植物工厂水蓄能型地下水源热泵供热系统节能运行特性研究

石惠娴,任亦可,孟祥真,陈慧子,欧阳三川,周 强

植物工厂水蓄能型地下水源热泵供热系统节能运行特性研究

石惠娴,任亦可,孟祥真,陈慧子,欧阳三川,周 强

(同济大学新农村发展研究院国家设施农业工程技术研究中心,上海 200092)

植物工厂供热系统中,采用传统能源存在一次能源利用率低且污染严重的问题。地下水源热泵节能环保,如果结合蓄能技术可进一步降低运行能耗。该文以上海崇明自然光植物工厂为例,对水蓄能型地下水源热泵供能系统进行节能运行特性研究。结果表明:水蓄能型地下水源热泵供能系统在冬季运行时,采用基于分时电价政策的间歇运行模式,即在电价低谷时,热泵机组边供热边蓄热;在电价高峰期,充分利用蓄热水箱供热。典型周内供能系统按照间歇模式运行可以维持室内温度17~26℃之间,系统稳定运行时,热泵机组制热功率与耗电功率的比值(coefficient of performance,COP)稳定在4.2左右。其中计算典型日水蓄能型地下水源热泵系统比不蓄能系统节省30.34%的费用,供能系统COP为3.17,进一步说明系统较为高效平稳。系统冬季运行一次能源利用系数0.99,相对于冷水机组与燃煤锅炉配套系统,节能率达到81.05%。计算不同能源冬季加热成本,燃煤、燃气和燃油方式分别是该系统运行成本的1.25、2.93和5.08倍。实践表明,水蓄能型地下水源热泵式供热系统不仅能够移峰填谷,降低运行费用,而且充分合理地利用地热能,节能减排,具有良好的经济和环保效益。

热能;泵;节能;自然光植物工厂;地下水源热泵;水蓄能;供热系统

0 引 言

地下水源热泵系统高效稳定、节能环保。与空气源热泵相比,以地下水作为冷热源,全年温度相对稳定,冬季比环境温度高,夏季比环境温度低,且冬季不存在结霜问题,运行稳定性好;与土壤源热泵相比,地下水源热泵的初投资较低,不需要敷设埋管而占据很大的土地资源,运行费用较低;与地表水源热泵相比,系统更为高效,地表水温度受气候影响较大,而且水质不好时换热器易结垢。所以在政策和地下水水质开发技术允许的情况下,可利用地下水源热泵系统对植物工厂供能。

地下水源热泵技术在植物工厂领域的应用研究比较广泛。主要集中在系统设计[1-2]、系统性能[3-6]和技术经济可行性[7-12],系统运行效果[13-15]、系统热力学分析[16-17]和结合作物产量系统评价[18]以及控制系统研究[19-20]几个方面。其中有研究者尝试各种蓄能型地源热泵应用于植物工厂中的运行特性[21-25]。左睿等[26]在常州15 000 m2的植物工厂中采用地源热泵供热进行经济性能分析,结果表明,地源热泵能耗仅为传统供热方式的20%~30%,采用地下蓄能装置可使其费用相对又降低40%~50%,直接能耗费用只有传统的10%~20%。Edward Foulds等[27]研究与光伏板和土壤储能系统结合的地源热泵机组,利用数学模型研究能源系统的运行特性;Emanuele Bonamente等[28]分别以水和相变材料为储热材料对原地源热泵蓄能系统进行优化,优化设计后系统性能系数可提高20%;Hüseyin Benli[29]设计了一个具有潜热储热水箱的地源热泵供热系统为玻璃温室加热,并研究了其热储能性能。

以上关于蓄能式地源热泵的研究主要集中在储能方式的改进,而对植物工厂蓄能式地源热泵供热系统运行研究较少[30-34],因此,本文将地下水式地源热泵技术和水蓄能技术结合,以上海崇明自然光植物工厂为例,进行水蓄能型地下水源热泵式供热系统节能运行特性研究。

1 植物工厂水蓄能型地下水源热泵式供热系统

上海市崇明国家设施农业工程技术研究中心共有面积为21 000 m2的大型自然光植物工厂,分为A、B、C三区,如图1所示。A区的7小栋植物工厂采用水蓄能型地下水源热泵空调系统,面积5 880 m2,每1小栋植物工厂长35 m,宽24 m,共6跨,每跨4 m,肩高6.5 m,顶高7.5 m,外围护结构为单层浮法玻璃,厚5 mm,以金属框架支撑。水蓄能型地下水源热泵系统冬季典型运行流程如图2所示。

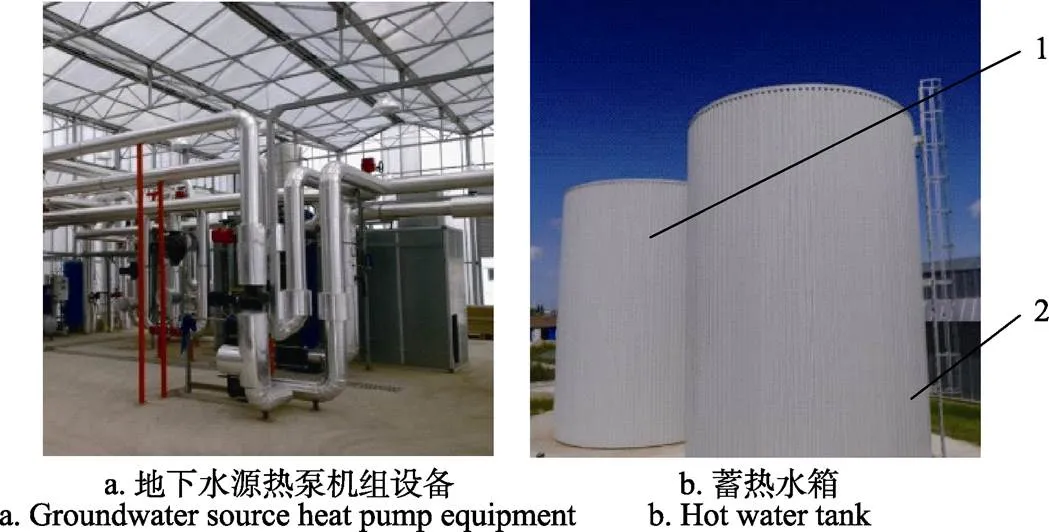

图2为冬季热泵机组和储热罐联合供热工况下系统运行流程图,图中箭头表示工质的流向。图2中,植物工厂水蓄能型地下水源热泵式供热系统包括地下水换热系统、热泵机组、空气处理机组和蓄能系统,根据该系统产能和需能的匹配和当地电价峰谷时段通过阀门控制,确定系统有5种运行模式。当处于电价低谷段并且热泵机组制热(冷)量大于植物工厂所需负荷时,采用机组边储热(冷)边供热(冷)模式;当热泵机组制热(冷)量和蓄热(冷)水箱可供热(冷)量均小于植物工厂所需负荷时,采用蓄热(冷)水箱和机组供热(冷)模式;当处于电价高峰值时段,采用蓄热(冷)水箱供热(冷)模式;当热泵机组停止运行时,采用冷水井储冷模式;夏季,当冷水井地下水温度小于12 ℃时,采用冷水井直供冷模式。供能设备主要采用地下水源热泵和蓄能罐,如图3所示。

图1 自然光植物工厂外观图

注:箭头表示工质的流向。

1. 400 m3蓄热水箱2. 600 m3蓄冷水箱

2 植物工厂水蓄能型地下水源热泵式供热系统基本运行特性

至2018年4月,位于上海市崇明国家设施农业工程技术研究中心的自然光植物工厂,已成功运行5个冬天。本文只针对系统冬季供热特性进行研究,因此选取2017年冬季2月8日-15日典型周运行数据进行分析。

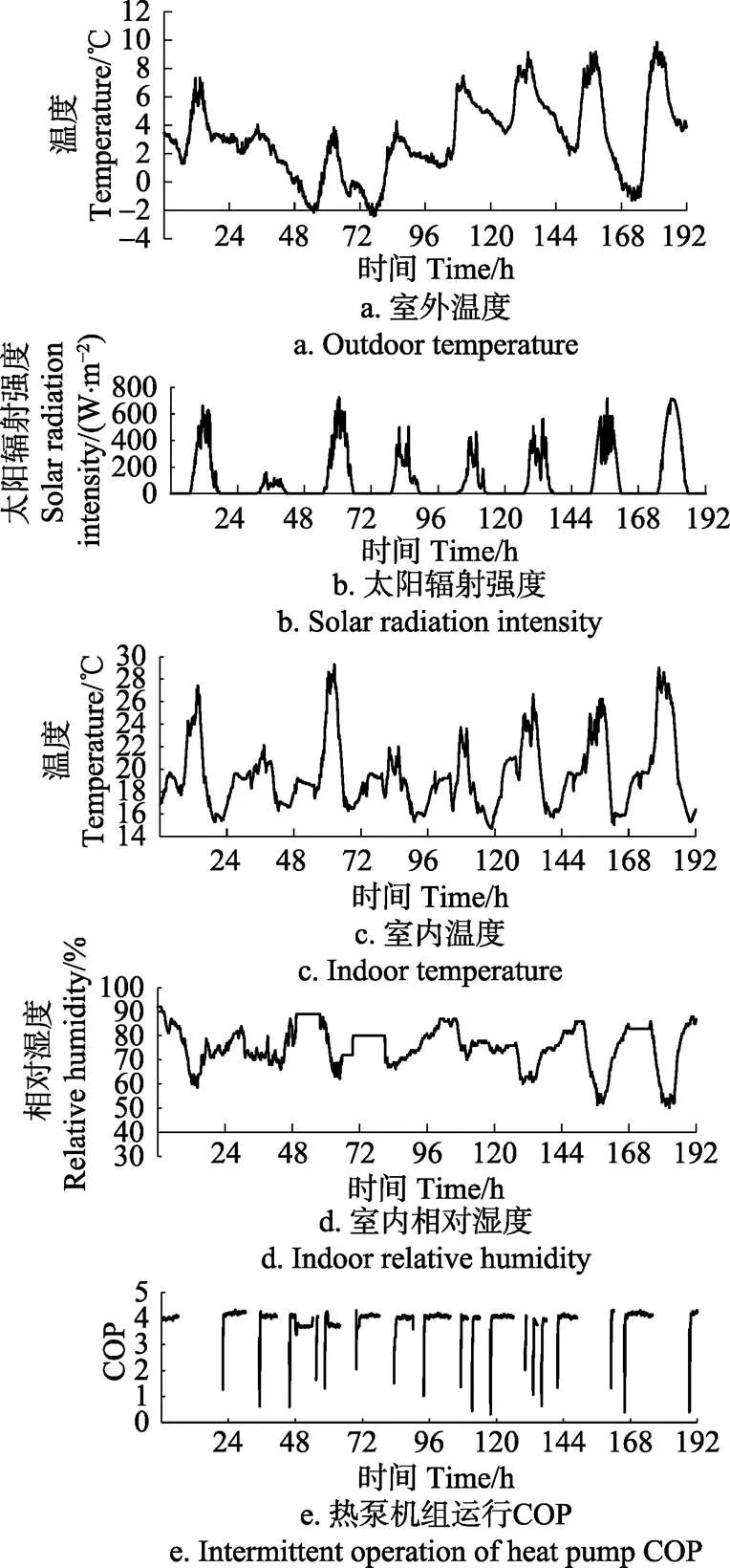

由植物工厂自动监控系统测量分别获得室外温度、太阳辐射强度、植物工厂内温度、相对湿度以及热泵机组制热功率与耗电功率的比值(coefficient of performance,COP)。2月8日-15日各参数变化如图4所示,横坐标0时表示2月8日0时。

注:横坐标0时表示2月8日0时; COP:制热功率与耗电功率的比值。

如图4c所示,利用水蓄能型地下水源热泵空调系统为植物工厂加温,可以将室内温度较好的维持在17~26 ℃之间,图上太阳辐射强度为0的时段即为夜间,与室内温度低谷段对应,温度相对较低,但能够满足作物在夜间的生长需求;白天受到太阳辐射影响,室内温度基本都在22 ℃以上,甚至能达到28 ℃。由图4d可知,室内相对湿度基本在60%~88%之间,能够避免室内高温高湿现象。由图4e可知,在系统稳定运行时,热泵机组COP在4.2上下浮动,运行较为高效平稳。

3 植物工厂水蓄能型地下水源热泵供热系统间歇节能运行特性分析

3.1 基于分时电价政策的系统间歇运行模式

选用系统正式运行期间具有代表性的2017年2月9日对试验系统进行具体分析。室外温度和太阳辐射强度如图5所示,从图5中可以看出,当日天气阴,全天 气温在4 ℃以下;太阳辐射强度在0~160 W/m2,平均 太阳辐射强度为62 W/m2。上海各时段电价分别为低谷段0.364元/(kW·h),平价段0.752元/(kW·h),高峰段1.222元/(kW·h)。根据上海市分时电价政策,抽水泵与热泵机组的启停状态及热泵系统运行模式如表1所示。

图5 2017年2月9日室外环境参数变化图

从表1可知,系统运行模式基本为:在电力低谷时刻,热泵机组全开,边供热边储热,在电力高峰时刻,热泵机组停开,利用蓄热水箱供热,在用电平段时刻,根据蓄热水箱储能量和植物工厂负荷需求进行合理调控。

3.2 冬季典型日系统间歇运行特性及热性能系数

基于分时电价政策的植物工厂水蓄能型地下水源热泵供能系统制热性能系数(COPsys)计算如公式(1)所示。

式中为系统供热量,kJ;comp为压缩机输入功率,kW;pumps为各水泵的输入功率之和,kW;f为空气处理机组风机的输入功率,kW;1、2、3分别为压缩机、水泵和空气处理机组风机的运行时间,s。

植物工厂得热量为太阳辐射和人工加热,散热量为贯流放热量、空气交换散热量、土壤导热量,考虑作物蒸腾作用、土壤蓄热作用等影响因素[35],通过热负荷计算得到系统2017年2月9日全天供热量为32 185.8 MJ;得到热泵机组运行13.92 h耗电量为8 024.65 MJ;得到空气处理机组的全天耗电量1 075.77 MJ;潜水泵运行5.67 h,耗电量为489.89 MJ,水源侧循环水泵运行13.92 h,耗电量为160.36 MJ,储热泵运行13.75 h,耗电量为59.4 MJ,用户侧循环水泵运行24 h,耗电量为332.64 MJ,水泵耗电量共为1 042.29 MJ,系统全天总耗电量为10 142.71 MJ,得到该系统COP(全天供热量与耗电量比值)为3.17,表明水蓄能型地下水源热泵式植物工厂空调系统运行高效稳定。

3.3 与不采用蓄能装置的地下水源热泵系统典型日运行费用比较

上海电力高峰时段电价1.222元/(kW·h),平段电价0.752元/(kW·h),低谷时段电价0.364元/(kW·h),根据2017年2月9日运行模式和分时电价计算全天系统运行费用,结果见表2。

表2 水蓄能型地下水源热泵供能系统2017年2月9日运行费用

将A试验系统与B不采用蓄能装置的地下水源热泵空调系统运行费用进行比较:

蓄热水箱的能量变化计算公式为=cmD,计算全天蓄能量时,D为蓄热水箱0时与全天最高温度的温度差;计算全天供能量时,D为最高温度与24时的温度差,得到蓄热水箱全天蓄能量为14 313.76 MJ,全天供能量为17 046.10 MJ。A系统蓄热水箱全天蓄能量为B系统热泵机组减少产热的部分,则热泵机组在原储热阶段减少产热14 313.76 MJ,平均少耗电3 408.04 MJ,即946.68 kW·h,各电价期减少运行费用总和为502.74 元;A系统的蓄热水箱全天供能量为B系统热泵机组增加产热的部分,则热泵机组在原蓄热水箱供热阶段多产热17 046.10 MJ,平均多耗电4 058.60 MJ,即1 127.39 kW·h,各电价期增加运行费用总和为1 163.20元;各水泵运行时间为24 h,水泵运行费用为217.72元。则不采用蓄能装置的地下水源热泵空调系统共增加运行费用689.85 元,全天总计为2 273.74 元。

以2017年2月9日为代表,水蓄能型地下水源热泵空调系统与不采用蓄能装置的地下水源热泵空调系统运行费用降低了689.85元,节省了约30.34%的费用,经济效益显著。

4 植物工厂水蓄能型地下水源热泵供热系统周年运行的节能、经济和环保效益

4.1 植物工厂水蓄能型地下水源热泵供热系统年运行节能特性

将系统与可能适合的冷水机组与燃煤锅炉配套和冷水机组与燃气锅炉配套2个方案进行冬季运行节能性分析和比较,进一步探讨水蓄能型地下水源热泵式空调系统的优越性。

1)系统一次能源消耗

式中¢为系统实际功耗,kJ;1为发电效率,2为输配电效率,本文根据中国现有发电和输配电平均水平进行估算,1、2分别取35%和90%。

2)一次能源利用系数

供热季节,不论何种加温方式均消耗一次能源,用能源利用系数来反映不同加温方式的能量转化效率具有可比性。计算公式如下

3)节能率

节能率又称系统一次能耗节能率,根据要比较的2种系统的一次能耗,以另一种系统的一次能耗为基础,可以算出节能率E

式中1为水蓄能型地下水源热泵空调系统一次能耗,kJ;2为待比较系统的一次能耗,kJ。

通过上述计算公式,分别计算3种不同供能方式一年内的一次能源消耗、一次能源利用系数和节能率,计算结果见表3。

表3 系统节能性分析(年)

从表3可以看出,水蓄能型地下水源热泵空调系统一次能源利用系数0.99,相对于冷水机组与燃煤锅炉配套系统和冷水机组与燃气锅炉配套系统的节能率分别为81.05%和74.83%。

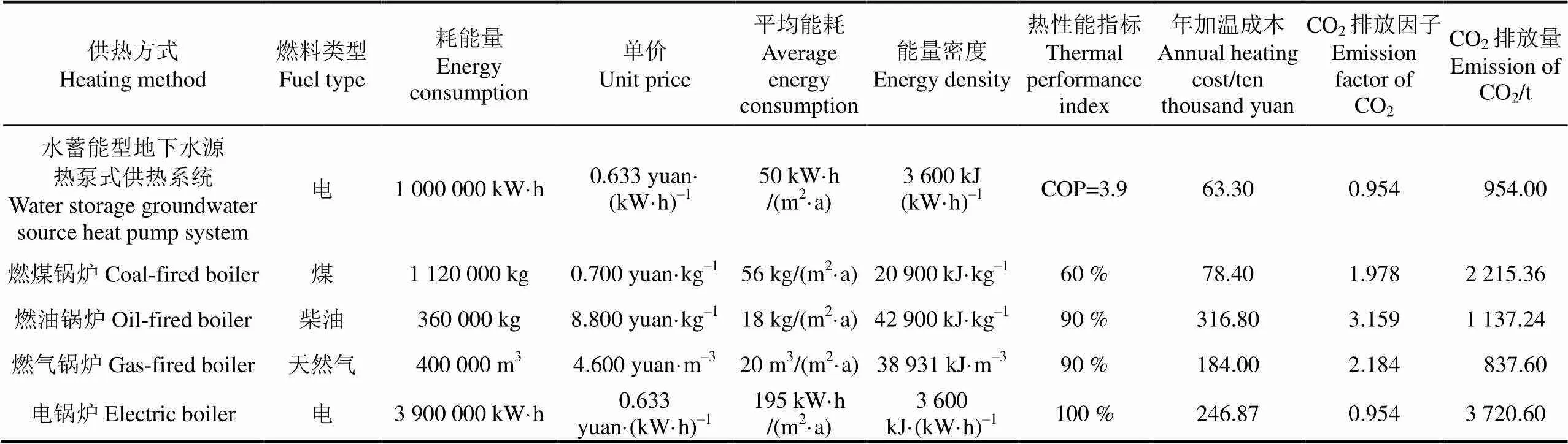

4.2 与传统供热方式比较加温期系统运行能耗、CO2排放量和成本

为进一步研究水蓄能型地下水源热泵供热系统运行能耗优势,以崇明21 000 m2自然光植物工程工厂为例,分别采用水源热泵、燃煤、柴油、天然气和电锅炉的方式为植物工厂供热,维持加温期持续运行,从加温期运行成本和CO2排放量进行对比分析;经运行统计,加热耗电量195 kW·h/(m2·a)。不同供热方式的运行能耗、成本与CO2排放量计算结果见表4。

与水蓄能型地下水源热泵系统相比,冬季以燃煤(700元/t)、燃气(4.6元/m3)、燃油(8.8元/kg)方式为植物工厂加热的成本分别是水蓄能型地下水源热泵系统的1.25倍、2.93倍、5.08倍,而CO2排放量分别是水蓄能型地下水源热泵系统2.32、1.19、0.88倍。

表4 崇明自然光植物工厂加温期不同供热方式的运行能耗、成本与CO2排放量

5 结 论

本文研究对象水蓄能型地下水源热泵式供能系统,为植物工厂加温的实际运行稳定,具有良好的经济和环保效益。

1)冬季利用水蓄能型地下水源热泵式供热系统加温可以维持室内温度在17~26 ℃之间,白天受太阳辐射影响,甚至可以达到28 ℃;系统稳定运行时,热泵机组全天供热量与耗电量比值在4.2左右,说明系统运行高效平稳。

2)系统连续运行阶段,在电价低谷时,热泵机组边供热边蓄热,在电价高峰期,充分利用蓄热水箱供热,在电价平端时,根据蓄能水箱蓄能量和植物工厂负荷调控。水蓄能型地下水源热泵式供热系统典型日全天供热量与耗电量比值为3.17;系统比不蓄能地下水源热泵系统可以节省30.34%的费用。说明此系统可以移峰填谷,避免电价高峰期高负荷运行,大大降低运行费用。

3)水蓄能型地下水源热泵式供热系统一次能源利用系数0.99,相对于燃煤锅炉系统和燃气锅炉系统,节能率分别为81.05%和74.83%;计算不同能源冬季加热成本和CO2排放量,燃煤、燃气和燃油的运行成本分别是该系统的1.25、2.93和5.08倍,CO2排放量分别是该系统的2.32、1.19、0.88倍,说明该系统具有很好的节能减排效益。

[1] 曲云霞,张林华,方肇洪,等. 地下水源热泵及其设计方法[J]. 可再生能源,2002(6):11-14. Qu Yunxia, Zhang Linhua, Fang Zhaohong, et al. The study and design on ground water heat pumps[J]. Renewable Energy Resouce, 2002(6): 11-14. (in Chinese with English abstract)

[2] 王吉庆. 水源热泵调温温室研制及试验研究[D]. 郑州:河南农业大学,2003.

Wang Jiqing. Development and Experimental Study of Water Source Heat Pump Temperature Control Greenhouse[D]. Zhengzhou: Henan Agricultural University, 2003.

[3] Van Ooteghem R J C. Optimal Control Design for a Solar Greenhouse[D]. Wageningen:Wageningen University, 2007.

[4] Chai L, Ma C, Ni J. Performance evaluation of ground source heat pump system for greenhouse heating in northern China[J]. Biosystems Engineering, 2012, 111(1): 107-117.

[5] 王吉庆,张百良. 水源热泵在温室加温中的应用研究[J]. 中国农学通报,2005,21(6):415-419. Wang Jiqing, Zhang Bailiang. Experiment of water heat pump in greenhouse heating[J]. Chinese Agricultural Science Bulletin, 2005, 21(6): 415-419. (in Chinese with English abstract)

[6] Andrew Chiasson, Design P E. Installation of a new down hole heat exchanger for direct use space heating[R]. Ghc Bulletin, 2005: 20-24.

[7] 方慧,杨其长,王柟,等. 浅层地热源节能技术及其在设施农业中的应用[J]. 农业工程学报,2008,24(10):286-290. Fang Hui, Yang Qichang, Wang Nan, et al. Geothermal technology and its applications in protected agriculture[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2008,24(10): 286-290. (in Chinese with English abstract)

[8] 田丰果,贺荣,孙铁方,等. 水源热泵在温室大棚温度调节中的应用[J]. 北方园艺,2008(12):91-93. Tian Fengguo, He Rong, Sun Tiefang, et al. Water source heat pump applied to thermoregulation of greenhouse[J]. Northern Horticulture, 2008(12): 91-93. (in Chinese with English abstract)

[9] 方慧,杨其长,孙骥. 地源热泵—地板散热系统在温室冬季供暖中的应用[J]. 农业工程学报,2008,24(12):145-149. Fang Hui, Yang Qichang, Sun Ji. Application of ground-source heat pump and floor heating system to greenhouse heating in winter[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2008, 24(12): 145-149. (in Chinese with English abstract)

[10] 柴立龙,马承伟,张晓蕙,等. 地源热泵温室降温系统的试验研究与性能分析[J]. 农业工程学报,2008,24(12):150-154.Chai Lilong, Ma Chengwei, Zhang Xiaohui, et al. Experimental investigation and performance analysis on ground source heat pump system for greenhouse cooling[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(12): 150-154. (in Chinese with English abstract)

[11] 赵建成,张海涛,安爱明,等. 地下水地源热泵与水蓄能设计实例的经济分析[C]//全国暖通空调制冷2006年学术年会,合肥,2006.

[12] 柴立龙,马承伟,张义,等. 北京地区温室地源热泵供暖能耗及经济性分析[J]. 农业工程学报,2010,26(3):249-254. Chai Lilong, Ma Chengwei, Zhang Yi, et al. Energy consumption and economic analysis of ground source heat pump used in greenhouse in Beijing[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(3): 249-254. (in Chinese with English abstract)

[13] 曹文龙,程希. 水源热泵系统在日光温室中的应用效益分析[J]. 农业科技与装备,2010(4):38-39.

Cao Wenlong, Cheng Xi. Beneficial analysis of the application of water source heat pump in sunlight greenhouse[J]. Agriculturl Science & Technology Equipment, 2010(4): 38-39.

[14] 柴立龙,马承伟,袁小艳,等. 基于Exergy研究的地源热泵降温系统性能分析[J]. 农业机械学报,2009,40(2):146-150. Chai Lilong, Ma Chengwei, Yuan Xiaoyan, et al. Performance analysis on ground source heat pump cooling system based on energy research[J]. Transactions of The Chinese Society for Agricultural Machinery, 2009, 40(2): 146-150. (in Chinese with English abstract)

[15] Mehmet Esen, Tahsin Yuksel. Experimental evaluation of using various renewable energy sources for heating a greenhouse[J]. Energy and Buildings, 2013, 65: 340-351.

[16] 柴立龙,马承伟. 玻璃温室地源热泵供暖性能与碳排放分析[J]. 农业机械学报,2012,43(1): 185-191. Chai Lilong, Ma Chengwei. Performance and carbon emission analysis on glass-covering greenhouse heating with ground source heat pump technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(1): 185-191. (in Chinese with English abstract)

[17] 孙维拓,张义,杨其长,等. 温室主动蓄放热-热泵联合 加温系统热力学分析[J]. 农业工程学报,2014,30(14):179-188. Sun Weituo, Zhang Yi, Yang Qichang, et al. Thermodynamic analysis of active heat storage-release associated with heat pump heating system in greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(14): 179-188. (in Chinese with English abstract)

[18] Bartzanas T, Tchamitchian M, Kittas C. Influence of the heating method on greenhouse microclimate and energy consumption[J]. Biosystems Engineering, 2005, 91(4): 487-499.

[19] 蔡军. 基于CFD的温室水源热泵控制系统研究[D]. 杭州:浙江工业大学,2010. Cai Jun. Research on Water-source Heat Pump Control System of Greenhouse based on CFD[D]. Hangzhou: Zhejiang University of Technology, 2010. (in Chinese with English abstract)

[20] 吴曼玲,陈一飞,李琦,等. 基于灰色预测的温室地源热泵系统温度变频调控及验证[J]. 农业工程学报,2016,32(16):183-187. Wu Manling, Chen Yifei, Li Qi, et al. Frequency transformation and its validation of ground source heat pump system based on grey predicti[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(16): 183-187. (in Chinese with English abstract)

[21] 钱堃,张钦. 结合水蓄能的地源热泵系统经济性分析[J]. 制冷与空调,2013,13(7):96-102. Qian Kun, Zhang Qin. Economic analysis of ground-source heat pump combined with water energy storage system[J]. Refrigeration and Air-donditioning, 2013, 13(7): 96-102. (in Chinese with English abstract)

[22] 李驰,余岳峰. 地源热泵与蓄能系统优化配置的设计[J]. 电力与能源,2011,32(5):413-417. Li Chi, Yu Yuefeng. Design and research on optimum distribution of the system of ground source heat pump and energy storage[J]. Power & Energy, 2011, 32(5): 413-417. (in Chinese with English abstract)

[23] 孙行健,石惠娴,陈慧子,等. 蓄能型地源热泵式植物工厂供能系统[J]. 节能技术,2015,33(2):125-130. Sun Xingjian, Shi Huixian, Chen Huizi, et al. Ground source heat pump with storage system of the plant factory[J]. Energy Conservation Technology, 2015, 33(2): 125-130. (in Chinese with English abstract)

[24] 卢晗. 地源热泵与水蓄能复合系统的研究[D]. 济南:山东建筑大学,2012. Lu Han. Study on Ground-Source Heat Pump Combined with Water Storage Air-Conditioning System[D]. Jinan:Shandong University of Architecture,2012. (in Chinese with English abstract)

[25] 齐月松,岳玉亮,刘天一. 地源热泵结合水蓄能系统应用分析[J]. 暖通空调,2010,40(5):94-97. Qi Yuesong, Yue Yuliang, Liu Yitian. Application analysis of combined ground-source heat pump and water energy srorage systems[J]. Heating Ventilating & Air Conditioning. 2010, 40(5): 94-97. (in Chinese with English abstract)

[26] 左睿,蒋绿林,高伟,等. 地热技术在温室供暖中的应用[J]. 安徽农业科学,2009,37(13):6139-6140. Zuo Rui, Jiang Lülin, Gao Wei, et al. Application of geothermal technology in greenhouse heating[J]. Journal of Anhui Agricultural Sciences,2009, 37(13): 6139-6140. (in Chinese with English abstract)

[27] Edward Foulds, Muditha Abeysekera, Wu Jianzhong. Modelling and analysis of a ground source heat pump combined with a PV-T and earth energy storage system[J]. Energy Procedia, 2017, 142: 886-891.

[28] Emanuele Bonamente, Andrea Aquino, Franco Cotana. A PCM thermal storage for ground-source heat pumps: Simulating the system performance via CFD approach[J]. Energy Procedia, 2016, 101: 1079-1086.

[29] Hüseyin Benli. Energetic performance analysis of a ground-source heat pump system with latent heat storage for a greenhouse heating[J] Energy Conversion and Management, 2011, 52(1): 581-589.

[30] 胡涛,周群,肖仁政,等. 水蓄能地源热泵系统的一种在线优化运行控制[J]. 太阳能学报,2018,39(2):496-503. Hu Tao, Zhou Qun, Xiao Renzheng, et al. An online optimal operation control of ground source heat pump system with water heat storage[J].Acta Energiae Solaris Sinica, 2018, 39(2): 496-503. (in Chinese with English abstract)

[31] 吕艺青,傅允准. 地源热泵系统夏季制冷间歇运行特性实验研究[J]. 太阳能学报,2018,39(2):453-460. Lü Yiqing, Fu Yunzhun. Experimental research of performance for refrigation intermittent operation in summer of GSHP system[J]. Acta Energiae Solaris Sinica, 2018, 39(2): 453-460. (in Chinese with English abstract)

[32] Li Huai, Xu Wei, Yu Zhen, et al. Discussion of a combined solar thermal and ground source heat pump system operation strategy for office heating[J]. Energy and Buildings, 2018, 162: 42-53.

[33] Yang Weibo, Zhang Heng, Liang Xingfu. Experimental performance evaluation and parametric study of a solar-ground source heat pump system operated in heating modes[J]. Energy, 2018, 149: 173-189.

[34] Lü Junxin, Wei Zhang, Zhang Jiaqi. Running and economy performance analysis of ground source heat pump with thermal energy storage devices[J]. Energy and Buildings, 2016, 127: 1108-1116.

[35] 刘振,秦朝葵. 上海地区温室供暖耗气量计算[J]. 城市燃气,2016(10):9-14. Liu Zhen, Qin Chaokui. Gas consumption of greenhouse heating in Shanghai[J]. Chengshi Ranqi, 2016(10): 9-14. (in Chinese with English abstract)

Research on energy-saving operating characteristics of water storage groundwater source heat pump heating system in plant factory

Shi Huixian, Ren Yike, Meng Xiangzhen, Chen Huizi, Ouyang Sanchuan, Zhou Qiang

(,200092,)

The groundwater source heat pump has high efficiency and environmental protection in greenhouse temperature control. The operating energy consumption can be further reduced if the water storage technology were combined. It was researched which energy-saving operating characteristics a water storage groundwater source heat pump heating system has in this study, taking the example of the natural light plant factory in Shanghai. The total area was 21 000 m2, of which the heating area was 5 880 m2. The heating system included a groundwater heat exchange system, a heat pump unit, an air handling unit, and an energy storage system. Considering the change in electricity price and the change in heat load over time, the operating mode of the heating system is intermittent operation. At the time of power trough, the heat pump unit was fully open and energy was stored in the tank while heating. At the peak of power, the heat pump unit was stopped and the system made full use of the hot water tank for heating. At the time of the level section, reasonable regulation was carried out according to the stored energy of the hot water storage tank and the plant heat load demanded. The typical operating week,February 8th to 15th in 2017,was selected from the winter heating months. The operation data of the typical week was recorded and analyzed. The outdoor temperature,the solar radiation intensity,the indoor temperature,the indoor relative humidity and the COP(ratio of heat supply to power consumption) of the heat pump were all tested every 5 minutes on the typical week. The result shows that in winter, the groundwater source heat pump with energy storage tank heating system could better maintain the indoor temperature between 17 and 26 ℃. The indoor temperature was relatively low at night, but it could meet the growth demand of the crop at winter. The influence of solar radiation was large, and the indoor temperature was basically above 22 ℃, and even reached 28 ℃. The indoor relative humidity was always between 60% and 88%, which could avoid indoor high temperature with high humidity. When the system was in stable operation, the heat pump unit COP(coefficient of performance)was about 4.2. The day of February 9th, 2017 was selected from the typical week. On the typical day,it was cloudy and the temperature was below 4 ℃ throughout the day; the solar radiation intensity was 0-160 W/m2and the average solar radiation intensity was 62 W/m2. The total power consumption of the system was 10 142.71 MJ, and the COP of the system was 3.17. It was further explained for the system characteristics of high efficiency and good stability. Compared with non-storage ground source heat pump system,the groundwater source heat pump with water energy storage system saved 30.34% of the cost on the typical day. The significant economic benefit of the test system was showed. During the continuous heating period in winter, for the test heating system, the primary energy utilization coefficient was 0.99. And compared with cold water unit and coal-fired boiler supporting system and chiller and gas boiler supporting system, energy saving rate were respectively 81.05% and 74.83%. Different energy heating costs were compared. For the operating cost, the coal, gas and fuel methods are 1.25, 2.93 and 5.08 times of the test heating system. And for the CO2emission, they were 2.32, 1.19, and 0.88 times of the test heating system. Practice shows that the groundwater source heat pump with water energy storage system has good economic and environmental benefit, which can not only reduce the operating costs, but also make full use of geothermal energy and be beneficial to energy conservation.

thermal energy; pumps; energy saving; natural light plant factory; groundwater source heat pump; water storage; heating system

石惠娴,任亦可,孟祥真,陈慧子,欧阳三川,周 强.植物工厂水蓄能型地下水源热泵供热系统节能运行特性研究[J]. 农业工程学报,2018,34(23):157-163. doi:10.11975/j.issn.1002-6819.2018.23.019 http://www.tcsae.org

Shi Huixian, Ren Yike, Meng Xiangzhen, Chen Huizi, Ouyang Sanchuan, Zhou Qiang. Research on energy-saving operating characteristics of water storage groundwater source heat pump heating system in plant factory[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(23): 157-163. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.23.019 http://www.tcsae.org

2018-06-22

2018-10-05

国家高技术研究发展计划(863计划)项目(2013AA103006-02)

石惠娴,副教授,博士,主要从事农业设施领域可再生能源应用研究。Email:huixian_shi@tongji.edu.cn

10.11975/j.issn.1002-6819.2018.23.019

S215;S625.4

A

1002-6819(2018)-23-0157-07