水稻秸秆序批式干发酵产沼气中试及其动力学研究

刘 杨,闫志英,姬高升,许力山,房俊楠, 曾 勇,宦臣臣,佟欣宇

水稻秸秆序批式干发酵产沼气中试及其动力学研究

刘 杨1,2,3,闫志英1,2※,姬高升1,2,许力山1,2,房俊楠1,2,3, 曾 勇1,2,宦臣臣1,2,佟欣宇1,2

(1.中国科学院环境与应用微生物重点实验室,成都 610041;2. 环境微生物四川省重点实验室,成都 610041; 3. 中国科学院大学,北京 100049)

干发酵处理有机废弃物或生物质废弃物等具有处理量大,用水量少,处理周期短等优势。该试验以水稻秸秆为原料(269 kg,TS为89.19% ±0.24%),用沼液(500 kg)调节水稻秸秆含水率至67.58%,覆膜堆沤3 d,并以运行良好沼气池污泥为接种物(300 kg,接种量为28.06%,TS为1.88±0.07%),室温(30~35 ℃)条件下进行周期为55 d的干发酵中试试验。试验结果表明:反应55 d后,秸秆累积产气量为308.20 m3/t,累积产甲烷量为167.44 m3/t,最高甲烷体积分数达57.88%,最大日产气量为2.33 m3。通过Gompertz 模型对水稻秸秆产甲烷曲线进行拟合,拟合出的产甲烷潜力值和实际的产甲烷潜力值很接近,2为0.990 7,显示出较高的准确性。该研究可为序批式干发酵法处理水稻秸秆提供理论依据和指导。

秸秆;沼气;动力学;干发酵;降解

0 引 言

中国是农业生产大国,农作物秸秆资源非常丰富,但资源化利用率却很低。通过中国主要作物产量和谷草比计算[1],2014年中国农作物秸秆理论总产量为8.97亿t,可收集部分为7.69亿t,可资源化利用部分为1.86亿t,仅占秸秆总产量的20.74%。中国农作物秸秆主要包括水稻秸秆、玉米秸秆和小麦秸秆,占秸秆总量的75%[2-3]。这些作物秸秆富含木质纤维素,不易被降解,大部分被直接丢弃或焚烧,不仅造成资源浪费,而且对环境造成极大破坏[4]。近年来,随着社会的发展和进步,环境问题和能源问题越来越受到国家关注,秸秆的无害化处理和资源化利用迫在眉睫,有效秸秆处理技术的开发不仅有重大生态效益,也有较大经济效益[5]。

目前中国对作物秸秆资源利用和开发的方式多种多样,其中厌氧消化产沼气是一种清洁且高效的资源化利用方式[6-7]。秸秆厌氧消化产沼气可将作物秸秆转变为清洁的、便于利用的甲烷,产生的副产物沼渣和沼液,因其富含氮和磷等植物营养元素,是优质的有机肥料,可用于农业生产,能有效地提高作物产量[8]。厌氧消化可分为湿发酵和干发酵,现阶段中国处理作物秸秆的方式主要为湿发酵,但湿法酵处理秸秆,存在装置规模较大、秸秆易结壳、搅拌耗能大、沼液量大难处理等问题[9]。而干发酵,以作物秸秆、畜禽粪便或是垃圾等有机物为原料(干物质TS质量分数为20%~40%),通过厌氧菌降解利用,转变为甲烷、二氧化碳等气体的过程[10]。干发酵原料的干物质浓度高而导致的进出料难、传热传质不均匀、易酸中毒等问题,是限制沼气干发酵的技术难点,对此国内外都在进行深入研究[11]。Mustafa等[12]用蕈菌和里氏木霉预处理稻草后进行厌氧消化,发现2种方式预处理后的稻草甲烷产率分别提高120%和78.3%。Guendouz等[13]设计了浆式混合厌氧消化反应器,进行实验室试验和现场试验,发现实验室试验能准确地模拟现场试验,并指出微生物对发酵原料的适应性和干发酵反应的操作条件。于佳动等[14]以玉米秸秆和牛粪为原料进行干发酵,研究不同含固率、物料配比、接种物浓度、秸秆粒径,以及喷淋频率、喷淋量等因素对厌氧干发酵的影响,发现喷淋频率、接种物浓度对厌氧干发酵产沼气有关键作用。何荣玉等[15]研究复合菌剂预处理秸秆和添加沼气发酵促进剂对秸秆干发酵的影响,发现预处理的同时添加沼气发酵促进剂,能明显提高沼气产气量。本研究以水稻秸秆进行序批式干发酵产沼气试验,探究秸秆干发酵产气效果并对其进行动力学分析。根据实验室预试验结果,进行中试规模放大试验,为水稻秸秆干发酵处理技术的推广和使用提供试验基础。

1 材料与方法

1.1 试验材料

供试发酵原料为水稻秸秆,取自成都市双流区永安镇农户。水稻秸秆为陈放秸秆,经粉碎机粉碎,粒径为1~2 cm,装袋备用。接种物为沼气池污泥,取自成都市双流区永安镇沼气站内正常产气的户用沼气池,产沼气中甲烷体积分数达60%以上。水稻秸秆和接种物理化性质如表1所示。

表1 水稻秸秆和接种物的特性

1.2 反应装置

中试试验为铁质车库式反应器(图1),有效体积 6 m3,装料体积2 m3,装置底部中央铺设滤板,滤孔孔径为0.5 cm,顶部设有工字型喷淋装置,外部有保温层;反应装置还包括滤液池,有效体积为3 m3的密闭容器,位于反应器底面下方,滤液在重力作用下从反应器中流入滤液池,滤液经循环泵可进入反应器喷淋物料,达到循环喷淋的效果;反应器和滤液池产生的沼气用不同的气袋收集,并用沼气流量计计量。

图1 中试试验装置图

1.3 试验设计

基于实验室预试验结果确定中试试验条件。由于现场条件受限,难以精准控制35 ℃恒温条件,因此试验在室温30~35 ℃条件下进行,反应装置设有加热和保温装置,可保证试验在相对稳定条件下进行[16]。现场试验以水稻秸秆为原料(269 kg,TS为89.19% ±0.24%),用沼液(500 kg)调节水稻秸秆含水率至67.58%,覆膜堆沤3 d,并以运行良好沼气池污泥为接种物(300 kg,接种量为28.06%,TS为1.88%±0.07%),混匀,装填至反应器中并密封反应器。发酵第2天起进行滤液喷淋,每天3次,试验周期为55 d。

每天定时用100 mL气袋采集气体样品和50 mL离心管采集渗滤液样品。通过测量产气量、产气浓度、pH值、氨氮浓度、挥发性有机酸(volatile fatty acid,VFA)以及纤维素、半纤维素、木质素等物质的变化,探究水稻秸秆干发酵产沼气的效果,并对试验结果进行动力学分析。

1.4 分析方法

总固体、挥发性固体:烘干法;pH值:METTLER FE28型酸度计;氨氮浓度:TU-1810SPC紫外可见分光度计[17];半纤维素、纤维素、木质素:范氏法[18];甲烷浓度:安捷伦7890A气相色谱分析仪;挥发性有机酸:安捷伦6890N气相色谱分析仪[19];采用扫描电子显微镜对发酵前后的水稻秸秆结构进行分析,发酵前后的水稻秸秆 70 ℃烘干12 h,粉碎机粉碎后过0.18 mm筛子,取少量固定于载物台上,然后在VEGE TS5136XM扫描电子显微镜下观察和拍照。

1.5 产甲烷动力学分析

对水稻秸秆干发酵产沼气试验过程进行动力学分析,采用修正Gompertz方程拟合累计甲烷产甲烷曲线[20-21]。

exp{-exp[R×e()1]}

式中为时刻的累计甲烷产气量,L/kg;为最终甲烷产气量,L/kg;R为最大产甲烷速率,L/(kg·d);为延滞期,d。、和R通过干发酵试验数据拟合得到。

2 结果与分析

2.1 干发酵前后水稻秸秆木质纤维素的变化

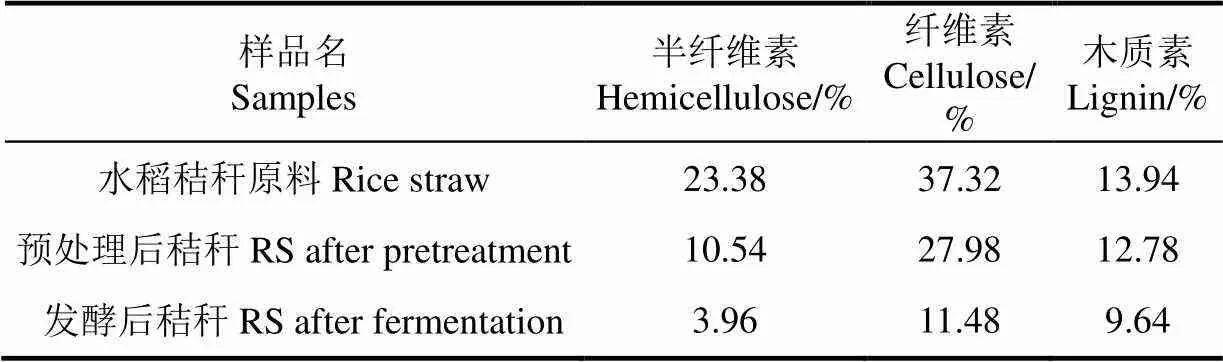

水稻秸秆富含各种有机物,主要为木质纤维素类物质,微生物能将其中木质纤维素等有机物降解消化,生成氢、有机酸等物质,这些物质被产甲烷菌转化利用,生成CH4、CO2、H2S、氢等气体。干发酵前后水稻秸秆木质纤维素的变化见表2。

从表2中可以看出,水稻原料中木质纤维素总质量分数达74.64%,经堆沤预处理和厌氧消化后,木质纤维素含量明显降低,秸秆预处理后,木质纤维素降解了31.27%,厌氧消化后,水稻秸秆木质纤维素降解了66.39%。半纤维素和纤维素变化较大,秸秆中半纤维素降解了83.06%,纤维素降解69.23%。秸秆中木质素变化不大,降解的是半纤维素和纤维素,这由其物质结构决定。半纤维素由2种或2种以上糖基通过糖苷键而形成的侧链或支链结构的非均一高聚糖,纤维素由D-葡萄糖基通过糖苷键连接聚合而成的多糖,这2种成分结构相对简单,易被细菌利用,而木质素含多种芳香环类物质,结构复杂多样,对微生物腐蚀具有较强抗性,不易被降解利用[22]。

表2 水稻秸秆木质纤维素变化

对水稻秸秆原料、堆沤预处理后和发酵后秸秆进行电镜扫描,结果如图2所示。

图2 水稻秸秆木质纤维素变化电镜图(×1000)

由图2a可以看出,水稻秸秆原料未经过任何处理,秸秆表面光滑平整、结构规整致密;堆沤后秸秆蜡质层遭到部分破坏,表面变得粗糙、致密结构被破坏,变得疏松(图2b);由图2c看出,发酵后水稻秸秆蜡质层被完全破坏,内部纤维结构也被破坏,出现很多的断层,比堆沤预处理后水稻秸秆破坏的更彻底[19]。说明堆沤预处理破坏了水稻秸秆阻碍微生物腐蚀的蜡质层和致密的纤维结构,为厌氧微生物创造利用秸秆内部纤维类有机物的条件,使后续发酵试验快速进入产气阶段[23]。

2.2 产气效果分析

试验共运行55 d,产气效果如图3a~3c所示。从图3a中看出,甲烷体积分数先迅速上升至30%,稍微波动后达到50%,并逐渐上升,第31天达到最大59.22%,随后在55%左右波动。由图3b可知,日产气量在第4天达到最大产量2.33 m3,下降后在第18天达到第2峰值1.7 m3,之后逐渐下降。整个试验累积产气量为308.20 m3/t,累积产甲烷量为167.44 m3/t(图3c)。

甲烷体积分数和日产气量是厌氧消化过程运行中的重要参数[24]。此试验甲烷体积分数较高且日产气量迅速达到产气高峰,说明厌氧消化过程良好运行。水稻原料经预处理后,秸秆完整、致密结构变疏松,其纤维中的碳水化合物迅速转化为单糖类物质,易被厌氧消化菌及产甲烷菌利用,快速产生沼气且甲烷体积分数较 高[2,4,16,24]。实际沼气工程应用中,为保证优质接种活性污泥和工程稳定运行,需花费大量时间培养驯化接种物,导致工程启动时间较长[25]。而此试验对接种物要求低,仅需预处理原料,就能快速启动、到达产气高峰,具有较强的实际应用价值。

图3 水稻秸秆序批式干发酵特性

2.3 发酵过程中pH值、氨氮质量浓度和总挥发性脂肪酸浓度的变化

发酵过程中的pH值、氨氮质量浓度和总挥发性有机酸浓度变化如图3d~3f所示。发酵过程的pH值变化如图3d,由图3d可看出 pH值呈现出先下降后上升再稳定的变化。在第10天下降至最低6.52,之后逐渐上升,最后在7.0左右波动。毕少杰等[26]的研究表明,厌氧消化反应过程pH值在6.5~8.5范围内是正常的,因为产酸菌生长的最适pH值为5.5~8.5,产甲烷菌生长的最适pH值为6.5~7.5。试验pH值在6.52~7.54范围内波动,这与厌氧消化过程中微生物的最适pH值相一致,在此状态下微生物状态较好[27]。

氨氮质量浓度一直处于波动的变化,变化范围为0.92~1.76 g/L(图3e)。虽然波动变化大,但可以看出氨氮质量浓度开始在1.2 g/L左右波动,第10天开始上升,升到最大值1.76 g/L后再下降,最终在1.2 g/L左右波动。Wiegant[28]和曹先艳等[29]认为氨氮质量浓度在6 g/L以下,不会出现氨抑制。试验的氨氮浓度远低于此阈值,属正常范围,未形成氨抑制。

图3f为总挥发性有机酸含量变化图。试验初期总挥发性有机酸含量迅速上升,第3天出现最大峰值6.43 g/L,再逐渐下降,第45天后基本没有挥发性有机酸。任南琪[30]的研究表明,厌氧消化反应酸化阶段产生总挥发性有机酸质量浓度大于4.5 g/L时,会造成pH值降低,形成酸性环境,抑制产甲烷菌活性,反应过程易崩溃。试验中总挥发性有机酸酸质量浓度最高超过4.5 g/L,但迅速降至4.5 g/L以下,时间较短,未造成酸抑制[23]。

pH值、氨氮质量浓度和总挥发性有机酸是厌氧消化过程中重要参数,相互之间有着密切联系[29]。试验初期,总挥发性有机酸迅速累积,反应体系的pH值逐渐下降,直至最低点;反应继续进行,氨氮质量浓度上升,改变酸性环境,反应体系pH值上升,并逐渐保持稳定。这是因为试验初期,有机物快速分解,迅速产生大量挥发性有机酸并逐渐累积,影响反应体系的pH值,而体系中存在一定浓度氨氮,能提供弱碱性环境,增强体系缓冲能力,避免反应崩溃[31-32]。结果表明试验日产气量规律,pH值、氨氮质量浓度适合微生物生长,总挥发性脂肪酸超过4.5 g/L,但快速下降,说明试验稳定运行。

2.4 动力学分析

厌氧消化过程中,一定程度上甲烷产量与微生物生长呈函数关系。Wang等[24]用修正Gompertz方程对秸秆、猪粪原料单发酵和共发酵的产沼气动力学进行了分析。王渝昆等[33]采用修正Gompertz方程对接种产甲烷复合菌剂试验组和接种活性污泥试验组进行动力学分析。本试验采用修正Gompertz方程模拟和分析水稻秸秆厌氧消化产沼气动力学过程。试验累积产甲烷量拟合结果如图4所示。

图4 水稻秸秆厌氧消化试验累积产甲烷曲线

从图4可以看出,试验结果拟合最终产甲烷量为170.6 L/kg。与以前所报道的相比,最终产甲烷量偏低[4]。其原因可能是水稻秸秆经过堆沤预处理后,好氧微生物降解和利用部分有机质,原料损失,水解微生物和产甲烷菌利用的有机质减少,产甲烷少[34]。秸秆厌氧消化依赖厌氧微生物中的纤维素降解菌,其产生酶类物质降解纤维结构,释放小分子有机物,促进后续甲烷发酵,但此过程缓慢,需较长时间进行[35]。试验55 d后仍产少量沼气,试验还未运行完成,拟合出的最终产甲烷量偏低。试验结果拟合的最大产甲烷速率为6.1 L/(kg·d),延滞期为8.0 d。预处理后,水稻秸秆结构被破坏,易利用的有机物质暴露出来,被产氢产酸菌降解利用,而此时甲烷菌活性不高,产生沼气主要为CO2、H2S等气体,之后产甲烷菌利用有机酸和氢等物质产生甲烷[35]。修正Gompertz方程模拟结果表明,预处理会损失部分原料,使甲烷最终产量降低,但其能缩短产沼气进程,显著提高厌氧消化产沼气效率,具有一定实际应用价值。

3 结 论

1)试验运行55 d,原料累积产气量为308.20 m3/t,累积产甲烷量为167.44 m3/t,最高甲烷体积分数达57.88%;反应过程pH值和氨氮质量浓度波动小,沼气中甲烷体积分数高,此试验运行良好。

2)试验结果通过修正 Gompertz 方程拟合,进行动力学分析,得到试验最终产甲烷量为170.6 L/kg,最大产甲烷速率为6.1 L/(kg·d),延滞期为8.0 d。预处理会损失部分原料,降低最终甲烷产量,但其能促进厌氧消化进程,提高产沼气效率。

[1] 李想,赵立欣,韩捷,等. 农业废弃物资源化利用新方向—沼气干发酵技术[J]. 中国沼气,2006,24(4):23-27. Li Xiang, Zhao Lixin, Han Jie, et al. New direction of agricultural waste resource utilization-biogas dry fermentation technology[J]. China Biogas, 2006, 24(4): 23-27.

[2] 张崇尚,刘乐,陆岐楠,等. 中国秸秆能源化利用潜力与秸秆能源企业区域布局研究[J]. 资源科学,2017,39(3): 473-481. Zhang Chongshang, Liu Le, Lu Qinan, et al. Research on China's straw energy utilization potential and regional distribution of straw energy enterprises[J]. Resources Science, 2017, 39(3): 473-481. (in Chinese with English abstract)

[3] Cui M M, Jiang L L, Yan T W. Potential evaluation and market assessment on crop straw resource utilization based on resource density[J]. Journal of China Agricultural University, 2016, 21(6): 117-131.

[4] Liew L N, Shi J, Li Y. Methane production from solid-state anaerobic digestion of lignocellulosic biomass[J]. Biomass and Bioenergy, 2012(46): 125-132.

[5] Hu H X, Ma Y H, Wang Y F, et al. Resource utilization of returned rapeseed straw and its effect on soil fertility and crop yields[J]. Nature Environment & Pollution Technology, 2013, 12(3): 449-454.

[6] Frigon J C, GuioT S R. Biomethane production from starch and lignocellulosic crops: A comparative review[J]. Biofuels, Bioproducts and Biorefining, 2010, 4(4): 447-458.

[7] Feijoo G, Soto M, Méndez R, et al. Sodium inhibition in the anaerobic digestion process: Antagonism and adaptation phenomena[J]. Enzyme & Microbial Technology, 1995, 17(2): 180-188.

[8] Yong Z, Dong Y, Zhang X, et al. Anaerobic co-digestion of food waste and straw for biogas production[J]. Renewable Energy, 2015(78): 527-530.

[9] Li W, Luo L, Dou Y, et al. Wet and dry coupling anaerobic fermentation process and fermentation characteristic test[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(5): 148-153.

[10] 李强,曲浩丽,承磊,等. 沼气干发酵技术研究进展[J]. 中国沼气,2010,28(5): 10-14. Li Qiang, Qu Haoli, Cheng Lei, et al. Research progress of biogas dry fermentation technology[J]. China Biogas, 2010, 28(5):10-14. (in Chinese with English abstract)

[11] 韩梦龙,朱继英,张国康. 接种物种类对玉米秸秆沼气干发酵过程的影响 [J]. 环境科学学报,2014,34(10): 2586-2591. Han Menglong, Zhu Jiying, Zhang Guokang. Effects of inoculum species on dry fermentation of corn stalk biogas[J]. Chinese Journal of Environmental Science, 2014, 34 (10): 2586-2591. (in Chinese with English abstract)

[12] Mustafa A M, Poulsen T G, Sheng K. Fungal pretreatment of rice straw withandto enhance methane production under solid-state anaerobic digestion [J]. Applied Energy, 2016, 180: 661-671.

[13] Guendouz J, Buffiere P, Cacho J, et al. Dry anaerobic digestion in batch mode: Design and operation of a laboratory-scale, completely mixed reactor[J]. Waste Management, 2010, 30(10): 1768-1771.

[14] 于佳动,赵立欣,冯晶,等. 序批式秸秆牛粪混合厌氧干发酵影响因素研究[J]. 农业工程学报,2018,34(15): 215-221. Yu Jiadong, Zhao Linxin, Feng Jing, et al. Influence factors of batch dry anaerobic digestion for corn stalks-cow dung mixture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(15): 215-221. (in Chinese with English abstract)

[15] 何荣玉,闫志英,刘晓风,等. 秸秆干发酵沼气增产研究 [J]. 应用与环境生物学报,2007(4):583-585. He Rongyu, Yan Zhiying, Liu Xiaofeng, et al. Study on yield increase of straw dry fermentation biogas[J]. Journal of Applied and Environmental Biology, 2007 (4):583-585. (in Chinese with English abstract)

[16] Akyol Ç, Ozbayra M E G, Ince O, et al. Anaerobic co-digestion of cow manure and barley: Effect of cow manure to barley ratio on methane production and digestion stability[J]. Environmental Progress & Sustainable Energy, 2016, 35(2): 589-595.

[17] 朱美华,葛沭锋,王庆刚,等. 用纳氏试剂法测定氨氮时校准曲线的时效性研究[J]. 能源环境保护,2018,32(4):51-54. Zhu Meihua, Ge Shufeng, Wang Qinggang, et al. Timeliness of calibration curve for determination of ammonia nitrogen by Nessler's reagent method[J]. Energy Conservation, 2018, 32(4): 51-54. (in Chinese with English abstract)

[18] 王金主,王元秀,李峰,等. 玉米秸秆中纤维素、半纤维素和木质素的测定[J]. 山东食品发酵,2010(3):44-47. Wang Jinzhu, Wang Yuanxiu, Li Feng, et al. Determination of cellulose, hemicellulose and lignin in corn stover[J]. Shandong Food Fermentation, 2010(3): 44-47. (in Chinese with English abstract)

[19] Yu L, Bule M, Ma J, et al. Enhancing volatile fatty acid (VFA) and bio-methane production from lawn grass with pretreatment[J]. Bioresource Technology, 2014, 162(6): 243-249.

[20] Ward A J, Hobbs P J, Holliman P J, et al. Optimisation of the anaerobic digestion of agricultural resources[J]. Bioresource Technology, 2008, 99(17): 7928-7940.

[21] Siripatana C, Jijai S, Kongjan P. Analysis and extension of Gompertz-type and Monod-type equations for estimation of design parameters from batch anaerobic digestion experiments[C]. Proceedings of the International Conference on Mathematics, Engineering and Industrial Applications, 2016.

[22] 张晓琰,彭学,政井英司. 木质素芳香族化合物降解菌. SYK-6的研究进展[J]. 微生物学报,2014,54(8):854-867. Zhang Xiaoyan, Peng Xue, Zheng Jingyingsi. Research progress of lignin aromatic compound degrading bacteria. SYK-6[J]. Journal of Microbiology, 2014, 54(8): 854-867. (in Chinese with English abstract)

[23] Wan C, Li Y. Fungal pretreatment of lignocellulosic biomass [J]. Biotechnology Advances, 2012, 30(6): 1447-1457.

[24] Wang M, Zhou J, Yuan Y X, et al. Methane production characteristics and microbial community dynamics of mono-digestion and co-digestion using corn stalk and pig manure[J]. International Journal of Hydrogen Energy, 2017, 42(8): 4893-4901.

[25] 孔维涛,胡栋,马福民,等. 低温沼气发酵优良菌系筛选及优势菌群分析[J]. 微生物学通报,2013,40(9):1590-1598.

Kong Weitao, Hu Dong, Ma Fumin, et al. Screening and Dominant population analysis of microbial strains in Biogas fermentation under the low temperature[J]. Microbiology China, 2013, 40(9): 1590-1598. (in Chinese with English abstract)

[26] 毕少杰,孙宇,孙志远,等. 酸化处理对牛粪厌氧发酵有机酸和细菌多样性的影响[J]. 中国沼气,2015,33(4): 18-25.Bi Shaojie, Sun Yu, Sun Zhiyuan, et al. Effects of acidification on anaerobic fermentation of organic acids and bacteria in cattle manure[J]. China Biogas, 2015, 33(4): 18-25. (in Chinese with English abstract)

[27] Luo L N, Li W Z, Dou Y C, et al. Effect of urea pretreatments on solid-state anaerobic digestion of rice straw for improving biogas production[J]. International Agricultural Engineering Journal, 2013, 22(1): 7-13.

[28] Wiegant W M, Zeeman G. The mechanism of ammonia inhibition in the thermophilic digestion of livestock wastes [J]. Agricultural Wastes, 1986, 16(4): 243-253.

[29] 曹先艳,赵由才,袁玉玉,等. 氨氮对餐厨垃圾厌氧发酵产氢的影响[J]. 太阳能学报,2008,29(6):751-755. Cao Xianyang, Zhao Youcai, Yuan Yuyu, et al. Effect of Ammonia nitrogen on hydrogen production by anaerobic fermentation of kitchen waste[J]. Acta Energiae Solaris Sinica, 2008, 29(6): 751-755. (in Chinese with English abstract)

[30] 任南琪. 厌氧生物技术原理与应用[M]. 北京:北京化学工业出版社环境科学与工程出版中心,2004.

[31] Rouches E, Herpoël-gimbert I, Steyer J P, et al. Improvement of anaerobic degradation by white-rot fungi pretreatment of lignocellulosic biomass: A review[J]. Renewable and Sustainable Energy Reviews, 2016(59): 179-198.

[32] Sheng K C, Xiang C, Pan J M, et al. Effect of ammonia and nitrate on biogas production from food waste via anaerobic digestion[J]. Biosystems Engineering, 2013, 116(2): 205-212.

[33] 王渝昆,袁月祥,李东,等. 产甲烷复合菌剂的性能评价及中试试验产气效果[J]. 农业工程学报,2014,30(16): 247-255. Wang Yukun, Yuan Yuexiang, Li Dong, et al. Performance of evaluation of methanogenic microbial inoculant and its effect of biogas production in pilot scale test[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(16): 247-255.

[34] Mustafa A M, Poulsen T G, Xia Y, et al. Combinations of fungal and milling pretreatments for enhancing rice straw biogas production during solid-state anaerobic digestion [J]. Bioresource Technology, 2016, 224(174)

[35] Chandra R, Takeuchi H, Hasegawa T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production[J]. Renewable & Sustainable Energy Reviews, 2012, 16(3): 1462-1476.

Pilot plant test of biogas production by rice straw sequencing batch dry anaerobic digestion and its kinetic analysis

Liu Yang1,2,3, Yan Zhiying1,2※, Ji Gaosheng1,2, Xu Lishan1,2, Fang Junnan1,2,3, Zeng Yong1,2, Huan Chenchen1,2, Tong Xinyu1,2

(1,,610041,; 2.,,610041,; 3.,, 100049,)

The organic waste can be converted by anaerobic digestion into a clean energy source of methane under gentleconditions. Dry anaerobic digestion, one kind of anaerobic digestion, was often used to treat municipal waste and had achieved great results for decades in Europe and America. The dry anaerobic digestion of biogas production technology is a better way than wet fermentation to handle rice straw. It has lots of advantages, such as bigger processing capacity, simpler device, lower energy loss and water consumption. However, dry fermentation of straw is very easy to fail due to heterogeneity of substrate, acid inhibition, etc. There were a few researches on the key technology in exploring the AD efficiency of rice straw based agricultural waste. Therefore, this paper studied the biogas production characteristics of pilot-scale dry anaerobic digestion using rice straw as feedstock. The parameters were determined by the laboratory pre-experiment, rice straw was stacked on the field for 3 days with moisture of 67.58% adjusted by 500 kg biogas slurry, rice straw pretreated (269 kg, TS of 89.19%) was mixed with inoculums (300 kg, 28.06%). The pilot-scale dry anaerobic digestion was conducted under the conditions of constant temperature at 30-35 ℃ for 55 days. The result of the pilot-scale experiment showed that the biogas yield of rice straw was 308.20 m3/t, the methane yield of rice straw was 167.44 m3/t, the maximum methane content reached 57.88% after 55 days of dry anaerobic digestion. According to the results of biogas production, the pilot-scale experiment had excellent daily biogas production and higher methane concentration, and the whole process ran stably. The modified Gompertz equation was commonly used to perform kinetic analysis of anaerobic digestion, so the Gompertz model was used to fit the methane production curve of rice straw. The fitted methanogenic potential value was quite close to the actual methanogenic potential value, and2value is 0.990 7, which indicated that the Gompertz model was also suitable for fitting the methane production in this study. Although the pilot-scale test ran successfully, the conditions could be optimized for a better result. The study can provide theoretical guidance and basis for batch dry anaerobic digestion on the treatment of rice straw.

straw; biogas; kinetic; dry anaerobic digestion; degradation

刘 杨,闫志英,姬高升,许力山,房俊楠,曾 勇,宦臣臣,佟欣宇.水稻秸秆序批式干发酵产沼气中试及其动力学研究[J]. 农业工程学报,2018,34(23):221-226. doi:10.11975/j.issn.1002-6819.2018.23.028 http://www.tcsae.org

Liu Yang, Yan Zhiying, Ji Gaosheng, Xu Lishan, Fang Junnan, Zeng Yong, Huan Chenchen, Tong Xinyu. Pilot plant test of biogas production by rice straw sequencing batch dry anaerobic digestion and its kinetic analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(23): 221-226. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.23.028 http://www.tcsae.org

2018-09-27

2018-10-28

国家重点研发计划(2017YFD0800803-02);环境微生物四川省重点实验室开放基金(KLCAS-2017-6)

刘杨,主要从事固体废弃物方向研究。Email:liuyang3@cib.ac.cn

闫志英,博士,研究员,主要从事生物质废弃物生物转化与资源化利用研究。Email:yanzy@cib.ac.cn

10.11975/j.issn.1002-6819.2018.23.028

X705

A

1002-6819(2018)-23-0221-06