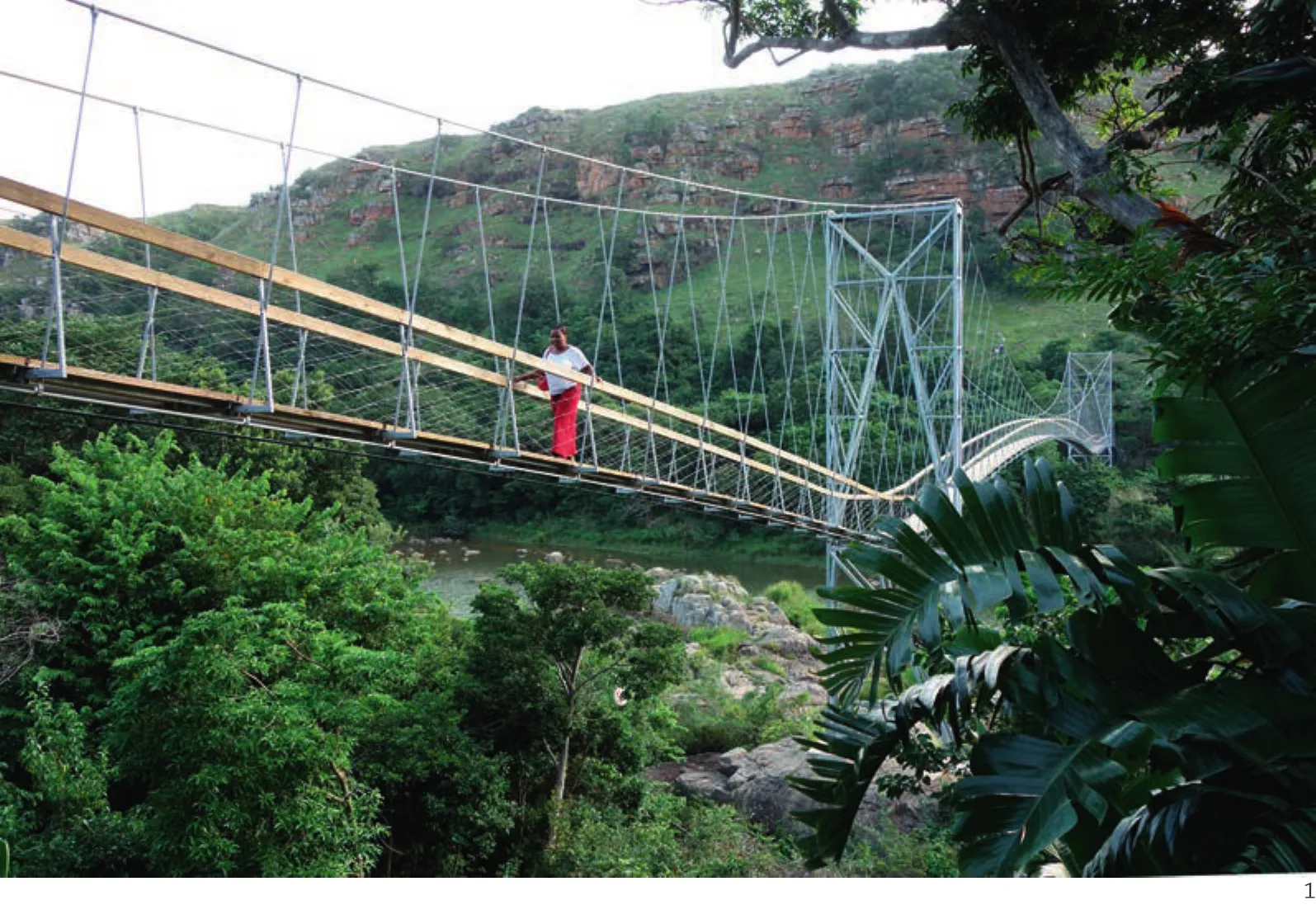

姆扎巴桥,东开普,南非

建筑设计:克恩顿州应用科学大学,集体营造NPO

1 近景/Nearby view

2 远景/Distant views

3 远景/Distant views

背景与介绍

社区项目“姆扎巴桥”用以应对周边居民对于安全渡过姆扎巴河的急迫需求,吊桥长为140m,由各方合力完成设计和实施。

位于南非东开普省的姆扎巴河将流域周边30km范围的居民与他们所需的健康及教育设施、就业机会和日常补给分隔开来。除了缺乏水电等基本设施,当地居民还忍受着腐败和不公平、不公正的社会现实。

在伊苏巴野生海岸学校,与大学及姆扎巴河口地区的居民一起工作的过程中,设计师们得知了孩子溺水的故事、学校食堂厨师的事故以及许多其他类似的事件。建造一座桥梁的想法深深地吸引了他们,设计师们希望它能够成为拯救生命的基础设施,并通过这个项目回答一系列的相关问题,例如如何建立可持续的伙伴关系、如何在极其窘迫的经济和工作条件下进行设计,以及如何在非专业人士主导参与的情况下实施建造。

设计师与各相关方

奥地利非盈利组织“集体营造”和来自克恩顿州应用科学大学的两名正在论文阶段的学生组成了设计团队, 一同进行该项目的设计和规划。代表当地社区的筹备指导委员会和客户一同参与了整个过程,并在必要的时候介入进行协商。部落权威人士的推动、监管委员会和当地各相关方保证了公众的成功参与和项目的可持续性发展。

来自南非和瑞士的工程师(吕辛格博士+迈耶事务所)、环境专家、马比扎纳市政部门和东开普经济发展环境事务和旅游部门的进一步支持和授权使得项目技术上的准确性和一致性得以建立。

通过这种使用者、学生和专家合作的方式,各方的参与者都得益于过程中的知识产出、文化交流、技能提高和责任意识的培养。

设计特点与过程

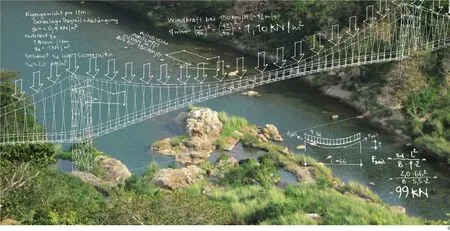

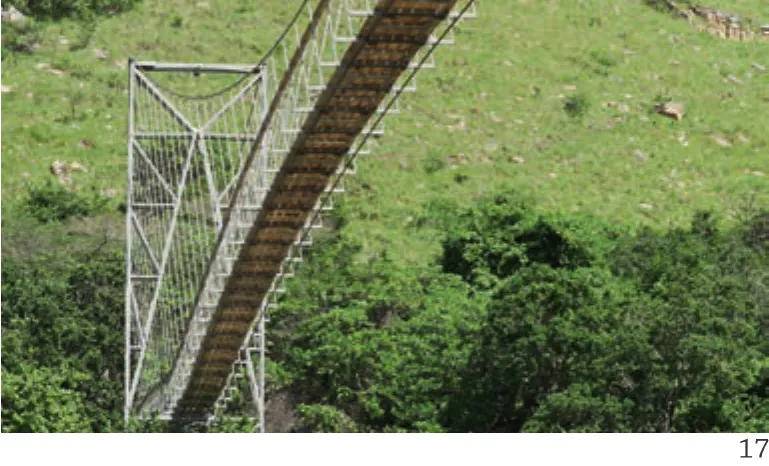

这座桥梁是悬索结构,两个塔架将其分成3个区域。支撑悬索下悬吊着中空的钢支架, 而人行步道位于其上,人行步道以下是稳定悬索。

两个塔架之间的跨度是66m,南边的塔架有15m由河岸的桩柱地基支撑,北边的塔架有13.2m由岩石支撑。174个吊架将133.85m的吊重索与131.9m的拉索相连。吊架与87个锁扣零件相连,承载着混凝土桥塔与钢桥塔之间的96个人行步道构件。

设计开展之前,设计人员就奥地利和南非地区的人行桥做了大量的相关研究。整个过程中,源于场地的信息、数据和会议,以及被反馈到奥地利的各项结果对于设计具有很好的指导作用。桥梁的设计考虑了地形条件、未来的使用需求和当地工程实施的特殊情况。主要考虑的因素有材料的节省、建设场地的难以抵达、社区群众自主建设的过程、维护的低成本、自然景观的适应性、跨度和宽度、风力以及可用性。

(场地选择)桥在姆扎巴河谷的选址保证了塔架的基座和拉索的锚点都能够落在岩石层上。另外,选址也确保了居民能够安全容易地由两岸进入桥梁。

(结构设计)基础设施的匮乏和所在地区的崎岖地形使得桥梁的建设难以使用重型设备。另外,供给运输的设备和单个构件需要在没有昂贵技术支持的情况下也能够实施。因此,在设计的早期,设计团队就决定建造一座轻量、小尺度的钢结构桥梁。

桥梁总体的几何形态是由克恩顿州应用科学大学和来自吕辛格博士+迈耶事务所的工程师们共同确定的,设计出的顶尖结构因此能够应对来自场地的各种新发现。设计团队根据连接构件之间所需的力、地表岩石的不同情况、沼泽和沙土的计算得出了地基的设计。他们还向当地社区演示了桥梁几何形态的3D模型,并获得了人们的认可。

规划桥梁结构的过程中,将跨度和力的大小之间的指数关系与材料的消耗都考虑在内,以此得到了最优的解决方案。根据一种使横向受力最小化的适宜的连接方式确定了塔架的高度。

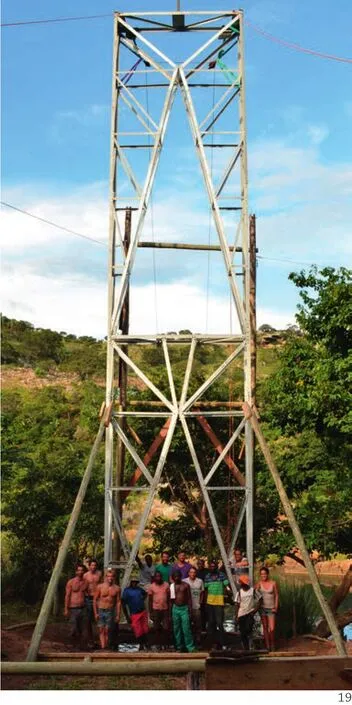

事实上,大部分的施工都是由未经过训练的人员完成的,这个情况也被考虑在了桥梁的规划里:塔架被设计成了可拆解的L型桁架,由简单的螺栓连接。这些部件可以在地面组装并立起,升起的过程由塔架底部的一个连接点支撑。采用预制的钢构件使生产过程不受气候和场地的局限,随后的电镀得以在可控的情况下开展,因此结构能够具有可靠的耐腐蚀性能,而这恰恰是在印度洋沿海区域的构筑物保持长久的重要前提。

从细节上的调整直到工程的结束,来自用户、工程师和建造过程中的反馈对设计起到了重要的指导作用。

Background & introduction

The community-driven project "bridging Mzamba"originated in the urgent need of and request by surrounding inhabitants for a safe crossing of the Mzamba River and included design and implementation of a 140 metres long suspension bridge in a collaborative manner.

Located in Eastern Cape, South Africa, the Mzamba River separates inhabitants in a 30km catchment area from health care, educational facilities to employment opportunity and even daily supplies. Besides lacking access to basic services, electricity or water people suffer from inequality, corruption and injustice.

While working at the grounds of Ithuba Wild Coast School with universities and inhabitants around Mzamba Mouth, the designers heard about the drowning of a child, the accident of school catering chef Mavis Dlamini and many other stories.They are fascinated by the idea to build a bridge and to contribute to a lifesaving infrastructure,questions of sustainable partnerships, design under scarce financial and working condition and the implementation with lay-people directed the process.

4 草图/Sketch(绘制/Drawing: Thomas Harlander, Florian Anzenberger)

Designers & stakeholders

The Austria based NPO build Collective teamed up with two thesis students of the Carinthia University of Applied Science for the design and planning phase. A Steering Committee representing the local community and client guided the process and carried on negotiations with necessary entities. The driving force of tribal authority, ward committee and local stakeholders ensured a successful public participation and sustainable development.

Further support and authorisation could be established in liaison with engineers from South Africa and Switzerland (Dr. Lüchinger+Meyer),environmental experts, the Mbizana Municipality and Eastern Cape Department of Economic Development Environmental Affairs and Tourism to ensure technical accuracy and compliance.

Through this collective approach with users,students and experts, the production of knowledge,cultural exchange, skills development and responsibility is achieved for all participants.

Design features & process

The bridge is a cable structure with two pylons,which divide the building into three fields. The hollow steel brackets on which the walkway rests are suspended from the supporting cables. Below the walkway level are the stabilisation cables.

Span-width between Pylons is 66 metres with the southern Pylon of 15 metres grounded on pile foundation on the river bank and the northern pylon with 13.2 metres is grounded on a rock. 174 hangers connect the 133.85 metres carrying ropes with the two 131.9 metres guy ropes. The hangers are connected to 87 binders which carry 96 walkway-elements between a concrete bridgehead and a steel bridgehead.

Extensive research about pedestrian bridges in Austria and South Africa was followed by a process related design. The design process had been very much guided by the information, data and meetings sourced on site and outcome sent to Austria. The design of the bridge structure took account of the topographical conditions and the needs of future use as well as taking the exceptional conditions of implementation under consideration. Main parametres were the reduction of material, a hardly accessible construction site, self-building process with community members, low maintenance,adaption with the natural landscape and of course span-width and forces of wind and usability.

5 剖面/Section(绘制/Drawing: Thomas Harlander, Florian Anzenberger)

建设过程

建设过程分为4个阶段:在支流上建立临时的通道,开始场地的基础设施搭建,南边塔架地基和桥塔、北边地基、塔架和索道的建设,以及最后一个阶段的吊架和人行步道构件的铺设,参与者应用相关的技能,学习如何运用混凝土、钢、木头和所需的工具。由15位居民和8位志愿者组成的团队密切地合作,并积极地同筹备指导委员会以及工程师们交流,从而保证技能的提升,桥的维护也因这份用心和认同感而受益。

挑战

工程也面临了很多的挑战,南非地区经济资助的渠道、不断变化的情况、因各相关方导致的工期延迟、施工场地难以进入,以及由于政治因素受影响的时间和资金。

(合作中的挑战)正如社区委员会主席所说,“与其他的地方不同,我们的社区没有焚烧汽车和动乱,我们从前并不向政府索求任何东西。我们宁愿向外寻求另外的解决方法,因为我们知道政府没办法为所有人提供服务。我们可以在开始之后再向他们提出提供基础设施的要求。”

由于缺乏政府方面的清晰条例和官方协定,整个工程的开展过程都是以试错为原则的,应对不断的改变的条件和参与者们自主决策的结构。团队用了整整3年的时间才确定欧洲和南非之间的合作关系、寻找经济支持和获得设计的认可,相较之下,实际的建设过程只花了9个月的时间。

(造价的挑战)正如设计师们所说,过程中最大的困难就是建设前后资金的匮乏,这阻碍了各种可能的可持续实践,如让社区参与主导的发展、应用研究结果和超越设计建筑成品本身的设计过程等。

整个工程的造价为200,000欧元,全部由赞助方、捐款和个人捐助负担。自2012年开始,经过多个阶段的商议、筹款、设计和建造,这个杰出的基础设施在2015年的10月得以实现,成为一个由当地社区成员和志愿者们自主建造的项目。

6 桥塔/Pylon(绘制/Drawing: Florian Anzenberger, Thomas Harlander)

影响、反思与评价

如今,姆扎巴桥将流域30km范围内的居民与他们所需的基础设施,如教育和医疗设施、工作岗位和日常的食物补给等联系在了一起。每天有大约100人使用这座桥梁,而在周末和节假日时则会达到更高的使用率。另外,它还成为了当地的地标和有益于社会经济发展的潜在旅游景点。

如何在官方结构薄弱的地区构建合作关系成为“搭建姆扎巴桥”这个杰出项目的主要议题,也使得它成为未来类似项目的有力案例。在政府和私人的领域都不具备实施建设所需基础设施的能力的时候,大学、非盈利性组织和社区需要承担什么样的角色?这个设计的过程中所遇到的各种挑战,经济上的局限、由于沟通和协调所造成的延迟、各相关方对于设计过程和技术指标的利益考量等,都为逐渐形成一个相关的准则提供了依据。

在项目实施的过程中,为了信息交流和项目的诠释,设计团队运用发展了合适的媒介,将每一个参与者都当作专家来对待,照片、图纸和视频都被包括在视觉表现的范围里。通过分析所记录的过程,集体的反思和同合作方一起探索式的反馈,设计师所积累的见解将成为未来项目开始的动机。

只有在一段时间的评估之后,该项目对于归属感和维护方面所采取的策略才能看到效果。在第一个阶段的使用,也就是工程完成的几个月后,团队会获取反馈以及对技术进行调试。对于该项目的社会经济发展影响的评估(能够抵达教育设施的儿童,夜间渡河的可能性等等)所获得的信息和价值都将成为此类共造所需基础设施和空间的案例的最好参照。

设计师们和各相关方的合作,一方面使得这些未来的使用者们学习到了不同的建造技术,另一方面鼓励了对该桥梁进行更加专业的维护。此外,由于居民们在姆扎巴桥梁建设上所付出的努力,他们很强烈地意识到这是“他们”的桥梁。其他类似的增加认同感的策略还有进行相关的展览和放映、阶段性的集体反思和庆祝,以及由全程参与者们组织的盛大的开幕仪式等。

酋长高兴地说“这是第一次筹划指导委员会在项目的实施后还在一起交流和工作!”

社区的成员及建设队伍成员强调了这个基础设施的积极影响:“如今,孩子们能每天上学了!小孩子,老人,每一天!甚至在夜里,你也可以去工作,去诊所。而且,我在这其中还贡献了自己的一份力量!”□(玛琳·瓦格纳 文,张靓秋 译)

(site) The location of the bridge at the Mzamba River Valley was chosen so that the establishment of the pylons and the anchoring of the tension cables could be made in rock formations. Furthermore, the chosen location allows an easy and safe access to the bridge from both sides.

(structure) The lack of infrastructure and the difficult terrain in the area of the proposed river crossing made it impossible to use heavy equipment for bridge construction. Furthermore,supply conveyor and assembly of the individual design elements should be able to take place without expensive technical aids. Therefore, it was decided early in the design process to construct the bridge as a lightweight, small-scale steel structure.

The general geometry of the bridge was developed at the CUAS in collaboration with engineers from Dr. Lüchinger+Meyer for the top structure and adopted in action with new findings on site. Foundations were calculated according to necessary force of connections and the diverse ground conditions of rock, swamp and sandy earth.In 3D Models geometry was developed, presented to the local community and adapted.

When planning the bridge structure the exponential relationship between span and size of forces was considered with material consumption and developed a corresponding optimised solution.The height of the pylons is also enabled by a suitable choice of the stitch minimising horizontal forces.

The fact that the assembly of the structure is made by a majority untrained helper, has been considered in the planning: the pylons were designed as resolved trusses of L-profiles with simple screw connections. These were assembled on the ground and erected and the lifting process was supported by a joint at the pylon foot. Prefabrication of steel components allowed a weather- and siteindependent production and subsequent galvanising under controlled conditions and thus promoted a reliable corrosion protection, which is an important prerequisite for the longevity of the construction in the coastal region near the Indian Ocean.

Continuous feedback from user, engineers and the construction process itself guided the design with fine-tuning of details until completion.

Construction process

In all four construction phases from a temporary access bridge over a tributary, set out and site infrastructure, southern foundation of pylon and bridgehead, northern foundations, pylons and ropes and in a last phase hangers and walkway-elements,participants applied and learned skills working with concrete, steel, wood and necessary tools. A team of fifteen residents and eight volunteers who worked together in close collaboration and informative exchange with the steering committee and engineers enabled skills development, benefit in maintenance through care and identification with the bridge.

Challenges

The challenges of this project range from the source of financial support in South Africa and the continuously changing conditions, delays caused by different stakeholders, the inaccessibility of the site and political instrumentalisation influenced the time framework and funding.

(Collaborations) As Nonhle Mbuthuma,chairperson of the Community Committee points out: "Our community is used to not getting anything from government but in contrast to other places we are not burning cars or riot. We rather reach out and try to find new ways because we know government is not able to provide service for all. We can meet them half way to provide infrastructure."

The process set up was guided by the principles of trial and error, adopted in action to react to changing conditions and self-organised decision-making structures of the participants due to the lack of clear regulations or official protocol from governmental side. It took three years to set up partnerships in Europe and South Africa, find financial support and adopt the design in contrast to only about nine months of actual construction phases.

(Cost) According to the designers, the biggest challenge is the scarcity of funds for pre- and postconstruction phases, hindering possible sustainable implementation through community driven development, applied research and design-practice beyond the architectural product.

Overall project costs of 200,000 Euros have been carried solely by sponsors, donations and personal contribution. In several phases of negotiations,fundraising, design and construction since 2012,this extraordinary infrastructure could be realised in October 2015 as a self-build project of community members and volunteers.

Impacts, reflections & comments

The Mzamba Bridge is now connecting residents of a catchment area of 30km to necessary infrastructure such as educational facilities, health care, jobs and general food supply. About 100 people are using the bridge on a daily basis with higher rhythms around weekends and holidays. Furthermore,it serves as a landmark and potential tourist attraction in the area to enable socio-economic development.

7 运输/Transportation

8 清理现场/Clean site

9 施工中/Under construction

10 施工中/Under construction

11 施工中/Under construction

项目信息/Credits and Data

地点/Location: Mzamba Mouth, Eastern Cape, South Africa, 31o5'44.89"S / 30o9'31.83"E

客户/Client: bridging MZAMBA Community Steering Committee

设计团队/Design Team: Thomas Harlander, Florian Anzenberger, Peter Nigst

项目管理与执行/Project Management and Implementation:build Collective NPO, Elias Rubin, Marlene Wagner

结构工程/Structural Engineers: Dr. Lüchinger + Meyer Bauingenieure AG

顾问/Consultants: Rudi Keudel-Schaffer, Bruce Plumbly,Wolfgang Steiner, Nonhle Mbuthuma, Felicity Swanepoel

主要赞助方/Main Sponsors: Friedrich Bauer, Gunter Weisbrod,Birgit Werner, Bank Austria, Pfeifer Seil und Hebetechnik, GEA,Teufelberger, ATE, Haslinger Stahlbau, HSG, Nuquip, Land Kärnten, Land Salzburg, Land Niederösterreich

支持方/Supporters: Mbizana Local Municipality, Eastern Cape Department of Economic Development, UNESCO

社区指导委员会/Community Steering Committee: Nonhle Mbuthuma, Mashono Dlamini, Nkhulwani Mnyamane,Macube Mathembu, Mavis Dlamini, Thandazile Gampe,Sajini Dlamini, Stera Ndovela, Mdumiseni Dlamini,Madoyisi Dimane, Ntlahla Hlebo, Portia Ogle, Xolani Zindela, Simon Nzimakhwe, Nhindelwa Dlamini

施工团队/Construction Team: Melan Juta, Pakhamini Ngeleka, Siyabonga Khuzwayo, Siyabonga Mxunjini, Aiysha Dlamini, Khona Gampe, Ntombizethu Mnyamana, Ntobeko Dlamini, Zenzile Chiya, Andile Dlamini, Siphiwe Dlamini,Ntomsetu Dlamini, Monde Mdunyelwa, Mjo Bhele, Mbongeni Dlamini, Xolani Mnyamana, Lizwe Dlamini, Yandisa Dlamini,Sithole Dlamini, Mthokozizi Ndlovu, Moses Mbuthuma,Richman Ntuli, David Mbuthuma, Lonwabo Dlamini,

Abraham Ngeleka, Jesko von Jeney, Virginia Clasen, Sebastian Schweinberger, Christoph Jach, Laura Stock, Lukas Hofbauer,Anna Weisbrod, Hadrien Clair, Valentin Kandler, Tobias Lackner, Simon Spenrath, Günther Egger, Reinhard Stundner技术数据/Technical Data: 悬索桥全长140m,跨距塔架66m,塔高15m,4组钢丝绳24mm 直径,总长531.5 m;基础: 38m3混凝土,174 组吊挂扁钢,87组桁架,96 通道组件/suspension bridge total length 140 m, span-width between pylons 66 m, pylon hight 15 m, 4 steelropes 24mm diameter, total 531.5 m, Foundation: 38m3concrete, 174 hangers fl at steel, 87 frames, 96 walkway elements

材料/Materials: 钢,混凝土/Steel, concrete

项目时间/Project Year: 2012 - 2015

摄影/Photos: Marlene Wagner(fig.1,7,8,10,14), Hadrien Clair(fig.2,3,16-18), Florian Anzenberger(fig.9), Anna Weisbrod(fig.11,13,19), Thomas Harlander(fig.15)

12 步道/Walkway(绘制/Drawing: Thomas Harlander, Florian Anzenberger)

13 步道实景/Views of walkway

14 步道实景/Views of walkway

15 远景/Distant view

评论

周政旭:这座吊桥凝聚的是来自奥地利、瑞士、南非等多国人士以及当地居民的期望、协作与长达4年的行动。与当地居民的需求相比,形式显得并不那么重要,与此同时跨度却成为首要考虑的问题。学生、工程师联手设计了这一轻盈的桥梁结构,并特意采取可由非熟练工人简单装配、适应度高的装配方式,将社区充分地动员到桥梁的建设当中。值得一提的是,钢结构在耐久性、抗风险性等方面具有优势,这也有利于吊桥持久地为该地居民提供便利。

李烨:所谓公益项目,往往是用较少的资金来引动更多的资源,形成有公共意义的结果。从这个角度看,本项目无疑是成功的。而对于本项目的设计层面,恰恰也符合这样的评判标准。

我们看到桥体的构件,如桥墩、拉索、踏板等,被分解为若干可以通过人工进行简单建造的部分,降低造价的同时,简化施工过程中的工程量、增加当地居民的参与度。桥体构件大量采用的扁钢,在尺度上与周围树林的环境产生微妙的契合;桥身漆成的浅灰色,与周边裸露的岩石相呼应;桥体的弧线步行者提供了有趣的过桥体验。

The main issue arising out of this extraordinary project, bridging Mzamba, is its potency as a case study providing a base for future partnership in areas weak for formal structure. What is the role of universities, NPO´s and communities for the implementation of needed infrastructure where governmental capacities or the private sector are failing? Guidelines can be developed through the experienced challenges from financial constraints and delays over communication and mediation,interest of diverse stakeholders to the design process and technical specifications.

In the process, the suitable media for exchange and narratives needs to be developed, visual representation through photography, drawings and film to be tested for inclusivity, treating all participants as experts. Analysing the documented process, collective reflection and exploratory feedback with partners accumulate to be shared as initial impulse and a first step to future projects.

Only after a certain time period will the outcome on strategies of ownership and maintenance be visible. A first utilisation phase was followed by feedback and technical adaptions a few months after realisation. An impact assessment on socio-economic development (children reaching educational facilities,river crossing possible at night, etc.) would generate information and values supporting arguments for the collective creation of needed infrastructure and space.

This collaboration between designers and different stakeholders allowed, on the one hand,the future users learning of different construction techniques; it also encourages, on the other hand, the professional maintenance of the bridge. In addition,the residents identify very strongly with "their" bridge over the Mzamba through their work performed.Additional strategies like exhibitions, screenings and collective reflection celebrating steps and a big official opening ceremony organised by participating members accompanied all implementation phases.

Headman Mashono Dlamini is happy to say that "It's the first project where the representing Steering Committee is still communicating and working together after the project!"

Community member and part of Construction team member Pakhamani Ngeleka underlines the positive impact of the infrastructure "Now the kids go to school every day! Children, old people every day! You can go to work and access to the clinic, even at night. And I have been playing my part making this possible!" □ (Text: Marlene Wagner)

16 桥身局部/Parts of the bridge

17 桥身局部/Parts of the bridge

18 桥身局部/Parts of the bridge

19 团队与桥塔/Team members with pylon

Comments

ZHOU Zhengxu: This suspended bridge concentrates on expectation, collaboration, and 4-year-long action by people from different countries including Austria, Switzerland,South Africa, as well as the local residents. Compared with the demanding of local residents, the form seems not so important, but the span becomes the prior question for consideration at the same time. Students and engineers join their hands in designing this light bridge structure, and purposely adopt a method for assembly construction that can be done by unskillful workers and with high degree of adaptation, so as to fully motivate the whole community into the construction of the bridge. It is worthy of mentioning that steel structure is particularly advantageous in lasting and anti-risk, which makes it possible for the bridge to provide convenience for local residents for a long period of time.

LI Ye: The so-called common wealth projects usually use a small amount of fund to motivate more resources so as to result in public significance. From this perspective,the project is no doubt successful. And the design of the project is also in line with such a criterion.

As we can see, the components of the bridge, like bridge piers, inhaul cables, and pedals, are disassembled into construction parts that can be built with simple human work. While reducing the construction cost, it also decreases the engineering volume during the implementation and increases the degree of participation by local residents. The large amount application of flat steel on the components of the bridge realises a delicate fusion between the scale of the bridge and the surrounding woods environment; the light grey painting on the bridge body responds with the uncovered rocks around; and the curve of the bridge provides an interesting bridge-passing experience for the pedestrians.