印染设备

隨着新型纺织品纤维、织物结构的出现以及节能减排要求的日趋严格,染色工艺必须不断改进和优化,并借助染色设备达到这个目的。目前人们对气液染色技术产生了新的认识,也验证了这个趋势。

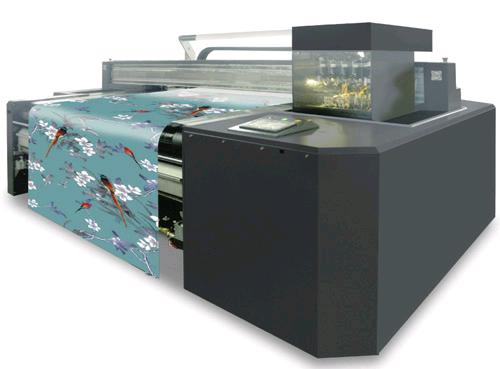

数码印花进入了快速发展的阶段,机器形式更加多样化和个性化,Single Pass打印方式越来越多被应用,喷头技术进步飞快、墨水品种更加丰富。

定形机能耗较大,历来是节能的重点。节能减排、绿色环保设备成为了新的亮点。

Environmental protection, diversity, personality

With the advent of new textiles, fibers, and fabric structures, as well as the increasingly strict requirements on energyconservation and emission-reduction, the dyeing process must be continuously improved and optimized with the aid of dyeing equipment. At present, people have a new understanding of the gas-liquid dyeing technology, and also verified this trend.

Digital printing has entered a phase of rapid development. Machine forms are more diversified and personalized. More and more applications of Single Pass printing methods are adopted. The nozzle technology is rapidly improving and the variety of ink is more abundant.

Stencil machine of larger energy consumption has always been the focus of energy conservation. Energy-saving and environment-friendly equipment has become a new focus.

宏华数码印花 开启高速印花生产新时代

Atexco: Opening up a new era of high-speed printing

2017上海国际纺织工业展览会于11月27~30日在上海新国际博览中心(浦东)隆重举行,届时宏华数码将携带多款数码印花机到场参展,为广大纺织印染行业带来最新的数码印花生产技术。

宏华数码作为国家数码喷印工程技术研究中心,数码印花设备龙头企业之一,20多年如一日专注研发数码印花设备,致力推动促进数码印花行业的发展。正是由于宏华人超高的科研热情和不懈努力,宏华的研发和技术实力已达国际领先水平,并具有自主知识产权体系的数码印花技术和设备研究,且相继获得中国纺织工业协会科学技术一等奖,2007国家技术发明二等奖,荣获56项专利技术,承担多个国家级项目。

伴随着全球数码印花行业的高速发展,宏华数码不断自主创新,开发出多款高速数码印花机。既有可以满足小批量、多样化的VEGA基础系列直喷导带机、也有适应工业级高速生产的VEGA3系高速数码印花机。VEGA系列数码印花机具有占地面积省,反应灵活,投入少,回报高的特点,满足并适应不同企业的印花生产需求,同时兼具速度快,精度高的超高速稳定打印品质,获得广大企业用户的好评和青睐,走在市场前列。

宏华数码拥有百余人的研发团队,同时与中美多所大学和研究机构建立战略合作关系。二十年的积累和发展,让宏华拥有了全球2000+客户的信赖,占据了国内70%的数码印花市场。宏华数码印花,致力为纺织行业提供优秀解决方案的国际品牌服务商。

Atexco (Hangzhou Honghua Digital Technology Stock Co., Ltd.) specializes in the R&D, manufacturing sales and service of digital ink-jet printing technology and equipment.

The products and solutions are widely used in the textiles printing, carpet printing and graphic printing industries worldwide.

Atexco was established in 1992 as a key company in the Software Park in the Hangzhou Hi-tech Zone and is a serial winner of the prestigious National Torch Prize. The company also undertakes projects in the Hi-tech Research and Development Program (part of the governments 863 plan) and the states High-tech Industrial Feasibility Project.endprint

Atexco is an international leader in garment CAD/ CAM/CIM systems, digital printing systems, inkjet direct manufacturing systems, advertising printing systems and carpet printing.

恒天立信多款智能染整初次亮相

恒天立信——智能染整的倡导者、绿色染整的贯彻者,将分别在 W5 馆 A11 展台展示染整及自动化的最新技术、E1 馆 B70 展台展示纱线整理工艺。两个展台总面积达 576 平方米,届时立信染整、特恩、高乐、立信门富士、德国门富士、纱力拉及立信水务将联手展现智能染整一站式服务的强大阵容。

CHTC FONGS: Smart Dyeing & Finishing innovations

CHTC Fongs has been committed to the development and manufacturing of dyeing and finishing equipment for more than 50 years. In the past decades, CHTC Fongs devoted to the development of energy-saving and emission reduction machines and now it becomes the basic conditions for dyeing factories. Today, we live in a digital era, though in the traditional textile industry, CHTC Fongs has been with the times. Together with its well-known brands: Fongs, Monforts Fongs, Xorella, THEN, Goller, FWT and Monforts, CHTC Fongs dedicated in the development of Smart Dyeing & Finishing and join with the customers to build the intelligent dyeing factory.

The CHTC FONGS Group is proud to present the “one-stop” sustainable solution in dyeing and finishing range of “pre-treatment, dyeing, post-treatment and waste water treatment” at ShanghaiTex 2017 in Hall W5, A11 and yarn conditioning and heat setting in Hall E1, B70, Shanghai New International Expo Center, China from Nov 27th to Nov 30th.

高乐(Goller)SINTENSA CYCLONE TANDEM 高效水洗机

高乐新型水洗箱依据独特的设计理念,可进一步优化及降低织物在运行中的张力,其原理主要通过以下两点来实现。优化的织物运行路径(路线)通过优化后的织物穿布路线,以及增加织物在主动辊筒和驱动转鼓包覆力设计。其目的是保持织物运行的速度与主动辊筒及驱动转鼓的速度一致,稳定织物在箱体内的运行条件,提升同步的准确性达到降低运行张力的要求。安装于驱动转鼓(表面筛孔)内,特别专利设计的驱动转子。原理是在设备运行時转子在液下可以以不同转速运转,因转子高速拨水而产生低压作用,使运行中的织物产生抽吸效果进而有效的避免打滑现象,可以获得更低的张力效果。

高乐新一代高效水洗机 SINTENSA CYCLONE TANDEM颠覆以往大体积高水位水洗箱的设计,真正做到节能减排、节省成本,令针织物平幅水洗工艺更顺畅、更高效。主要适用于织物连续平幅水洗、退桨、除油、漂白/染色/印花后水洗。

GOLLER SINTENSA CYCLONE TANDEM High efficiency washing compartment

The newly-designed GOLLER washing compartment - SINTENSA CYCLONE TANDEM reduces fabrics running tension by means of the following two points.

By optimizing fabrics running route. The optimized fabrics running route and the increased cladding intensity of the driven rollers and driven drums can keep the speed of the running fabric in accord with the speed of driven rollers and driven drums, stabilize the processing conditions for fabric in the washing compartment and enhance the accuracy of synchronization so as to facilitate the minimization the running tension of fabric.endprint

By the specially-designed rotor being installed on the driven drum (perforated). The rationale behind is that when the range is running, the rotor can rotates at different speeds under liquor and the high-speed water stirring of rotor can result in low pressure and thus achieving the suction effect of the running fabric. As a result of this, the problem of fabric-slipping can be avoided and the lower running tension can be resulted.

The new generation of GOLLER high efficiency washing compartment - SINTENSA CYCLONE TANDEM is an innovation to the typical washing compartment in large size and in large volume, which can indeed guarantee energy-saving, emission reduction and production costs-saving and make the open-width washing process for knitted fabric more smooth and efficient.

立信染整 FONGS TECWIN高温染色机

恒天立信新研发的高温染色机TECWIN,其设计理念是优化TEC系列高温染色机的各项性能,扩大其适用性。设计中已保留一些原有的优良配置,增加了新设计改进,更切合市场需求。该设备具备以下各项专利设计:

前雾化喷嘴

标准配置: 在织物提升入主喷嘴前,增加一次液体与织物接触,避免织物产生折痕。

任选配置: 风喷嘴配合前雾化喷嘴使用,可助解决某些布种染色问题。

自动可调节喷嘴

可调间隙喷嘴由牙箱马达带动;更换喷咀更便捷。

储布槽疏水筛

特别设计不锈钢底筛布槽,高效疏水,解除部分铁氟龙管夹布的风险。

高低水位溢流

低水位溢流:可保持主泵于低液位运行,保持水布分离,防止化纤溢流洗水时,因水位过高造成织物浮乱,影响行布表现。

高水位溢流:有效地收集溢流液面上的漂浮泡沫或杂质。

除此之外,水布分离的设计,讓小圆筒棉布及各类化纤织物等堆迭整齐,增加载量,行布更顺畅和进一步降低浴比。配合可变载调节板及布槽的优化,解决窄幅棉布跑双布后不能分布的问题。

FONGS TECWIN High temperature dyeing machine

FONGS TECWIN is designed to adopt the ever-changing textile market nowadays. The reliability and versatility is further improved from the last generation.

TECWIN is equipped with several patented designs:

Front sprayer

-Standard Feature: Increase the degree of dye liquor interchange before passing through the main nozzle.

-Optional Feature: Front sprayer with air nozzle provide an alternative function to resolve some special fabric dyeing problems.

Automatic adjustable nozzle

The nozzle gap can be adjusted by gear motor automatically for much easy handling and no replacement is required.

Liquid Dispersion Storage Chamber

Special designed stainless steel bottom sieve facilitates the liquid dispersion process and thus reducing the risks of fabric scratching or trapping caused by the PTFE tubes design.

Upper and lower overflow

-Lower Overflow : Maintaining pump operation with low water level to prevent disturbance caused by rinsing at a high water level.

-Upper Overflow: Overflowing the surficial dirts or foam effectively.endprint

Furthermore, the Dye Liquor Separation Design allows body size fabrics to stack in a much organized way which maximizing the loading capacity, providing smoother operation and lowering the liquor ratio. Equipped with the adjustable loading chamber with optimized chamber design to resolve the separation difficulties occurred when running double rope fabrics.

立信染整 DYECOWIN 高溫染色机

DYECOWIN为恒天立信精心研发的新一代溢流高温染色设备。该新机型突破传统设计,以提升处染化纤织物的生产效能为方向,配合先进的科研技术,大大降低染色浴比;当中更有多项专利设计,为化纤织物染色带来新的标准。DYECOWIN高温染色机适用于多种化纤织物、多种针织纬编织物、梭织织物。该设备具备以下显著特点:

大幅降低生产成本DYECOWIN高温染色机突破传统长缸大浴比的设计理念,大大降低染色浴比,满载行机浴比低至1:5。缸尾装配专利设计的分水装置,根据不同织物的运行特性,灵活调整染液分配,保证织物堆放整齐。处染不同布种时,通过设定不同分水板位置,可改善布槽内堆布现象。如无需改变堆布表现时设定分水板全关,可令水布分离加快回水到缸底,降低染色浴比;水洗时亦可提高水洗效率。

染色效果更优越DYECOWIN高温染色机全新的无提升滚筒设计,克服了织物运行过程中易缠绕滚筒的弊端,让染色更高效;避免了因喷嘴与滚筒参数设定不匹配带来的布面疵点,如擦伤及亮光印等。

提高生产效率DYECOWIN高温染色机具有方形导布管设计,可实现织物在运行过程中自由松弛扩张,有利于色折痕的消除,适合于开边染色,省却加工工序。另配合专利设计提高容布量,同时可防止勾丝、擦伤等产生,使敏感织物布面质量得到保证。配合CONJET喷嘴及专利设计的导布管,可保证织物滑移畅顺,达到所需工艺的最短循环时间要求,提高生产效率。专利设计的出布滚筒采用独特不锈钢配胶条设计,其提布力更大、出布更高效。轻薄织物实际行布速度可高达600m/min。

实行智能化系统管理DYECOWIN高温染色机配置的新一代FC30EX程序控制器,水、电、气能耗统计报表一目了然。精准的温控及水洗系统,使染色更高效、更稳定。配合中央电脑系统 VIEWTEX或THEN-TDS联结起来,可实现对整个染色车间的智能化管理和控制。

FONGS DYECOWIN High temperature dyeing machine

DYECOWIN is the revolutionary high temperature dyeing machine setting new standards for the industry. It is integrated with the cutting-edge patented technologies to cut down the liquor ratio and to enhance the productivity of the dyeing processes.

Reduce production cost: DYECOWIN is a major breakthrough in the long tube machine operating with a much lower running liquor ratio as low as 1:5. The patented fluid distributor at the rear of the machine can effectively adjust the distribution of dyeing liquor according to different fabric types, ensuring an organized fabric stacking pattern.

Optimize the dyeing quality: The winchless design can overcome the tangling problem on the conventional dyeing machines. The fabric surface defects such as scratch marks and light spots caused by unsynchronized motion between nozzle and winch can so be avoided. The patented “CONJET” nozzle technology can ensure high quality of finished products by enabling automatic and precise adjustments of flow volume and nozzle pressure.

Enhance productivity and efficiency: The rectangular fabric transportation pipe allows fabric to have free relaxation and run smoothly along the channel, thus reducing crease marks effectively. This design also favors open width dyeing so as to simplify the production process. The patented stainless steel storage chamber is capable of increasing the loading capacity, combining with the use of “CONJET” nozzle, sensitive fabric can be run smoothly without scratching and snapping. The surface quality of fabric is assured with minimized cycle time.endprint

FC30EX program controller: Our latest generation program controller – FC30EX can integrate with our Viewtex and THEN-TDS central computer system, providing a comprehensive control management.

高乐(Goller)EFFECTA Modul Anti-Curl高性能水洗机

EFFECTA Modul Anti-Curl是高乐跟据市场需求设计而成的一款新型水洗箱,此设计有助增加水洗箱在应用上的灵活性,并为客户带来崭新的水洗体验。

减少卷边和皱痕出现。EFFECTA Modul Anti-Curl是特别为处理梭织高弹性纬纱的裤子和牛仔面料而设计的水洗箱。透过巧妙地把两排导布辊放置于水洗箱顶层导布辊与底层导布辊的中间来大大的缩短面料自由游走的空间,从而减少卷边和皱痕的出现。另外,由两排额外的导布辊对面料提供额外的轧点水洗,也有助于提升水洗效能。

提高EFFECTA水洗箱与其他单元的兼容性。EFFECTA Modul Anti-Curl是专门为提高EFFECTA水洗箱与其他单元的兼容性而设计的水洗箱。透过采用与SINTENSA CYCLONE TANDEM 水洗箱一樣的设计理念,把组合式的辊车中间箱与EFFECTA水洗箱并合,而成为EFFECTA Modul Anti-Curl水洗箱。此外,这款组合式设计能更有效地提高EFFECTA与各款单元的兼容性,如与Sintensa系列中最新型号的SINTENSA CYCLONE TANDEM水洗箱、Oxidator化学药剂施加、膨化,收缩及水洗箱、Universa堆置及水洗箱等单元的并合。在提高应用兼容性的大跃进下,EFFECTA Modul Anti-Curl水洗箱除了丰富了高乐的产品线和令高乐的产品线更完整外,也令高乐更能胜任于任何一种连续平幅水洗的应用上。该机主要适用于织物连续平幅水洗、退桨、煮练、漂白/除油/染色 /印花后水洗。

GOLLER EFFECTA MODUL ANTI-CURL High performance washing compartment

GOLLER EFFECTA MODUL ANTI-CURL is a newlydesigned washing compartment which maximizes the flexibility in applications and brings the washing experiences to a brand new level.

By minimizing the occurrence of curling edge and crease marks

EFFECTA MODUL ANTI-CURL is designed particularly for Woven bottom weight and denim with high content of elastic weft processing. The ingenious way of putting the 2 rows of middle support rollers between the row of top rollers and the row of bottom rollers of EFFECTA MODUL ANTI-CURL has substantially shortened the free fabric path in between and thus minimizing the occurrence of curling edge and crease marks. A higher washing efficiency can also be achieved since the extra 2 rows of middle support rollers provide more nips for fabrics during washing process.

By enhancing the compatibility of EFFECTA with different units

EFFECTA MODUL ANTI-CURL is designed specifically for enhancing the compatibility of EFFECTA with different units. It applies the same design principle as the one of SINTENSA CYCLONE TANDEM by incorporating the modular-design intermediated trough with squeezer into the washing compartment - EFFECTA MODUL ANTI-CURL in this case. This modular design has further enhanced the compatibility of EFFECTA with the latest version of Sintensa washing compartment- SINTENSA CYCLONE TANDEM, Oxidator chemical application, swelling, shrinkage and washing compartment and Universa dwelling and washing compartment, etc. With the advancement of applications compatibility, EFFECTA MODUL ANTI-CURL not only complete Gollers product portfolio but also enable Goller to be excelled in every continuous open-width washing occasion.endprint

特恩AIRJETWIN高温气流染色机

针对各种织物表面质量及风格的要求提高,推出最新一代的多功能染色设备AIRJETWIN高温气流染色机。AIRJETWIN=AIR(气流)+JET(溢流)+TWIN Function(双功能)主要适用于针织棉、化纤物、棉和化纤混纺、梭織棉等织物染色。该设备具备以下显著特点:

单风机多管设计单风机配合优化的管道设计,使每管分风均匀;

强大的喷嘴组合功能(独特功能)雾化喷嘴;溢流水喷嘴;结合各种喷嘴或独立使用,能配合各种染色工艺或面料材料;

缸内XY摆布功能(独特功能)织物能于缸内双向(纵向及横向)摆动,使织物能于储布槽内整齐堆叠,能使织物运行顺畅,提升布速,减少缠绕及压底的情况出现;

高效出布滚筒(专利设计)采用独特的不锈钢配胶条的专利设计,具有更高的提布力,出布效果顺畅;加上可变载储布槽、缸底清洁过滤器等,全方位加强染整处理的多样性及便捷性。

THEN AIRFLOW AIRJETWIN Aerodynamic high temperature dyeing machine

AIRJETWIN high temperature airflow dyeing machine, the latest generation of dyeing equipment, is now being offered to fulfill the various requirements of dyeing process nowadays. Through finite element analysis FEA), the airflow and water flow situation is well-analyzed for design optimization. In addition, by combining different THENS and FONGS product advantages, the entire performance is further enhanced through a holistic design integration.

Single-blower for multi-tube design

By utilizing single blower with frequency inverter and optimizing pipe network design, the air volumetric flow rate of each tube is evenly distributed.

Integrating nozzle system

By adjusting various combinations of multiple spraying nozzle and sprayers, the best dyeing performance of a huge variety of fabrics can be achieved.

XY internal plaiter

Fabric is capable of being two-way (horizontal and vertical) plaited inside the vessel to organize the fabric stacking

pattern inside the storage chamber. It allows the smooth fabric lifting, enhancing the fabric lifting speed and reducing fabric tangling in the chamber.

Overhead sprinkler system

Effective cleaning is provided through purging to rinse the kier head, ensure no residue color is left.

德国门富士Monforts ThermoStretch Skewing Unit整纬装置

德国门富士Monforts新推出的ThermoStretch整纬装置为牛仔布整理提供了新的改进功能,更环保、更高效!从此可以取代需要昂贵蒸气来驱动的烘筒作轧压。

此装置还提供更温和的牛仔布拉伸处理,使牛仔布手感更为理想。从此开启了弹力牛仔布应用之门。

此ThermoStretch装置可用作纬向延伸的单元,而不对织物的属性作调节或加热。德国门富士Monforts对牛仔布后整理技术具有深入的研究并了解当中的技术诀窍。其串联双橡胶棍及双预缩单元使工作速度超过80米/分。

使用“双橡胶棍及双预缩单元”组合的Thermostretch单元可保证织物达到从所未有的最小残余收缩值和最高的生产速度。在越南及墨西哥之牛仔纺织品市场,这种崭新的牛仔布整理技术已取得显着的产能提升及节能减排之成效。牛仔布技术专家会在大会现场为各位详尽介绍各种最新的牛仔布整理技术。除此以外,德国门富士Monforts亦会重点介绍其应用于产业用纺织品上的TexCoat 涂层及整理技术, 其应用于安全气囊的效果尤为显着。

德国门富士Monforts是唯一一家能够提供完整的涂层生产线的制造商,该涂层生产线可根据后续的Monforts烘干技术量身定制。德国门富士Monforts系统可做到从涂层单元到拉幅定型机之最短织物流程,并提供不同涂层系统,如悬浮刮刀、辊刮刀、磁控刮刀或印刷头。所有这些选项也可以用于更宽的工作阔度,工程同由德国门富士Monforts提供。endprint

MONFORTS THERMOSTRETCH Skewing unit

The new ThermoStretch skewing unit from Monforts offers new and improved features for Eco friendly denim finishing avoiding the excessive use of ‘expensive to generate steam that was previously necessary for the cylinder dryers; thereby replacing the need for padding together with steam-operated cylinder dryers.

It also provides a much gentler treatment of the denim fabric during stretching than was previously achievable together with an optimised fabric hand. It also opens the ‘doorfor stretchable denim applications.

The ThermoStretch unit also continues to be available as a “long stretch” unit but without conditioning/heating properties for the fabric.

Monforts has in depth “knowhow” in high speed processing ranges for denim finishing with the “double rubber”twin compressive shrinking unit working in tandem for working speeds even above 80 metres / minute.

The larger fabric content of the ThermoStretch unit in combination with the ‘double rubber twin compressive shrinking unit ensures minimum residual shrinkage values and highest production speeds which could not be achieved before.

In the denim industry, this concept is making a significant contribution to higher productivity and lower energy consumption and the company has references in Vietnam and Mexico. Denim technologists will be at the exhibition to offer detailed advice to visitors on the latest denim finishing processes. Monforts will also highlight its texCoat coating processes and finishing of technical textiles, especially airbag materials at the show.

立信門富士Montex 6500 Air Filtration Omni 拉幅定形机

Montex 6500 Air Filtration Omni(下简称6500 Omni)是在原有Montex 6500定型机基础上,结合现有最先进的热能回收和空气过滤系统技术,形成的一款更先进、更环保的定型机。6500 Omni定型机配置的热能回收和空气过滤系统,不仅具有分离废气中油脂和有机物等功能,而且还具备热回收率和超低耗能的优势,可力纺织企业达到减低碳排放的目标。

模块设计使其能灵活的运用空间,而这装置亦带有智能控制自动清洁功能。通过可移动喷嘴在收集槽杆上来回移动进行常规过滤槽清洁。使维护要求降至最低。这款环保型定型机亦一如以往带有以下德国门富士独特的设计。

TwinAir双风道:门富士专利设计的双风道系统使得上,下风量可以完全独立调节,烘干时不会产生痕迹及温度最均匀。还可以加装Optiscan自动平衡系统。此外标准形喷风嘴系统CAD Stream,其“Layon-air”气垫式喷风嘴使织物飘游于空中,产生蓬松效果,尤其轻微的振动效果,可提高产量,减低成本及增加利润,还具有更高的蒸发能力,并且织物连悬浮于空中,就算在箱体之间接合点也不中断。

Qualitex 750可编程逻辑控制系统 (PLC),该系统可扩充及适用于现代纺织品整理的各种需要及变化。系统具有可编程控制功能,可用于设备上任何面板操作、储存设定的数据、可结合测量及控制仪的设定值、批次管理、网络连接、自动喷嘴压力控制、远程联机服务及维护管理等,以上操作通过触控式平板执行控制。

设备也可选配自家开发的Monformatic控制系统。该项性能特别为综合工艺(烘干与定形)而设计,可准确地设定定形时间。

可选配Q-Soft中央工艺控制系统(软件),其中央接口可用于生产计划及编制文件。所有工艺的数据可以储存于标准化的数据库,所有设定值与实际值都以可读/可改形式归档。endprint

MONFORTS FONGS MONTEX 6500 AIR FILTRATION OMNI Stenter Frame Range

Montex 6500 Air Filtration Omni (Abbeviation 6500 Omni), is based on the Montex 6500 stenter range in combination of the most advanced heat recovery and air filtration technology to evolve this stenter range into a more advanced environmental friendly machine.

The heat recovery and air filtration device of this 6500 Omni stenter can filter the wax and oil from the exhausted air with high efficient but low energy consumption. The heat recovery is so high which could contribute the textile industry to achieve low carbon release target a step further.

The modular design could allow different space requirement by different textile mills. Also this device run with automatic cleaning function controlled by PLC by running its nozzles along the bar over the top of the filtration units. This will minimize the daily maintenance to the machine.

TwinAir: Monforts patented Twin-Air technology allows top and bottom airflow to be regulated separately. When drying without marking and the most even temperature possible across the fabric. Also, it also could be equipped with Optiscan for Auto-Balance system.

For this standard Nozzle System CAD Stream, its “Layon-Air” fabric supporting properties in air and with bulking effect through increased volume by its microtumbler effect. Attractive cost/benefit ration with higher evaporation rates. It also provides continuous fabric support even at the chamber transition points.endprint