. Cutting-edge technologies in green manufacturing mainly refer to those concerning comprehensive utilization of resources, energy conservation, “green standard,”“green factory,” “green product.” “green industrial park,” “green supply chain,” etc. According to relevant statistics,①An introduction to the 2017 development of sector and telecommunications. Retrieved from Http://www.gov.cn/xinwen/2018-01/30/content_5262153.htm#2.2018-01-30.in 2017 the Ministry of Industry and Information Technology of the PRC funded 331 key projects, 428 projects applying new models of intelligent manufacturing and 225 major projects of green manufacturing technology. Some key technological problems were tackled including those concerning the gear transmission system for highspeed trains and pump-use sealing elements for nuclear power generation-systems.

Table 2 Policy Planning and Action for cutting-edge Technological Breakthrough

Sunway TaihuLight

To enhance the core competitiveness of advanced manufacturing, China also strives to make technological breakthroughs through special operations in the following nine major areas and industrialize corresponding technologies; major technical equipment, high-end ship and marine engineering equipment, rail transit equipment,intelligent robots, intelligent vehicles, modern agricultural equipment, high-end medical devices and medicines, new materials, and manufacturing sector intelligentization. More specifically, China strives to develop a next-generation 600km highspeed maglev train, build a testing and debugging platform to solve major technical problems such as suspension and guidance and on-board power supply, develop China standard urban rail vehicles and key systems (traction, signals, etc.), develop intelligent manufacturing systems and equipment(rolling stock, train control systems, high-speed turnouts, etc.), enhance international cooperation in developing ocean liners, master relevant design and construction technologies, design and build multi-purpose ships ultra-large container carriers,green ships, etc. Also research, develop and demonstratively apply high-end offshore oil and gas exploration equipment, such as the 7th-generation semi-submersible platform (drilling ship), develop next-generation intelligent robots (autonomousprogrammed industrial robots, human-machine cooperation robots, two-arm robots, etc.), engage in the development and production of sensors,on-board chips and central processing units, onboard operating systems, wireless communication equipment, Beidou high-precision positioning devices and other products. Develop new-type highperformance tractors and multi-operational tillage and cultivating machines, large combined harvesters,sugarcane harvesters, efficient devices for straw collection and utilization, mulching film and residual plastic film recovery devices, develop core spare parts (ample power agricultural machinery engines, transmission systems, electro-hydraulic control systems, intelligent systems, etc.),achieve industrialization of ultrasonic endoscopes, surgical robots, total laboratory automation/TLA and innovative medical devices, engage in the research and development of automotive ultra-high steel plate and spare parts-use steel, high-speed rail’s key partsuse steel, high-performance si-steel, engine-use superalloy materials, marine-engineering and hightech ship-use steel, key nuclear power equipmentuse steel, large die-casting mold-use hot-work die steel, polar environment use steel, large hydropoweruse high-level penstock and spiral case-use steel,aviation-use light alloy materials, high-end rare earth functional materials, electronic information-use key materials, new-type rare metal materials, graphene,tempered vacuum glass, high-performance silicon nitride ceramic materials, high-performance quartz glass, etc.

In January 2018, the National Development and Reform Commission announced its decision①National Development and Reform Commission. Retrieved from http://www.ndrc.gov.cn/gzdt/201710/t20171013_863539.html.2018-01-22.to implement 56 major projects in three areas, i.e. the“Internet +”, artificial intelligence and the digital economy, in a bid to facilitate the construction of a supporting platform for the “Internet +” public services, promote key technological breakthroughs in deep learning, speech recognition, facial recognition, machine vision, logical reasoning, etc.,and apply data share-and-exchange platforms to data acquisition, processing, analysis and mining in areas such as medical treatments, transportation,finance, logistics and environmental protection. This is beyond doubt one more major move of substantial significance towards becoming a manufacturer of quality.

4. Advanced manufacturing development at the enterprise,sector and region levels

At present, scientific technology and related industries are undergoing a new round of profound changes. The competitive landscapes of some important industries are experiencing major restructuring, with the role of high technologies(information, big data, digital simulation, etc.)increasingly highlighted in advanced manufacturingrelated research, development and design. While engaged in strengthening industrial development at the grass-roots level and seeking cutting-edge technological breakthroughs, China also attaches great importance to fostering leading enterprises and prioritizes the development of new materials,new information technology, new artificial intelligence, high-end intelligent re-manufacturing and additive manufacturing. Moreover, China has also initiated the development of “Made in China 2025” pilot demonstration cities, demonstration projects of intelligent manufacturing, and advanced manufacturing clusters. Table 3 shows policy planning and actions concerning the development of relevant advanced manufacturing enterprises,industries and regions issued in recent years.

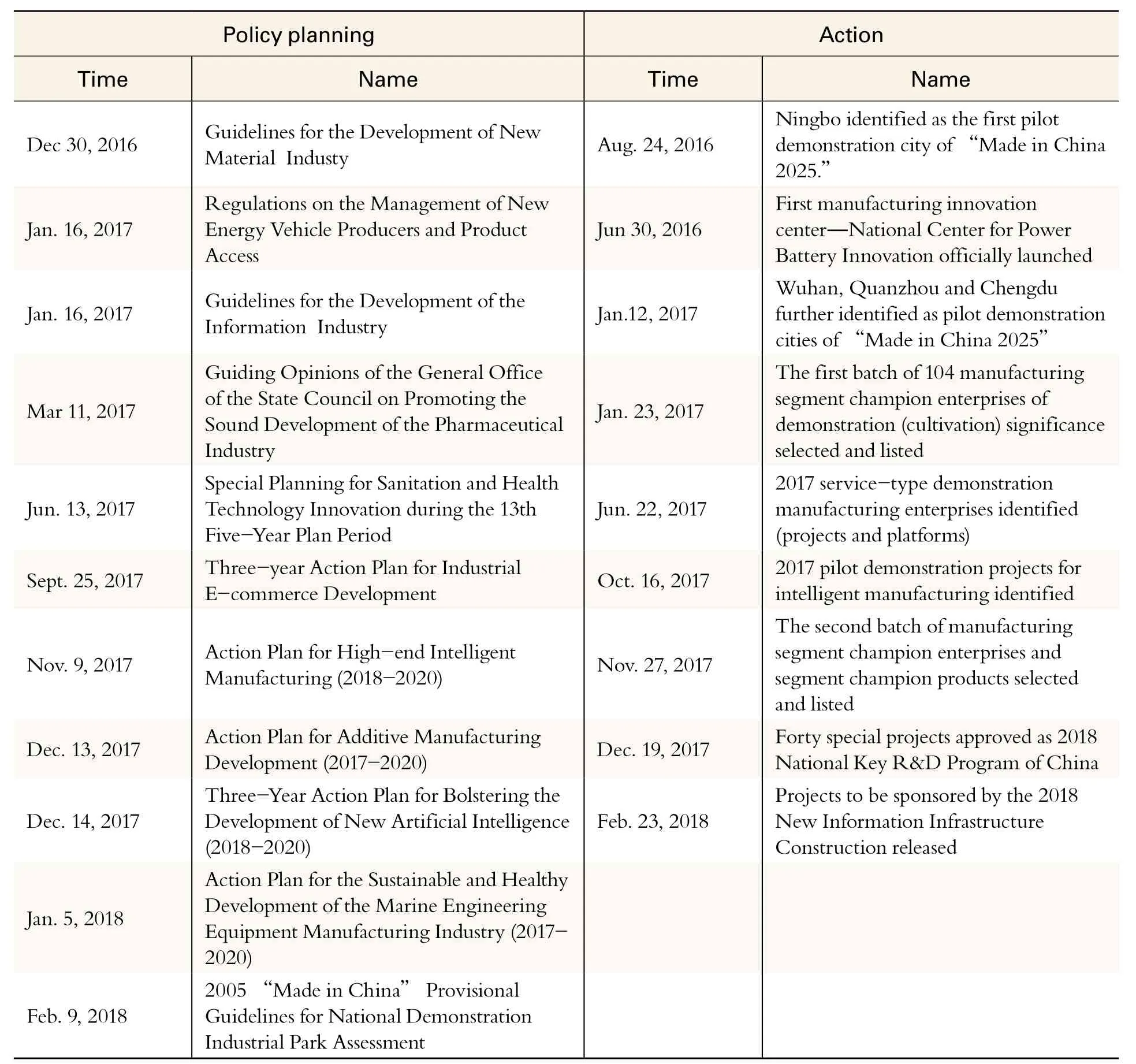

As shown in Table 3, China will prioritize the development of advanced manufacturing in the areas of new materials, information, new-energy vehicles(NEV), bio-medicine and ocean engineering equipment. New materials feature outstanding performance and special functions and their related discoveries, inventions and applications are of crucial importance to manufacturing technology and product quality. In recent years, China has focusedon new material development in three major areas,i.e. advanced basic materials, key strategic materials and cutting-edge new materials. Advanced basic materials mainly include basic components-use steel,high-performance ocean engineering-use steel, highstrength aluminum alloys, high-strength titanium alloys, magnesium alloys, high-end polyolefin,special-purposed synthetic rubber, engineering plastics, etc. Key strategic materials mainly include high-temperature resistant and anti-corrosion alloys,high-strength light alloys, high-performance carbon fibers, reverse osmosis membranes, aramid fibers,

efficient high performance luminescent materials,high-performance permanent magnets, highend catalysts, new-type display materials, widebandgap semiconductor materials, etc. Cuttingedge new materials mainly include shape memory alloys, liquid metals, graphene, metal and high polymer additive manufacturing materials, selfrepair materials, low-temperature superconducting and low-cost high temperature superconducting materials, intelligent bionic materials, supermaterials, etc.

Table 3 Policy Planning and Action Concerning the Advanced Manufacturing Development at Enterprise, Sector and Region Levels

The Chinese information industry is built on a weak foundation with its core chips and basic software still relying on imports. Such a reality severely restricts the in-depth integration of information technology with the advanced manufacturing sector. During China’s transformation to a manufacturer of quality, China attaches great importance to the integration of information technology with advanced manufacturing and prioritizes the development of the Internet, quantum computing, stratosphere communications, satellite communications, visible light communications,the Internet of Vehicles (IoV), land-sea-sky integrated networks, artificial intelligence, brainlike calculation, etc. Information sector-boosting actions mainly include: gathering superior resources for information technology-original innovation and integrated innovation, deploying and building a number of innovation centers in strategically core areas such as integrated circuits, basic software,big data, cloud computing, the Internet of things(IoT) and industrial networks to enable the research and development of key generic technologies.Combining the three networks (the Internet of things, mobile Internet and industrial Internet) into an organic whole, and researching, developing and applying cloud computing and information security technology to the new information network,researching and developing security chips, core security information chips, secure operation systems, secure databases and secure middleware;developing mobile intelligent terminal chips, digital TV chips, network communications chips, smart wearable chips, etc.

The pharmaceutical industry directly concerns the public demand for health and is therefore a key sector beneficial to national welfare and people’s lives. During China’s transformation to a manufacturer of quality pharmaceutical sectorboosting actions mainly include: promoting industrial production of major drugs, developing and producing new drugs and enabling chiral synthesis, researching and developing chemical drug preparation technologies (controlled crystallization,enzyme catalysis, etc.) to improve the technical performance of new-type preparations (prolonged action preparations, sustained-release preparations and targeting preparations); developing key components (digital detectors, superconducting magnets, X-ray tubes with high heat capacity,etc.), facilitating precise and upgrades of medical equipment and instruments, practicing TCM material stock breeding, popularizing TCM material planting (breeding) techniques and promoting TCM modernization.

China prioritizes the development of advanced manufacturing industry which concerns national welfare and people’s lives and is of strategic significance and at the same time works on the construction of pilot demonstration manufacturing cities and parks. Take Ningbo as an example. This city enjoys favorable geographic location, convenient transportation, a well-developed economic base, a solid foundation for advanced manufacturing, clear strategic positioning, and more importantly, unique advantages in new materials, core components,etc. In 2016, Ningbo was identified as a pilot demonstration city of “Made in China 2025.” In 2017, more cities (Wuhan, Quanzhou, Chengdu, etc.)were further identified as pilot demonstration cities of “Made in China 2025.” The Chinese government introduced indexes concerning advanced manufacturing systems, regional collaborative innovation, talent introduction and cultivation,policy guarantees, as well as the advancement of manufacturing priorities and conducts assessments of National Demonstration Industrial Parks in terms of innovation-driven capacity, product quality, green development, structure optimization,talent cultivation as well as the proportion of R&D staff in enterprises above a designated size in a bid to promote the construction of demonstration manufacturing parks in an all-round way. In 2017 China identified 97 pilot demonstration projects of intelligent manufacturing. According to the Annual Development Report of China’s Intelligent Manufacturing 2016-2017,①Retrieved from Http://www.js.xinhuanet.com/2017-05/21/c_1121009068.htm.2017-05-21.as of 2016 China had a total of 158 intelligent manufacturing parks already completed or under construction and 40 robotassisted industrial parks already completed or under construction. China is now witnessing the formation of four major industrial clusters, i.e. the Yangtze River Delta, the Pearl River Delta, the Circum-Bohai-Sea and Central and Western China. Beijing,Shanghai, Guangdong and Suzhou have become clusters of industrial robots.②Mi, 2018

As a phased achievement of China’s transformation to a manufacturer of quality, in 2017 the Chinese government issued the list③Retrieved from http://business.sohu.com/20170212/n480521043.shtml.of the first batch of 104 manufacturing segment champion enterprises④Manufacturing segment champion enterprise refers to an enterprise which long specializes in a certain product market segment, features a cutting-edge production technology and process, and tops corresponding global segment in terms of product market share.of demonstration (cultivation)significance. The government aims to better guide and serve the first batch of enterprises, encourage and support relevant governments to shift their focus to production innovation, quality improvement and brand building and strive to forge internationally well-known brands. The Chinese government also plans to build national centers for manufacturing innovation in 22 areas which respectively are next-generation information photo electronics,printing and flexible displays, robots, lightweight materials and molding processing technologies and equipment, gas turbines, high-end CNC machine tools, rare-earth functional materials, sensors,advanced integrated circuit technologies, industrial information security, advanced composites,intelligent voice, graphene, deep ocean engineering equipment, digital design and manufacturing,intelligent connected vehicles (ICV), industrial cloud manufacturing, industrial big data, highend medical apparatus and instruments, resources cycling, high-end pharmaceutical preparations and green pharmaceuticals, advanced functional fibers, etc. China has made significant progress in manufacturing development at the enterprise, sector and region levels.

5. Supporting policy systems

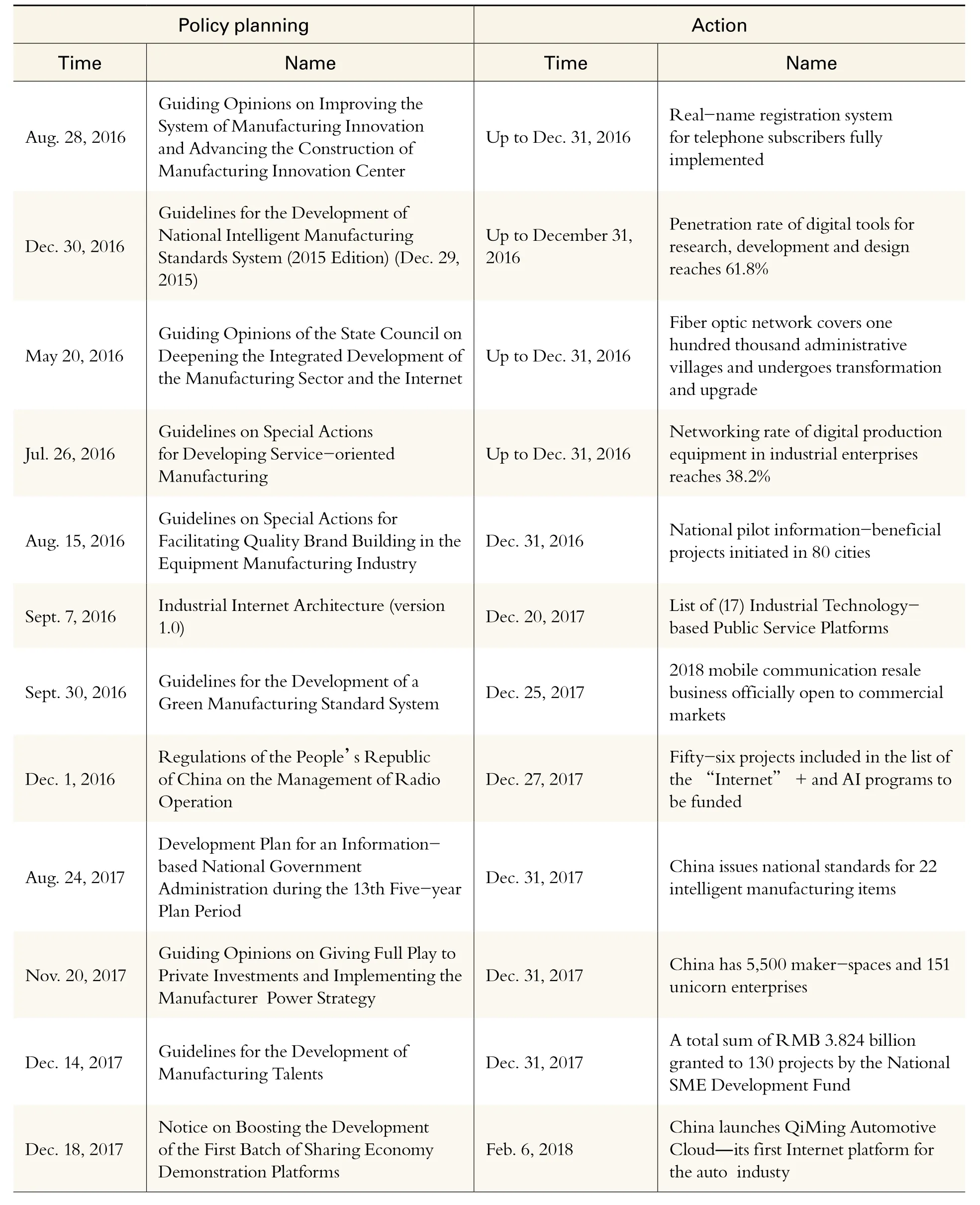

A talent pool is an important support for the implementation of the manufacturing development strategy. The key to becoming a manufacturer of quality lies in its talent pool. During its transformation to a manufacturer of quality, China will continue increasing investments in human capital, reforming its education and training systems,cultivating and introducing world-class technological and managerial talents. To successfully transform to a manufacturer of quality, China in recent years has adopted a series of related measures and supporting measures concerning talent training, brand building,manufacturing standards building, intellectual property protections, information-based government administration, radio management and serviceoriented manufacturing development to further promote its transition to a manufacturer of quality.Corresponding policy plans and actions are listed in Table 4.

According to Table 4, to ensure the fulfillment of “Made in China 2025,” China has enacted a series of supporting policies to boost its transformation to a manufacturer of quality.

Below are China’s main actions of manufacturing talent cultivation: striving to build a system of modern vocational education by initiating pilot projects to explore possible training models of practical technical talents at universities and colleges which are appropriate and cooperative,extensively cultivating applied undergraduate talents and future manufacturing engineers, expanding the scope of primary manufacturing research and development, expanding the enrollment scale of PhD students in major scientific research areas,expanding the enrollment scale of undergraduate students in manufacturing-related subjects (electronic information, mechanics, material science, ocean engineering, bioengineering, aerospace and high-end equipment manufacturing, electronic information,biology and chemical engineering, energy power,other material-related areas), introducing pilot programs for modern apprenticeship co-sponsored by universities and enterprises, establishing vocational education groups for the advanced manufacturing sector, and developing and offering courses concerning research methodology, subject frontiers, fundamentals of entrepreneurship,employment and entrepreneurship guidance, etc. to practice innovative and entrepreneurship education throughout the whole process of talent cultivation.

In terms of brand building, China has made the following efforts: improving the four basic systems of quality and brand development, prioritizing the quality improvement of equipment manufacturing products, advancing the standardization of green development and green manufacturing, taking the initiative to enhance the building of region/sectorspecific quality brands, carrying out region-specific branding for industrial clusters, construction of national well-known demonstration areas, qualitydriven campaigns and other activities, advocating breakthroughs in quality, technology and processes and pushing forward the innovative development of quality and technology.

The Chinese government engages private enterprises in its transformation to a manufacturer of quality through the following activities: fostering a batch of specialized enterprises (“little giants”),guiding private manufacturing enterprises to provide high-end environmental-friendly intelligent services, supporting private enterprises to undertake tasks related to its transformation to a manufacturer power, and giving full play to the important role of private enterprises in major projects and key tasks. Now, some private enterprises are already engaged in intelligent manufacturing, standardizing intelligent manufacturing in an all-round way, some private enterprises participate in the production and manufacturing of cutting-edge technology,advanced special manufacturing equipment and production lines, some private enterprises invest in environmental-friendly transformation, green product production, and other energy conserving and environmental-friendly industries and expandtheir business scope to the research, development,production and maintenance of military products,thus enabling the integrated development of military and civilian enterprises.

Table 4 Supporting Policy Systems and Action

Source: Ministry of Industry and Information Technology of the PRC: http://www.miit.gov.cn/; National Development and Reform Commission: http://www.ndrc.gov.cn/; Ministry of Science and Technology of the PRC: http://www.most.gov.cn/; The State Council of the PRC: http://www.gov.cn/; Amdaily: http://www.amdaily.com/

China also attaches great importance to developing manufacturing standards systems, such as the intelligent manufacturing standard system and the green manufacturing standard system. To be more specific, the intelligent manufacturing standard system focuses on basic common standards and key technical standards (industrial Internet,industrial software, intelligent equipment, intelligent factories, intelligent services, etc.) while the green manufacturing standard systems emphasize green supply chains, green products, green enterprises,green industrial park, etc. As of the end of 2017, the Chinese manufacturing sector saw the penetration rate of “mass entrepreneurship and innovation”platforms rising by 70%,①Retrieved from Http://www.gov.cn/xinwen/2018-01/30/content_5262153.htm#2.2018-01-30.the penetration rate of digital R&D tools rising by 63.3%, and the networking rate of digital production equipment exceeding 39%.China has formulated over 60 key intellectual manufacturing standards and formulated and revised a total of over 150 intellectual manufacturing standards. Its “informatization and industrialization-integrated” standard series had been identified as international standards by the ISO. It is expected that by 2020 more than 500 intellectual manufacturing standards will be revised to ensure the total popularization of basic common standards and key technical standards in advanced manufacturing industries to form two sound and complete standard systems for intelligent manufacturing and green manufacturing.

Moreover, China also advances informationbased government administration, striving to build a big data center connecting the whole country and form a top-level architecture shared by major platforms, driven by data algorithms and cogoverned by large systems. So far, China has built five national manufacturing innovation centers and fostered 48 provincial-level manufacturing innovation centers②Li, 2018.and formed a manufacturing innovation system with national innovation centers at the core and provincial level-innovation centers being important supporting parts. Some international coordinating bodies (such as the working group of German-Chinese Sector 4.0 cooperation, working groups of European/ French/ Italian industrial energy efficiency and green manufacturing cooperation, etc.) have also initiated effective and fruitful operations and are actively promoting China’s manufacturer of quality transformation in the international arena.

6. Action framework and vision for follow-up actions

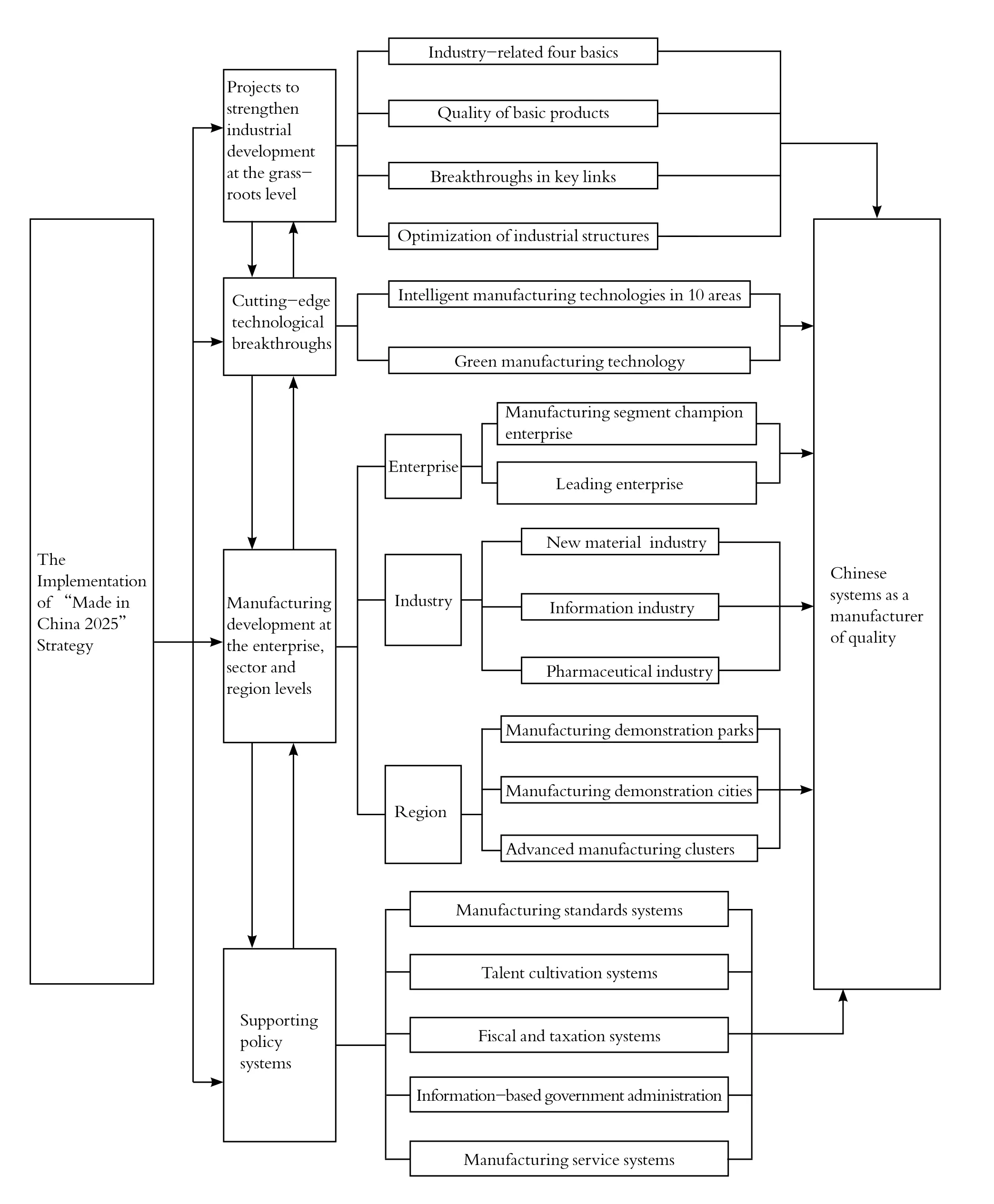

To push forward the transformation to a manufacturer of quality, China revolves around“Made in China 2025,” is relying on projects to strengthen industrial development and is exploring cutting-edge technology in manufacturing industries and regions. China is advancing its transformation to a manufacturer of quality in an all-round way.Based on the information presented regarding the transformation to a manufacturer of quality, this paper outlines an action framework for this cause,which is shown in Fig.1.

Figure 1 outlines the action framework for China’s current transformation to a manufacturer of quality. This of course should only be deemed a rough framework. After all, China's transformation to a manufacturer of quality concerns a wide range of aspects (major projects, major special projects,serial policies and regulations, action plans, etc.),which are hard to describe in their entirety. As this transformation advances, the framework will change accordingly. For example, more importance will be attached to the strengthening of industrial development, there will be breakthroughs in cuttingedge technologies, priorities will be given to new industries, and the supporting policy systems will be enriched.

Given the above analysis, we can conclude that China has made significant progress in its transformation to a manufacturer of quality and has already produced substantial results. Yet, a review of China’s transformation uncovers that there are still some weak areas that need to be strengthened and further improved. More specifically, China still lags the world’s leading players in some domain technologies, contributes very limitedly (merely 1%)①Heads of 50 manufacturing enterprises invited to Zhongnanhai. Retrieved from Http://www.gov.cn/xinwen/2017-08/28/con-tent_5221040.htm.2017-08-28.to the formulation of international standards,invests insufficiently in building a system of supporting policies concerning finance, banking and taxation, and underperforms in cultural development as a manufacturer of quality. Given this, more efforts need to be made to improve these deficiencies.

First, China should attach more importance to the R&D, in key areas still lagging, on the global stage. Globally, China is a large manufacturer with a sound industrial system. During the development of its manufacturing industry, China has introduced numerous world-class manufacturing technologies.Restricted by its economic development level and weakness in basic research, however, China is still behind major players in some high techdriven manufacturing areas, including but not limited to chip technology, semiconductor equipment, IT, cutting-tool engineering, core telecommunications technology, core mobile phone technology, agricultural machinery and equipment manufacturing, high-speed trains, airliners,automobile electronic technology, computer design of automobiles technology, advanced combat aircraft and destroyers, police equipment technology, plastic machinery technology, seamless steel tubing,instruments and meters technology, motor-meter technology, coal production equipment technology,wind energy development, solar cell technology,primary magnesium production, valve regulating technology, building energy conservation, plastic granulator manufacturing, excavator manufacturing,external wall thermal insulation, marine corollary equipment manufacturing, computer technology,next-generation display technology (laser displays),logistics equipment technology, water-saving engineering, dehydration technology, coating technology, door and window-building technology,building ceramic and floor technology, sodium carbonate production, refrigerator manufacturing,fluorine chemical and fluoropolymer production,large forging press manufacturing, high-temperature cable production, breeding techniques, new technology of microbial strain transformations,aerospace medical technology, bio-medical technology, new biotechnology, microecologics,etc. Some of these technologies have already been included in “Made in China 2025” or the “1+X”Plan, some have not. Most of these technologies come from emerging industries or even emerging industries with strategic significance, and some even concern national economy and people’s livelihood,for which they should be given greater importance.Eventually, all technologies should be included in“Made in China 2025” or the “1+X” Plan, to avoid any further widening of the technology gap with other leading players.

Fig. 1 China’s Action Framework for Transformation to a Manufacturer of Quality

Second, China should enhance the internationalization of its manufacturing standards systems. During the strategic transformation to a manufacturer of quality, China places emphasis on the development of standards systems. However, compared with the research and development of cutting-edge technology and the strengthening of industrial development,the development of manufacturing standards systems is lagging behind. At present, some of the Chinese manufacturing standards are already out of date, with some standards remaining unrevised or un-updated for years and therefore failing to catch up with their corresponding worldadvanced levels. Some manufactured goods do not even have any manufacturing standards, or only have semi-manufacturing standards. Some products, from material selection and design to manufacturing processes, manufacturing equipment and manufacturing environments, do not have any standards to follow. Because of this they feature apparent defects which severely affect product quality. There are also other manufactured goods lacking a service system, a full-coverage service network, or corresponding mechanisms for product after-sale services, maintenance and repair, waste products and faulty product recalls and compensation, which affects a products’ brand reputation. Consequently, China should accelerate the development of advanced manufacturing standards systems, formulate more delicate and specific standards for manufactured goods’ process planning, production, application and services,abandonment and recycling, etc., and develop multidimensional manufacturing standards systems.China should actively adapt to future development trends in the advanced manufacturing sectors,formulate and improve an advanced manufacturing ecosystem which incorporates system reference architecture, network security, factory networking,supply chain integration, and seamless transmission of data from workshop level to enterprise level,improve the agility, quality, productivity and sustainability of advanced manufacturing, and satisfy multi-objective requirements for nextgeneration industrial upgrades. China should enhance its development of quality management systems, improve standards concerning enterprise product management, resource supply, product realization, quality monitoring, quality analysis and improvement, etc., enhance the supervision of the whole pre-delivery process (including customer demand, design and development, production,inspection, sales and delivery), and improve the quality of advanced goods manufactured in China.

China should strive to align its “Made in China”standards to international manufacturing standards,support and encourage appropriate enterprises to participate in the formulation of internationally advanced manufacturing standards, and thereby acquire a say in the production, sales and services of advanced manufacturing products. China should also establish a special operating mechanism for the internationalization of manufacturing standards,develop an international cooperation platform and coordinating mechanism for manufacturing standards, enhance its contact with the International Standardization Organization (ISO),follow the latest development of advanced international standards,absorb state-of-the-art international technology,and strengthen the competitiveness of Chinese manufacturing standards in the international arena.

Third, China should enhance its building of a system of supporting policies concerning finance,banking and taxation. The transformation to a manufacturer of quality is a complicated massive system which involves top-level design, strategic planning, action plans, as well as other supporting policies and measures. Judging from the current progress of the transformation to a manufacturer of quality, China’s already implemented supporting policies and measures concerning finance,banking and taxation are yet to render satisfactory performance, with some policies being fragmented,incomplete and unsystematic, some policies are region-specific, varying from place to place, for which they can hardly be combined to give play to their due role. The Central Government should enhance the top-level design of supporting policies and formulate a series of policies concerning finance, banking and taxation to support China’s transformation to a manufacturer of quality.

China should establish a finance-guiding fund,enable manufacturing financing, and amplify and extend small and micro-startup financing. It should establish and perfect an investment decisionmaking mechanism for government to participate in various investment funds, major technological transformation of traditional industries and key special development projects. It should increase credit loan placement in the manufacturing industry, maintain rational and stable increases in the manufacturing industry and implement differentiated manufacturing credit policies.Meanwhile, it should increase the proportion of direct financing in advanced manufacturing enterprises, broaden channels of equity financing for advanced manufacturing sectors, give full play to the guiding role of finance in manufacturing startups’listings, financing and direct debt financing, and establish a variety of private equity funds. Moreover,it should raise the level of corporate securitization,explore effective credit demands for manufacturing enterprises, increase loan delivery in technological transformation projects, reduce manufacturing enterprises’ financing costs, build an emergency mechanism for re-lending businesses, reduce the financing risks facing manufacturing enterprises,and create a favorable financing environment for the development of the advanced manufacturing industry.

China should develop a detailed tax policy system to further enable its transformation to a manufacturer of quality, enact preferential tax policies targeting major development areas,major projects, key special development projects,prioritized development industries, manufacturing development parks and manufacturing clusters which are designated by “Made in China 2025”and the “1+X” Plan. It should support advanced manufacturing enterprises in the research and development of new technologies, new processes and new products, help relevant enterprises with independent innovation and technology transfer,and help R&D institutions to purchase advanced equipment. It should also leverage the taxation system to support replacement of technical equipment and fixed asset product replacement, help relevant enterprises to develop energy-saving and environmental-friendly products and technologies,encourage manufacturing enterprises to use energysaving and environmental-friendly products and technologies, implement differentiated export rebates (exemption) policies, stimulate advanced manufacturing enterprises to invest overseas thus enabling those enterprises to go global, and facilitate the development of technologically advanced service providers.

Fourth, China should enhance its development of an advanced manufacturing culture. China’s transformation to a manufacturer of quality echoes the call of modern industrial civilization, which cannot exist without a modern culture. An advanced and outstanding manufacturing culture is of great significance to the advancement of technological innovation, the improvement of product quality and the optimization of the developmental environment.The development history of the industrial revolution has well demonstrated that advanced scientific technologies and cultures form an intellectual driver and cultural basis for technological and industrial innovation. So far, the development of a manufacturing culture is only mentioned in “Made in China 2025” and the “1+X” Plan concerning the construction of several special or major projects (talent education and cultivation,vocational education, in-service training, other cultural construction issues). No special plan for manufacturing cultural development has yet been made, which is surely to stand in the way of China’s transformation to a manufacturer of quality.

An advanced culture is a prerequisite for a manufacturer of quality. In this regard, enterprises should advocate and cultivate professional ethics of dedication, diligence, rigorousness and excellenceseeking among their staff, improve their cultural attainment, and become a driver of culture and a source of power. Relevant industries should enhance corresponding enterprises’ sense of social responsibility, foster persistence, perseverance and determination among entrepreneurs and inspire entrepreneurs to innovate, to explore, to share and to cooperate. Society should foster a social climate that advocates hard work and diligent laborers,exquisite craftsmanship and innovative and daring entrepreneurship and develop an entrepreneurial environment that welcomes innovation, tolerates failure, shows compassion and repays society.

A country cannot expect to grow powerful without competitive enterprises. Therefore, China should guide manufacturing enterprises to draw on the advanced experience worldwide and develop and improve their corporate cultures. It should continue to develop new cultural formats for the manufacturing sector, diversify manufacturing cultural products, consolidate the leading role of innovative design, focus on the inheritance and innovation of traditional manufacturing techniques,foster a batch of demonstration parks for cultural innovation and entrepreneurship, and establish a number of studios for advanced manufacturing designers. It should also compile a national industrial heritage list, accelerate the development of a manufacturing museum system, develop manufacturing tourism, and shape a new image of credibility, excellence, innovation and green for the Chinese industry. Finally, China should also strengthen foreign exchanges, continue to absorb advanced corporate cultures worldwide, constantly enrich the cultural connotations of China’s transformation to a manufacturer of quality and enhance the core competitiveness of the Chinese manufacturing industry.

Contemporary Social Sciences2018年6期

Contemporary Social Sciences2018年6期

- Contemporary Social Sciences的其它文章

- The Study of Higher Vocational English EGP+EOP Teaching Model Reform

- Lower-Elementary Level School Pupils’ Developmental Trajectories of Chinese Verbal Vocabulary Knowledge and Influential Factors

- On the Farmers’ Role Differentiation and the Effective Implementation of Rural Vitalization Strategy—A Perspective from the Targets, Process and Evaluation of Policy Implementation

- The Overseas Reception of Chinese Science Fiction Works from a Perspective of Western Interpretation Preference—A Case Study of Reader’s Reception of Liu Cixin’s The Three-Body Problem in the USA

- International Communication Theories: Main Development Stages and Reflections

- A Legal and Economic Study of Cooperation among the BRICS Countries under BRI