石墨烯基全固态平面超级电容器电化学性能

张光宇 刘琳婧 徐芮 王欣 李闯 吕胤霖 陈玉娟 朱大福 杨昕瑞

摘 要:针对全固态平面超级电容器性能偏低的问题,采用一种由在硅片上直接生长的方法制备出石墨烯薄膜作为电极,利用双电层超级电容器工作原理,采用PVA/H2SO4凝胶电解质,制备得到石墨烯基全固态平面超级电容器。循环伏安测试结果表明:该超级电容器具有双电层电容特性。循环伏安曲线没有氧化还原峰,说明双电层电容完全提供电极的容量。当扫描速率为50mV/s时,该超级电容器的循环伏安特性较好,面积比电容为290.24μFcm-2,能量密度为22.68μWhcm-2。为平面微型超级电容器的研究提供了重要参考。

关键词:平面超级电容器;凝胶电解质;双电层;循环伏安

DOI:10.15938/j.jhust.2018.03.024

中图分类号: O646

文献标志码: A

文章编号: 1007-2683(2018)03-0139-04

Electrochemical Properties of Graphene-based All-solid-state Planar Supercapacitors

ZHANG Guang-yu, LIU Lin-jing, XU Rui, WANG Xin, LI Chuang,

L Yin-lin, CHEN Yu-juan, ZHU Da-fu, YANG Xin-rui

(School of Applied Sciences, Harbin University of Science and Technology, Harbin 150080, China)

Abstract:For a problem of low performance of planar supercapacitors, graphene films were prepared by a method of direct growth on silicon wafers as electrodes, and PVA/H2SO4 is used as gel electrolyte. Graphene-based all-solid-state planar supercapacitor was prepared with working principle of electric double layer capacitor. The results of cyclic voltammetry showed that the supercapacitor had characteristics of double layer capacitance, and there was no redox peak in the cyclic voltammetry curves, indicating that the electric double layer provided capacity of electrodes. When the scanning rate was 50mV/s, the supercapacitor had better performance of cyclic voltammetry. The area capacitance was 290.24μFcm-2 and the energy density was 22.68μWhcm-2. This paper provides an important reference for further research on planar micro-supercapacitors.

Keywords:planar supercapacitors; gel electrolyte; electric double layer; cyclic voltammetry

0 引 言

隨着电子产品的小型化、微型化,传统的超级电容器日益显露出其局限性[1-2]。由于碳基材料具有高的比表面积、良好的导电性、与其它材料的相容性和可控的孔径分布等特性,使其在电能存储设备如超级电容器和电池领域中被广泛的研究[3-5]。石墨烯和碳纳米管等新型碳材料逐渐应用于超级电容器,取代了传统的碳电极。随着便携式电子产品和体内电子器件的快速发展[6-7],促进了世界范围内平面超级电容器的研制[8-10]。平面超级电容器具有体积小、功率密度高、安全性好、易与片上系统集成等优点,已经成为传统超级电容器的有力竞争者[11-13]。电极材料、薄膜电极生产技术以及平面超级电容器的结构是影响器件性能的关键因素,它们决定了平面超级电容器的比电容、功率密度、能量密度、循环稳定性以及分解电压等。

石墨烯作为一种由sp2杂化碳原子紧密排列成蜂窝状晶格结构的二维碳材料。由于其独特的二维结构及优异的性能(如高导电性、高比表面积和高比电容等),使其成为一种理想的双电层超级电容器的电极材料[14-17]。2011年,文[18]制备了两种石墨烯超薄平面超级电容器, 分别是基于化学气相沉积法制备的单层石墨烯和还原氧化石墨法制备的多层石墨烯薄膜,面电容分别为80μFcm-2和394μFcm-2。2013年,文[19]制备了高功率密度和能量密度的石墨烯基平面微型超级电容器,功率密度为495Wcm-3,能量密度为2.5mWhcm-3。2014年,文[20]制备了不同插指数的高性能全固态石墨烯基平面微型超级电容器,功率密度为1270Wcm-3,能量密度为3.6mWhcm-3。

本文基于一种由在硅片上直接生长的方法制备的石墨烯薄膜电极,采用PVA/H2SO4凝胶电解质,制备了石墨烯基全固态平面超级电容器。

1 全固态平面超级电容器制备

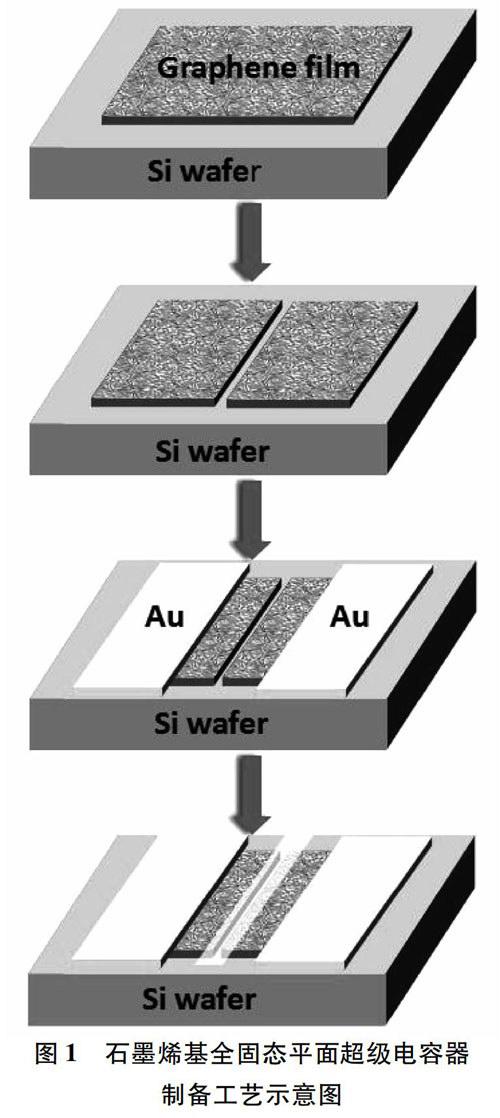

根据传统超级电容器的结构,设计了全固态平面超级电容器。石墨烯基全固态平面超级电容器的制备工艺如图1所示。整个工艺流程分成四个部分,分别为:采用一种由在硅片上直接生长的方法制备石墨烯薄膜;用物理切割法(尖锐物体切割)将石墨烯薄膜均匀的分成两个部分;将石墨烯薄膜中间的间隙部分挡住,在石墨烯薄膜两侧溅射金集电极,其中溅射的金覆盖部分石墨烯薄膜;将PVA/H2SO4凝胶电解质均匀地涂抹在薄膜间隙中,从而制备出石墨烯基全固态平面超级电容器,如图2所示。

用光學显微镜可以清晰的看出,划开的石墨烯薄膜边缘几乎是平滑的,并测量出间隙为56.54μm,如图3所示。

凝胶电解质的制备工艺为:将3gPVA粉末与5mL浓硫酸(98%)加到100mL去离子水中,在85℃恒温水浴2h且不断搅拌,直到溶液变清晰透明。所制备的PVA/H2SO4凝胶电解质如图4所示。

2 全固态平面超级电容器的循环伏安测试

采用CHI600E/700E(上海辰华仪器有限公司)电化学工作站对石墨烯基全固态平面超级电容器进行循环伏安测试。

图5为不同扫描速率下的循环伏安曲线,工作电位为0~1.5V。可以看出,循环伏安曲线基本呈现对称的梭形,表明该超级电容器具有双电层电容特性;循环伏安曲线没有氧化还原峰,说明双电层电容完全提供电极的容量。扫描速率越小,图形越接近矩形,电极片的循环伏安特性越好。

根据循环伏安曲线,可知在充放电过程中电流(I)随电压(V)的变化关系。超级电容器的比电容为:

C=1v(Vf-Vi)∫VfViI(V)dV(1)

式中,v为扫描速率。超级电容器的面积比电容为:

CS=CS(2)

式中,S为超级电容器的面积。本实验超级电容器的面积为1cm2,比电容和面积比电容的数值相同。不同扫描速率下的面积比电容如表1所示。

图6为不同扫描速率下的面积比电容变化曲线。随着扫描速率的增加,面积比电容逐渐降低。当扫描速率为50mV/s时,面积比电容为290.24μFcm-2。

超级电容器的能量密度为:

E=CV22S(3)

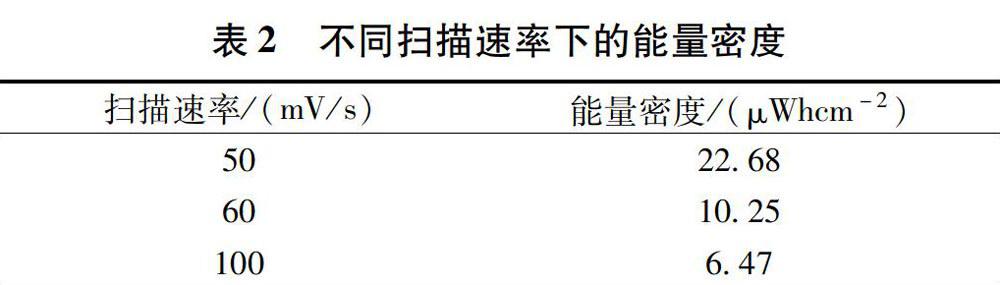

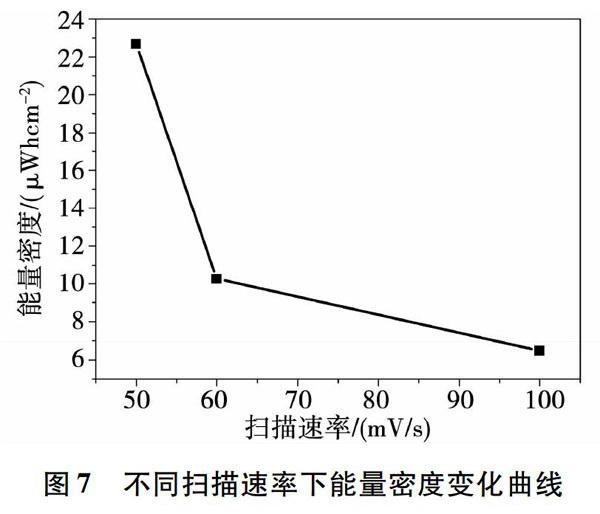

不同扫描速率下的能量密度如表2所示。

图7为不同扫描速率下的能量密度变化曲线。随着扫描速率的增加,能量密度逐渐降低。当扫描速率为50mV/s时,能量密度为22.68μWhcm-2。

3 结 论

采用一种由在硅片上直接生长的方法制备出石墨烯薄膜作为电极,利用物理切割法(尖锐物体切割)且部分镀金,制备出全固态平面超级电容器电极。经注入PVA/H2SO4凝胶电解质,得到石墨烯基全固态平面超级电容器。循环伏安测试结果表明,循环伏安曲线呈现对称的梭形,该超级电容器具有双电层电容特性;循环伏安曲线没有氧化还原峰,说明双电层电容完全提供电极的容量。当扫描速率为50mV/s时,该超级电容器的面积比电容为290.24μFcm-2,能量密度为22.68μWhcm-2。

参 考 文 献:

[1] FRACKOWIAK E. Carbon Materials for Application [J]. Physical Chemistry Chemical Physics Pccp, 2007, 9(15):1774-85.

[2] LAMBERT S M, PICKERT V, et al. Comparison of Supercapacitor and Lithium-ion Capacitor Technologies for Power Electronics Applications [C]// Iet International Conference on Power Electronics, Machines and Drives. IET, 2010:241-241.

[3] ELZBIETA F, QAMAR A, et al. Carbon/carbonSupercapacitors [J], Journal of Energy Chemistry, 2013, 22 : 226-240.

[4] MINATO E, TAKUMA I, et al. DeterminingWater Content in Activated Carbon for Double-layer Capacitor Electrodes [J]. Journal of Power Sources, 2016(3): 1-6.

[5] KATARZYNA L, AGNIESZKA S, et al. TheCapacitance Properties of Activated Carbon Obtained from Chitosan as the Electrode Material for Electrochemical Capacitors [J]. Materials Letters, 2016, 173 : 72-75.

[6] HUI S Y. Planar Wireless Charging Technology for Portable Electronic Products and Qi [J]. Proceedings of the IEEE, 2013, 101(6):1290-1301.

[7] SHNAWAH D A, SABRI M F M, et al. A Review on Thermal Cycling and Drop Impact Reliability of SAC Solder Joint in Portable Electronic Products [J]. Microelectronics Reliability, 2012, 52(1):90-99.

[8] LI R, PENG R, et al. High-rate in-plane Micro-supercapacitors Scribed onto Photo Paper using in-situ Femtolaser-reduced Graphene Oxide/Au Nanoparticle Microelectrodes [J]. Energy & Environmental Science, 2016, 9(4):1458-1467.

[9] LIU Z, WU Z, et al. Ultraflexible In-Plane Micro-Supercapacitors by Direct Printing of Solution-Processable Electrochemically Exfoliated Graphene [J]. Advanced Materials, 2016, 28(11):2217-2222.

[10]ZHOU Xiao-Lin, WANG Min, et al. Supercapacitors Based on High-surface-area Graphene [J]. Science China, 2014, 2 : 278-283.

[11]HSIA B, MARSCHEWSKI J, Wang S, et al. Highly Flexible, all solid-state Micro-supercapacitors from Vertically Aligned Carbon Nanotubes [J]. Nanotechnology, 2014, 25(5):55401-55409.

[12]BEIDAGHI M, WANG C. Supercapacitors: Micro-Supercapacitors Based on Interdigital Electrodes of Reduced Graphene Oxide and Carbon Nanotube Composites with Ultrahigh Power Handling Performance [J]. Advanced Functional Materials, 2012, 22(21):4501-4510.

[13]HU H, PEI Z, et al. Recent Advances in Designing and Fabrication of Planar Micro-supercapacitors for on-chip Energy Storage[J]. Energy Storage Materials, 2015(1):82-102.

[14]SUN G, AN J, et al. Layer-by-layer Printing of Laminated Graphene-based Interdigitated Microelectrodes for Flexible Planar Micro-supercapacitors [J]. Electrochemistry Communications, 2015, 51:33-36.

[15]KURRA N, JIANG Q, et al. A General Strategy for the Fabrication of High Performance Micro-supercapacitors [J]. Nano Energy, 2015(16):1-9.

[16]CHEN Y, XU J, et al. Enhanced Electrochemical Performance of Laser Scribed Graphene Films Decorated with Manganese Dioxide Nanoparticles [J]. Journal of Materials Science Materials in Electronics, 2016, 27(3):2564-2573.

[17]WU ZS, FENG X, CHENG HM. Recent Advances in Graphene-based Planar Micro-supercapacitors for On-chip Energy Storage [J]. National Science Review, 2014, 1(2):277-292.

[18]YOO JJ, BALAKRISHNAN K, et al. Ultrathin Planar Graphene Supercapacitors [J], Nano Letters, 2011, 11: 1423-1427

[19]WU ZS, PARVEZ K, et al. Graphene-based In-plane Micro-supercapacitors with High Power and Energy Densities [J]. Nature Communications, 2013(10):1038.

[20]WU ZS, PARVEZ K, et al. Photolithographic Fabrication of High-performance All-solid-state Graphene-based Planar Micro-supercapacitors with Different Interdigital Fingers [J]. Journal of Materials Chemistry A, 2014, 2(22):8288-8293.