不同材质传热风道性能及蓄热土壤温度场CFD模拟

鲍恩财,张 勇,曹晏飞,王 昭,张 欣,曹 凯,杨俊伟,邹志荣

不同材质传热风道性能及蓄热土壤温度场CFD模拟

鲍恩财1,张 勇1,曹晏飞1,王 昭2,张 欣3,曹 凯1,杨俊伟1,邹志荣1※

(1. 西北农林科技大学园艺学院,农业部西北设施园艺工程重点实验室,杨凌 712100;2. 北京三润泰克国际农业技术有限公司,北京 114011;3. 华盛顿州立大学生物系统工程系,精细与自动化农业系统研究中心,普罗瑟 WA 99350)

风道在园艺设施中应用较为广泛,通常作为土壤及墙体热量传递的载体。该文搭建了风道传热试验台,以聚氯乙烯管道(polyvinyl chloride pipe,PVC)、镀锌铁皮管道(galvanized iron pipe,GI)及钢筋网外缠绕土工布管道(steel mesh skeleton-geotextile composite pipe,SFG)3种管材作为传热风道,以土壤为蓄热体进行试验,结合计算流体力学(computational fluid dynamics,CFD)对蓄热土壤温度场进行分析。结果表明,SFG的传热效果最好,测试期间的换热量达到299.44 kJ,约是GI的4倍、PVC的3倍;SFG进、出口上、下、左、右4个方向的有效蓄热范围均远大于240 mm,PVC与GI的有效蓄热范围相似;通过CFD所建立的3个传热风道计算模型的最大相对误差为4.4%,模拟发现蓄热土壤截面温度从进风口到出风口具有一定的“坡降”。因此,SFG的传热效果明显优于PVC与GI,具有较高的应用潜力和一定的推广价值。

土壤;流体力学;传热;传热风道;传热性能;蓄热范围;CFD

0 引 言

设施园艺是利用特定的保护设施与配套设备,人为地创造适于作物生育的环境空间,有计划地进行园艺产品的安全、优质、稳产、高产生产的一种综合农业技术体系,其中的设施主要包括中小拱棚、塑料大棚、连栋温室、日光温室4大类[1-2]。为了维持园艺设施在冬季正常使用而又不耗费大量能源,国内外学者做了大量的研究,主要方式有主动采光[3]、相变材料蓄热[4-5]、太阳能集热[6-7]、空气源热泵[8-9]、地源热泵[10-11]、水循环集放热[12]、后墙主动蓄热[13]、地下热交换[14-15]等。

传热风道在园艺设施的土壤及墙体中均有应用。上世纪80年代,马承伟[16-17]在塑料大棚上应用地下热交换系统,研究发现该系统可有效地贮存太阳能并用于夜间加温,能使塑料大棚在不用燃料加温的情况下在夜间维持10 ℃左右的棚内外气温差。孙忠富[18]研究了地—气热交换系统的热性能,结果表明,地—气热交换系统可使塑料大棚在夜间升温2.0~4.4 ℃,在白天降温2.5~6.5 ℃。袁巧霞[19-20]设计了一种半被动式塑料大棚地下热交换系统,试验表明,该系统可在夜间维持8~9 ℃的棚内外气温差,同时棚内地温可提高10 ℃左右,并分析了该系统在中国的适宜范围、适合的蔬菜品种及主要参数的选择。在此基础上,袁巧霞[21]将波纹塑料管和陶土管作为地下热交换系统的管道材料,通过试验及理论分析比较得出,波纹塑料管的换热性能和析湿特性优于陶土管,且使用成本较低。吴德让等[22-23]运用传热学的基本理论,建立了日光温室地下热交换系统土壤温度场的数学模型,同时通过对比试验研究了日光温室采用地下热交换系统在冬季生产喜温蔬菜的可行性和实用性。孙周平等[24]在彩钢板保温装配式节能日光温室地下0.5 m设计安装了空气—地中热交换系统进行蓄热,经过整个冬季的测试发现,空气—地中热交换系统与水循环蓄热系统结合使用可代替传统土墙的蓄热能力,进而确保日光温室冬季的温热环境。张勇等[13]提出了一种能够将白天富余能量进行有效存储的主动蓄热后墙日光温室,与传统9 m跨的被动蓄热日光温室进行了对比分析,结果表明,主动蓄热后墙日光温室的气温有了较明显提高。

计算流体力学(computational fluid dynamics,CFD)在管道传热[25-27]及温室模拟[28-29]方面均有应用。如Bansal等[30]为减少冬季建筑物的热负荷,基于CFD建立了土壤—管道—空气换热系统的瞬态和稳态2种模型,从管道材料和空气流速角度分别研究了该系统的热性能,结合试验发现管道内的空气流速对系统的影响较大,但不受管道材料的影响,这与袁巧霞[21]的测试结果并不一致,可能是因为管道本身是否密闭(如陶土管具有一定的透气、透湿性)、管道的表面结构(如波纹管与直管)不同而导致的研究结果的不同;Zhang等[31]建立了中国西北地区的日光温室模型,利用CFD模拟分析了不同厚度后墙日光温室对室内空气温度分布的影响。

综上,将传热风道应用于园艺设施的土壤及墙体中进行空气热交换操作简便、效果明显,但对传热风道周身是否密闭的传热效果研究未见报道,本文采用周身密闭型风道和透气型风道进行对比研究,其中透气型风道采用钢筋网管道作为风道的骨架,起支撑作用,以土工布单层缠绕钢筋网管道作为传热面,搭接重叠100 mm;根据园艺设施实际使用的工况,设计了一种可测试不同材质风道传热性能的试验台,将测试结果与CFD模拟结果对比分析不同材质风道传热性能,并对蓄热土壤温度场进行模拟分析,从风道材质角度提出进一步改进园艺设施换热系统的方法。

1 材料与方法

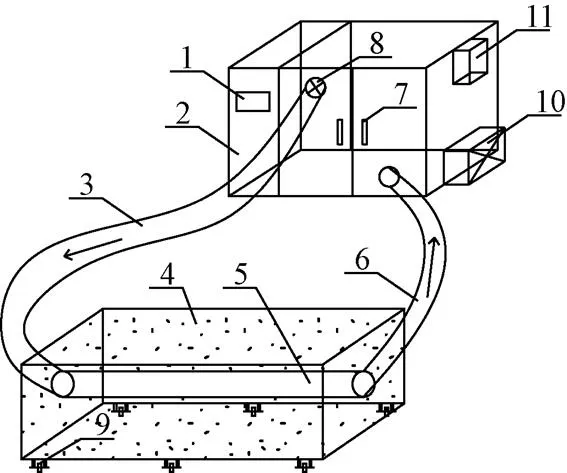

1.1 风道传热试验台

风道传热试验台主要由制热箱体、输送管道及试验箱体3部分组成,如图1所示。制热箱体由混凝土养护箱改造而成,配套压缩机及电源控制柜,箱体上有控制面板,可设置箱体内的温湿度;输送管道包括进风管道及出风管道,分别安装在箱体门的上下部位,输送管道外部做绝热处理,进风管道的热风进口处安装有风机;试验箱体内部填充蓄热体,中部埋置传热风道;输送管道与传热风道连接处可拆卸,用于连接不同材质的传热风道。

1. 控制面板 2.制热箱体 3.进风管道 4.蓄热土壤 5.传热风道 6.出风管道 7.门把手 8.风机 9.滚轮 10.压缩机 11.电源控制柜

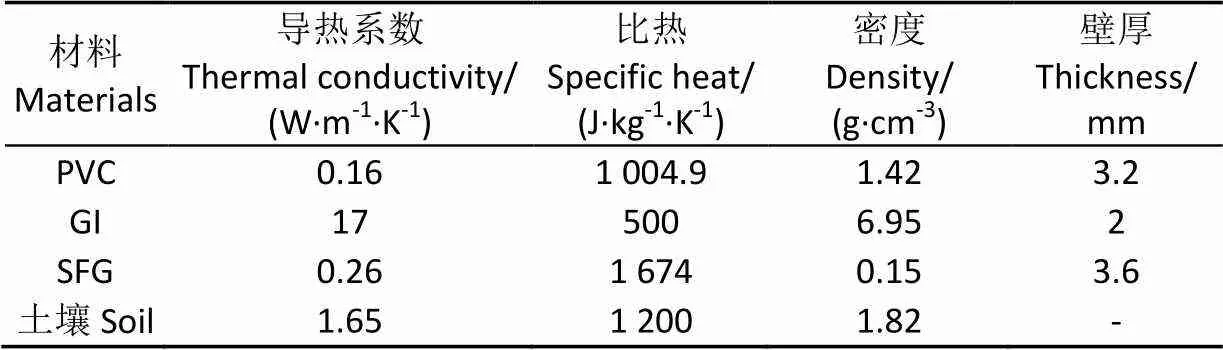

输送管道采用铝箔管道外裹绝热棉毡;蓄热体为人工夯实的土壤,取自西北农林科技大学园艺学院试验基地(34°15′N,108°03′E)地表下1~3 m处,为使3个试验台的蓄热土壤的条件一致,在同尺寸的试验台内填实同等质量的土壤,压实后测试得到蓄热土壤含水率13.9%、压实度90.3%;3种传热风道材质分别为聚氯乙烯管道(polyvinyl chloride pipe,PVC)、镀锌铁皮管道(galvanized iron pipe,GI)及钢筋网外缠绕土工布管道(steel mesh skeleton-geotextile composite pipe,SFG),输送管道及传热风道直径均为200 mm。课题组前期研究表明后墙主动蓄热循环系统中混凝土预制板传热风道上下表面各200 mm的高度范围内均属于蓄热体[32],为保证传热风道四周的蓄热体厚度不少于200 mm,本试验台设计试验箱体的端面尺寸为800 mm×800 mm,试验箱体长2 m。在箱体四周采用120 mm厚彩钢板外贴隔热,试验过程中所有缝隙处采用聚氨酯泡沫填缝剂填充。传热风道及土壤的性能参数如表1所示(部分参数来源于GB 50176-2016《民用建筑热工设计规范》)。

表1 传热风道及土壤的性能参数

注: PVC表示聚氯乙烯管道;GI表示镀锌铁皮管道;SFG表示钢筋网外缠绕土工布管道,下同。

Note: PVC means polyvinyl chloride pipe, GI means galvanized iron pipe, SFG means steel mesh skeleton-geotextile composite pipe, the same below.

1.2 试验台测试

传热风道进、出口的空气温湿度由PDE-KI环境数据记录仪(哈尔滨物格电子技术有限公司生产,温度测量范围:−30~70 ℃,准确度±0.5 ℃,分辨率0.1 ℃;湿度测量范围:0~99%,准确度±3%,分辨率1%)采集,分别位于风道进、出口几何中心。端面蓄热土壤温度由PDE-R4温度数据记录仪(哈尔滨物格电子技术有限公司生产,温度测量范围−30~70 ℃,准确度±0.5 ℃,分辨率0.1 ℃)采集。在传热风道的上、下、左、右4个方向各布置5个测点,测点间距60 mm,布点情况如图2所示.。所有测点记录数据的时间间隔均为5 min。进、出口的风速由testo425风速仪(德国testo公司生产,风速测量范围0~20 m/s,精度±(0.03 m/s+5%测量值),分辨率0.01 m/s)采集。

注: A表示在管道上部;B表示在管道下部;L表示在管道左侧;R表示在管道右侧,下同。

1.3 数据处理

本文试验数据采用Excel 2007进行平均值和标准误的求解及表格的制作,用SPSS20.0进行显著性测试。

2 试验台测试结果与分析

2.1 风道传热量计算

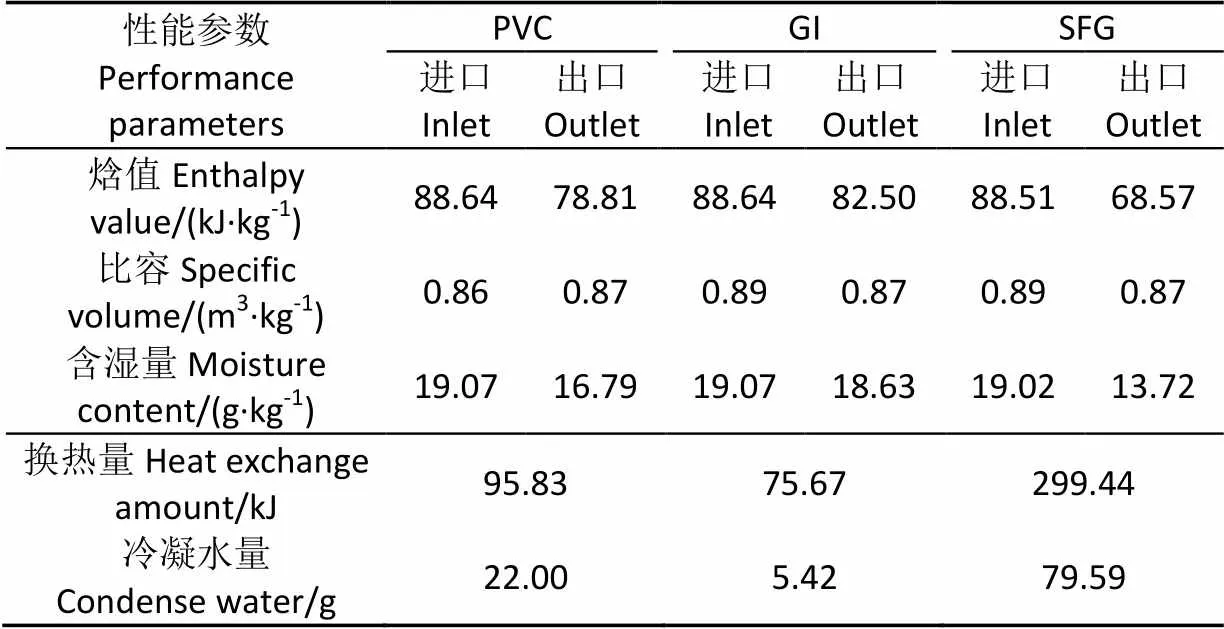

对3种传热风道分别进行测试,均连续通风4 h,各风道的进、出口温湿度如表2所示。由表2可知,进口的温湿度没有差异,出口的温湿度均存在显著差异(<0.05),说明3种传热风道的传热量明显不同。

表2 传热风道进、出口空气平均温湿度

注: 同列不同字母表示处理间差异显著(<0.05)。

Note: Different letters in the same column meant significant difference at 0.05 level.

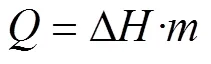

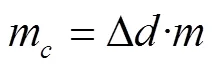

根据表2的传热风道进、出口空气平均温湿度值结合空气风速和管径等参数,计算得到通风4 h后各风道的传热量及冷凝水量,计算公式如下

式中为风道内空气流速,m/s;为风道截面面积,m2;in、out分别为进、出口空气的比容,m3/kg;为风机运行时间,s。

in、out、in、out、in、out由文献[2]计算得来,所有参数代入式(1)~(3)计算的结果如表3所示。

表3 传热风道进、出口空气性能参数

由表3可知SFG的传热量最大,约是PVC的3倍、GI的4倍;冷凝水量也最大,但试验中发现SFG内并没有残留的液态水,而PVC和GI内有液态水存在,这与SFG的土工布具有透湿性有关。

2.2 风道传热范围分析

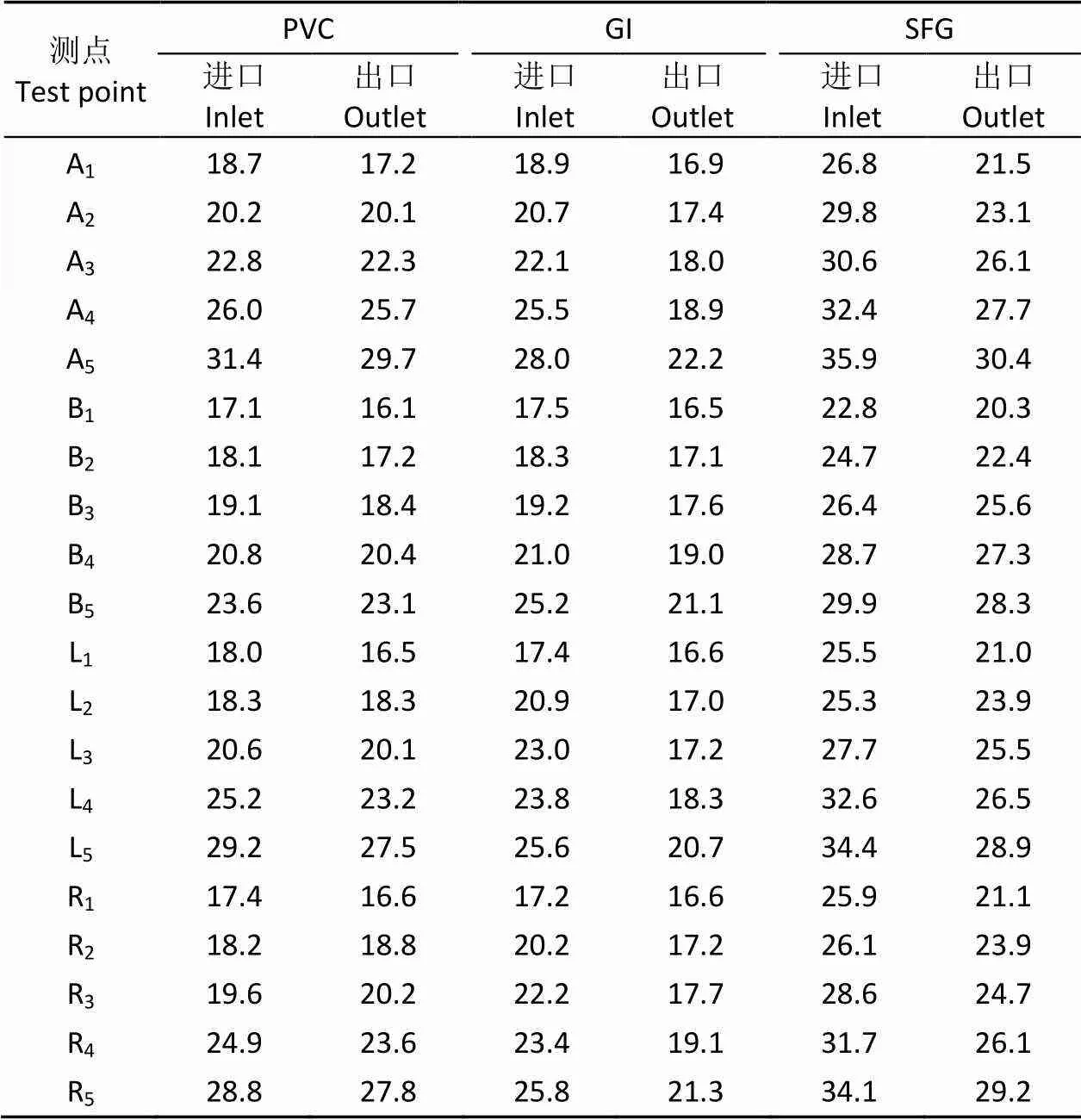

通风4 h后各测点的结果如表4所示。

表4 蓄热土壤端面温度

参考温波法[33]和温波传递理论[34]确定蓄热范围的方法,本文规定试验期间土壤温度波动超过1 ℃的位置为有效蓄热范围,温度波动超过5 ℃的位置为高效蓄热范围。由表4可以看出,PVC传热风道进口上、下、左、右有效蓄热范围分别为:大于240 mm、180~240 mm、略大于240 mm、略大于240 mm;出口上、下、左、右有效蓄热范围分别为:180~240、120~180、180~240、180~240 mm。进口上、下、左、右高效蓄热范围分别为:120~180、0~60、60~120、60~120 mm;出口上、下、左、右高效蓄热范围分别为:120~180、0~60、60~120、60~120 mm。

GI传热风道进口上、下、左、右有效蓄热范围分别为:大于240、180~240、180~240、180~240 mm;出口上、下、左、右有效蓄热范围分别为:120~180、120~180、60~120、120~180 mm。进口上、下、左、右高效蓄热范围分别为:120~180、0~60、120~180、120~180 mm;出口上、下、左、右高效蓄热范围分别为:0~60 mm、0、0、0。

SFG传热风道进口上、下、左、右有效蓄热范围均远大于240 mm;出口上、下、左、右有效蓄热范围均大于240 mm。进口上、下、左、右高效蓄热范围均大于240 mm;出口上、下、左、右高效蓄热范围分别为:大于240、180~240、180~240、180~240 mm。

分析可知,各传热风道进、出口的上、下、左、右4个方向均有相同的温度变化趋势,在热浮力作用下热量向上传递的影响导致3种传热风道的上部蓄热范围大于下部,而左右基本对称。

3 蓄热土壤温度场CFD模拟

试验台测试结果仅能反应传热风道端面土壤测点的温度变化,为了更直观地了解蓄热土壤的温度场情况,本文通过STAR-CCM+ v10.04软件进行CFD模拟。该软件采用连续介质力学算法,性能稳定、精度高、可靠性强,前处理功能强大,如几何模型表面错误修复、对模型进行拓扑封闭、面网格和体网格的生成[35],国内外研究[36-37]中均有应用。

3.1 控制方程

假设热空气为理想气体,传热风道、土壤密度均匀,气密性良好且传热风道与空气、空气与蓄热土壤完全无间隙接触,蓄热土壤四周为绝热壁面,进口进气流匀速等温。模拟将热空气简化为不可压定常流,流场中气体的流动遵循基本的物理守恒定律包括:质量守恒定律、动量守恒定律、能量守恒定律及组分守恒定律[38]。

3.2 几何模型

模型采用STAR-CCM+自带组件进行参数化建模,按照试验箱体实际尺寸和相关关系创建。采用TRIM网格,整体域网格基本尺寸为32 mm,对传热风道及热空气进行加密处理,加密尺寸8 mm,网络单元数量为773 178个。

3.3 边界条件

风道进口边界为热风进口,流速依照试验台的实际测量数据设定为1.51 m/s;假设蓄热土壤初始温度分布均匀、壁面设置为绝热,实测土壤初始温度为16.5 ℃;分析得到风道内空气的湍流强度和水力半径分别为3.4%和0.05 m,风道出口边界为压力出口。模拟时各风道的进、出口温湿度根据实测结果设置。

3.4 模拟结果验证

通过对比传热风道进、出口位置温度测点的试验值与模拟值来验证所建模型的准确性,结果如表5所示。

表5 蓄热土壤端面温度模拟值

由表4和表5可知,PVC传热风道进、出口20个测点的最大绝对误差分别为0.5、0.7 ℃,最大相对误差分别为2.9%、3.2%;GI传热风道进、出口20个测点的最大绝对误差分别为0.8、0.7 ℃,最大相对误差分别为4.4%、3.9%;SFG传热风道进、出口20个测点的最大绝对误差分别为1.1、0.5 ℃,最大相对误差分别分别为3.8%、2.3%。

因此,3种材质传热风道的进、出口温度场的模拟结果与试验结果吻合度较高,均在5%的误差范围内。说明该计算模型可用于不同材质风道传热性能及蓄热土壤温度场分布的研究。

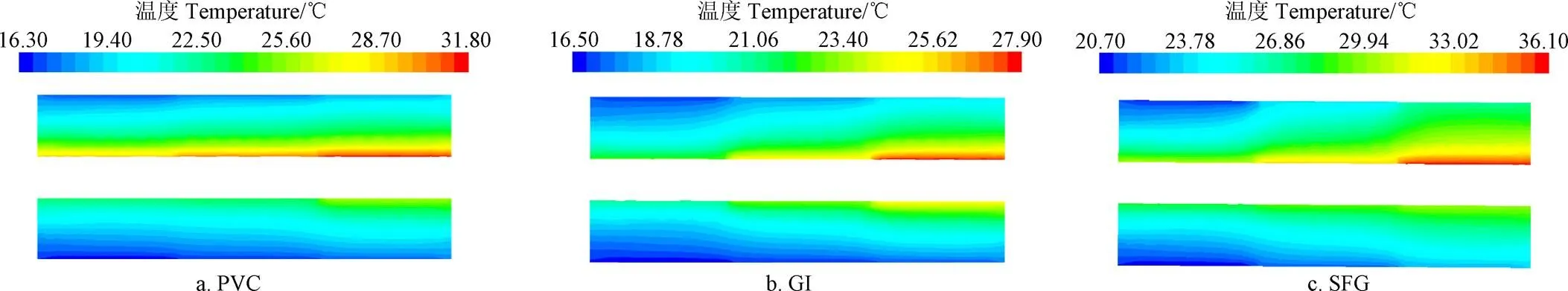

3.5 数值模拟分析

通过CFD模拟得出3种材质传热风道周围蓄热土壤截面的温度云图,因风道内设置为均质热空气,为避免视觉误导,此处省略该部分的显示,分析结果如图3所示。

注:热空气从传热风道右侧进入。

由图3可以看出蓄热土壤内部的温度分布情况,在风道上边缘,从进风口到出风口温度分布呈现一定的“坡降”,风道下边缘的温度走势与上边缘一致,但“坡度”较小。从温度范围及“坡降”大小均可以看出,SFG的蓄热效果明显大于PVC及GI,PVC略大于GI,这也反映了表5的模拟结果,同时验证了表3、表4的计算结果。

4 讨 论

1)由表2的结果可知,3种材质传热风道进口的热空气温、湿度基本一致,而出口温度表现为PVC>GI> SFG,说明SFG的传热效果最好,对应土壤的蓄热量最多,表3的计算结果也说明了这点。本文的试验结果与SFG中土工布具有透气、透湿性有关;出口湿度表现为GI>PVC>SFG,这是因为SFG中的土工布具有透气、透湿性使得土壤吸收了空气热量的同时也吸收了湿度,但SFG的透气率、透湿率与传热量、吸湿量的关系尚缺少研究。

2)土工布的使用寿命在80 a以内[39],在建筑、水利、铁路、公路、港口、采矿、军工等多个领域均有应用[40],因此在园艺设施的应用基础较好。且3种传热风道的市场价格为GI>PVC>SFG,而传热效果为SFG>PVC>GI,因此,采用SFG作为园艺设施传热风道具有明显优势,下一步将在园艺设施内开展实际使用效果的试验研究。

3)本文建立的CFD模型可应用于复杂工况下的传热模拟研究,如日光温室主动蓄热墙体[13]进风口不同风速对蓄热性能的影响,且通过CFD对温度场的分布计算出蓄热体的有效蓄热“体积”,对传热风道的合理布置具有实际应用意义,这在后续研究中将通过模拟结合实测的方式加强分析。

5 结 论

通过试验台测试发现钢筋网外缠绕土工布管道(steel mesh skeleton-geotextile composite pipe,SFG)的传热效果最好,本试验条件下的换热量达到299.44 kJ,约是镀锌铁皮管道(galvanized iron pipe,GI)的4倍、聚氯乙烯管道(polyvinyl chloride pipe,PVC)的3倍。SFG进、出口上、下、左、右4个方向的有效蓄热范围均远大于240 mm;进口上、下、左、右高效蓄热范围均大于240 mm,出口上、下、左、右高效蓄热范围分别为大于240 mm、180~240 mm、180~240 mm、180~240 mm。而PVC的传热效果略优于GI,说明透气型风道的传热效果明显优于密闭型风道。

通过CFD建立的3个传热风道计算模型的最大相对误差为4.4%,说明该模型可用于研究不同材质风道传热性能及蓄热土壤温度场分布情况。通过对蓄热土壤温度场进行模拟,发现截面分布显示从进风口到出风口具有一定的“坡降”。

因此,钢筋网外缠绕土工布管道的传热效果明显优于聚氯乙烯管道及镀锌铁皮管道,后两者效果相似,钢筋网外缠绕土工布管道具有较高的应用潜力和一定的推广价值。

[1] 邹志荣. 园艺设施学[M]. 北京:中国农业出版社,2002.

[2] 马承伟,苗香雯. 农业生物环境工程[M]. 北京:中国农业出版社,2005.

[3] 张勇,邹志荣,李建明. 倾转屋面日光温室的采光及蓄热性能试验[J]. 农业工程学报,2014,30(1):129-137.

Zhang Yong, Zou Zhirong, Li Jianming. Performance experiment on lighting and thermal storage in tilting roof solar-greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(1): 129-137. (in Chinese with English abstract)

[4] 王宏丽,邹志荣,陈红武,等. 温室中应用相变储热技术研究进展[J]. 农业工程学报,2008,24(6):304-307.

Wang Hongli, Zou Zhirong, Chen Hongwu, et al. Research advances in technologies of phase-change heat storage and its application in greenhouses[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(6): 304-307. (in Chinese with English abstract)

[5] Berroug F, Lakhal E K, El Omari M, et al. Thermal performance of a greenhouse with a phase change material north wall[J]. Energy and Buildings, 2011, 43(11): 3027-3035.

[6] 戴巧利,左然,李平,等. 主动式太阳能集热/土壤蓄热塑料大棚增温系统及效果[J]. 农业工程学报,2009,25(7):164-168.

Dai Qiaoli, Zuo Ran, Li Ping, et al. Active solar heating system with thermal storage soil for plastic film greenhouse and its effects[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(7): 164-68. (in Chinese with English abstract)

[7] Ozgener O, Hepbasli A. Performance analysis of a solar-assisted ground-source heat pump system for greenhouse heating: an experimental study[J]. Building and Environment, 2005, 40(8): 1040-1050.

[8] 孙先鹏,邹志荣,赵康,等. 太阳能蓄热联合空气源热泵的温室加热试验[J]. 农业工程学报,2015,31(22):215-221.

Sun Xianpeng, Zhou Zhirong, Zhao Kang, et al. Experiment on heating effect in greenhouse by solar combined with air-source heat pump[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(22): 215-221. (in Chinese with English abstract)

[9] 孙维拓,郭文忠,徐凡,等. 日光温室空气余热热泵加温系统应用效果[J]. 农业工程学报,2015,31(17):235-243.

Sun Weituo, Guo Wenzhong, Xu Fan, et al. Application effect of surplus air heat pump heating system in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(17): 235-243. (in Chinese with English abstract)

[10] 方慧,杨其长,张义. 基于热泵的日光温室浅层土壤水媒蓄放热装置试验[J]. 农业工程学报,2012,28(20):210-216.

Fang Hui, Yang Qichang, Zhang Yi. Experimental study on shallow soil assisted heat release-storage system with water-water heat pump in solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(20): 210-216. (in Chinese with English abstract)

[11] 孙维拓,杨其长,方慧,等. 主动蓄放热-热泵联合加温系统在日光温室的应用[J]. 农业工程学报,2013,29(19):168-177.

Sun Weituo, Yang Qichang, Fang Hui,et al. Application of heating system with active heat storage-release and heat pump in solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(19): 168-177. (in Chinese with English abstract)

[12] 马承伟,姜宜琛,程杰宇,等. 日光温室钢管屋架管网水循环集放热系统的性能分析与试验[J]. 农业工程学报,2016,32(21):209-216. Ma Chengwei, Jiang Yichen, Cheng Jieyu, et al. Analysis and experiment of performance on water circulation system of steel pipe network formed by roof truss for heat collection and release in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 209-216. (in Chinese with English abstract)

[13] 张勇,高文波,邹志荣. 日光温室主动蓄热后墙传热CFD模拟及性能试验[J]. 农业工程学报,2015,31(5):203-211. Zhang Yong, Gao Wenbo, Zou Zhirong. Performance experiment and CFD simulation of heat exchange in solar greenhouse with active thermal storage back-wall[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(5): 203-211. (in Chinese with English abstract)

[14] 王永维,程绍明,姜雄晖. 温室地下蓄热系统温度的分布试验[J]. 农业机械学报,2006,37(9):112-115.

Wang Yongwei, Cheng Shaoming, Jiang Xionghui, et al. Study on the Heat Storing and Heating Performances of an Underground Heat Storage System in Greenhouse[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(9): 112-115. (in Chinese with English abstract)

[15] Santamouris M, Mihalakakou G, Balaras C A, et al. Energy conservation in greenhouses with buried pipes[J]. Energy, 1996, 21(5): 353-360.

[16] 马承伟. 塑料大棚地下热交换系统的试验研究[J]. 北京农业机械化学院学报,1984(4):69-78.

Ma Chengwei. Experimental research on the underground heat exchange system used for the vinyl-house[J]. Journal of Beijing Agricultural Mechanization Institute, 1984(4): 69-78. (in Chinese with English abstract)

[17] 马承伟. 塑料大棚地下热交换系统的研究[J]. 农业工程学报,1985,1(1):54-65.

Ma Chengwei. Studies on the vinyl-house heating by the underground heat exchange system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1985, 1(1): 54-65. (in Chinese with English abstract)

[18] 孙忠富. 地—气热交换塑料大棚中热量平衡的研究[J]. 农业工程学报,1989,5(2):35-46.

Sun Zhongfu. Studies on the heat balance of polyvinyl chloride (PVC) greenhouse with an earth-air heat exchanger[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1989, 5(2): 35-46. (in Chinese with English abstract)

[19] 袁巧霞. 塑料大棚太阳能地下热交换系统的增温效应[J]. 华中农业大学学报,1995,14(3):297-302.

Yuan Qiaoxia. Evaluating heating efficiency of underground heat exchange system with solar energy for vinyl-house[J]. Journal of Huazhong Agricultural University, 1995, 14(3): 297-302. (in Chinese with English abstract)

[20] 袁巧霞. 塑料大棚地下热交换系统的应用问题探讨[J]. 湖北农业科学,1997(1):38-40. Yuan Qiaoxia. Application discussion of underground heat exchange system for plastic-house[J]. Hubei Agricultural Sciences, 1997(1): 38-40. (in Chinese with English abstract)

[21] 袁巧霞. 温室地下热交换系统两种常用管材性能分析[J]. 湖北农业科学,2001(4):65-67.

Yuan Qiaoxia. The performance analysis of two kinds of pipe materials used in greenhouse underground heat exchange system[J]. Hubei Agricultural Sciences, 2001(4): 65-67. (in Chinese with English abstract)

[22] 吴德让,李元哲,于竹. 日光温室地下热交换系统的理论研究[J]. 农业工程学报,1994,10(1):137-143. Wu Derang, Li Yuanzhe, Yu Zhu. Theory research on earth tube heat exchangers in a sun-light greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1994, 10(1): 137-143. (in Chinese with English abstract)

[23] 吴德让,李元哲,于竹. 日光温室地下热交换系统的实验和优化设计研究[J]. 农业工程学报,1994,10(1):144-149.

Wu Derang, Li Yuanzhe, Yu Zhu. Optimal design and test research of earth tube heat exchangers in a sun-light greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1994, 10(1): 144-149.(in Chinese with English abstract)

[24] 孙周平,黄文永,李天来,等. 彩钢板保温装配式节能日光温室的温光性能[J]. 农业工程学报,2013,29(19):159-167.

Sun Zhouping, Huang Wenyong, Li Tianlai, et al. Light and temperature performance of energy-saving solar greenhouse assembled with color plate[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(19): 159-167. (in Chinese with English abstract)

[25] Alizadehdakhel A, Rahimi M, Alsairafi A A. CFD modeling of flow and heat transfer in a thermosyphon[J]. International Communications in Heat and Mass Transfer, 2010, 37(3): 312-318.

[26] Congedo P M, Colangelo G, Starace G. CFD simulations of horizontal ground heat exchangers: A comparison among different configurations[J]. Applied Thermal Engineering, 2012, 33: 24-32.

[27] Lin S, Broadbent J, McGlen R. Numerical study of heat pipe application in heat recovery systems[J]. Applied Thermal Engineering, 2005, 25(1): 127-133.

[28] 佟国红,李保明,Christopher D M,等. 用CFD方法模拟日光温室温度环境初探[J]. 农业工程学报,2007,23(7):178-185.

Tong Guohong, Li Baoming, Christopher D M, et al. Preliminary study on temperature pattern in China solar greenhouse using computational fluid dynamics[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(7): 178-185. (in Chinese with English abstract)

[29] Guohong T, Christopher D M, Tianlai L, et al. Temperature variations inside Chinese solar greenhouses with external climatic conditions and enclosure materials[J]. International Journal of Agricultural and Biological Engineering, 2008, 1(2): 21-26.

[30] Bansal V, Misra R, Agrawal G D, et al. Performance analysis of earth-pipe-air heat exchanger for winter heating[J]. Energy and Buildings, 2009, 41(11): 1151-1154.

[31] Zhang X, Wang H, Zou Z, et al. CFD and weighted entropy based simulation and optimisation of Chinese Solar Greenhouse temperature distribution[J]. Biosystems Engineering, 2016, 142: 12-26.

[32] 鲍恩财,朱超,曹晏飞,等. 固化沙蓄热后墙日光温室热工性能试验[J]. 农业工程学报,2017,33(9):187-194.

Bao Encai, Zhu Chao, Cao Yanfei, et al. Thermal performance test of solidified sand heat storage wall in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(9): 187-194. (in Chinese with English abstract)

[33] 李明,周长吉,魏晓明. 日光温室墙体蓄热层厚度确定方法[J]. 农业工程学报,2015,31(2):177-183.

Li Ming, Zhou Changji, Wei Xiaoming. Thickness determination of heat storage layer of wall in solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(2): 177-183. (in Chinese with English abstract)

[34] 白青,张亚红,孙利鑫. 基于温波传递理论的日光温室土墙体蓄热层及墙体厚度分析[J]. 农业工程学报,2016,32(22):207-213.

Bai Qing, Zhang Yahong, Sun Lixin. Analysis on heat storage layer and thickness of soil wall in solar greenhouse based on theory of temperature-wave transfer[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(22): 207-213. (in Chinese with English abstract)

[35] 李明,李明高. STAR-CCM+与流场计算[M]. 北京:机械工业出版社,2011.

[36] 郭伟. 发动机进气系统的CFD分析及实验研究[D]. 哈尔滨:哈尔滨工业大学,2012.

Guo Wei. The Analysis and Experimental Study of the Engine Intake System Based on CFD[D]. Harbin: Harbin Institute of Technology, 2012. (in Chinese with English abstract)

[37] Ji H S, Wang Q, Guo Z Y. CFD-based simulation of the temperature distribution in multi-span greenhouse with warm air heating system[C]//Applied Mechanics and Materials. Trans Tech Publications, 2013, 316: 1138-1142.

[38] 王福军. 计算流体动力学分析:CFD软件原理与应用[M]. 北京:清华大学出版社,2004.

[39] 陈文化. 重载铁路盐渍土路基中土工布使用寿命评估[J].铁道工程学报,2015,32(9):55-59.

Chen Wenhua. Life prediction for saline soil roadbed of heavy haul railway[J]. Journal of Railway Engineering Society, 2015, 32(9): 55-59. (in Chinese with English abstract)

[40] 陈文化. 地基处理[M]. 北京:人民交通出版社,2011.

Performance of different material heat transfer pipes and CFD simulation of thermal storage soil temperature distribution

Bao Encai1, Zhang Yong1, Cao Yanfei1, Wang Zhao2, Zhang Xin3, Cao Kai1, Yang Junwei1, Zou Zhirong1※

(1.,712100; 2.114011; 3.)

Heat transfer pipe has been widely adopted in horticultural facilities, such as Chinese solar greenhouses, which serves as a media to transfer heat between hot air and soil or north wall, and has many advantages such as easier operation, lower cost and better effect. Many scholars have studied the pipe heat transfer performance from piping materials and air flow, and they found the piping material has little influence on heat transfer, but air flow rate has a big influence on heat transfer. However, whether the holes on the heat transfer pipe wall have positive roles in heat transfer is still elusive. Therefore, we compared the heat transfer ability between closed type pipe and breathable type pipe. To study the temperature distribution of thermal storage soil, a typical heat transfer pipe experimental platform with 3 different kinds of pipe material, including polyvinyl chloride (PVC), galvanized iron (GI), and steel mesh skeleton - geotextile composite (SFG), was established in this research. Combined with computational fluid dynamics (CFD) technique, the heat storage experiment on soil was performed. Results showed that there was no temperature and humidity difference at the inlet of heat transfer pipe among 3 kinds of different material, however, the temperature difference was significant at outlet: PVC > GI > SFG; in addition, the humidity level also showed a clear trend of GI > PVC > SFG. This can be attributed to the physical characteristics of SFG such as the high permeability for air and moisture, from which the soil had a chance to absorb both heat energy and moisture from the hot air. Additionally, SFG resulted in the most effective heat transfer activity with a heat exchange amount of 299.44 kJ during the whole test, which was at least 4 times that of GI, and 3 times that of PVC. The location with soil temperature fluctuation more than 1 ℃ is in effective heat range, and that with soil temperature fluctuation more than 5 ℃ is in efficient heat range. The effective heat storage ranges at inlet of SFG were much greater than 240 mm in all 4 directions, i.e. up, down, left, and right direction; the effective heat storage ranges at outlet of SFG were more than 240 mm; the efficient heat storage ranges at inlet of SFG were also more than 240 mm; and the efficient heat storage ranges at outlet of SFG were higher than 240, 180-240, 180-240, and 180-240 mm respectively in the 4 directions. Our results showed that the heat transfer ability of SFG was the best in our experiment, and PVC was slightly better than GI. Therefore, the heat transfer ability of breathable type pipe was better than closed type pipe. Moreover, each CFD simulation model was established individually based on 3 different pipes, with the maximum relative error between measurement and simulation value of 4.4%. Simulated results showed that the temperature was distributed unevenly at the end surface of the soil: a higher temperature at the upper layer, a lower temperature at the lower layer, and a symmetrical distribution between left and right sides. There was also a distinguishable decrement of section temperature between the air inlet and outlet. Therefore, we conclude that SFG performs significantly better than both PVC and GI, which can be potentially applied in Chinese solar greenhouses or other similar agricultural facilities, and/or popularized to the construction market.

soils; fluid mechanics; heat transfer; heat transfer pipe; heat transfer performance; range of heat storage; CFD

2017-09-25

2018-01-11

国家“863”计划项目(2013AA102407);中国博士后基金项目特别资助(2015T81053);博士后科学基金(2014M562458);主动采光蓄热温室、超大跨度塑料大棚结构优化与智能化环境调控装备研制(2016BZ0901);设施农业采光蓄热技术提升研究与示范(2016KTCL02-02)

鲍恩财,男,安徽合肥人,博士生,主要从事设施园艺工程方面的研究。Email:baoencai1990@163.com

邹志荣,男,陕西延安人,教授,博士,博士生导师,主要从事设施园艺方面的研究。Email:zouzhirong2005@163.com

10.11975/j.issn.1002-6819.2018.04.028

S625.3

A

1002-6819(2018)-04-0232-07

鲍恩财,张 勇,曹晏飞,王 昭,张 欣,曹 凯,杨俊伟,邹志荣. 不同材质传热风道性能及蓄热土壤温度场CFD模拟[J]. 农业工程学报,2018,34(4):232-238.doi:10.11975/j.issn.1002-6819.2018.04.028 http://www.tcsae.org

Bao Encai, Zhang Yong, Cao Yanfei, Wang Zhao, Zhang Xin, Cao Kai, Yang Junwei, Zou Zhirong. Performance of different material heat transfer pipes and CFD simulation of thermal storage soil temperature distribution[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(4): 232-238. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.04.028 http://www.tcsae.org